Patents

Literature

51 results about "Bricklayer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bricklayer, which is related to but different from a mason, is a craftsman who lays bricks to construct brickwork. The terms also refer to personnel who use blocks to construct blockwork walls and other forms of masonry. In British and Australian English, a bricklayer is colloquially known as a "brickie". A stone mason is one who lays any combination of stones, cinder blocks, and bricks in construction of building walls and other works. The main difference between a bricklayer and a true mason is skill level: bricklaying is a part of masonry and considered to be a "lower" form of masonry, whereas stonemasonry is a specialist occupation involved in the cutting and shaping of stones and stonework.

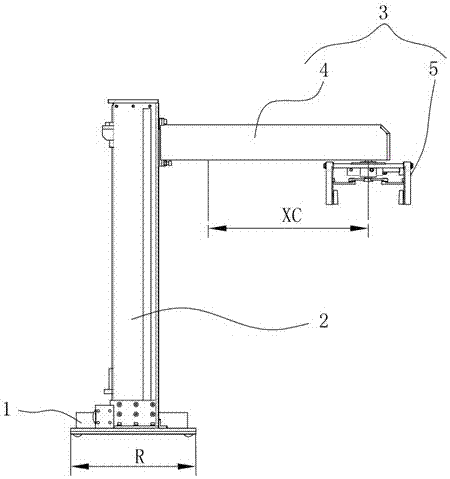

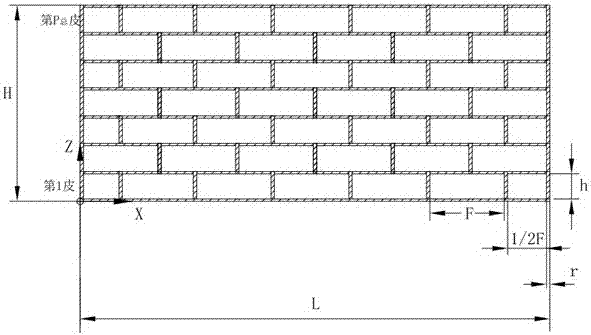

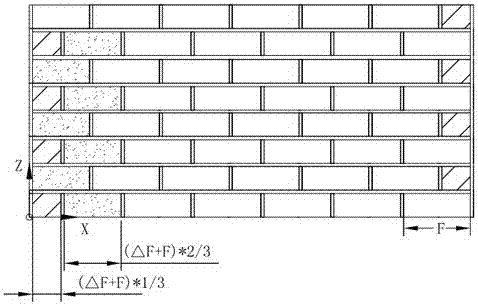

Masonry algorithm of straight wall of bricklayer robot

ActiveCN107357294AAccurate locationAccurate calculationBuilding material handlingPosition/course control in two dimensionsBrickControl system

The invention discloses a masonry algorithm of a straight wall of a bricklayer robot. The algorithm is implemented as follows: step a, determining a reference coordinate system; step b, calculating a standing posture position of a robot; step c, calculating a brick taking position; step d, calculating the number of layers of bricks, the number of bricks in each layer, and a central point coordinate of each brick; and step e, calculating a masonry track and sending an action instruction to a program control system to enable the system to perform a corresponding action so as to realize construction of a straight wall body. According to the invention, the brick taking position moves synchronously with a bricklayer robot; the standing posture coordinate of the bricklayer robot, the brick taking position coordinate, and the coordinate of each brick of the wall body are built, so that positions of brick clamping and brick laying become accurate. Therefore precise calculation is realized and the overall masonry quality and efficiency are improved.

Owner:HUAWAY IOT TECH

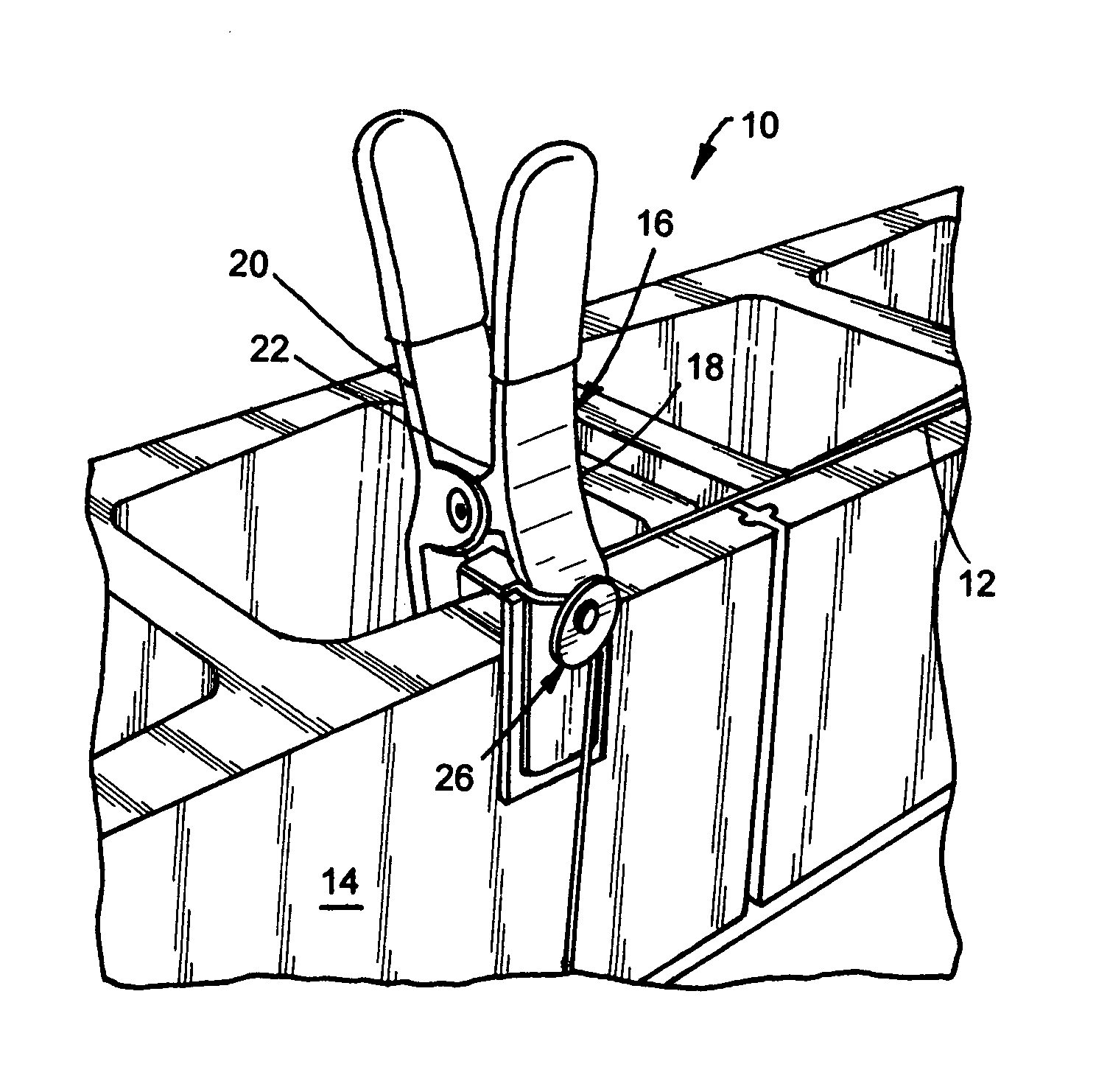

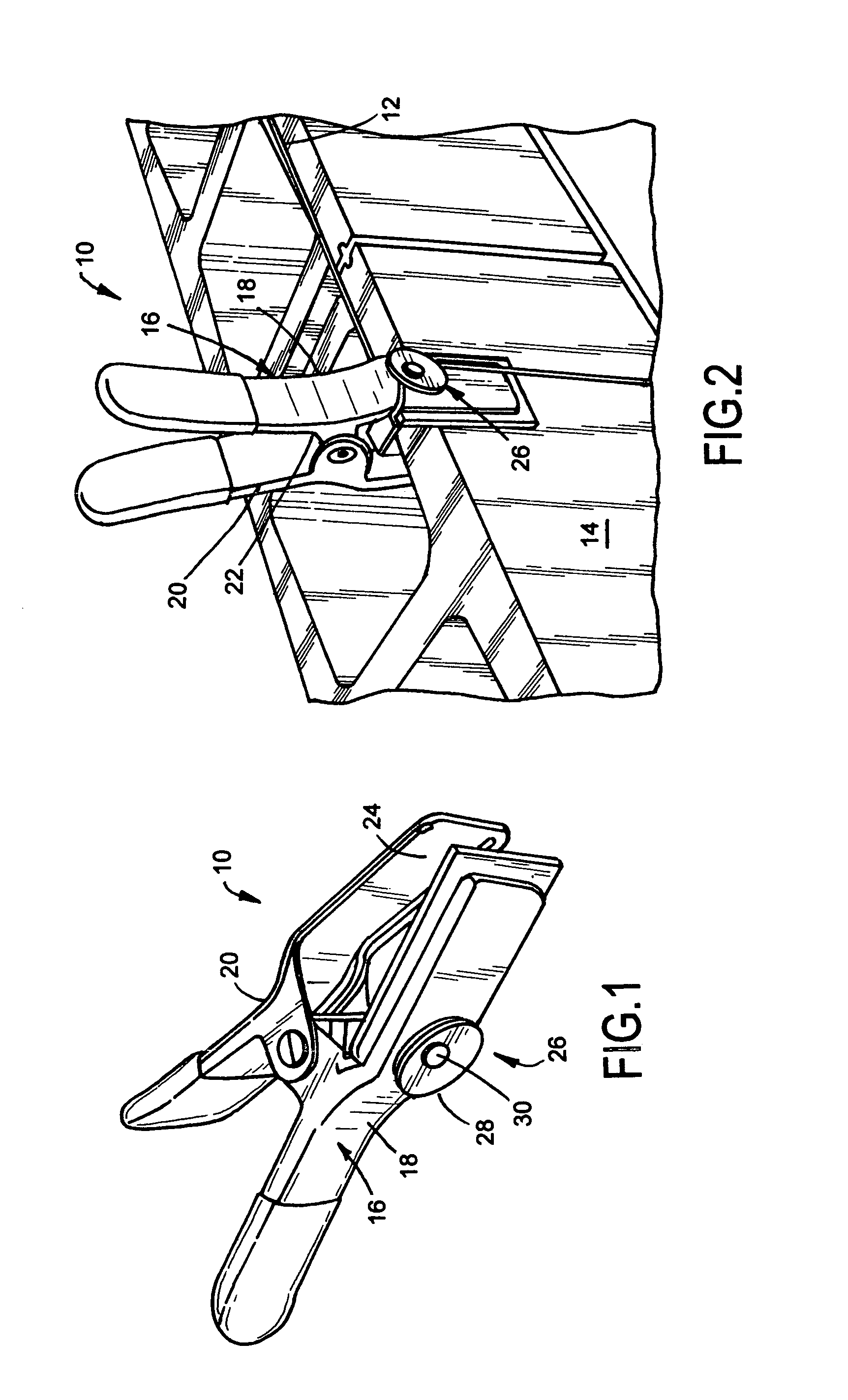

Stretch liner clamp

A clamp mechanism for assisting a bricklayer or mason worker in positioning and aligning a next row of bricks being laid upon a previous row of bricks using an alignment string is provided. One end of the alignment string is secured in a desired position adjacent the previous row of bricks. The clamp mechanism comprises a clamp having a first clamp arm and a second clamp arm. A spring mechanism biases the first clamp arm and the second clamp arm in a general direction toward each other. A string receiving mechanism is associated with the clamp for receiving a portion of the alignment string. Upon the alignment string being secured to the string receiving mechanism and the clamp being positioned upon a brick in the previous row of bricks, the alignment string indicates the proper positioning and alignment of the next row of bricks.

Owner:PACHECO MARTIN I +1

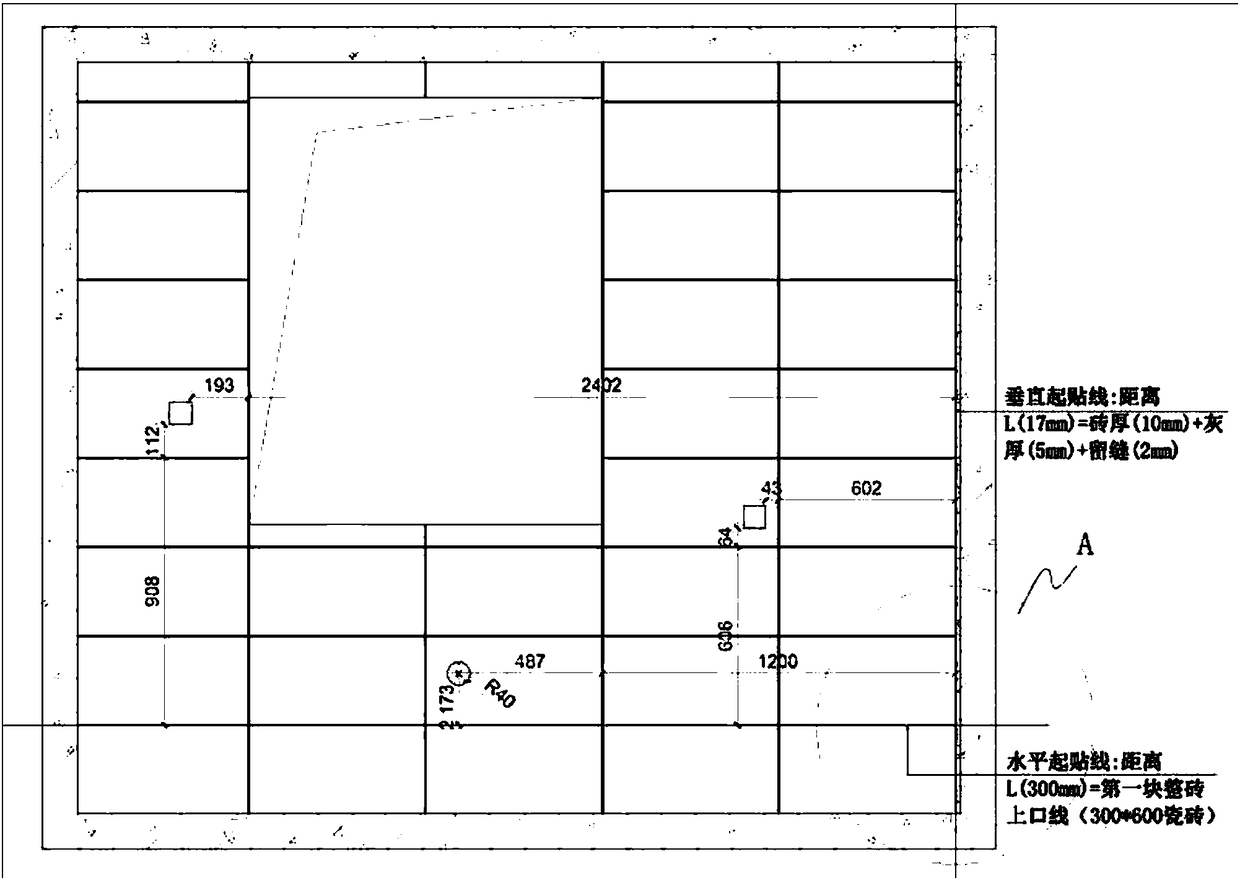

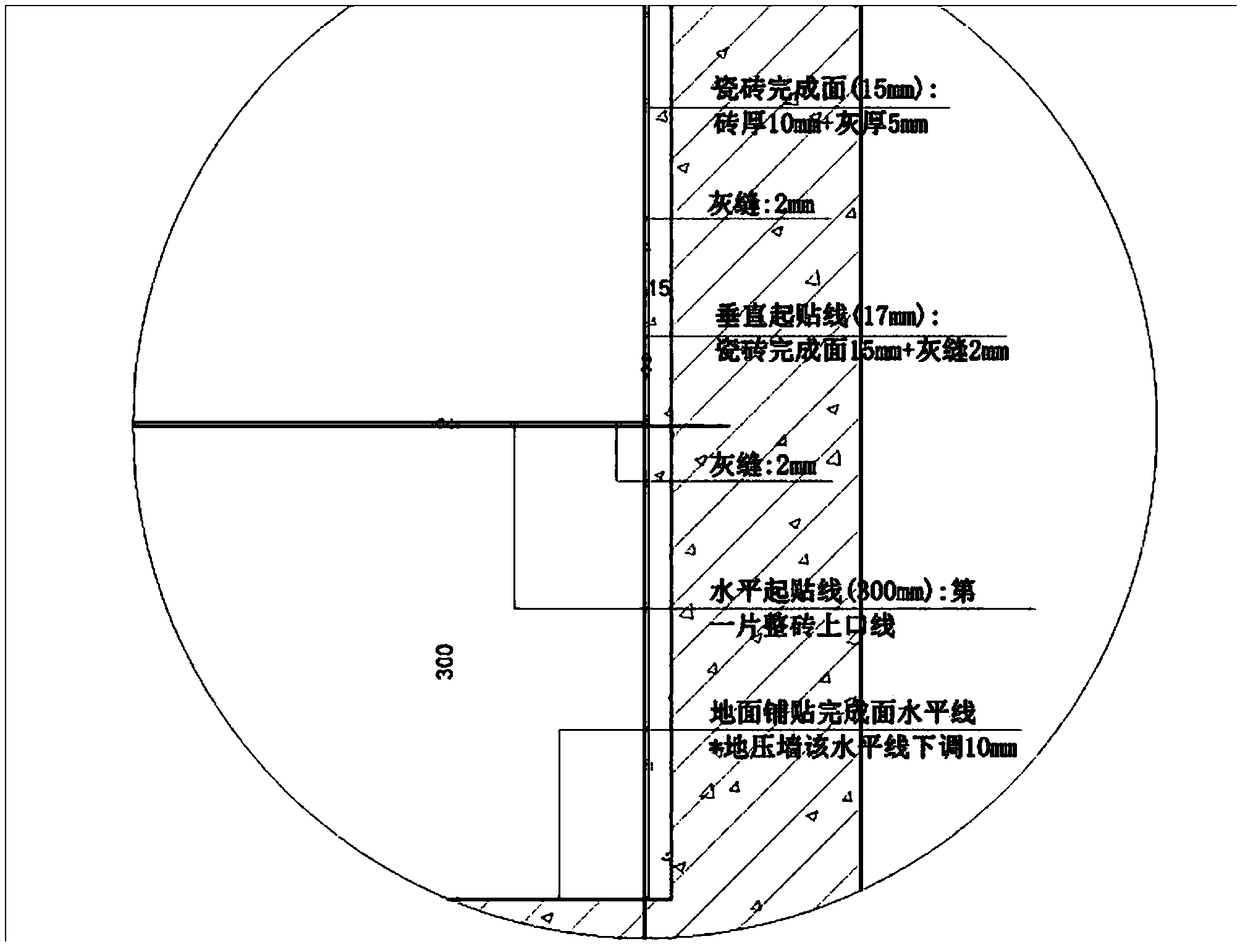

Method and tool for mounting assembly type ceramic tiles

InactiveCN108571154AImprove construction efficiencyPaste firmlyBuilding constructionsAdhesiveSurvey result

The invention relates to a method and a tool for mounting assembly type ceramic tiles. The mounting method comprises the following steps: carrying out a survey by a surveyor on a site where tiles arepre-tiled to obtain a survey result, wherein indexes of the survey include the flatness, verticality and squareness of internal and external corners of a base layer; according to the survey result, leveling a substandard wall or ground base by a leveling bricklayer; according to a preset tiling plan, sticking a start tiling line for positioning a tiling position of a single tile on the leveled base by the surveyor, and determining a processing size of the single tile according to the start tiling line; processing the ceramic tile in a factory according to the processing size, wherein the processing comprises cutting and punching the ceramic tile; and according to a construction drawing, scraping an adhesive on the base and the processed tile by a tiling bricklayer along the start tiling line with a tiling tool to tile the tiles. The method and tool provided by the invention improve the construction efficiency and ensure the construction quality.

