Structure of stone wall constructed by strip stone cut by machine and method thereof

A technology for cutting strips and machines, which is applied in the processing of building components, building structures, building materials, etc., can solve the problems of poor shear resistance of ash joints, reduce labor costs, save decoration costs, and enhance shear strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

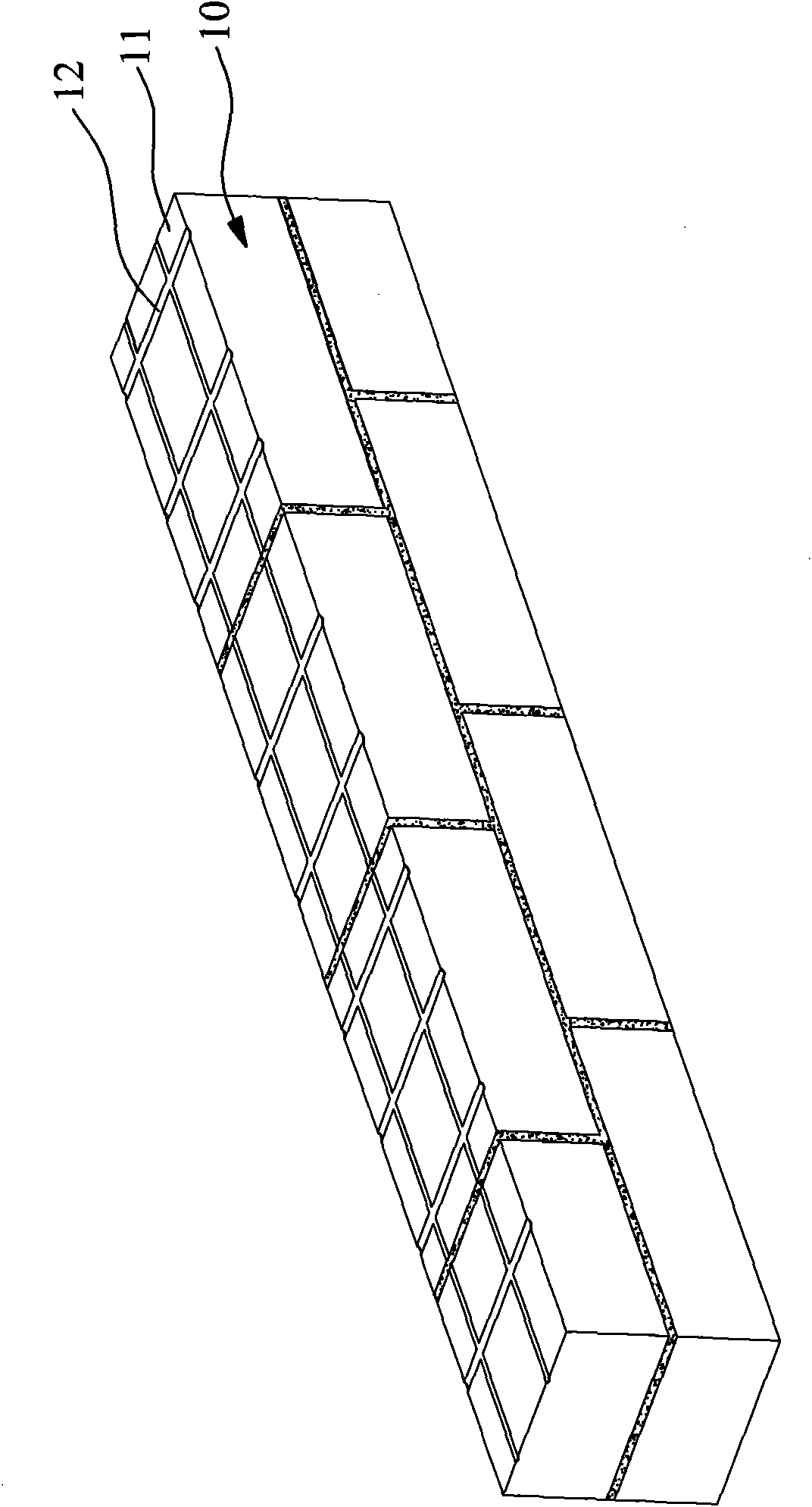

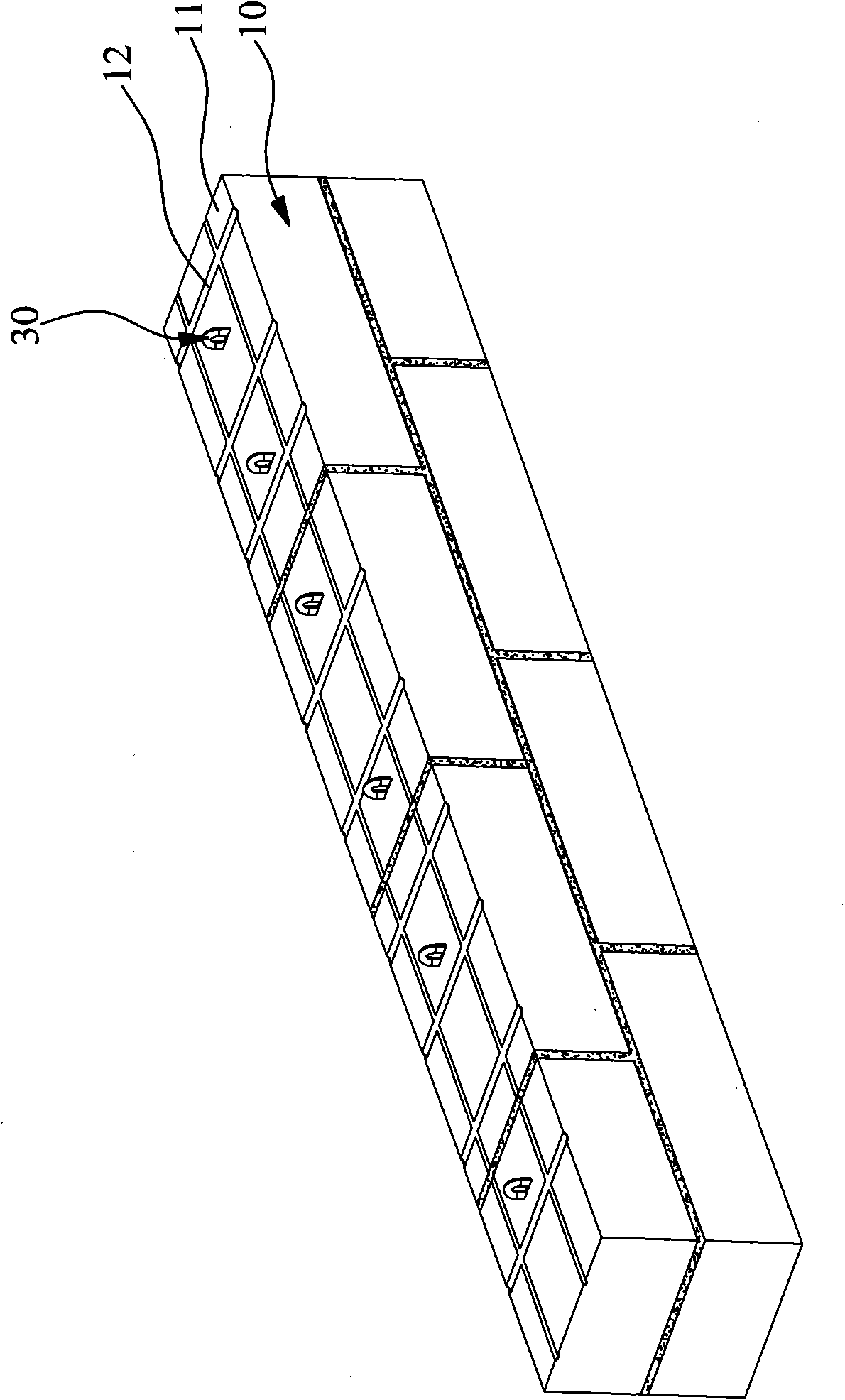

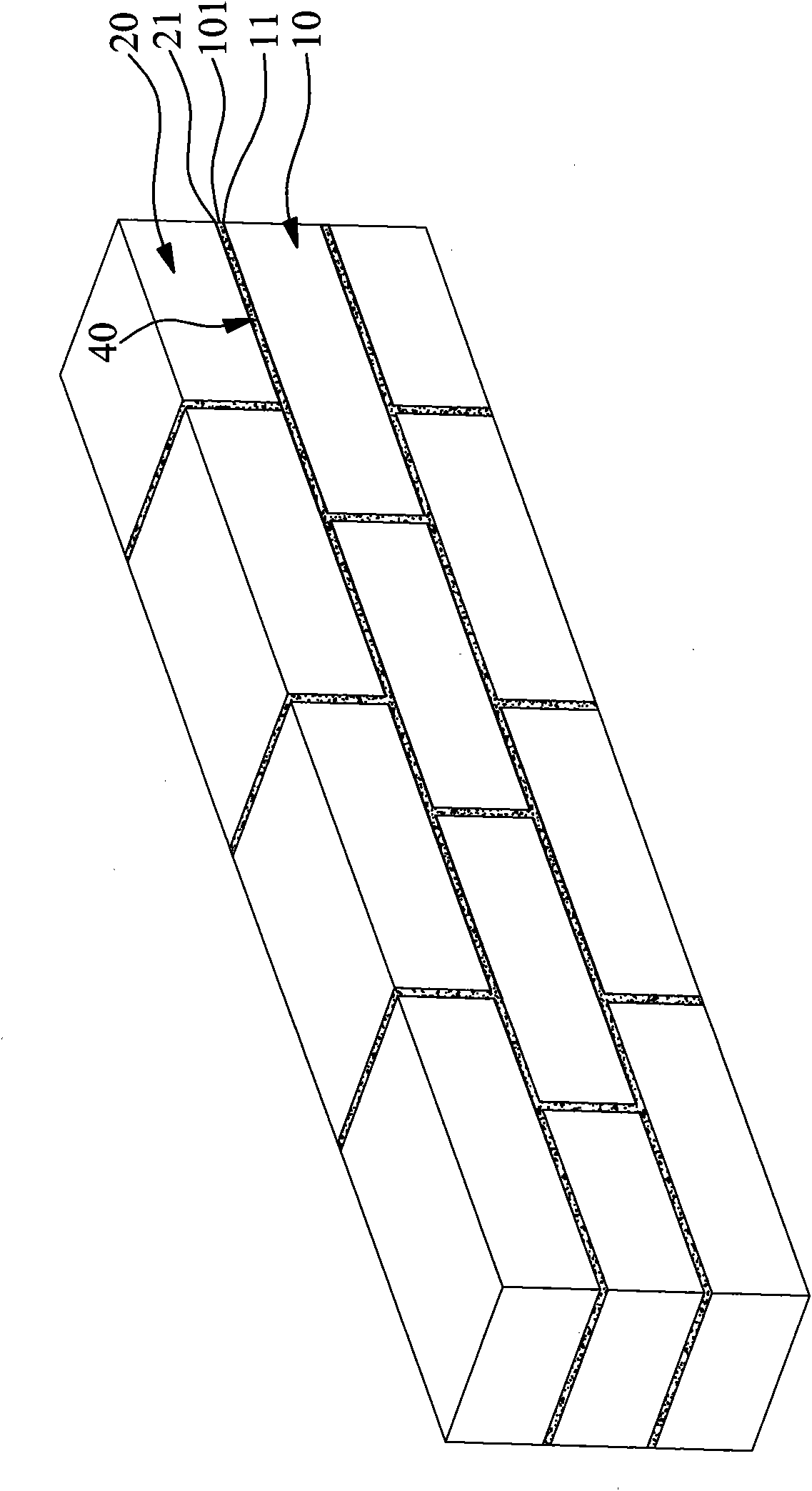

[0041] Please refer to Figure 1 to Figure 4 As shown, it has shown the specific structure of the first embodiment of the present invention, including the lower row of stones 10, the upper row of stones 20 and the shear key 30, and the upper row of stones 20 of the lower row of stones 10 are all Machine cut.

[0042] Wherein the lower row of stones 10 has a masonry interface 11 bonded with the upper row of stones 20, and the masonry interface 11 is provided with criss-cross grooves 12, and the grooves 12 can use a hand-held electric cutter It can be formed by pulling and cutting, and can also be formed by other methods.

[0043] The upper row of stones 20 is placed on the lower row of stones 10, the upper row of stones 20 has a masonry interface 21 bonded to the lower row of stones 10, and criss-cross grooves 22 are arranged on the masonry interface 21 , the flute 22 is the same as the aforementioned flute 12, and is also formed by drawing and cutting with a hand-held electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com