Patents

Literature

122results about How to "Avoid uneven temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

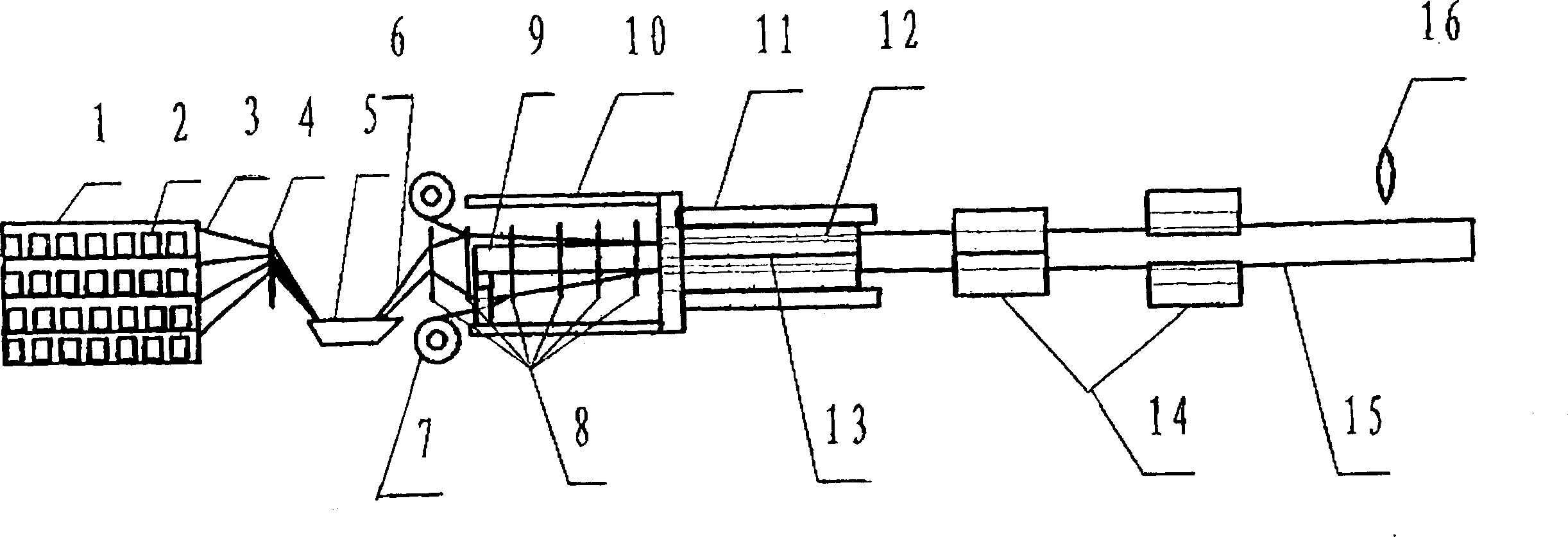

Technological method for pultrusion of glass fibre reinforced plastics pipe and die thereof

The present invention relates to a pultrusion process for making glass fibre reinforced plastics tube and its special-purpose die equipment. Said process includes the steps of soaking yarn, felt-yarncombination, preforming, solidfying and forming and tube-discharging and coaling. Its special-purpose die equipment includes a die cavity whose internal diameter is equal to the external diameter of formed glass fibre reinforced plastic tube, the periphery of said die cavity is equipped with heating device, a die core whose external diameter is equal to the internal diameter of formed glass fibrereinforced plastic tube is cover-mounted in the interior of die cavity, the centre of said die core is hoelow, and its interior is equipped with heating device. Said invention adopts common heating method in exterior and interior of said die cavity, so that the interior and exterior of glass fibre reinforced plastic tube are solidified well, and its surface is smooth.