Owner:上海相品家居建材有限公司

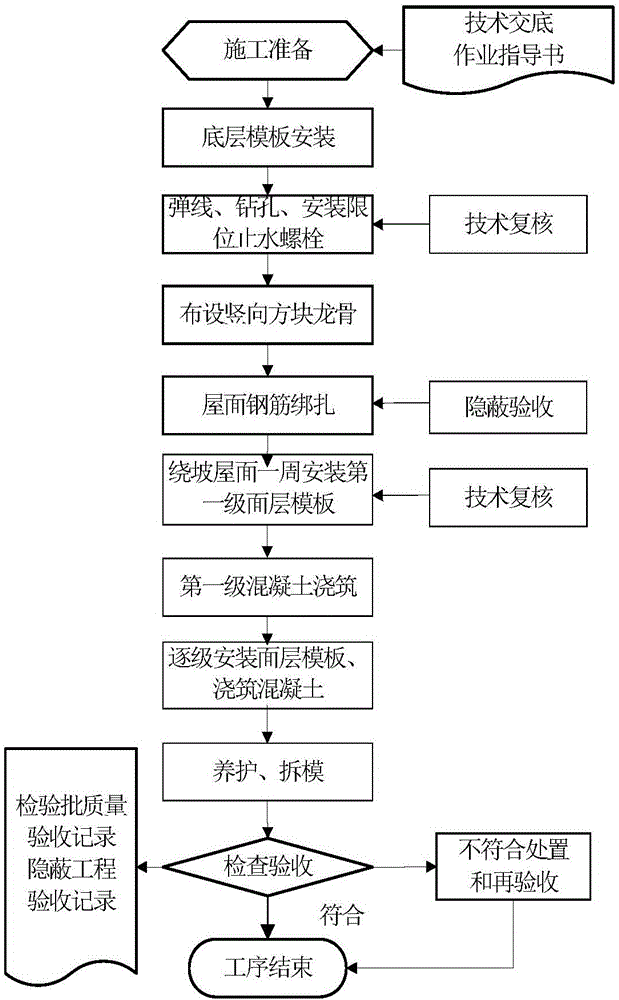

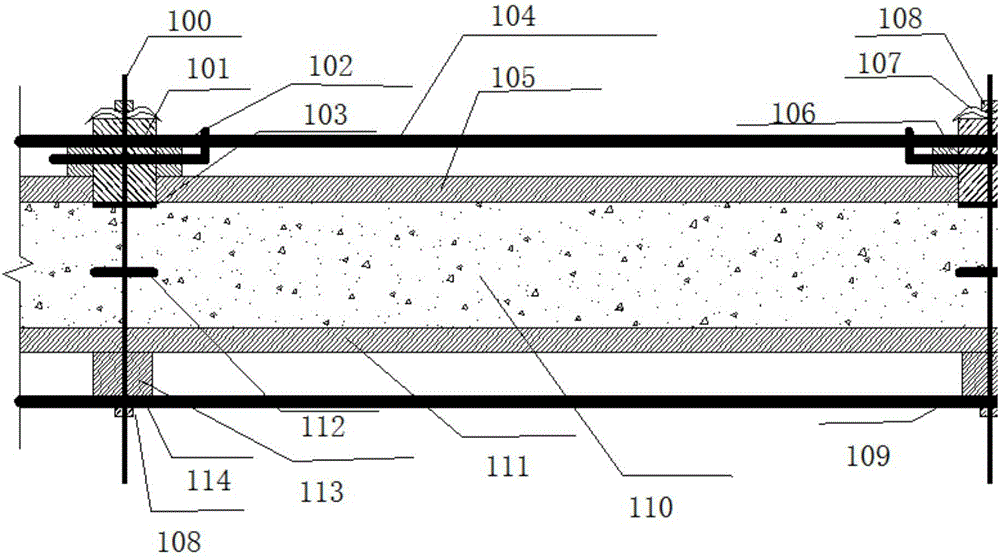

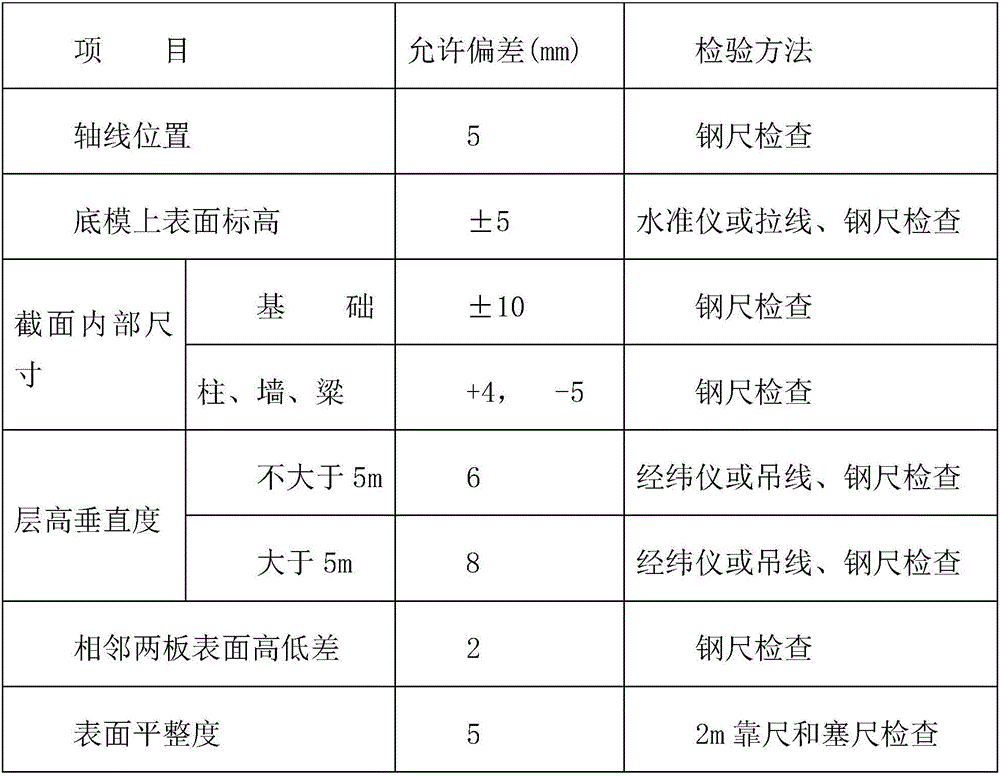

Cast-in-situ concrete construction method for pseudo-classic architecture slope roof

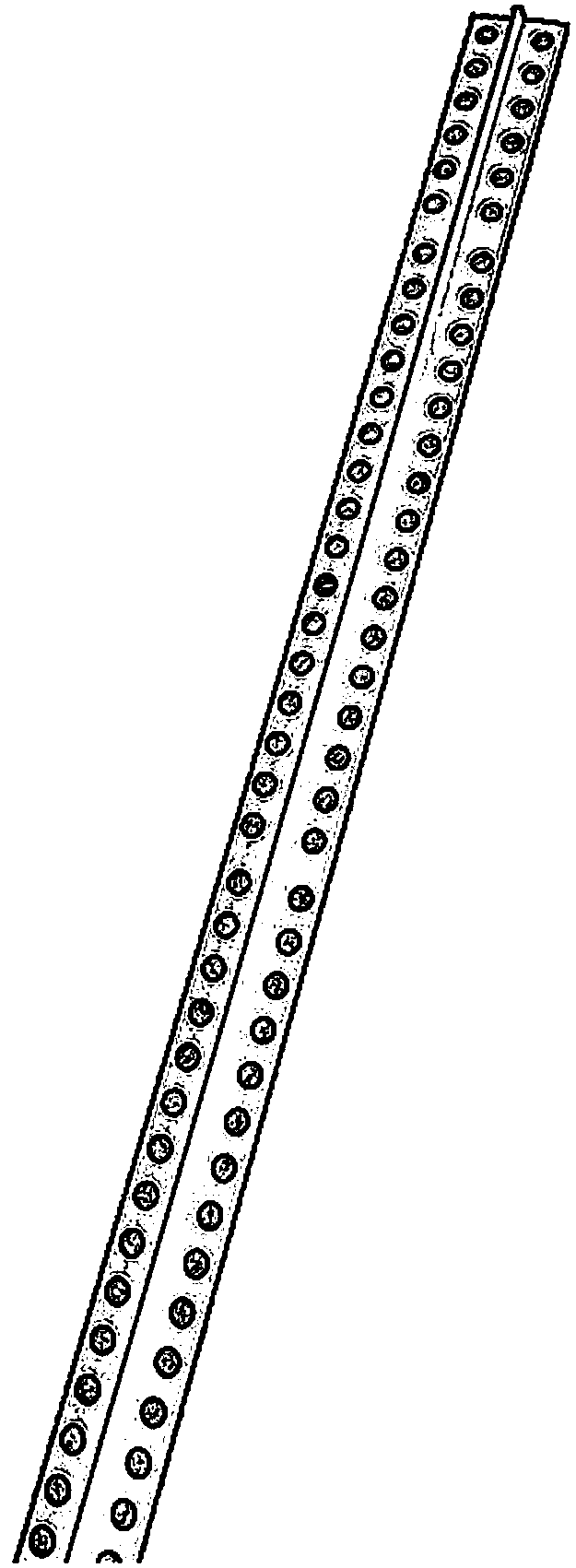

InactiveCN106401041AReduce lossGuaranteed structural qualityBuilding roofsForms/shuttering/falseworksKeelEngineering

The invention provides a cast-in-situ concrete construction method for a pseudo-classic architecture slope roof. Firstly, after a bottom layer formwork of the slope roof is installed, vertical keels of the bottom layer formwork are disposed in the direction from the slope bottom to the slope top according to the slope roof trend, and the vertical keels of the bottom layer formwork and the bottom layer formwork are fixedly clamped and located through limit water stop bolts so as to control the structure thickness and the basis of installing face layer formworks; according to the lofting result, the face layer formworks are graded and prefabricated in advance, when installed, the face layer formworks are placed between vertical keels of the face layer formworks, and gib-head bolts are inserted into circular holes of the vertical keels of the face layer formworks and the face layer formworks to fix the vertical keels of the face layer formworks and the face layer formworks, wherein the circular holes are drilled in advance. Carpenters move around the slope roof and install the face layer formworks from bottom to top according to grades, concrete can be poured once one grade is installed, and bricklayers move around the slope roof and pour the concrete on which one grade of formworks is installed; methods of grade-by-grade installation and grade-by-grade pouring are adopted, and installing and pouring are reciprocally, orderly and circularly conducted until pouring is completed.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

Building paste spreader

When a brick layer lays bricks and paves cement paste, the brick layer leaks the cement paste on the bricks via a paste bucket, which costs half of the work; an iron sheet of 2mm is used for manufacturing a rectangular frame without the upper bottom and the lower bottom, which is 23cm in width, 30cm in length and 30cm in height; the lower opening of one end of the rectangular frame is provided with a plurality of small openings having a depth of 1.5cm, which is of a shape that a plurality of m are connected together; a roller wheel shelf is welded in the middle part below the side of the otherend of the rectangular frame, and the roller wheel shelf is mounted with a roller wheel rolling in the direction parallel to the bottom edge of the long side; the rolling face of a bearing is on theextension line of the bottom side; four roller wheel shelves are welded below each side of the rectangular frame, each shelf extends 1cm outwards and 8cm downwards, and is respectively mounted with aroller wheel, the roller wheels are vertical to the first roller wheel in angle, has consistent rolling direction and a slight combination and departure elasticity; the three lower sides besides the mside of the rectangular frame are cut off 0.5cm; the cement paste is poured into the rectangular frame, and the rectangular frame is pushed by hands to lead the cement paste to flow down from the M opening; and (the dryness of the bricks are matched with the thickness of the paste) the working time for laying the bricks are saved by half.

Owner:许修武

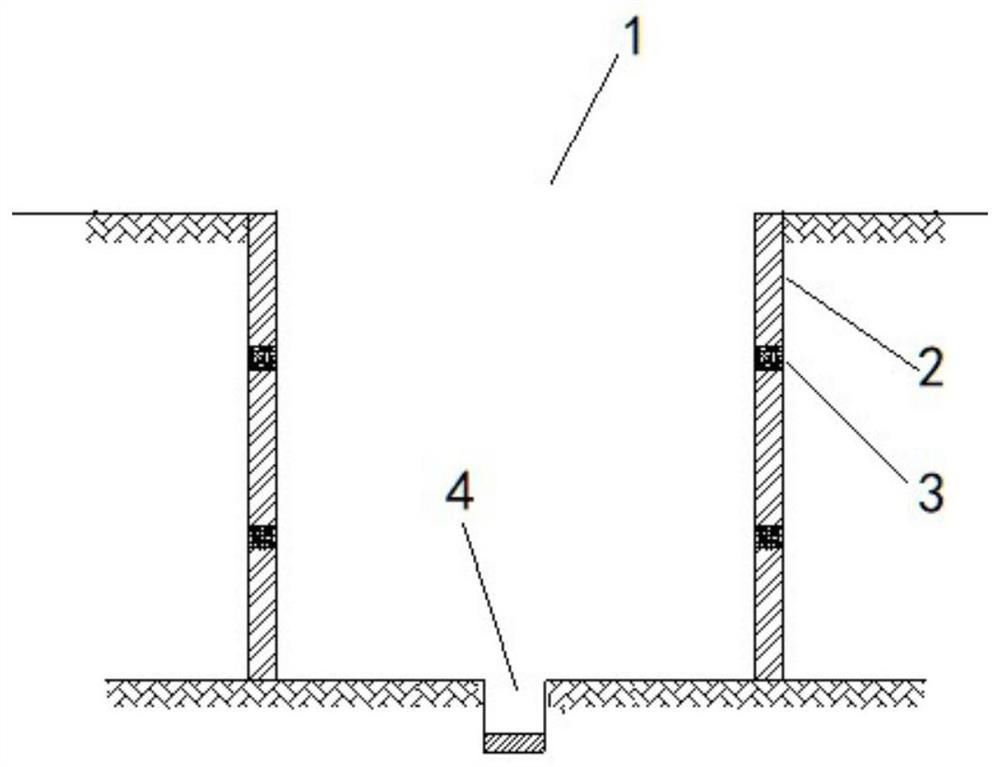

Reverse construction method for pipe-jacking bricked working well

InactiveCN112431225AAccurately control the diameterControl diameterArtificial islandsUnderwater structuresReinforced concreteBrick

The invention discloses a reverse construction method for a pipe-jacking bricked working well. The method comprises the following steps of 1) determining the wall thickness of the well; 2) carrying out measuring, paying off and positioning; 3) carrying out earth excavation; 4) building a well chamber; 5) carrying out well bottom construction; 6) pouring a well chamber inner side protection wall; and 7) backfilling the well chamber, wherein in the step 3) and the step 4), earth excavation, well wall building and reinforced concrete ring beam pouring are conducted layer by layer from top to bottom, after construction of the upper layer is completed, construction of the next layer is conducted till all building work of the well chamber is completed, and steel bars of a lower-layer ring beam need to be pre-buried when the upper-layer well wall is built. When the well wall is built, the method for controlling the diameter of the well chamber comprises the steps that after the first layer ofwell chamber is excavated, part of the wall body is built firstly, then two steel pipes are crossed to form a cross shape, and the steel pipes are hung down from the center of the well chamber and fixed to the built wall body; and plumb bobs are tied to the two ends of each steel pipe, the distance between the paired plumb bobs corresponds to the inner diameter of the well chamber, and the plumbbobs and plumb bob lines are used as references for a bricklayer during bricklaying.

Owner:CHINA NAT CHEM ENG NO 14 CONSTR

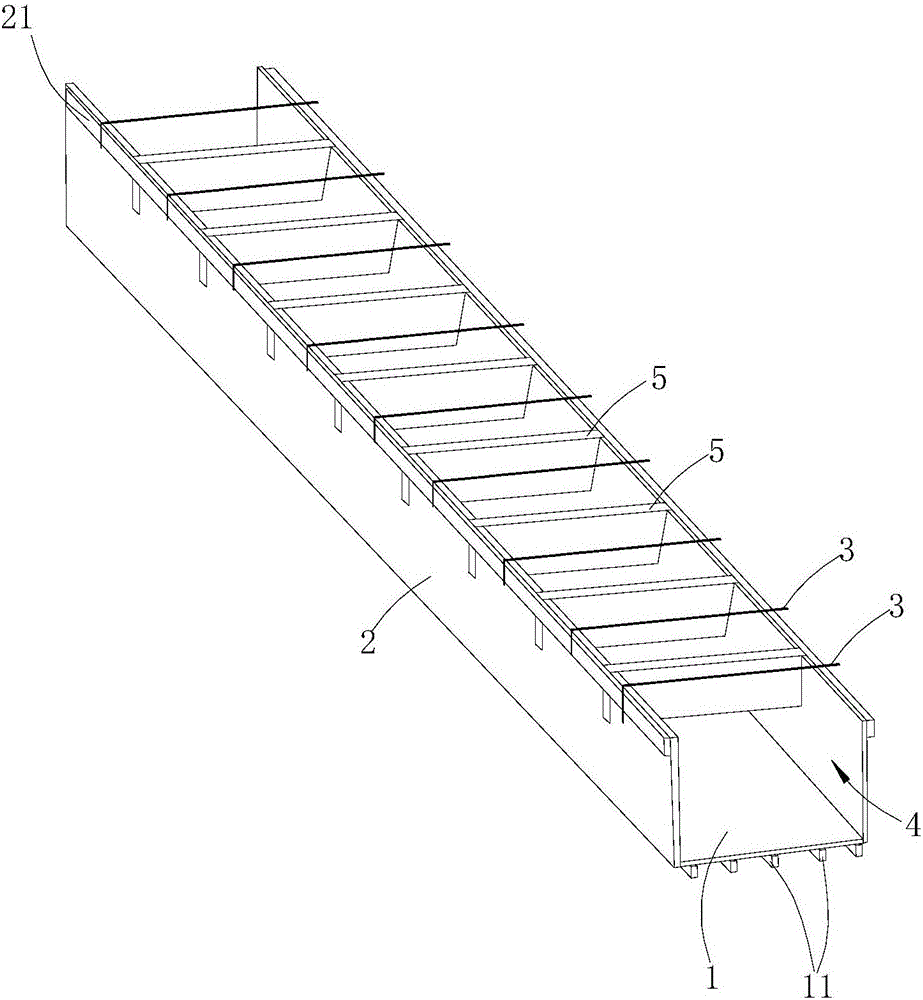

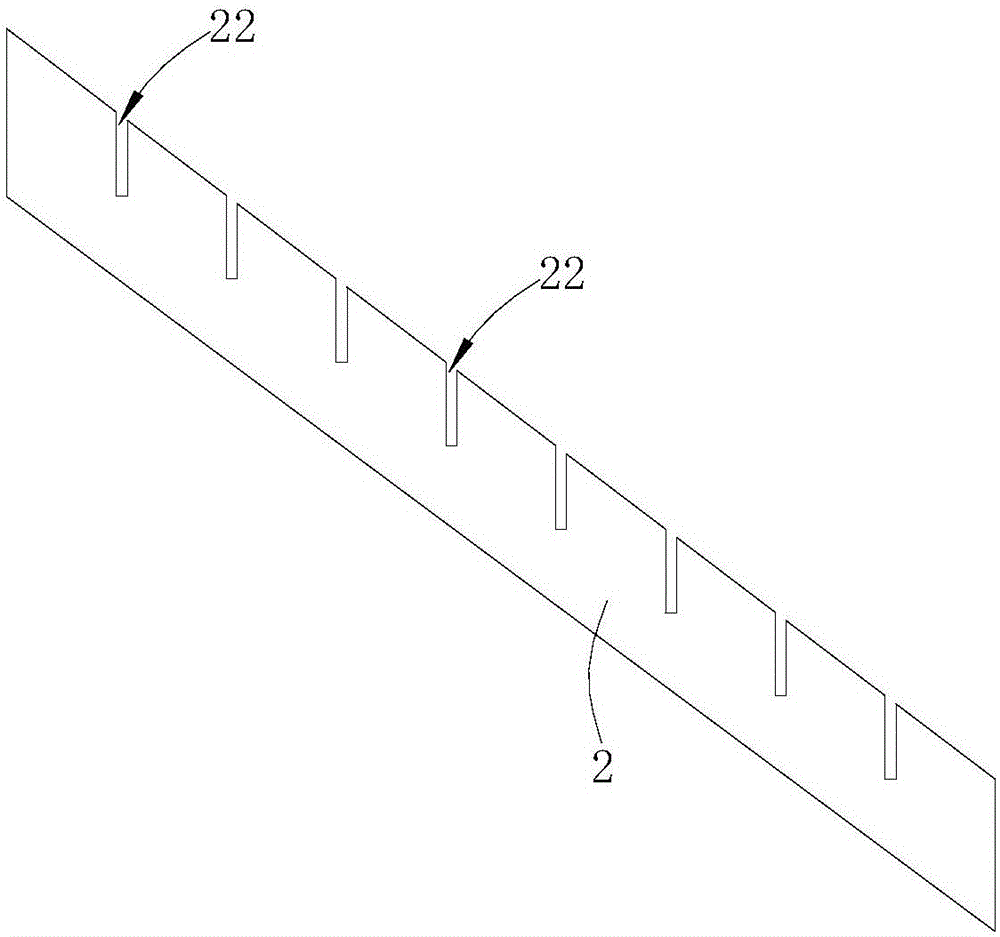

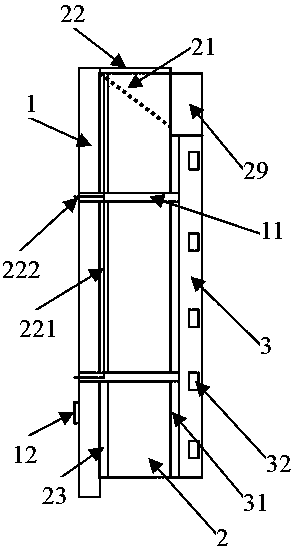

Stair concrete pouring formwork device and stair concrete pouring method

InactiveCN106088589AImprove work efficiencyImprove appearance qualityForms/shuttering/falseworksBuilding material handlingRebarBricklayer

The invention provides a stair concrete pouring formwork device. The stair concrete pouring formwork device comprises a bottom formwork, two side formworks and a plurality of transverse baffles. The two side formworks are fixedly connected to the two sides of the bottom formwork correspondingly. The bottom formwork and the two side formworks form a pouring chamber. Clamping groove openings are formed in the side formworks. The transverse baffles are inserted in the clamping groove openings of the side formworks. The stair concrete pouring formwork device has the beneficial technical effects that installing, dismantling and carpenter and bricklayer construction are convenient; concrete forming is good; the project quality is effectively ensured; and repeated use can be achieved. The invention further provides a stair concrete pouring method. The stair concrete pouring method comprises the following steps that chiseling is conducted on the floor section positions; secondary reinforcement binding is conducted on steel bars; the formwork device is loaded, the pouring chamber is formed, concrete is poured into the pouring chamber, and the transverse baffles are inserted in the clamping groove openings of the side formworks; leveling is conducted; and the formwork device is dismantled, so that pouring operation is completed. The width and the height of formed concrete stair steps are standard, and the stair appearance quality is improved.

