Concrete block

A technology of concrete blocks and blocks, which is applied in the direction of building materials, can solve the problems of low durability, large heat loss of walls, unfavorable energy saving, etc., and achieve the effect of simple material source, high masonry efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

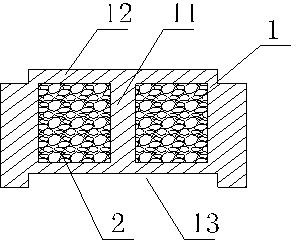

[0010] like figure 1 As shown in a concrete block, the cross section of the block 1 is square, and the center of the square is vertically provided with a rib 11; the middle part of the upper side of the square is raised 12, and the lower side corresponds to The location part is recessed 13 , and the height of the protrusion 12 is the same as that of the recess 13 . In this way, two identical blocks can be stacked up and down, and the depression 13 of the upper block and the protrusion 12 of the next block are snapped together very well, and the overall force is mainly reflected in the two sides of the square and the ribs in the middle 11. Therefore, the left and right sides of the square are twice as thick as the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com