Coke oven refractory material matching board construction method

A construction method and technology for refractory materials, which are applied in coke oven bricklaying operations and other directions, can solve problems such as damage or loss, uneven ash joints, rework, etc., and achieve the effects of improving work efficiency, saving time, and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below by means of embodiments and in conjunction with the accompanying drawings.

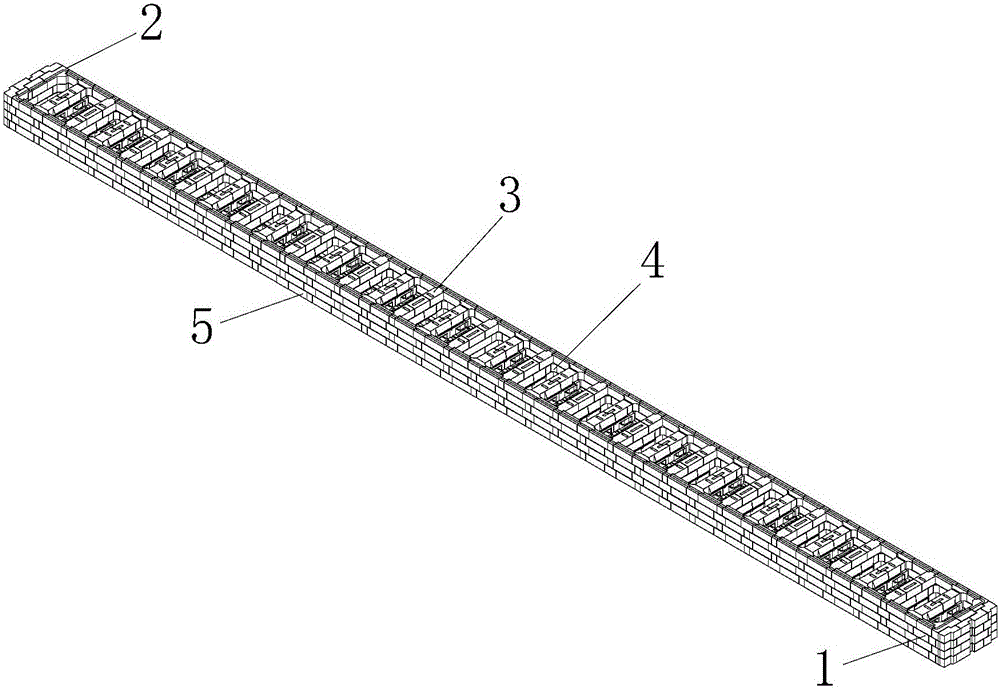

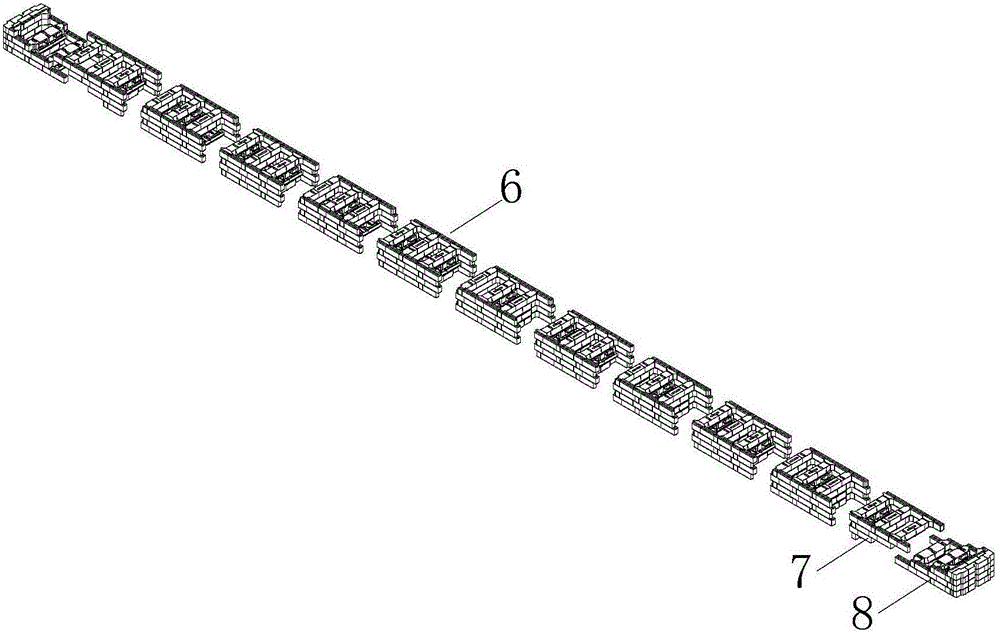

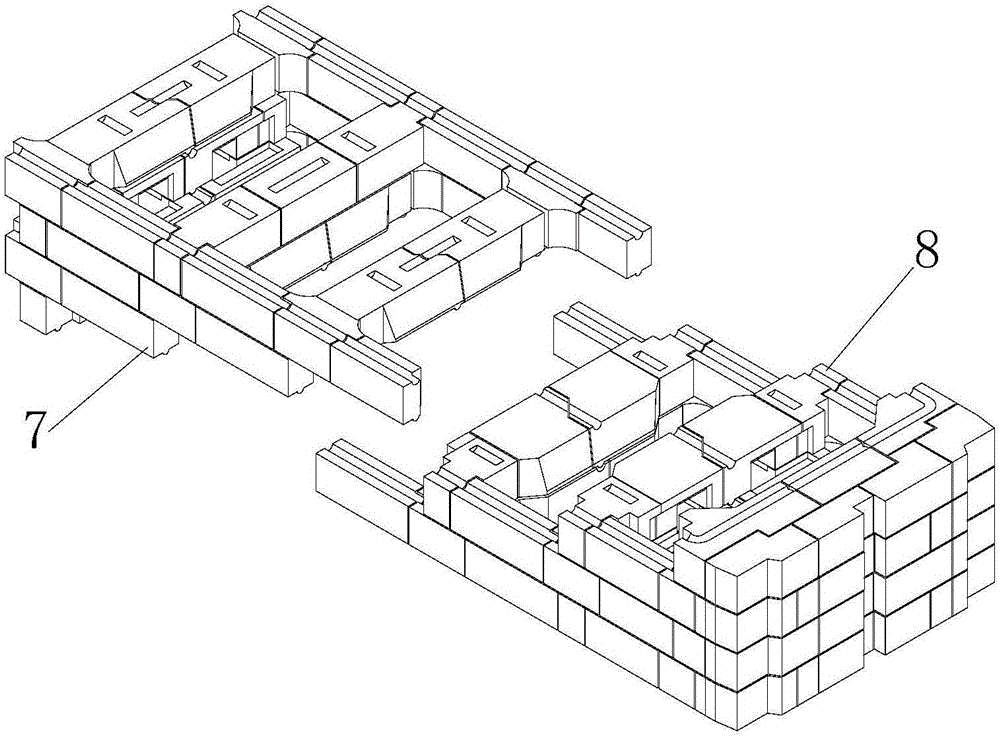

[0029] Such as Figure 1-Figure 8 Shown, a kind of coke oven refractory material matching plate construction method of the present invention comprises the following steps:

[0030] Step 1. Establish a three-dimensional information model for the bricks, respectively define the brick type, brick layer, volume and set the corresponding materials, use the volume and bulk density of the bricks to calculate the weight of all bricks, and use the brick layer information and schedule to determine the brick type. The time of the warehouse and the location of the brick type classification and stacking;

[0031] Step 2. By adding annotation parameters, divide the daily masonry volume of the wall into multiple sets, corresponding to brick slab 1 to brick slab n; when matching boards, accurately allocate the number of brick types according to the masonry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com