Owner:ANHUI WATER RESOURCES DEV

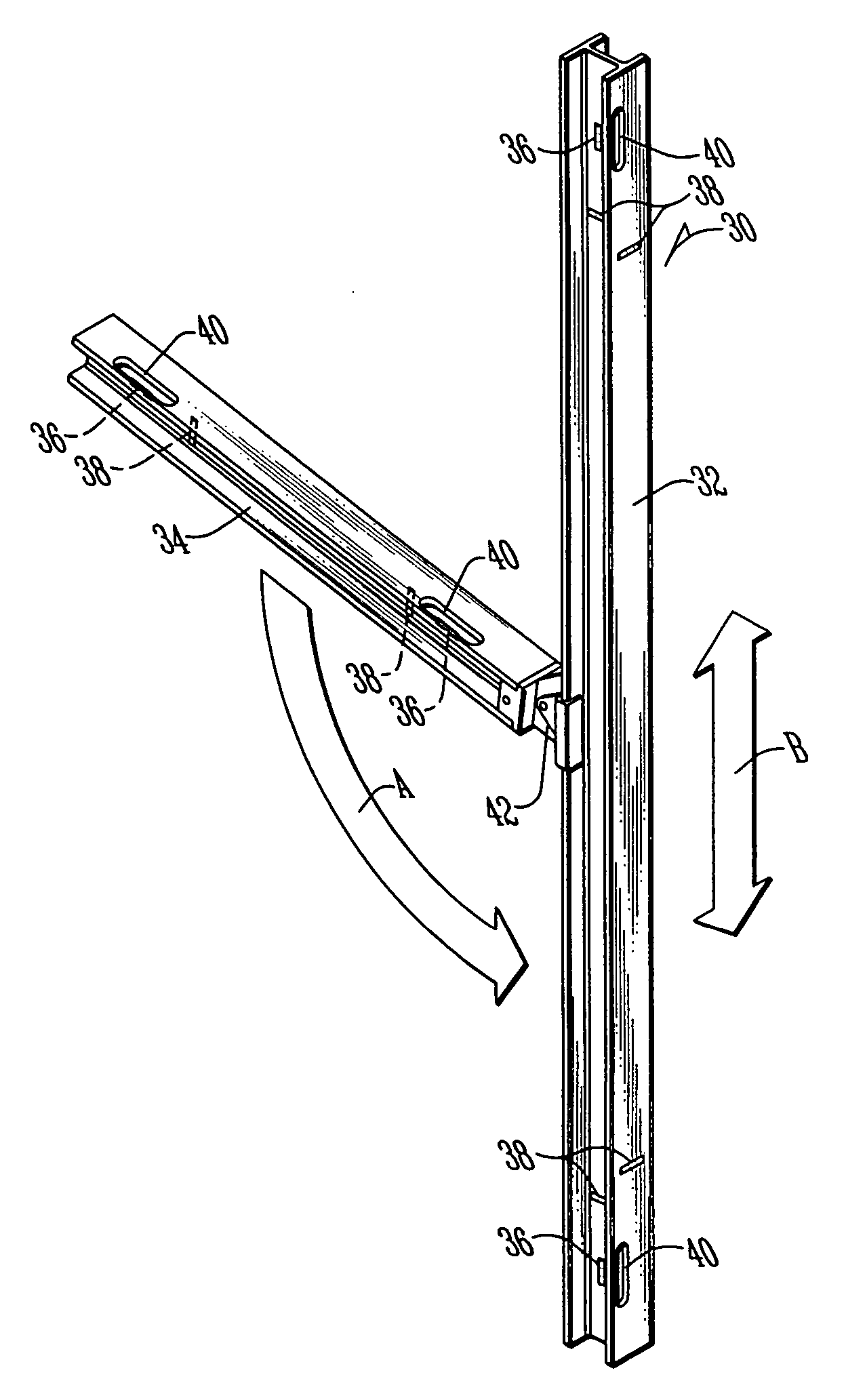

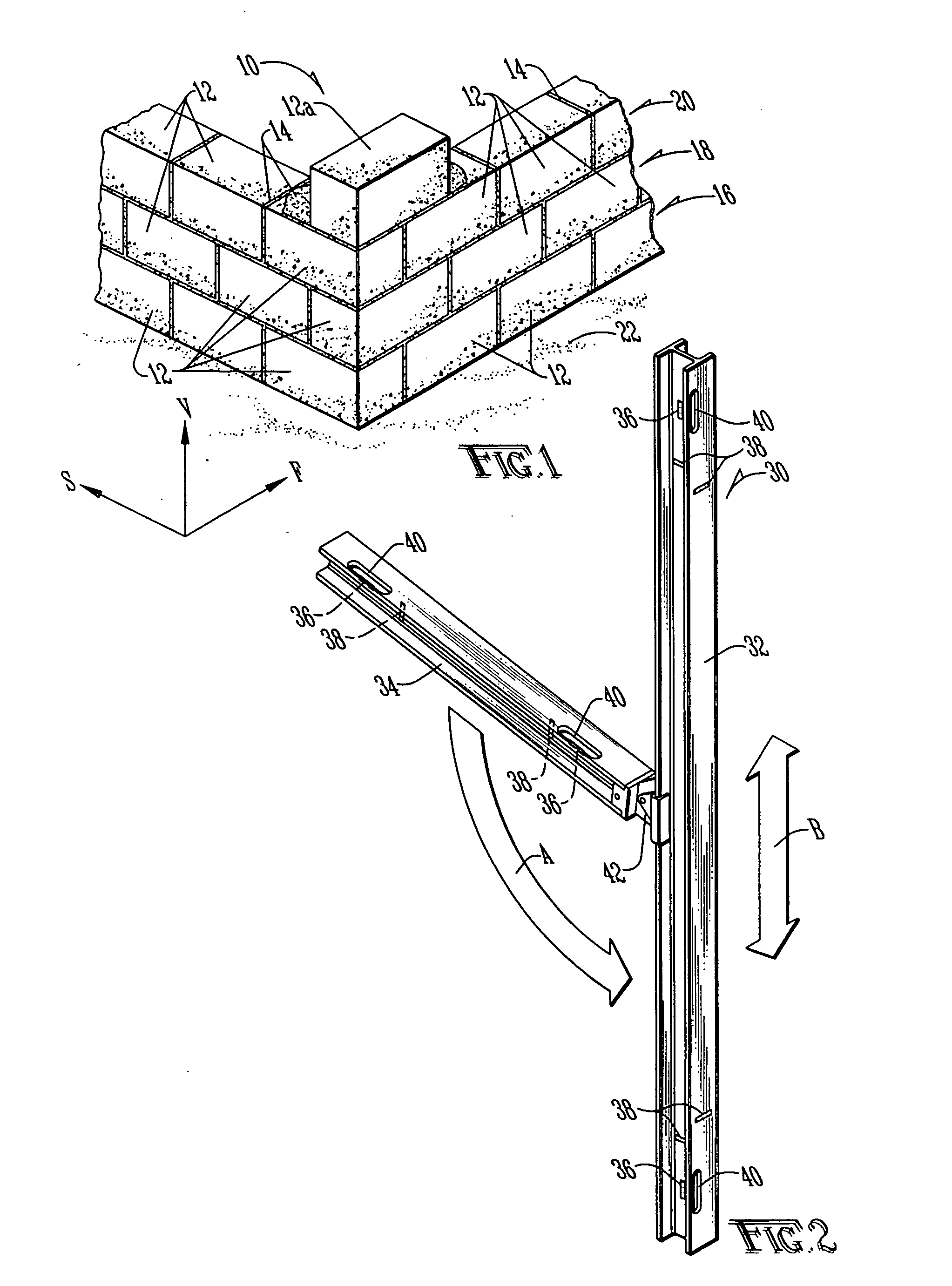

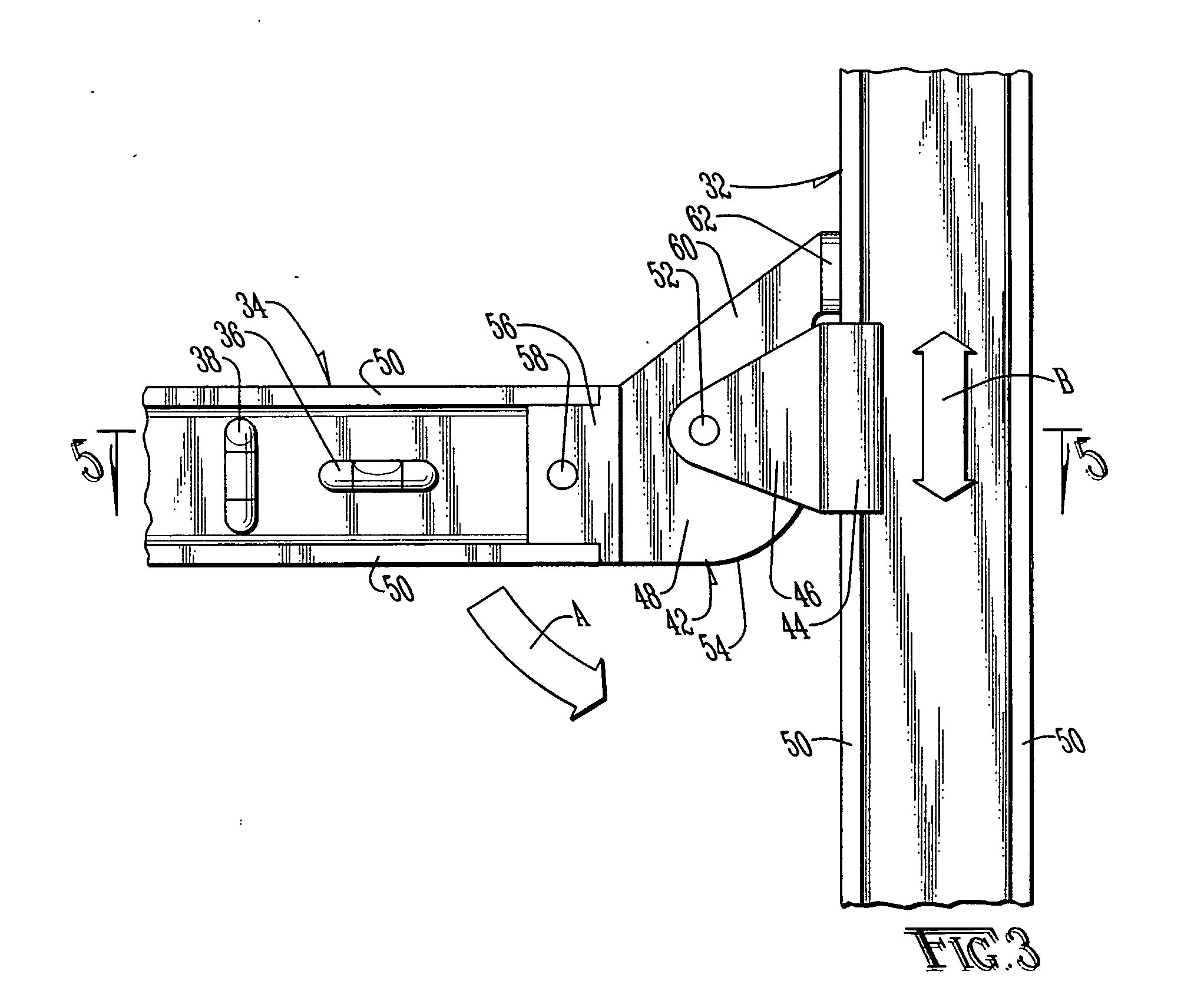

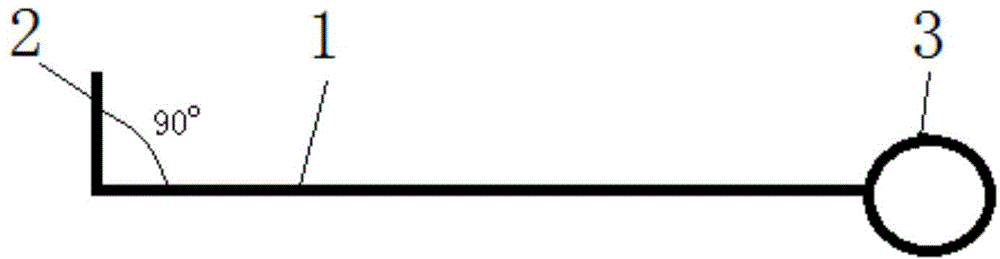

Bricklayer's combination level and plumb

InactiveUS20050000101A1Improve performanceEasy to adaptBuilding material handlingStraightedgesEngineeringBricklayer

A bricklayer's combination level and plumb having a first I-section beam, a second I-section beam, and a connector pivotally and slidably connecting the second I-section beam to the first I-section beam wherein the second I-section is angularly displaceable up to and including a right angle relative to the first I-section beam.

Owner:HANNAH JOSEPH

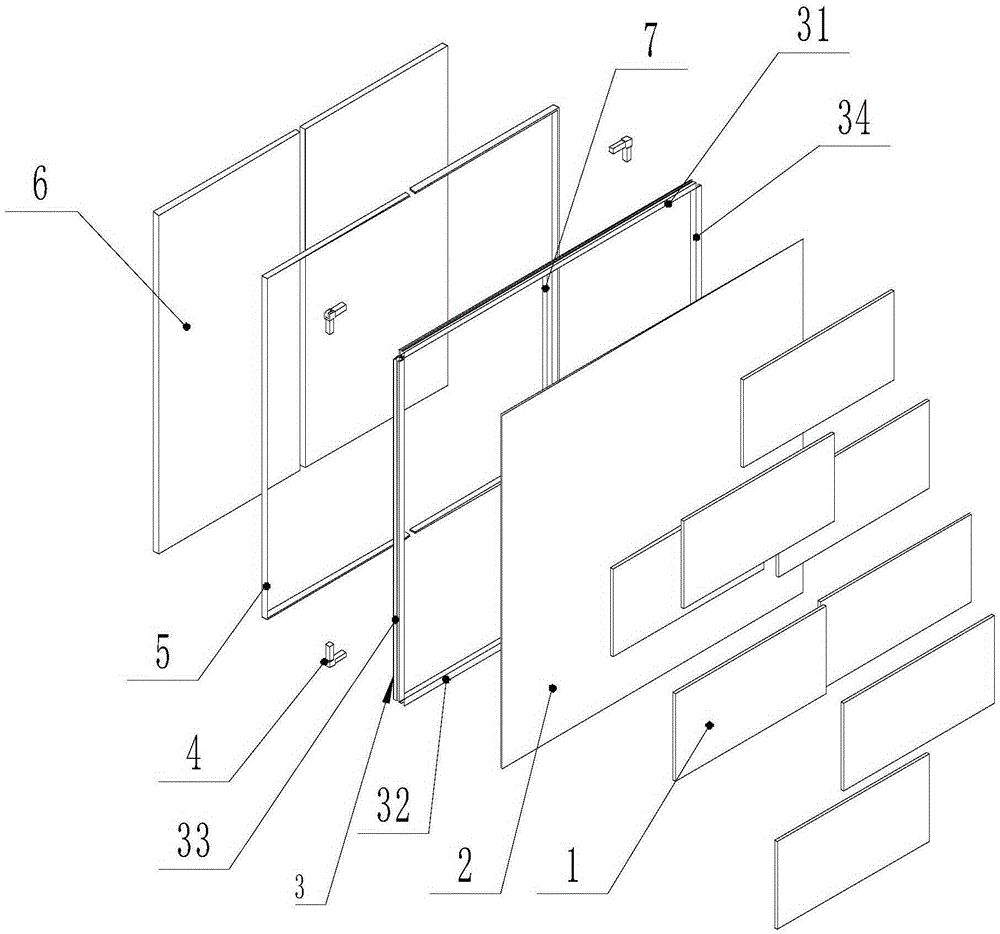

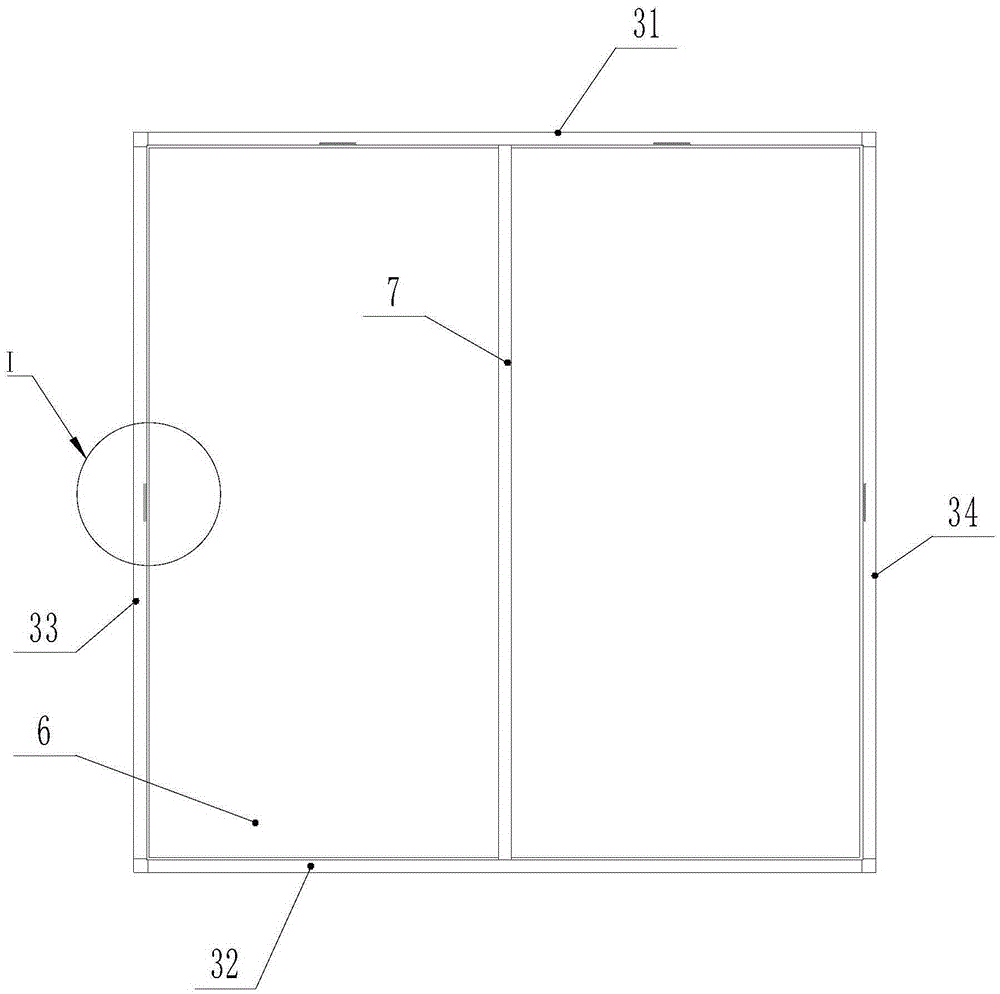

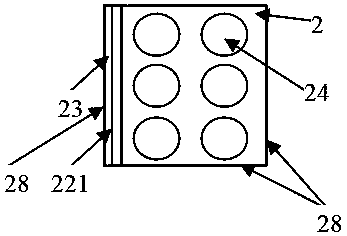

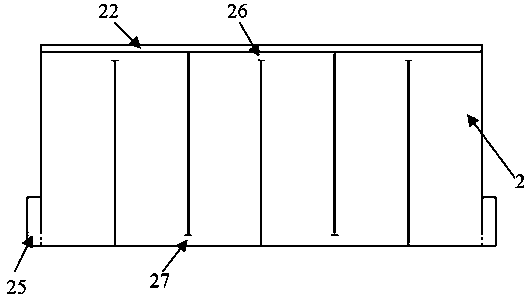

Prefabricated composite wall panel

InactiveCN105421707AEasy to layLow construction skills requiredCovering/liningsFlooringArchitectural engineeringEnvironmental quality

The invention discloses a prefabricated composite wall panel comprising a decorating plate layer, a periphery framework and a functional plate layer, wherein the periphery framework comprises an upper frame, a lower frame, a left frame and a right frame; the periphery framework is adhered to the inner side surface of the decorating plate layer; a space confined by the periphery framework is filled with the functional plate layer; the periphery edge of the functional plate layer is adhered to the periphery framework; the outer side surf ace of the functional plate layer is adhered and fixed together with the inner side surface of the decorating plate layer; through slots are formed in the upper end surface of the upper frame and the lower end surface of the lower frame; at least two locating slots are formed in the inner side surface of the upper frame; and at least one locating slot is formed in the inner side surface of each of the left frame and the right frame. The composite wall panel is not needed to be constructed by professional bricklayers and is simple in construction and high in wall flatness after being paved; and mixing and stirring concrete on a construction field are not needed, so that the construction time is short, and the environmental quality of the construction field is improved.

Owner:ORCA COLORS CO LTD

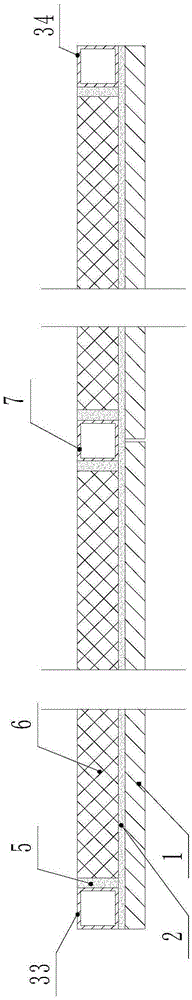

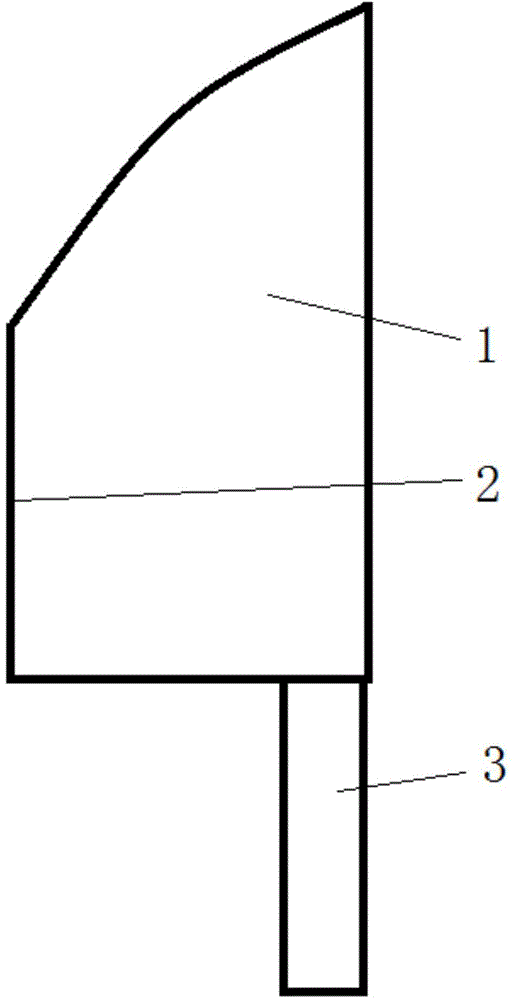

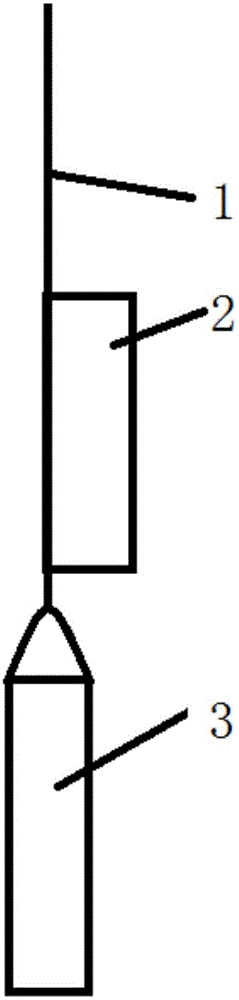

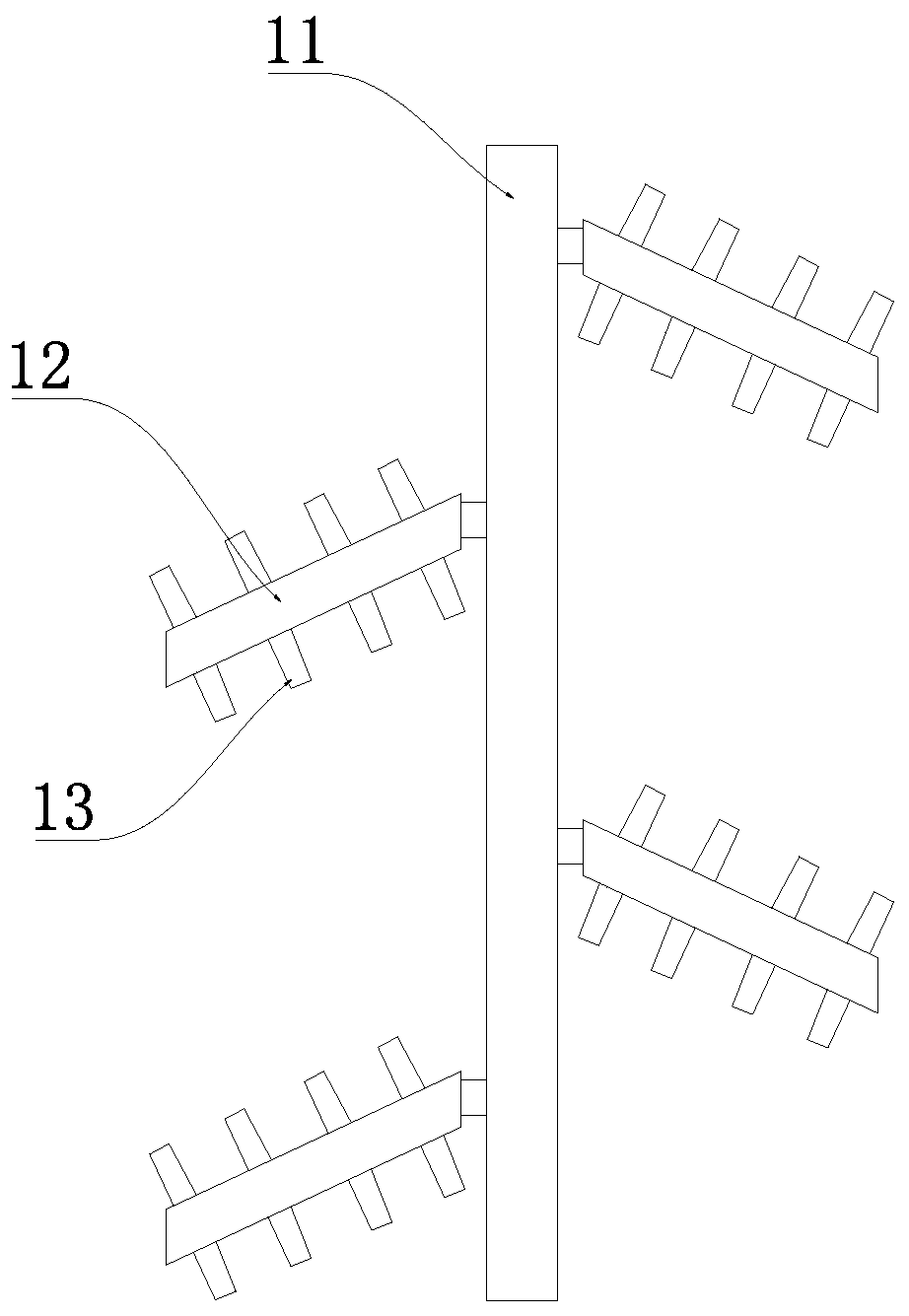

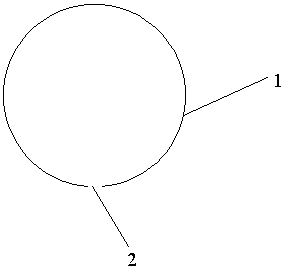

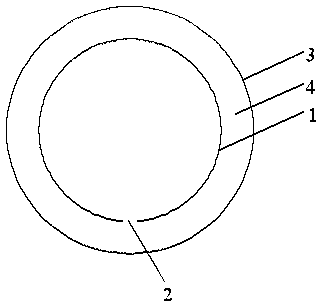

Safe bricklayer cleaver used for brick building

InactiveCN104831942APrevent accidents of falling off and hurting peopleBuilding material handlingBrickArchitectural engineering

A safe bricklayer cleaver used for brick building is designed for protecting the safety of brick building workers, and belongs to the field of building safety. The safe bricklayer cleaver used for the brick building is composed of a cleaver quakeproof device (1), a cleaver falling-off prevention device (2) and the cleaver (3), wherein the cleaver quakeproof device (1) is composed of a rope (11) and a soft cushion (12); the cleaver falling-off prevention device (2) is composed of an iron ring (21), a wrist winding band (22), a buckle band (23) and a buckle (24); the cleaver (3) is composed of a cleaver body (31) and a hilt (32); the cleaver body (31) is fixedly bonded with the hilt (32); the cleaver quakeproof device (1) is bonded with the hilt (32) in a winding mode through the outer portion of the hilt (32) of the cleaver (3); the cleaver falling-off prevention device (2) is connected with the end portion of the hilt (32) through the end portion of the hilt (32) of the cleaver (3) in a buckled mode. The safe bricklayer cleaver used for the brick building has the advantage that when the cleaver is used to cut a brick, a hand of a worker can be prevented from being cracked by shattering or an accident that the cleaver falls off to hurt people is avoided.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

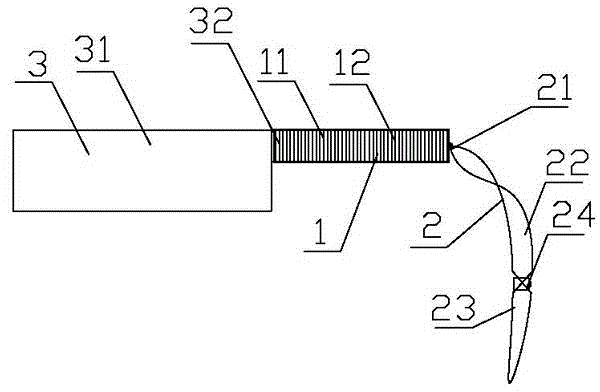

Automatic plastering plate

InactiveCN102936950AImprove work efficiencyIncreased area of plastered wallsBuilding constructionsEngineeringBricklayer

The invention discloses a stainless steel square automatic plastering plate of which the middle is slightly folded and the upper and lower ends are raised a little. The automatic plastering plate is composed of an upper plastering plate and a lower plastering plate, wherein a handle is arranged in an upward position of the lower plastering plate, and the inside of the handle is hollow and is connected with a conveying pipe; a switch is arranged on the handle; after the switch is turned on, the mortar is conveyed to the handle through the conveying pipe and enters a convex trough and a convex channel of the lower plastering plate; and a bricklayer holds the handle and drags up and down for uniform plastering. The automatic plastering plate can perform the primary plastering work of the wall, and realizes high efficiency and good effect.

Owner:仇英兰

A kind of equipment for applying mud to tiles for building construction

ActiveCN111894245BImprove the efficiency of cement applicationFast reset workBuilding constructionsAdhesiveArchitectural engineering

Owner:邱隆芸

Construction process for bricklaying and hanging brick

InactiveCN110748035AUniform colorIncreased shear strengthWallsBuilding material handlingBrickArchitectural engineering

The invention relates a construction process for bricklaying and hanging brick. Compared with a traditional bricklaying process, and the process is more reasonable; through the steps of material selection, watering, mortar laying masonry method, cooling and masonry supplying, the material selection can detect the external condition of brick bodies, the brick bodies with good appearance and uniformcolor can be selected, so that the wall of masonry is more attractive, and the effect that the wall of the masonry is firmer is reached; watering can improve the bonding force between the brick bodies and mortars, and the shear strength of the wall of the masonry is improved; the mortar laying masonry method is different from the ordinary masonry method, reinforcing steel bars or laying strips are laid on the two sides of the upper parts of the brick bodies while the masonry is carried out, the use rate of the mortars is reduced, the reinforcing steel bars or the laying strips are taken out after the brick bodies are stabilized, and the appearance of the wall is higher. When the vertical connection mortars are particularly insufficient and even completely free of mortars, the shear strength of the wall of the masonry is reduced by 40%-50%, and masonry supplying methods that mortar supplying is carried out on the vertical seam and the horizontal seam, so that a better bonding effect isachieved. The construction process has the advantages that the process is simple, the effect of bricklaying is good, and production raw materials can be saved.

Owner:永威置业集团有限公司

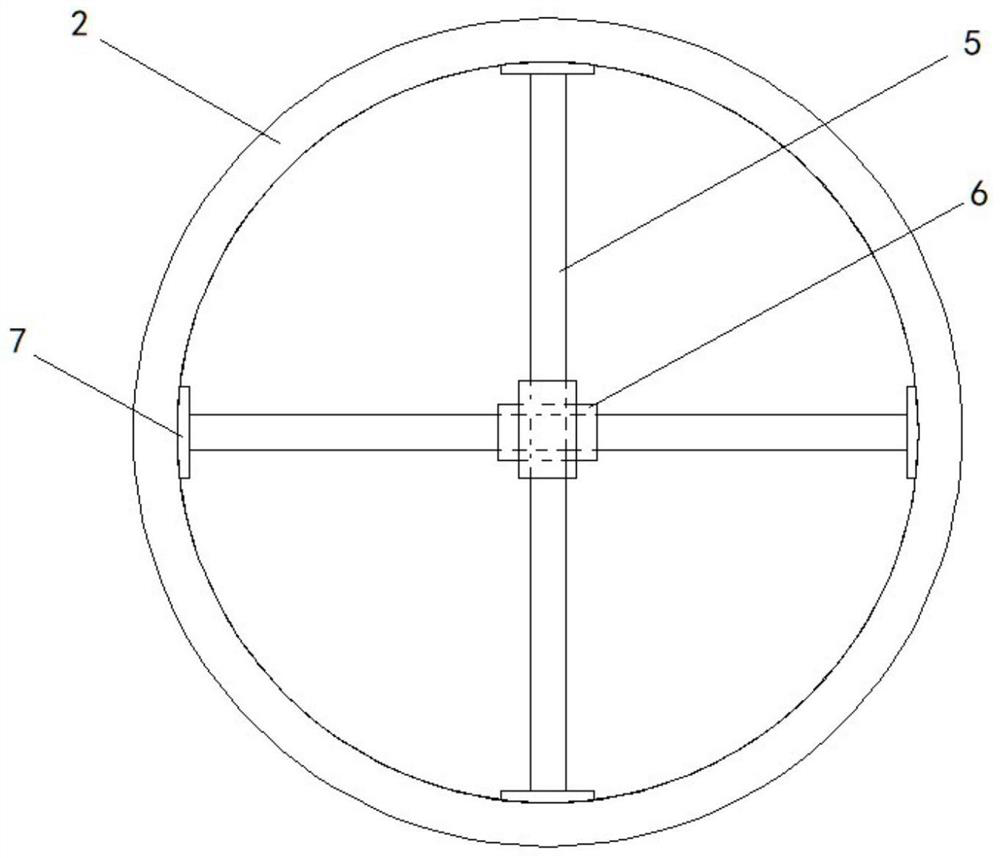

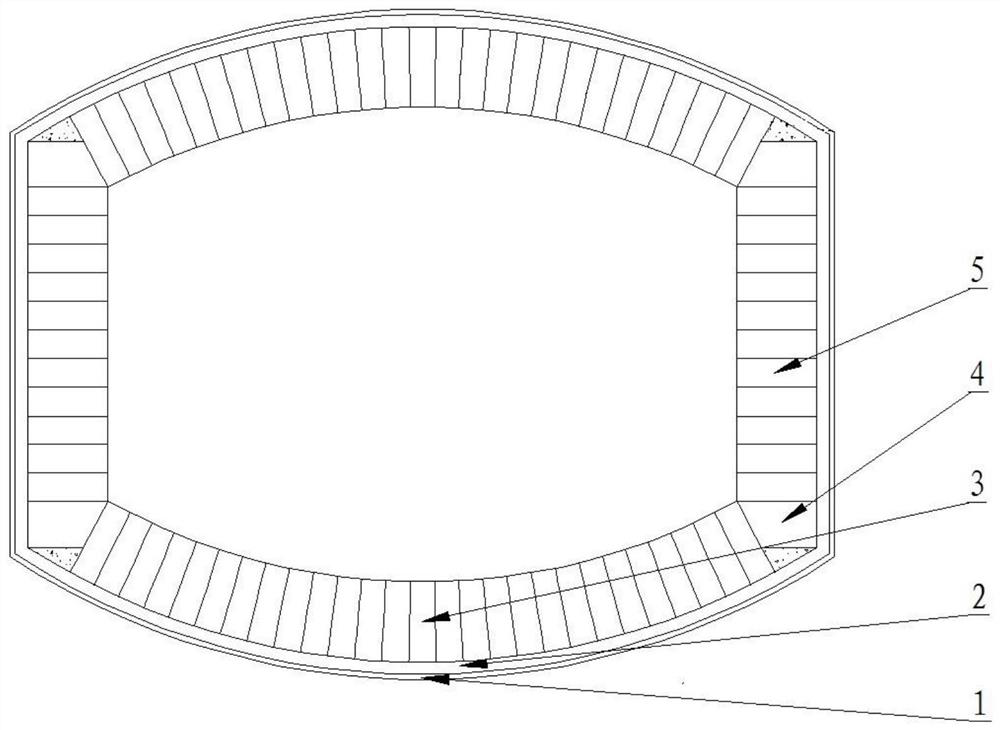

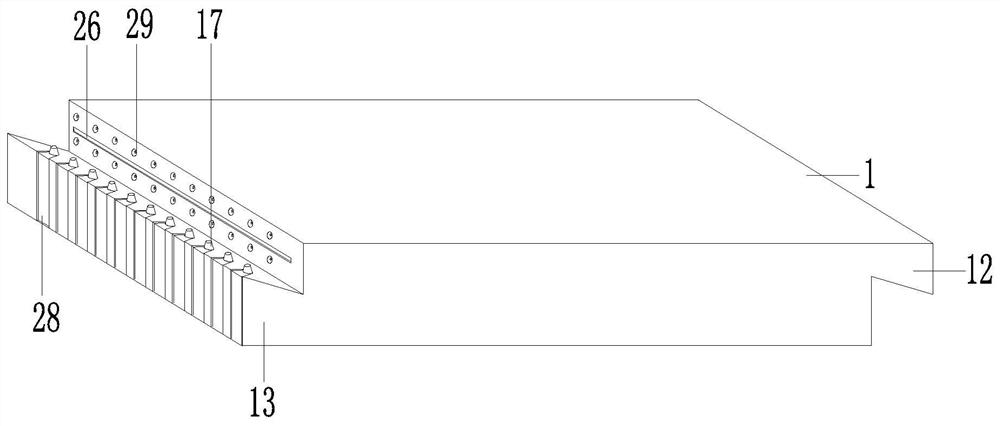

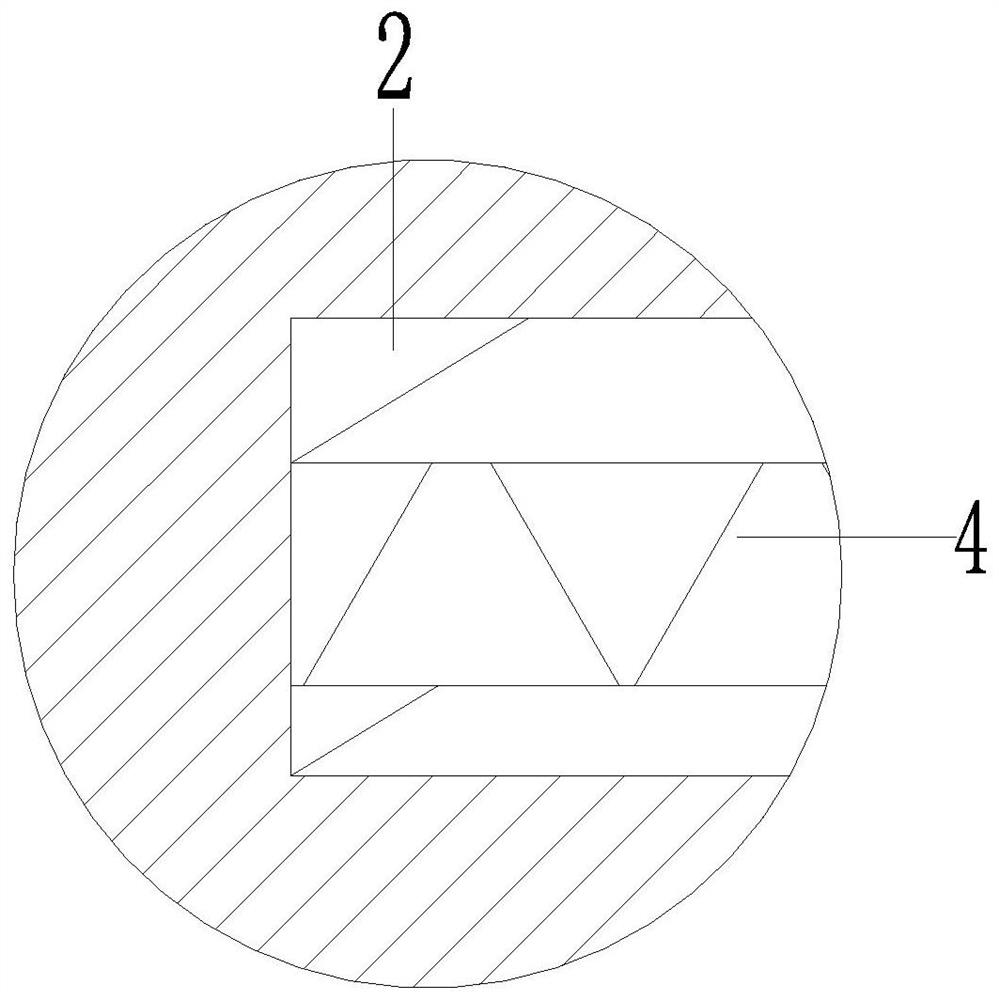

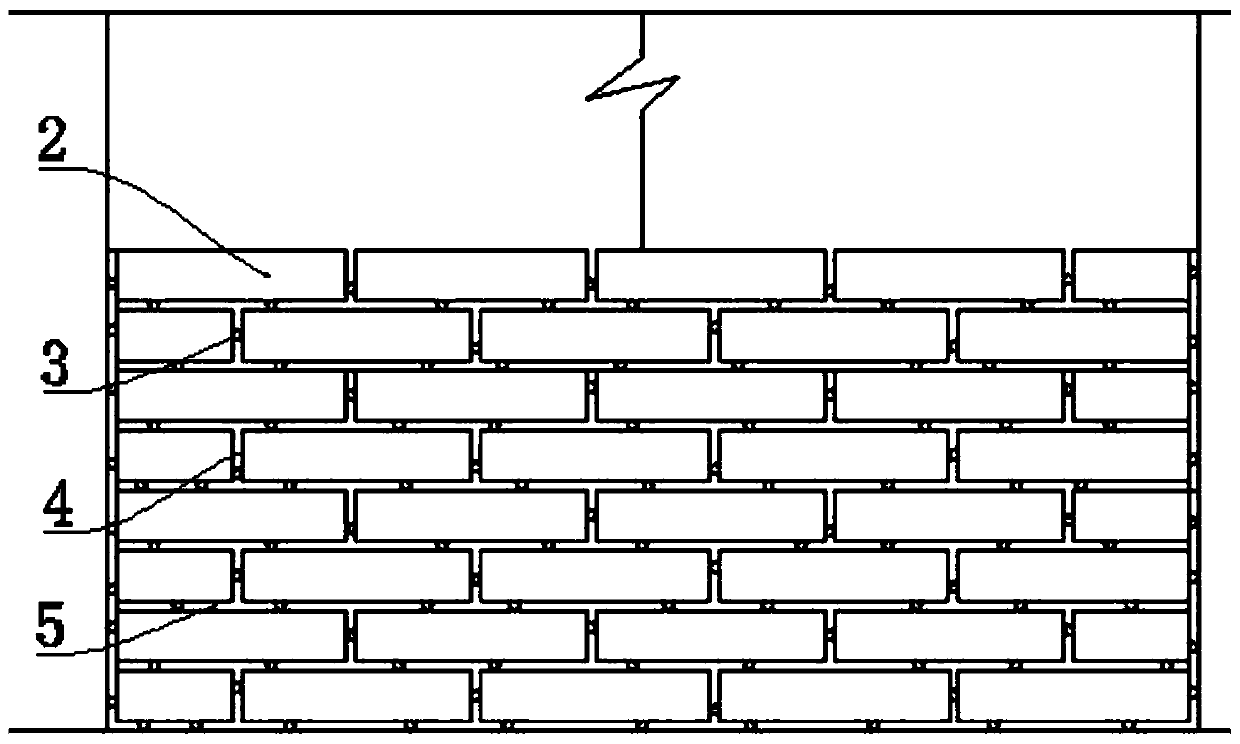

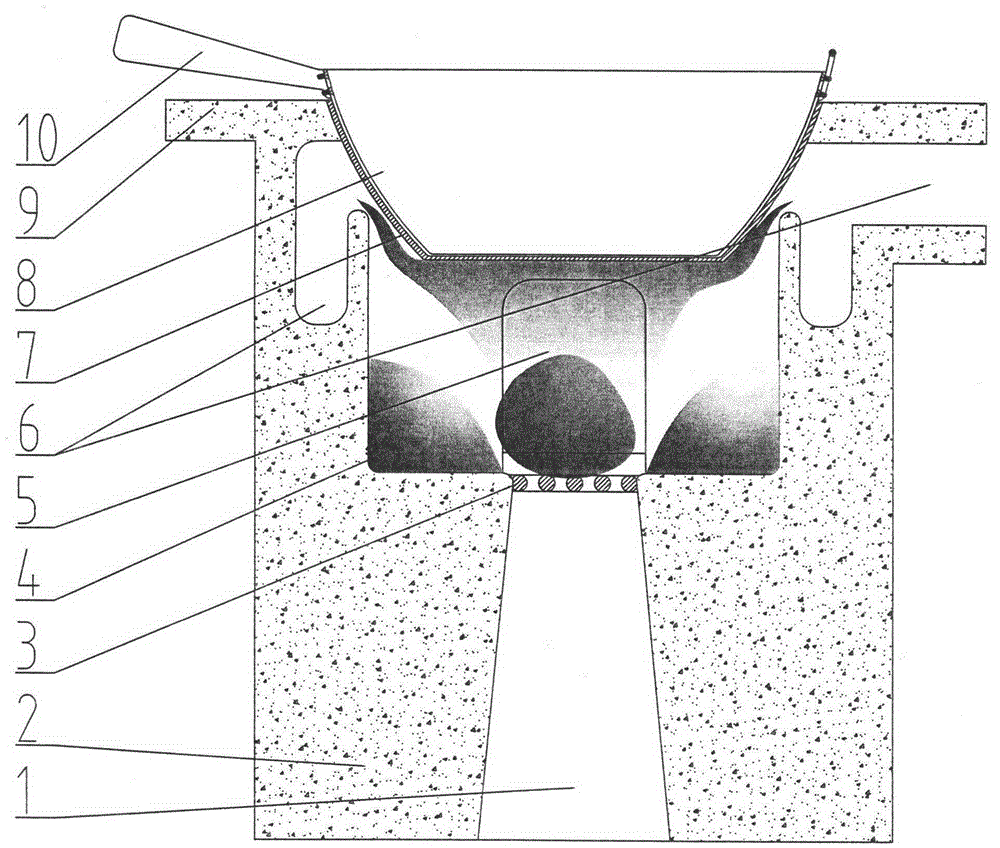

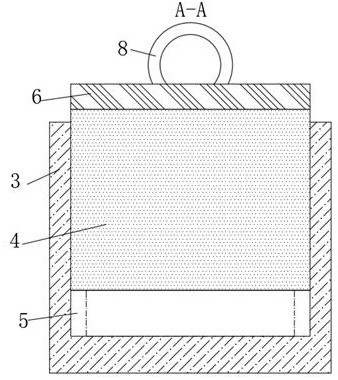

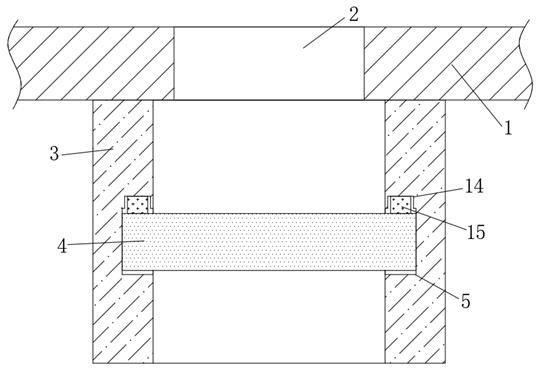

Lining building structure of horizontal converter mouth

PendingCN112082380AExtended maintenance cycleExtended service lifeRotary drum furnacesBrickArchitectural engineering

The invention discloses a lining building structure of a horizontal converter mouth. The lining building structure comprises multiple transition bricks (1), multiple arch bricks (2), multiple lockingbricks (3), multiple tongue bricks (4) and multiple side wall bricks (5). The horizontal converter mouth comprises four inner side faces, two opposite inner side faces of the horizontal converter mouth are built into locking brick layers through the multiple locking bricks (3), and the other two opposite inner side faces of the horizontal converter mouth are built into side wall brick layers through the multiple side wall bricks (5). The bottoms of the locking brick layers are flush with the bottoms of the side wall brick layers, arch brick layers are built at the bottoms of the locking bricklayers and the bottoms of the side wall brick layers through the multiple arch bricks (2), and transition brick layers are built at the bottoms of the arch brick layers through the multiple transitionbricks (1). The locking bricks (3) are in building connection with the side wall bricks (5) through the tongue bricks (4). By means of the lining building structure of the horizontal converter mouth,the problems that a lining of the horizontal converter mouth is high in building difficulty, too fast in erosion, short in service life and the like can be solved.

Owner:JINCHUAN GROUP LIMITED

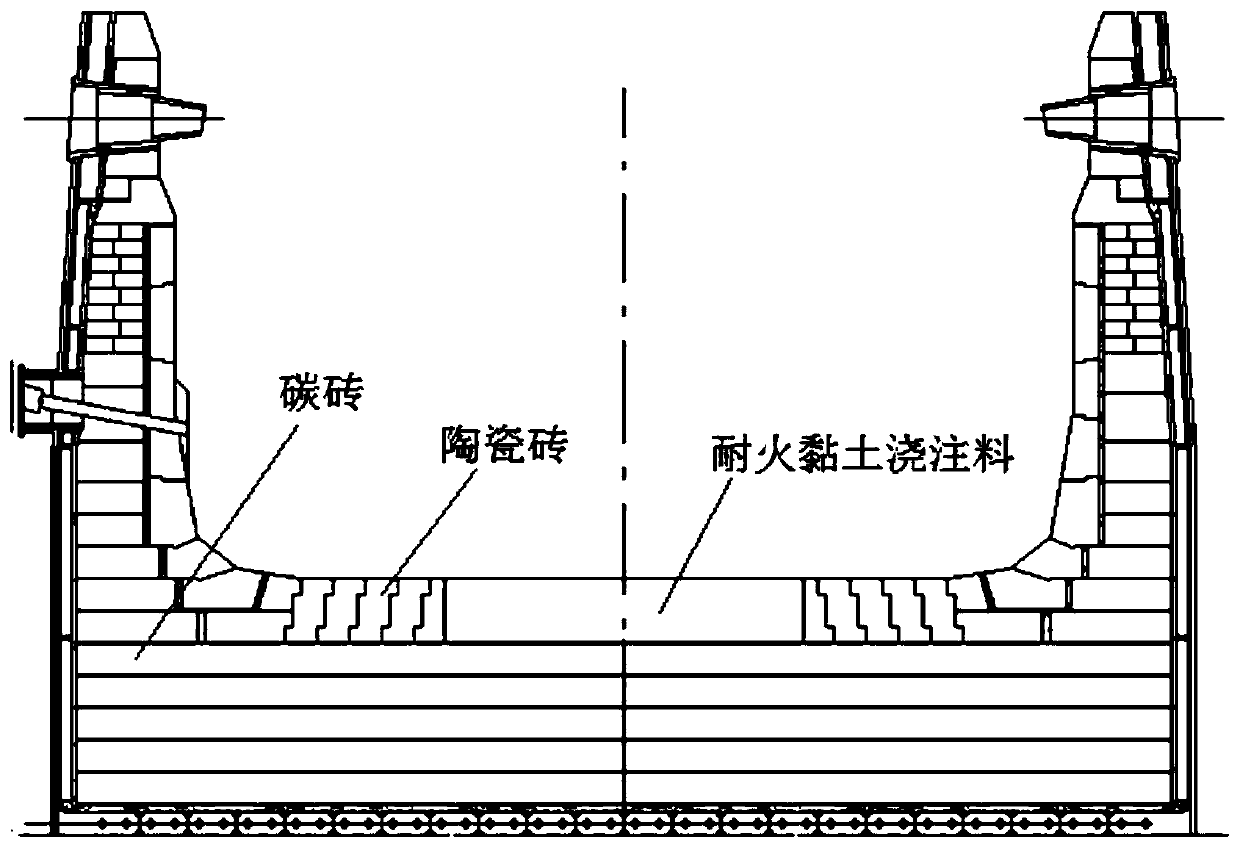

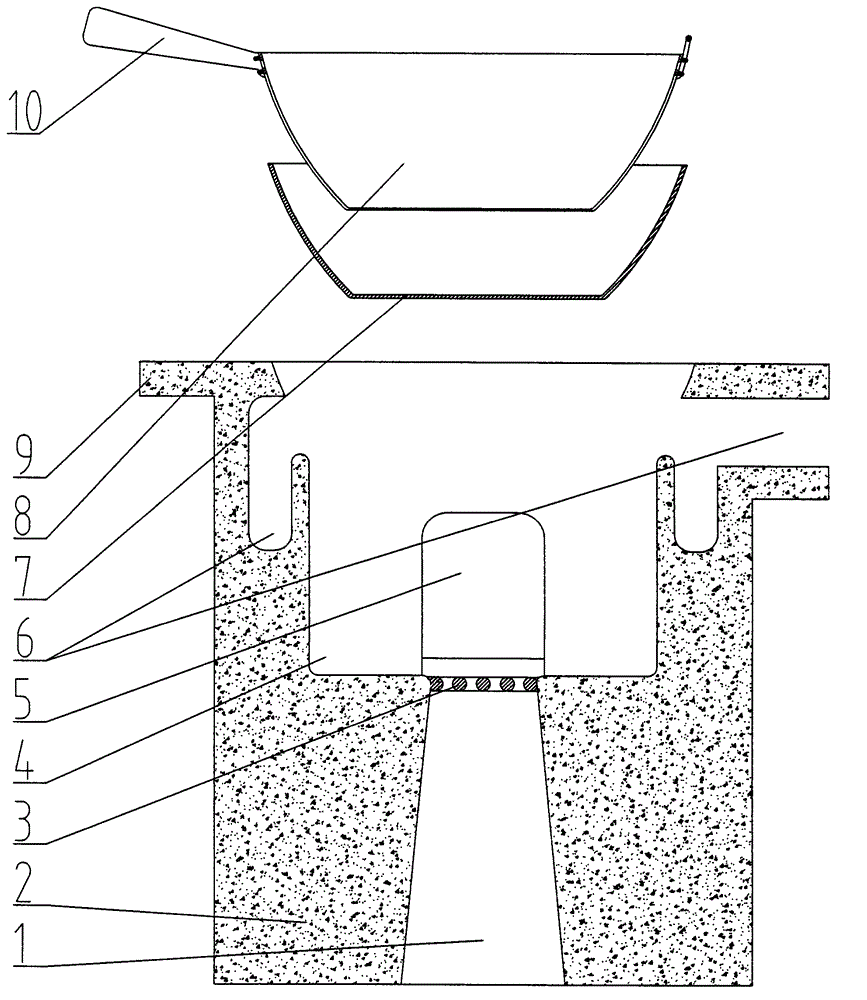

Laying method of blast-furnace bottom for guiding furnace bottom to be in shape of pot bottom

The invention relates to a laying method of a blast-furnace bottom for guiding the furnace bottom to be in the shape of pot bottom. Ceramic bricks are not laid in the center of a furnace bottom ceramic brick layer, a refractory clay pouring material is adopted for pouring, after a blast furnace is put into operation, the refractory clay pouring material in the center of the furnace bottom is gradually eroded by molten iron, and thus the furnace bottom is in the shape of pot bottom. According to the laying method, the ceramic bricks are not laid in the center of the furnace bottom ceramic bricklayer, the refractory clay pouring material is adopted for pouring, the characteristic of poor molten iron erosion resistance of the clay material is used, the pot bottom is gradually eroded and formed after 6-9 months of blast furnace operation, then the whole furnace bottom gradually forms a 'pot bottom' shape, the service life of the first generation of the blast furnace can be effectively prolonged, meanwhile because the clay pouring material is low is price and fast in construction, the investment is saved, and the construction speed is increased.

Owner:ANGANG STEEL CO LTD

Sound insulation ceramic tile mounting method

PendingCN113123547AQuality assuranceGood volume absorptionCovering/liningsFlooring insulationsAdhesiveBricklayer

The invention relates to the technical field of ceramic tiles, and discloses a sound insulation ceramic tile mounting method. The sound insulation ceramic tile mounting method comprises the following steps that S1, a site where sound insulation ceramic tiles are pre-paved is investigated by an investigator to obtain an investigating result; S2, a leveling bricklayer performs leveling treatment on the substandard wall and / or ground base layer according to the investigating result; S3, the investigator pastes a tiling starting line used for positioning the paving position of the single sound insulation ceramic tile on the leveled base layer according to a preset paving scheme, and determines the processing size of the single sound insulation ceramic tile according to the tiling starting line; S4, the factory performs processing according to the processing size of the sound insulation ceramic tiles; and S5, according to a construction drawing, a paving and tiling worker uses a paving and tiling tool to scrape an adhesive on the processed sound insulation ceramic tiles on the base layer along the tiling starting line, the sound insulation ceramic tiles are spliced and paved, hammering is carried out through a rubber hammer, and it is guaranteed that the adjacent sound insulation ceramic tiles are pressed tightly. The mounting stability of the sound insulation ceramic tiles can be greatly guaranteed.

Owner:孙辉东

Anti-falling cement shovel plate for bricklayer on construction site

InactiveCN110924698AEasy to pass throughPrevent fallingBuilding material handlingStructural engineeringCement paste

The invention discloses an anti-falling cement shovel plate for a bricklayer on a construction site. The anti-falling cement shovel plate comprises a flat plate, a shaft barrel is vertically and fixedly connected to the left side of the front end of the flat plate, and a rotating shaft is vertically inserted into the shaft barrel; an L-shaped baffle is horizontally arranged on the upper end face of the flat plate, the left side of the L-shaped baffle is fixedly connected with the upper end of the rotating shaft, a pull plate is fixedly connected to the lower end of the rotating shaft and is parallel to a right side plate of the L-shaped baffle, and a connecting rod is vertically and fixedly connected to the lower end face of the flat plate and located on the right side of the pull plate. According to the invention, fingerstalls are fixedly connected to the left side of the lower end face of the flat plate, so that fingers of a user can conveniently penetrate through a holding device; then the cement paste is shoveled to the flat plate through the inclined shovel head at the right end of the flat plate; and then the pull plate located on the right side of the fingerstalls is shiftedleftwards with fingers, the pull plate drives the L-shaped baffle to rotate to the coinciding position of the front side edge and the right side edge of the flat plate through the connected rotatingshaft, the flat plate inclines forwards, and therefore, the L-shaped baffle blocks cement paste; the plate provided by the invention is simple in structure, convenient to use and good in using effect.

Owner:钱厚文

Inner corner correcting bricklayer's cleaver

InactiveCN105587131AAchieve direct wipingThe construction effect is beautiful and generousBuilding material handlingEngineeringBricklayer

The invention discloses an inner corner correcting bricklayer's cleaver which comprises a rectangular or sharp-point cleaver board and a cleaver handle of the bricklayer's cleaver. A vertical board is installed in the rear-section position of a blade of the cleaver board and is parallel to the cleaver handle in direction. By the adoption of the inner corner correcting bricklayer's cleaver, a concave right-angle line of the corner of a wall can be directly straightened, so that the concave right-angle line of the corner of the wall is straight, and the attractive and elegant construction effect is guaranteed.

Owner:SHAANXI ZHONGHAOYUAN HYDROPOWER ENG CO LTD

Mortar type exterior wall coating material

The invention relates to an exterior wall coating material, which is an exterior wall coating material directly pressed and coated by a bricklayer. According to the present invention, the exterior wall coating material does not have high requirement on the base layer surface of the wall, only requires the leveling with cement mortar, can save a lot of cement, and can finish the coating decorationat one time; and the production process of the coating material is simple, and the product can be obtained only through mixing stirring.

Owner:刘从荡

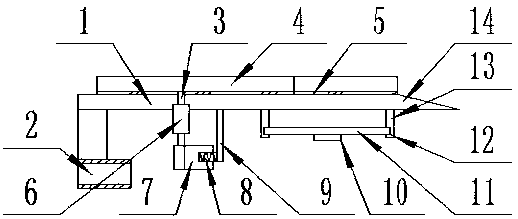

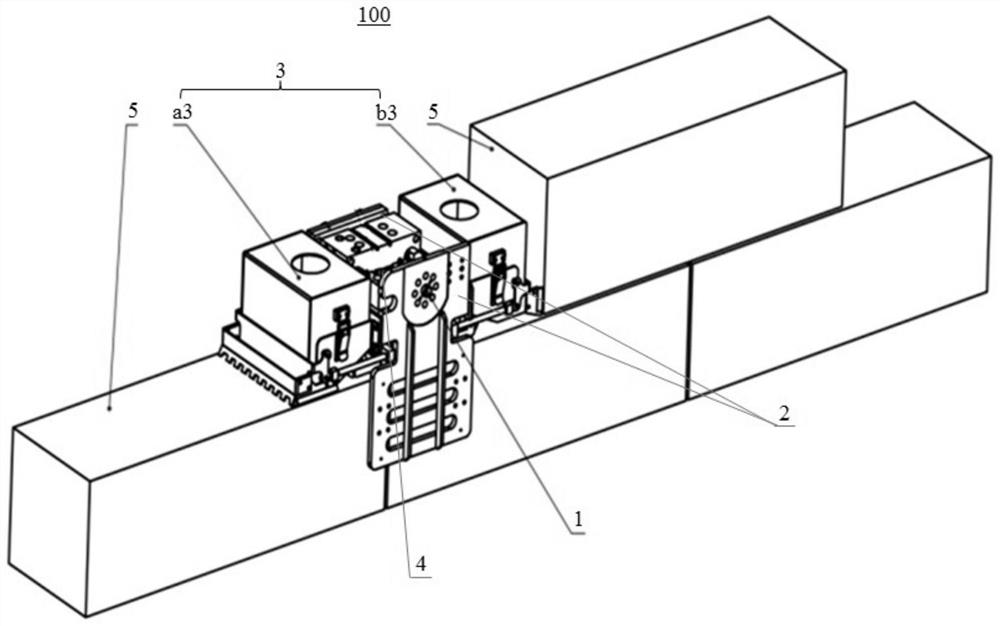

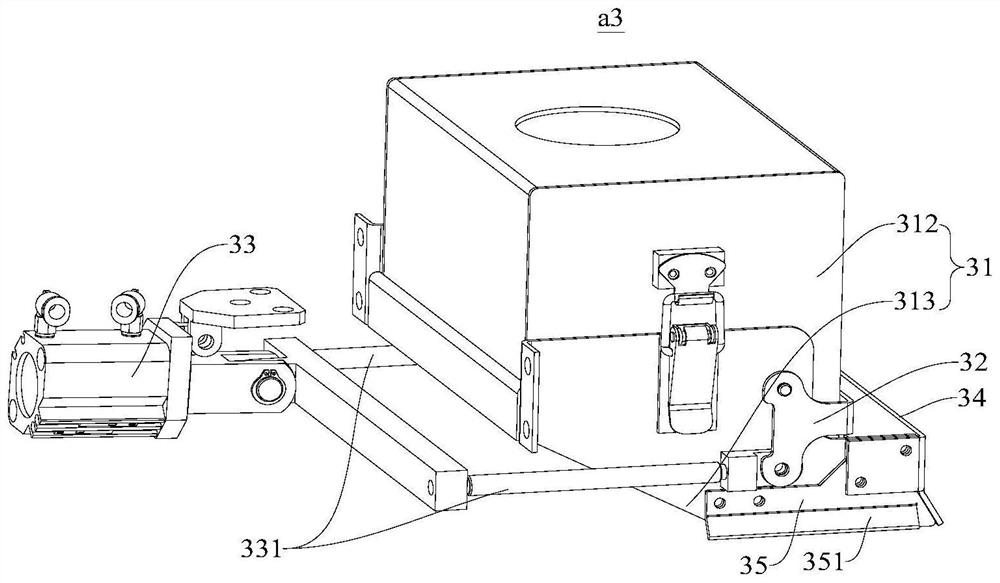

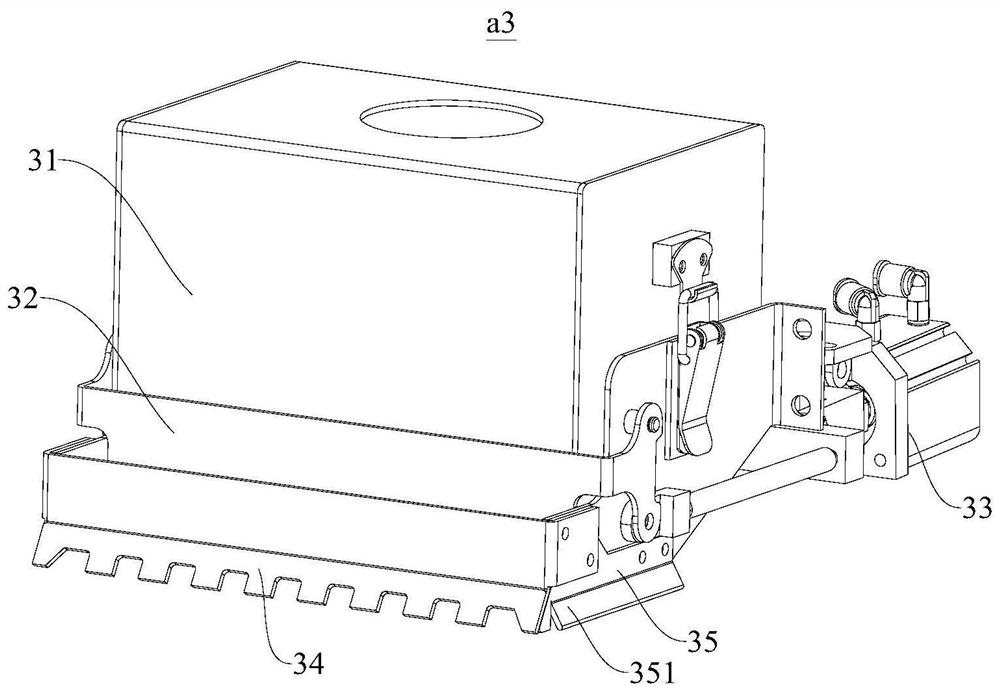

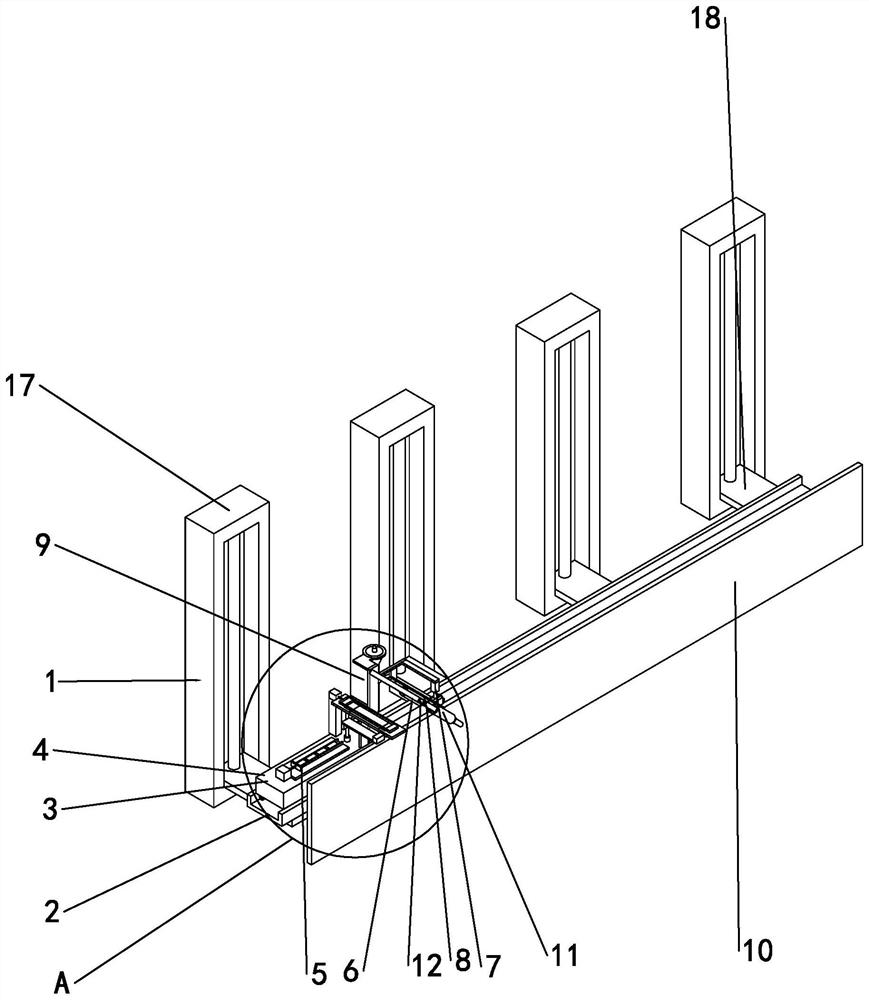

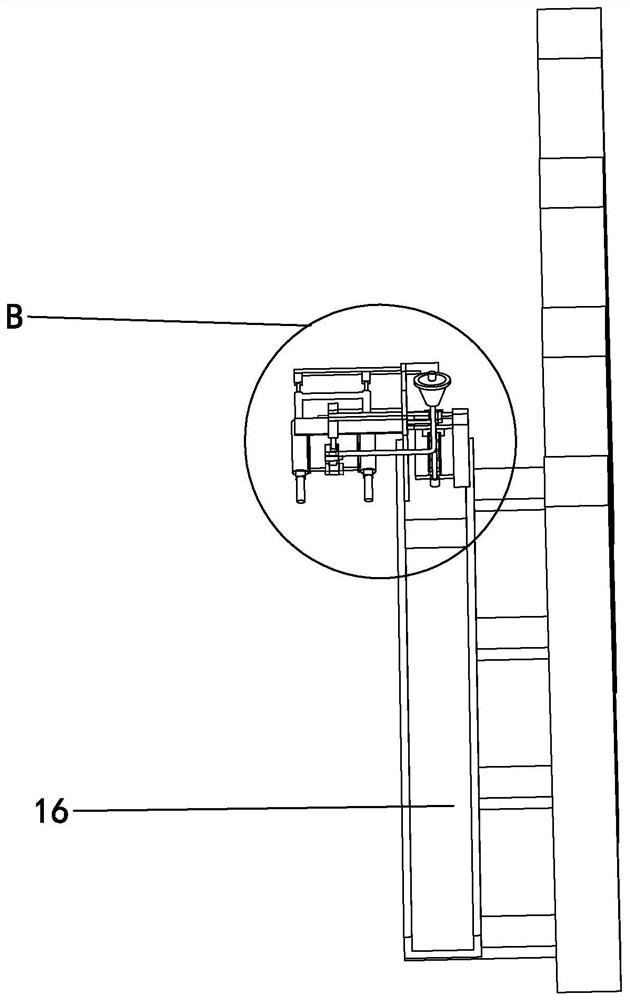

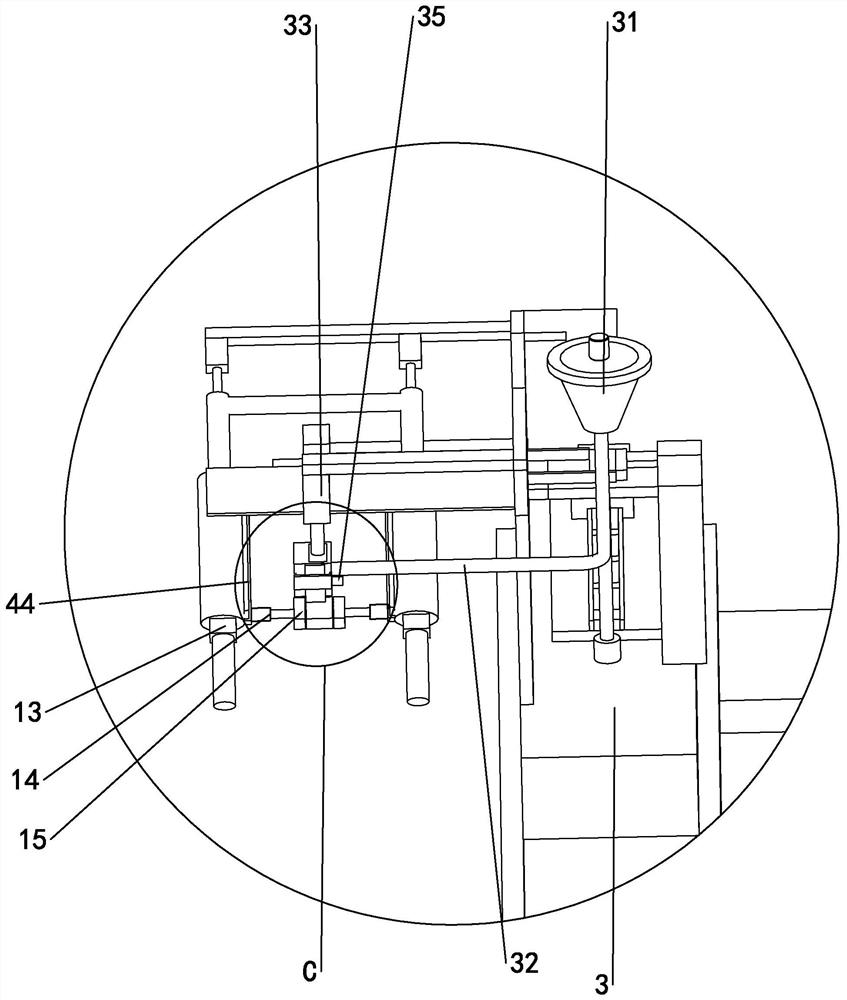

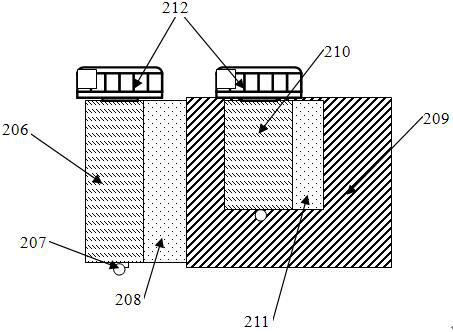

Bricklaying institutions

ActiveCN111519919BReduce labor intensityImprove efficiencyBuilding material handlingBrickEngineering

The invention discloses a brick laying mechanism, comprising: a base; a clamping assembly, the clamping assembly is arranged on the base, and the clamping assembly can move along the clamping direction to clamp and place bricks; The slurry assembly is installed on the base, and the number of the slurry components is two, and the two slurry components are located on both sides of the clamping component in the direction perpendicular to the clamping direction. The plastering components are respectively a horizontal plastering component and a vertical plastering component. The horizontal plastering component is used for plastering in the horizontal direction, and the vertical plastering component is used for plastering in the vertical direction. According to the brick laying mechanism of the embodiment of the present invention, the efficiency and quality of brick laying can be improved, and the labor intensity of workers can be reduced.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

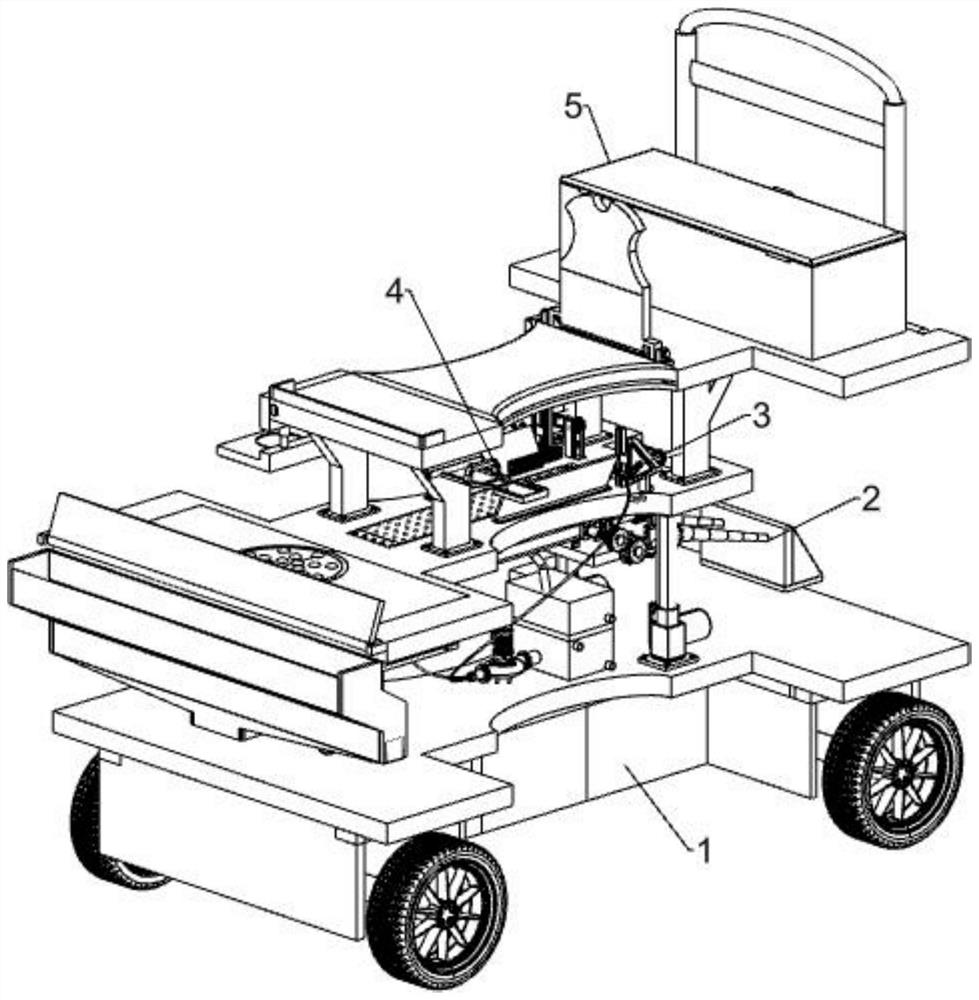

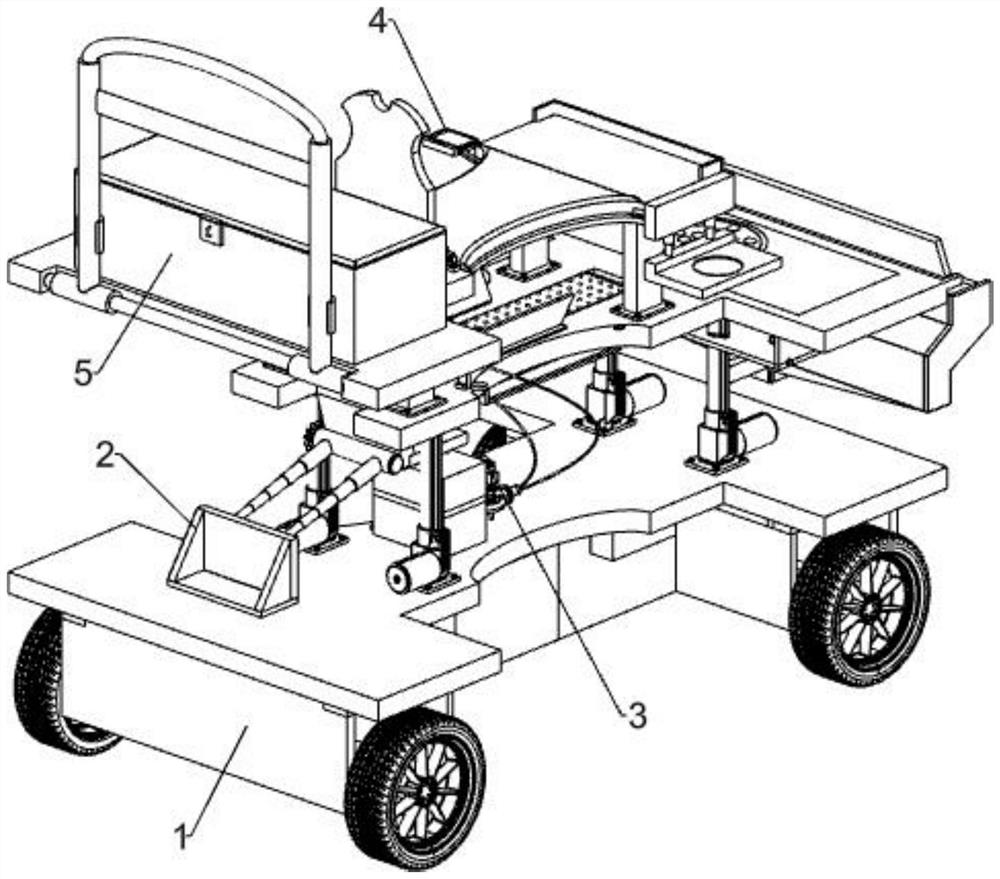

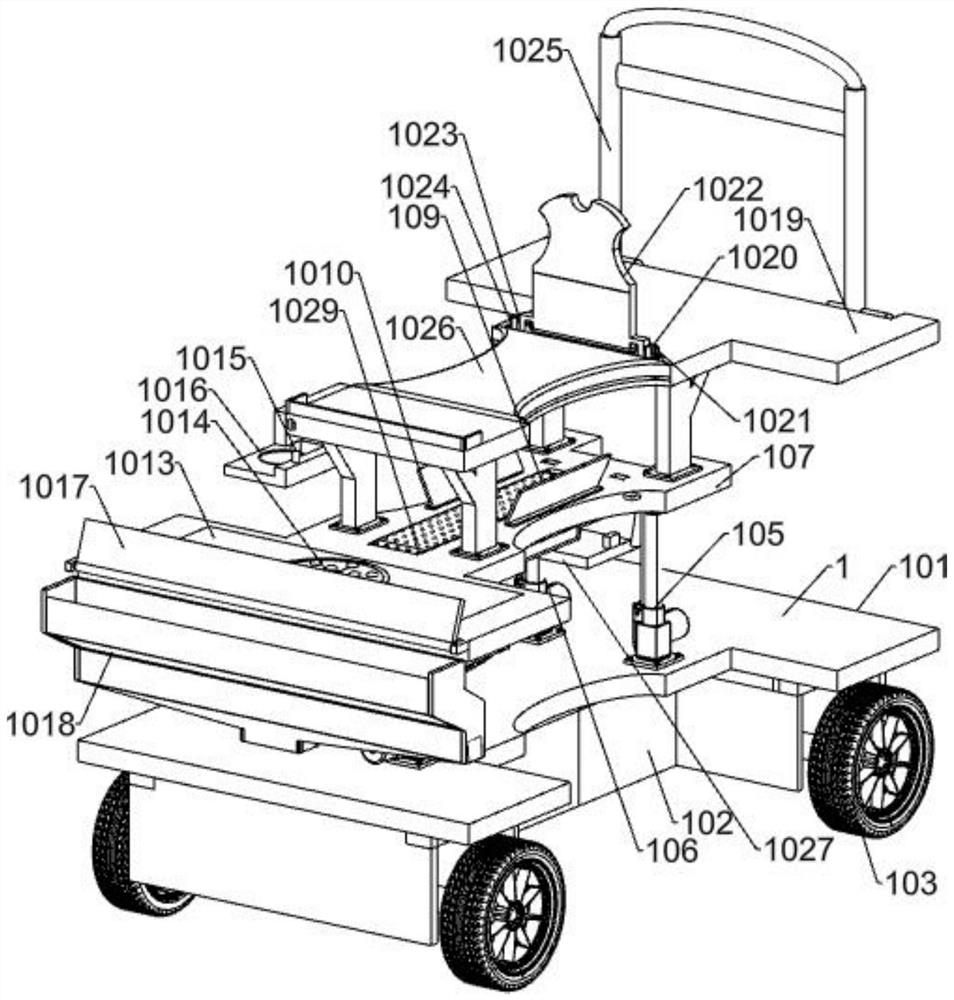

Bricklayer auxiliary device for building materials

InactiveCN112343315ARealize the discharge functionAvoid wastingBuilding constructionsMixing operation plantArchitectural engineeringWastewater

The invention relates to building material related devices, in particular to a bricklayer auxiliary device for building materials. The device comprises a lifting moving mechanism, a waste water collecting mechanism, a ceramic tile placing mechanism, a stirring and pushing mechanism, a top end box body and a feeding mechanism, wherein the waste water collecting mechanism is fixedly installed on thelifting moving mechanism, the top end box body is fixedly installed on the waste water collecting mechanism, the feeding mechanism is fixedly installed on the top end box body, the ceramic tile placing mechanism is fixedly installed on the waste water collecting mechanism, and the stirring and pushing mechanism is fixedly installed on the top end box body. The device facilitates a bricklayer to operate indoors, continuous filling is not needed, the device can ascend and descend, the problem that the bricklayer bends down to take materials during wall tiling is solved, the device has a stirring function, and manual stirring by the bricklayer is not needed.

Owner:那亚洲

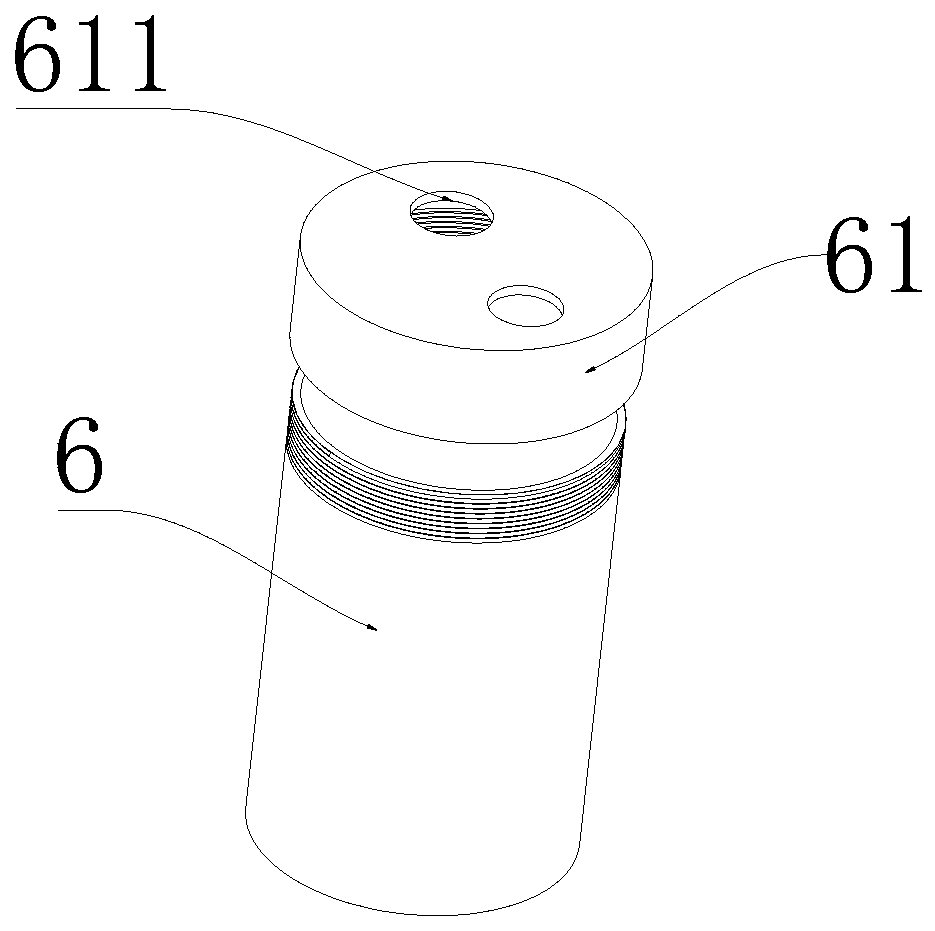

Bricklaying mortar joint width control method

ActiveCN111502075AReduce control concernsGuaranteed positioningWallsCement mixing apparatusConstruction engineeringStructural engineering

The invention discloses a bricklaying mortar joint width control method. Prefabricated blocks are mixed into coarse mortar to prepare prefabricated mortar, so that the control attention of workers tomortar joints in the bricklaying process is reduced; bricks are pressed to abut against the corresponding prefabricated blocks, and primary positioning of the bricks can be achieved, so that the working efficiency is improved, and the mounting quality is also improved; meanwhile, the difficulty of the bricklaying process is reduced, redundant positioning steps are simplified, other tedious steps are not added, and positioning of the bricks can be guaranteed only through the prefabricated blocks, so that the operation difficulty is reduced, and dependence on skilled workers is reduced; and theerror of the mortar joint width can be controlled by controlling the diameter error of the prefabricated blocks, the whole process is normalized, and the uniformity of the mortar joint width in the whole masonry process is ensured.

Owner:廖家前

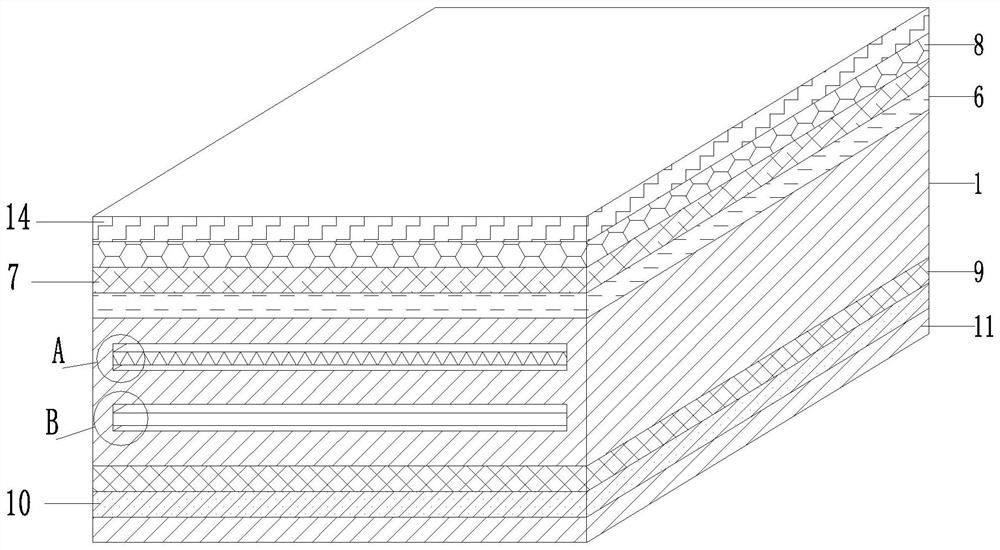

An energy-saving and environment-friendly wall for buildings

ActiveCN108204055BAvoid uneven temperatureShorten the flow distanceWallsChemical industryBrickHeat conducting

The invention relates to an energy-saving and environment-friendly wall for buildings. The energy-saving and environment-friendly wall is sequentially provided with a base layer, a light porous bricklayer, a tack layer and a solar panel layer from inside to outside. Heat conducting liquid is circularly arranged in the light porous brick layer, and light porous bricks are matched with the heat conducting liquid to realize the real-time adjustment of indoor temperature and humidity through the wall. By arranging solar panels to make full use of solar energy, not only can the overheated sunshineheat be absorbed and the energy consumption of the wall for cooling be reduced, but also solar energy can be converted into electric energy to be used by electrical components inside the wall, thus the energy conservation and environment protection of the wall of the buildings are truly realized.

Owner:龙元明筑科技有限责任公司

A construction method for building refractory bricks of a rotary kiln by using brick supporters

The invention belongs to the technical field of laying methods for refractory bricks of rotary kilns, and particularly discloses a construction method for laying refractory bricks of a rotary kiln through a bricklaying supporting device. The construction method comprises the following construction steps that S1, the construction portion of the inner wall of a kiln shell of the rotary kiln is cleaned; S2, a plurality of longitudinal straight lines and circumferential lines are drawn on the inner wall of the kiln shell of the rotary kiln; S3, the bottoms of the refractory bricks are laid, namely the lower semicircles are laid; S4, the bricklaying supporting device is mounted; S5, the tops, namely the upper semicircles, of the refractory bricks are laid; S6, opening sealing and seam sealing work is prepared; S7, after sealing is completed, a lead screw is tightened, and the bricklaying supporting device is contracted, so that brickwork of the circle is made to automatically draw close to the center of the circular ring in a centralized mode; S8, seams in the brickwork and the inner wall of a cylinder are checked; S9, after the refractory bricks of the first circle are laid, the lead screw is tightened, and the bricklaying supporting device is contracted for withdrawing from the first circle; and S10, the steps from the step S3 to the step S9 are repeated for laying of the next circle. By the adoption of the construction method, quality accidents, such as falling and breaking of the refractory bricks, frequently occur during operation of the rotary kiln are avoided to a great extent.

Owner:XINMI WANLI IND DEV

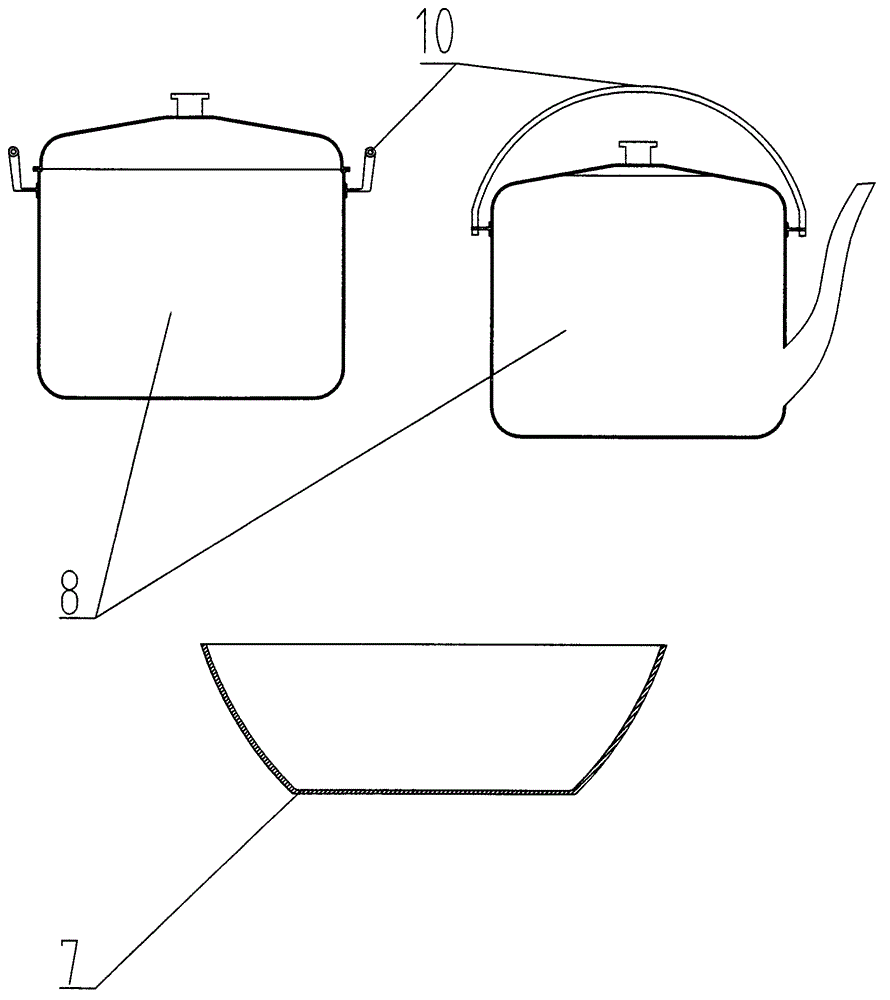

Smokeless cookstove used for burning straws

InactiveCN104676651ADomestic stoves or rangesLighting and heating apparatusElectricityHeat transmission

The invention relates to a smokeless cookstove used for burning straws. The smokeless cookstove comprises a stove bench, a stove door and an internal stove bridge, ash storing places are arranged on two sides of the stove bridge, a flue is arranged above the stove bridge, a bottom pot is disposed on the flat stove table surface, and a movable pot is buckled in the surface; the straws are placed into the internal stove bridge from the stove door to be allowed to burn, fire directly burns the bottom of the bottom pot, and smoke enters a chimney from the flue; a great deal of oxygen under the stove bridge helps to burn, the straws unfinished in burning are shifted to the ash storing places to be heated continuously; another bunch of the straws is placed into the internal stove bridge, and the fire power can be kept vigorous all the time; extra ashes are leaked to the ash storing places from the stove bridge; frying can be performed by transmitting heat to the movable pot by heat transmission method of a rice cooker; pots can be lifted up optionally, and cookers of aluminum pots, aluminum kettles and the like can be optionally replaced; the movable pot and the bottom pot for frying can be manufactured in factories and are the core of the invention; a stove bench graph is delivered while the pot is sold, and a bricklayer can perform construction according to the graph. By the arrangement, smokeless indoor can be guaranteed even if the pot is lifted up during frying, and timbers, leaves, the straws or rice straws can be burnt like natural gas.

Owner:熊生银

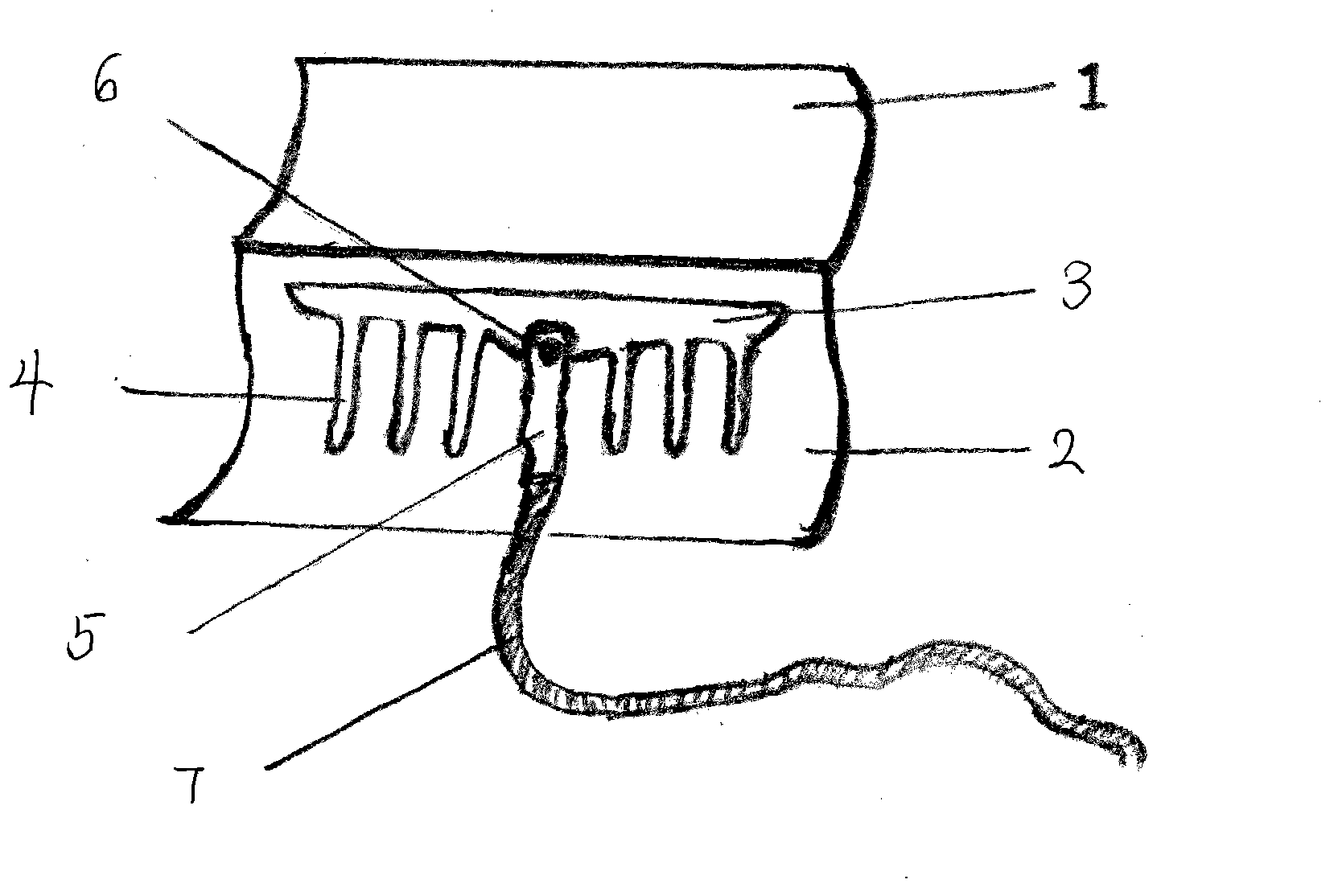

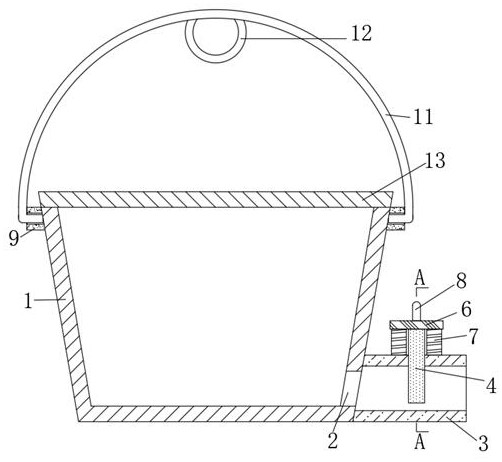

Mortar basin for bricklayer and based on building environment-friendly construction

PendingCN112252671APrevent overflowAvoid pollutionBuilding constructionsArchitectural engineeringBricklayer

The invention discloses a mortar basin for a bricklayer and based on building environment-friendly construction, and relates to the field of building construction equipment. The mortar basin comprisesa mortar basin body, a mortar outlet hole is formed in the lower end of one side wall of the mortar basin body, a mortar taking pipe is fixedly connected to the lower end of the outer wall of one side of the mortar basin body, an inner cavity of the mortar taking pipe communicates with the mortar outlet hole, and a sealing plate is arranged in the middle of the inner cavity of the mortar taking pipe. Sliding grooves are formed in the inner walls of the two sides of the mortar taking pipe, the two ends of the sealing plate are correspondingly located in the two sliding grooves, the upper end of the sealing plate penetrates through the inner wall of the upper end of the mortar taking pipe and extends to the position above the mortar taking pipe, and a limiting plate is fixedly connected with the upper end of the sealing plate. The mortar taking pipe communicates with one side of the mortar basin body, the sealing plate is arranged in the inner cavity of the mortar taking pipe, tension springs are fixedly connected to the two sides of the lower end face of the limiting plate, the mortar taking pipe is controlled to be opened by sliding the sealing plate, so that mortar in the mortarbasin body flows out, the tension springs provide tension to automatically close the sealing plate, and therefore, the use is more convenient.

Owner:杭州佧斯家居设计有限公司

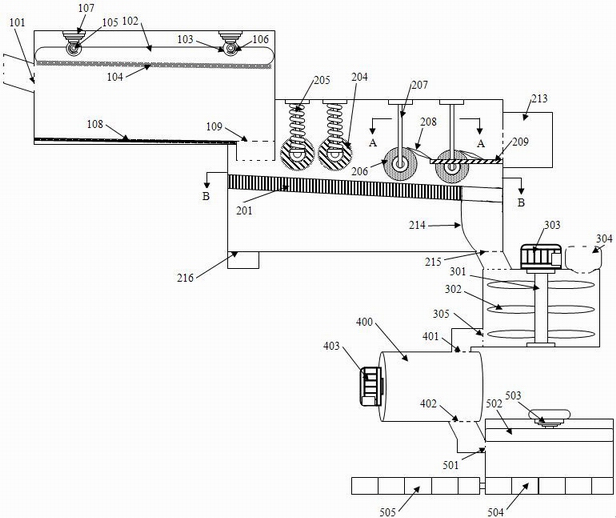

A building aerated brick construction device

ActiveCN111608404BTelescopic lengthIncrease contactBuilding material handlingBrickArchitectural engineering

The invention relates to the construction field, in particular to a building aerated brick construction device. The technical problem to be solved by the present invention is to provide a building aerated brick construction device. A construction device for building aerated bricks, comprising a moving and turning lifting mechanism, a material feeding mechanism, a water brush mechanism, a control panel and a tool box; A water brush mechanism, and the front middle part of the water brush mechanism is connected with the feeding mechanism. The invention realizes automatic feeding of the aerated bricks, and brushes water at the contact position with the cement, so that the aerated bricks can be better in contact with the cement. At the same time, the device can be moved left and right and up and down, and the corresponding vertical height can be placed on the aerated bricks materials, which greatly reduces the workload of bricklayers and small workers, improves construction efficiency, and at the same time increases the comfortable working condition of bricklayers.

Owner:河南军昇实业有限公司

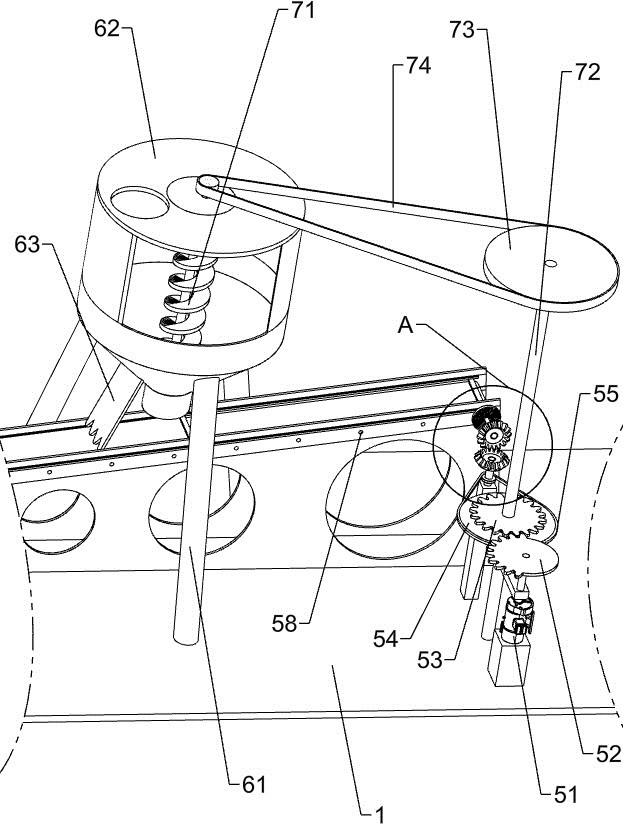

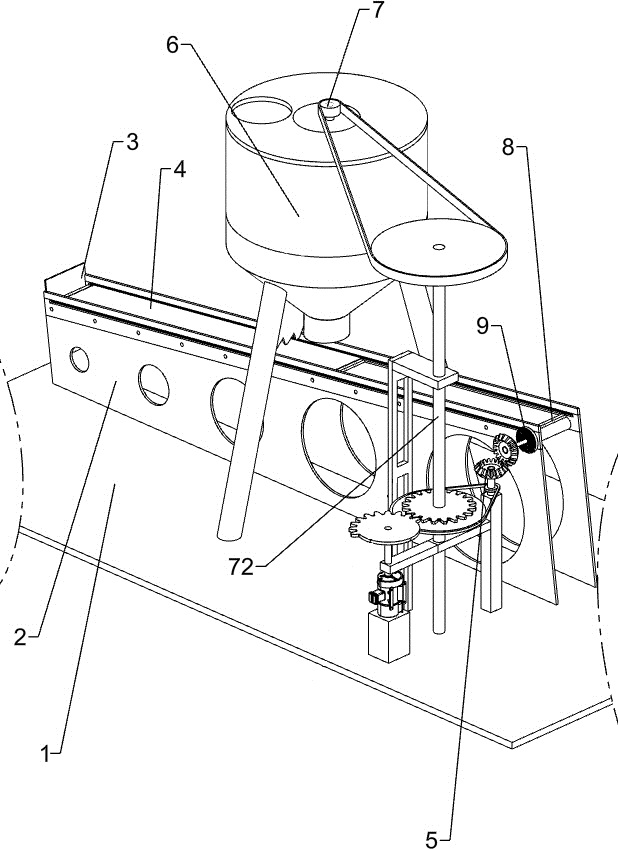

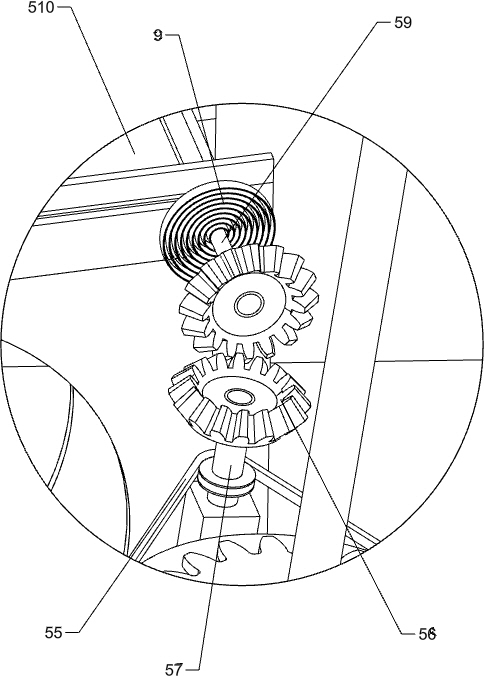

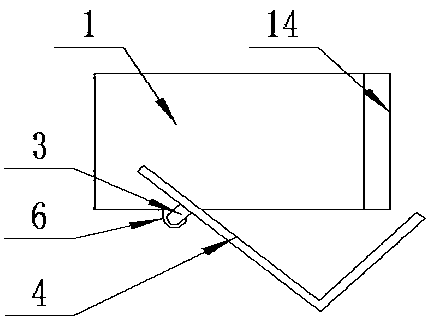

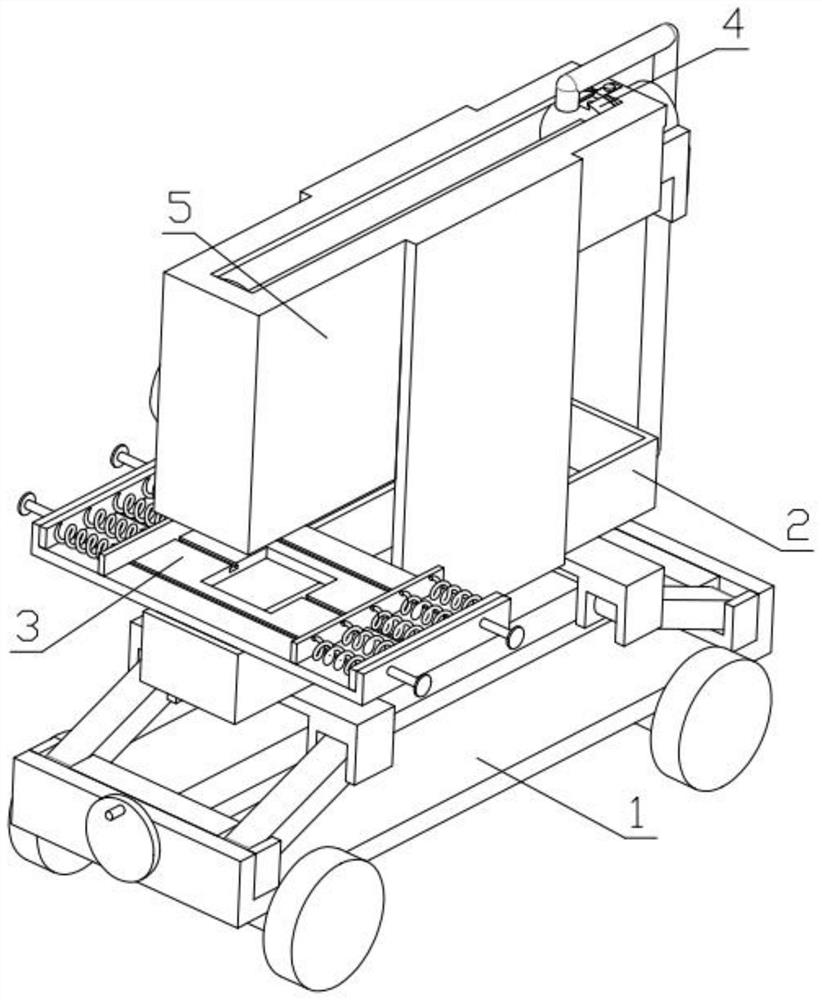

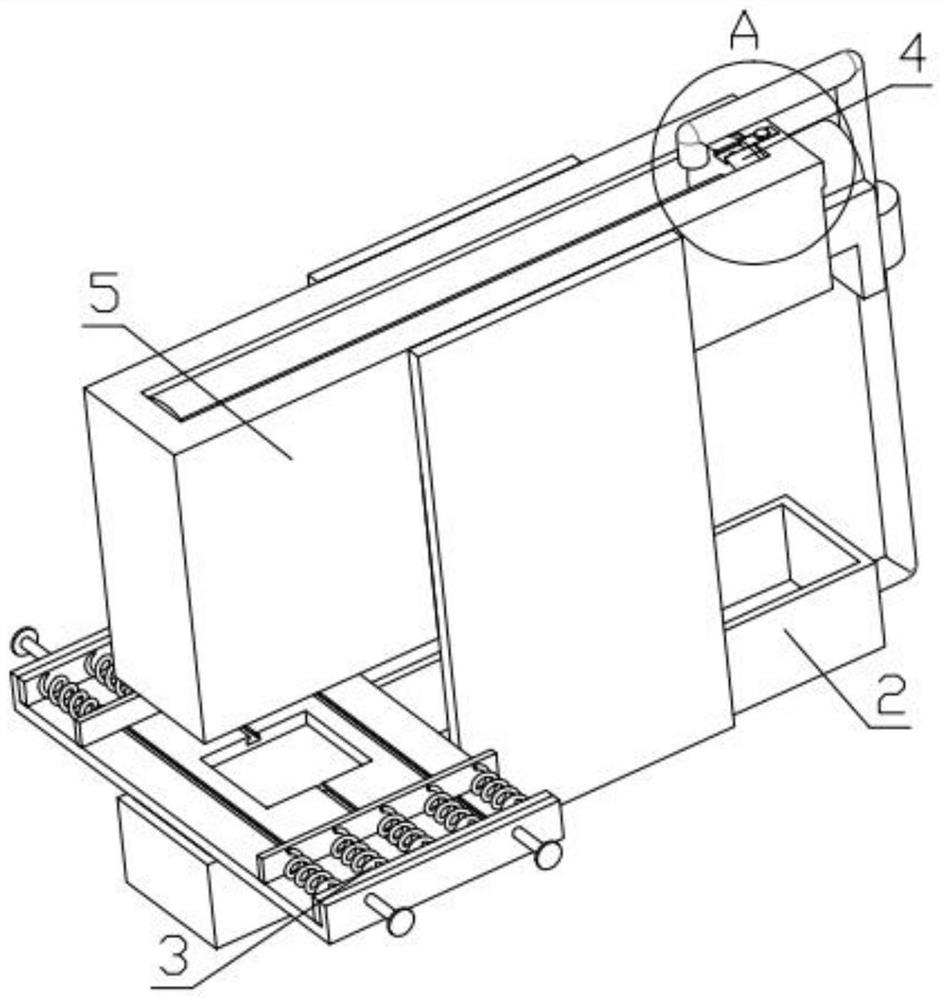

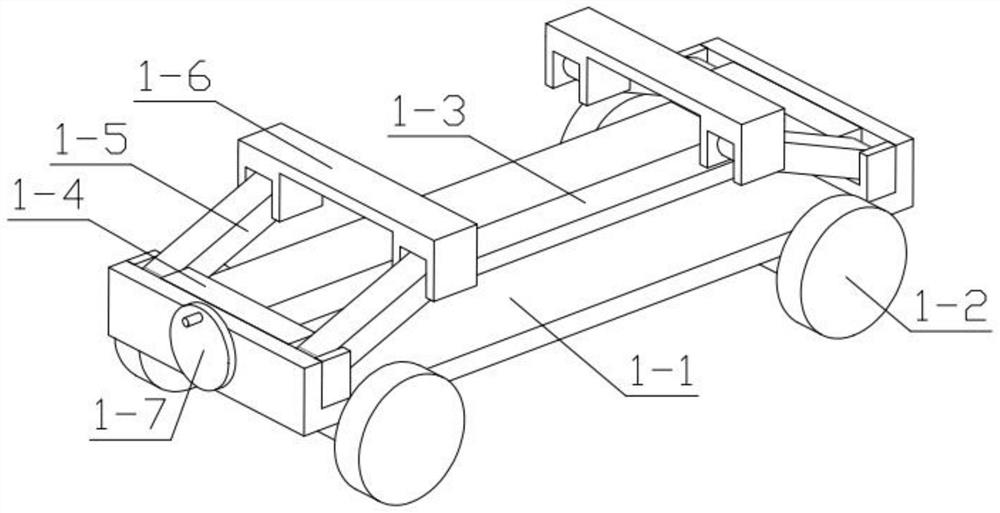

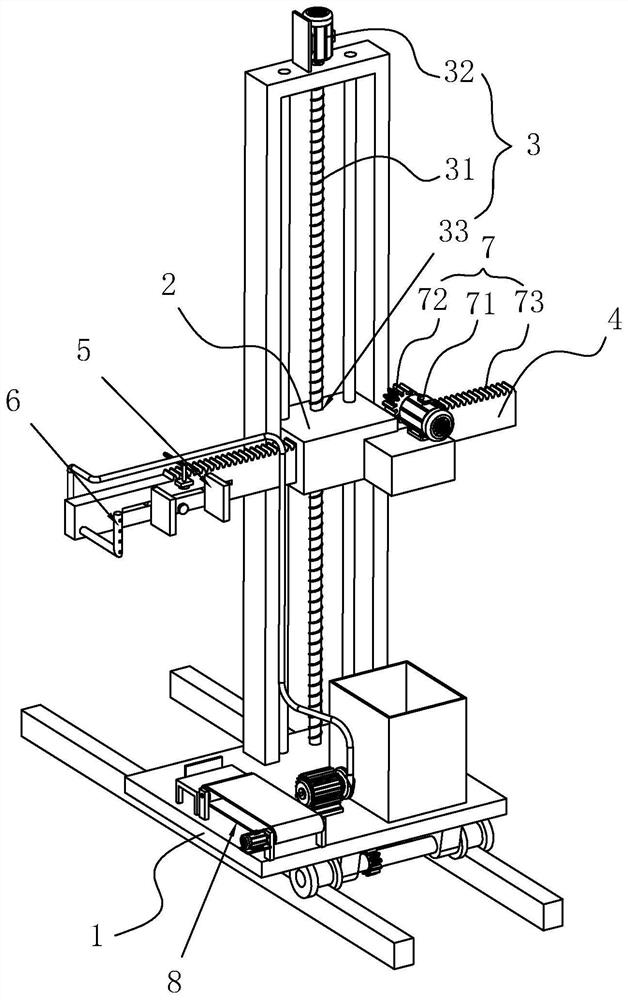

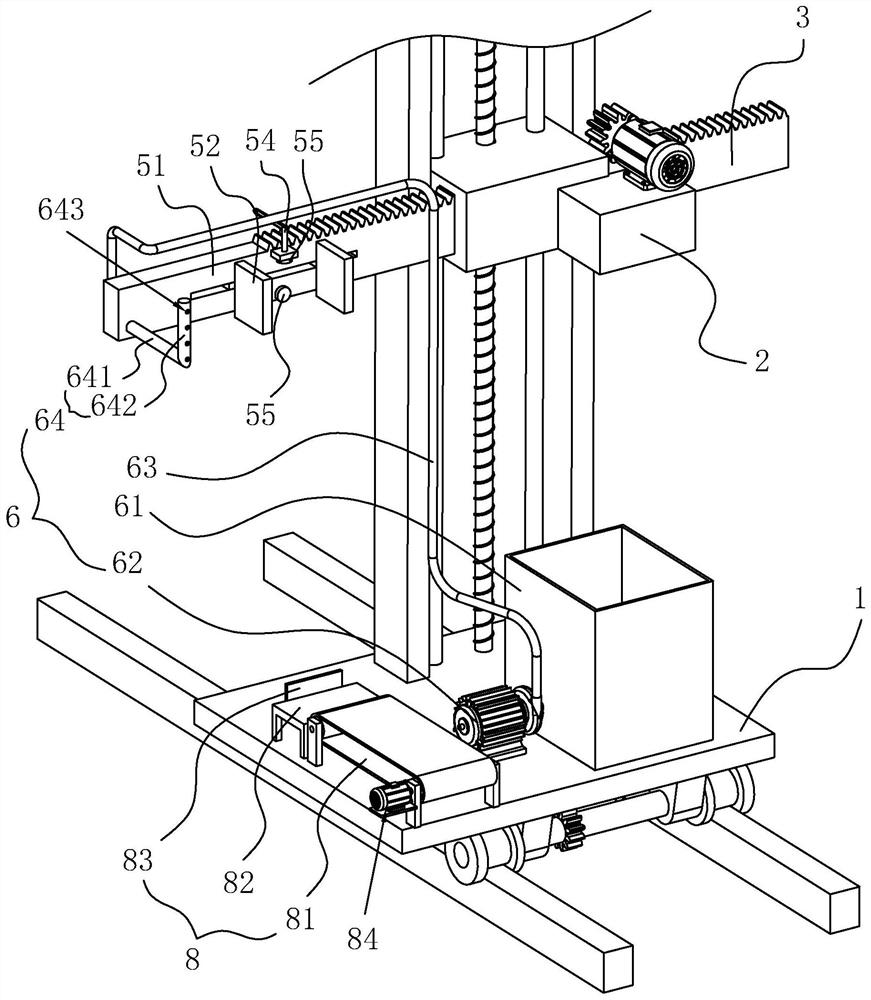

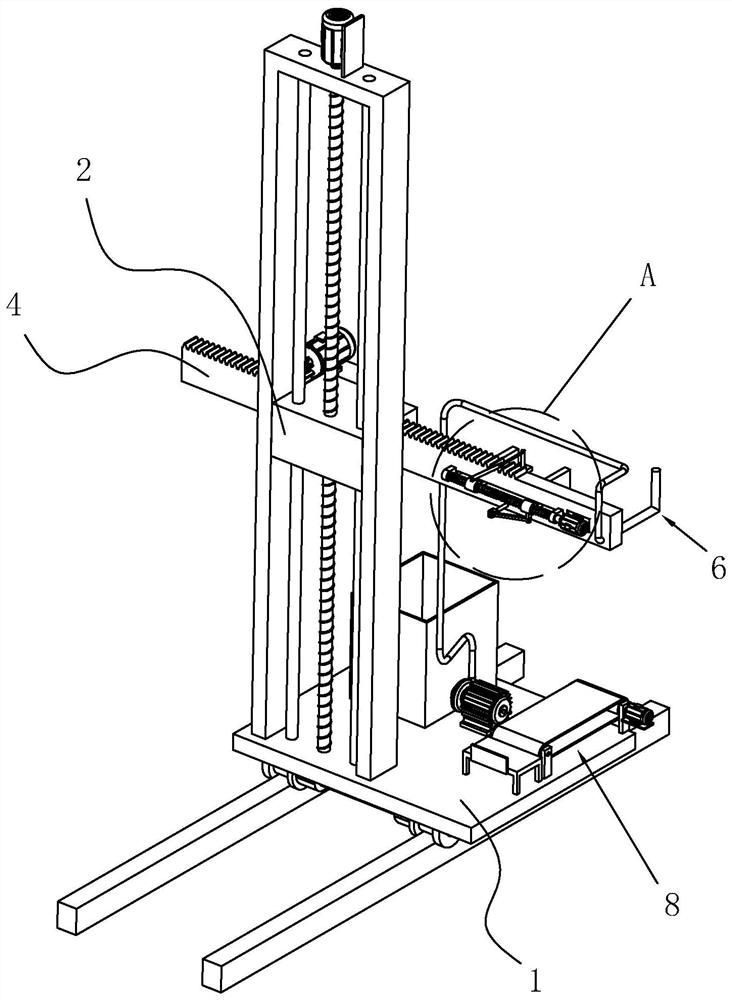

A kind of masonry engineering construction device and its construction technology

ActiveCN112227749BReduce workloadImprove masonry qualityBuilding material handlingBrickArchitectural engineering

The application relates to a masonry construction device and its construction technology, which includes a base that moves intermittently in a straight line on the ground, a lifting seat is arranged on the base to move up and down in the vertical direction, and a first mechanism for driving the lifting seat to go up and down is arranged on the base. Drive device, the lifting seat is provided with a support rod sliding along the horizontal direction, the support rod is located on the side of the lifting seat away from the lifting seat, and the clamping device and the spraying device are arranged in sequence, and the lifting seat is provided with a first for driving the support rod to slide. Two driving devices, a brick feeding device is arranged on the base below the clamping device. When using the construction device for bricklaying work, move the base to the position to be laid, first clamp the block, then drive the lifting seat to the height to be laid, drive the support rod to move to the wall to be laid, and during the moving process Among them, the mortar is sprayed on the wall and the blocks are placed on the wall successively. This application has the effect of reducing the workload of the staff and improving the quality of masonry.

Owner:飞帆集团有限公司

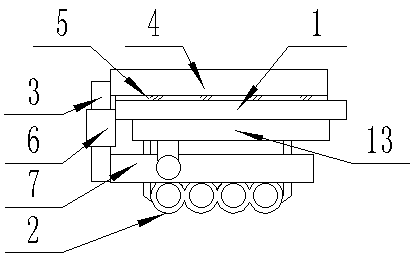

Bricklaying machine for automatic construction engineering

The invention discloses a brick-laying machine for automatic construction engineering, which comprises a lifting mechanism, a track is laid on the lifting mechanism, a brick-laying vehicle is arranged on the track, an installation platform is installed on the brick-laying vehicle, and a brick-feeding mechanism is installed on the installation platform , a bricklaying mechanism and a cementing mechanism, the bricklaying mechanism includes a fixed frame, and a bricklaying frame is provided on the installation platform, and the fixed frame is fixedly installed on the bricklaying frame. It is a brick wall, and the fixed frame is installed obliquely. The two sides of the fixed frame are sliding sleeves. The internal cross section of the sliding sleeve is square. There are two sliding sleeves, and one end of the sliding sleeve is provided with a bricklaying cylinder. One, the sliding sleeves are equipped with sliders, the sliders are connected to the piston rod of the bricklaying cylinder one, the sides of the sliders are connected to the pneumatic telescopic rods, and the sliding sleeves are provided with The strip-shaped opening for the movement of the pneumatic telescopic rod, and the end of the pneumatic telescopic rod far away from the slider is provided with a brick clamping assembly.

Owner:嘉兴瑞达建设有限公司

A construction waste brick making device

ActiveCN111688014BUniform sizeWell mixedRotary stirring mixersTransportation and packagingBrickArchitectural engineering

The invention relates to a construction waste brick making device, which comprises a hammer crushing chamber, a screening and magnetic separation part, a river sand mixing chamber, a sand mill cylinder and a brick forming chamber. After hammering and rolling the construction waste, the ferromagnetic metal in it is removed by a magnetic separation mechanism with a specific structure, and after being evenly mixed with the river sand, the construction waste particles are processed by the rotating horizontal drum sand mill. After the sand is further ground, the mixture is extruded into bricks, thus realizing the efficient reuse of construction waste.

Owner:FENGLIN ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com