Owner:柳惠平

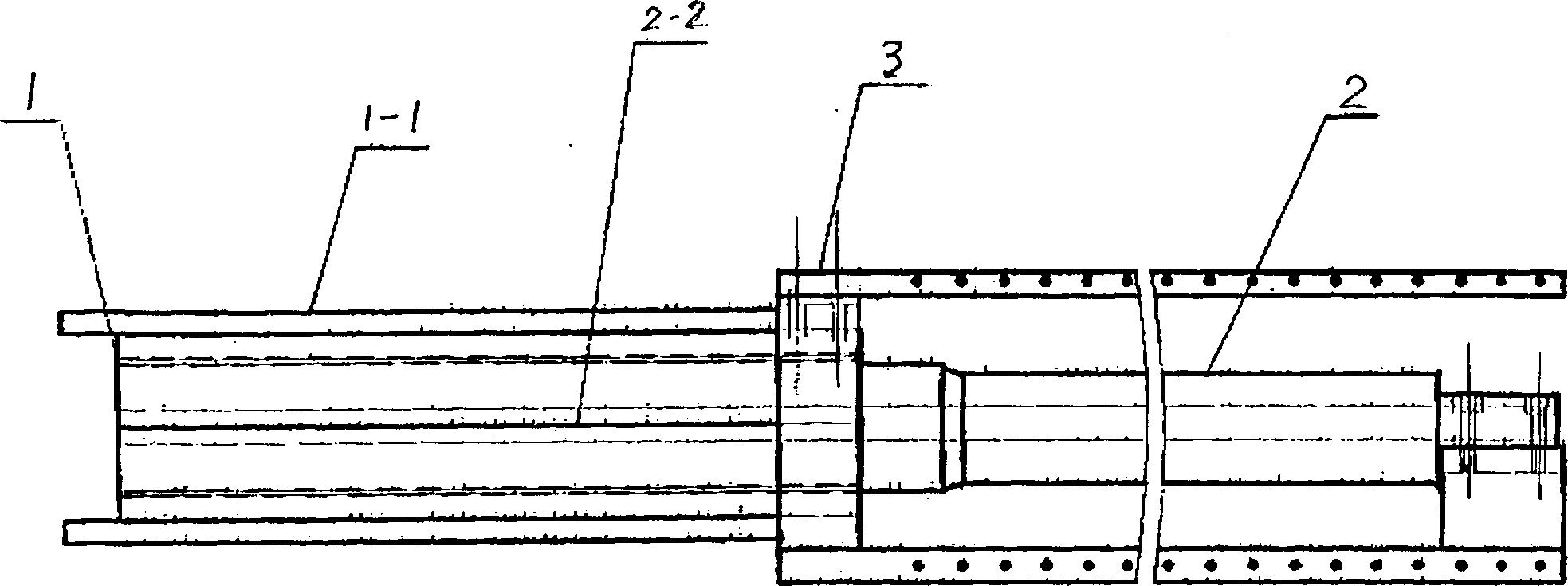

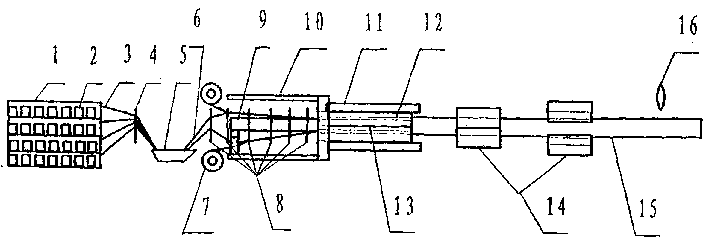

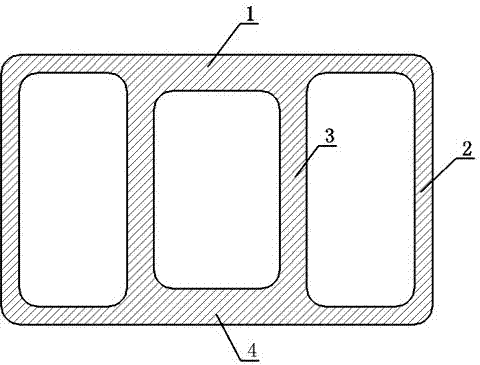

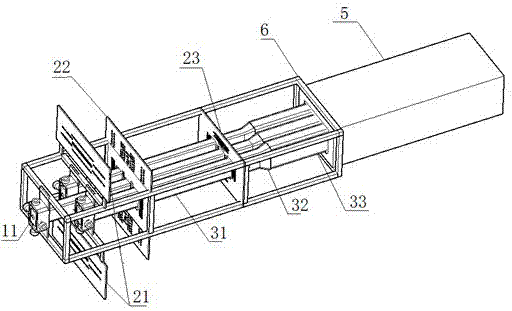

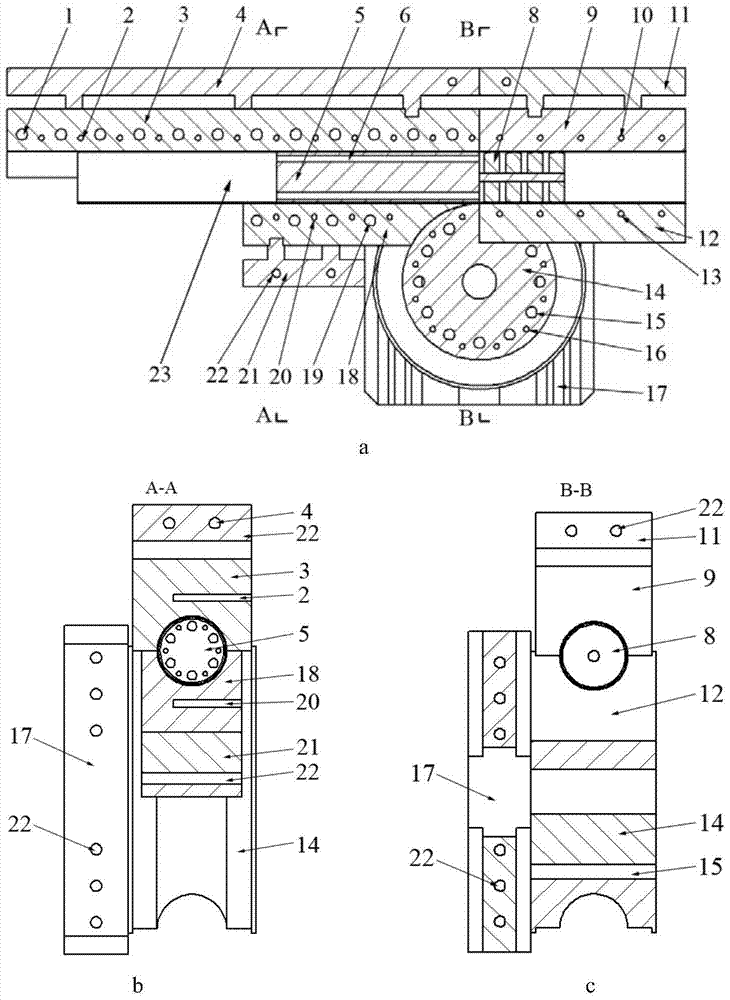

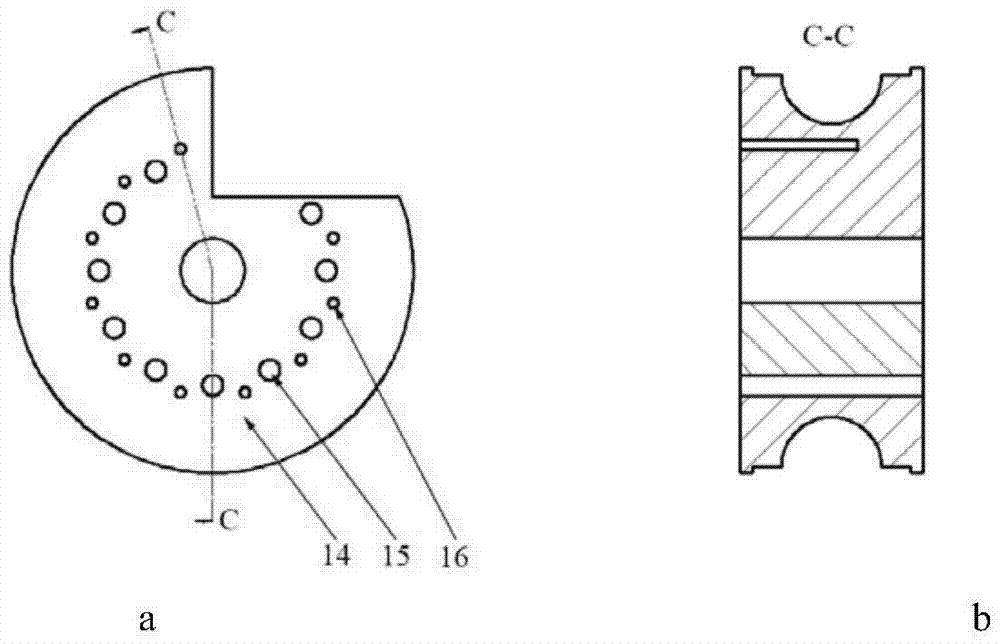

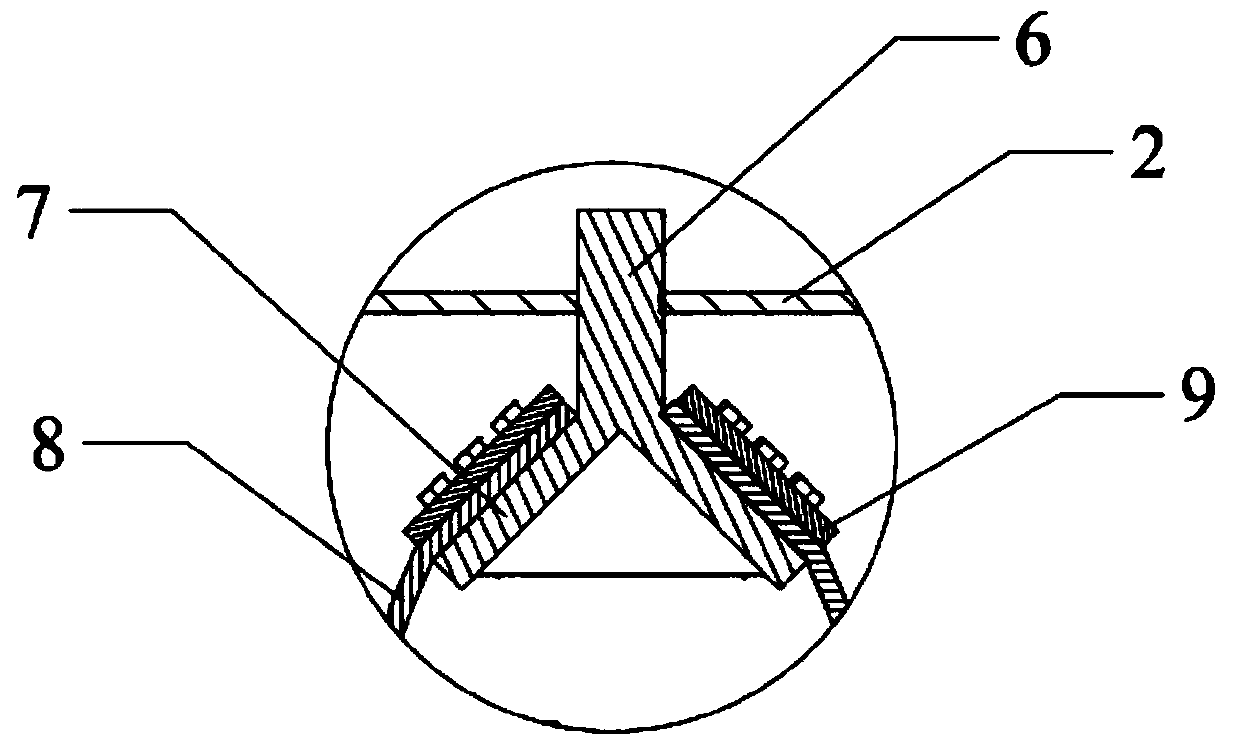

Fiber reinforced plastic (FRP) pultruded profile for bridge, forming equipment and preparation method

ActiveCN103031806AReduce spacingIncreased shear strengthBridge structural detailsWeather resistancePultrusion

The invention relates to a fiber reinforced plastic (FRP) pultruded profile for a bridge, forming equipment and a preparation method. The FRP pultruded profile for the bridge has the characteristics that the pultruded profile has the width of 220 mm to 250 mm and the height of 130 mm to 160 mm; and the section is shaped like a three-cavity rectangular frame. The forming equipment has the characteristics that an inner cavity of a thermal forming die adopts a three-cavity structure with the same shape as that of the FRP pultruded profile with the section shaped like the three-cavity rectangular frame; the forming equipment comprises a die core bracket, a die outer cavity and three die cores; and a die core heating device is inserted into a cavity of the die core. The preparation method comprises the following steps: preparing glue solution; selecting a fiber pultrusion yarn and fiber fabric and gumming; entering the thermal forming die through a pre-forming die, heating and solidifying; performing fixed-scale cutting; and forming the FRP pultruded profile for the bridge, wherein the section of the FRP pultruded profile is shaped like the three-cavity rectangular frame. The FRP pultruded profile for the bridge has light self-weight which is 20 to 40 percent of a concrete board, is high in bearing capacity, convenient in construction, quick in mounting, high in shearing strength and high in weather resistance, solves the problem that the common FRP bridge deck slab is damaged before bending damage, avoids sudden accidents and is favorable for popularization and application.

Owner:北玻院(滕州)复合材料有限公司

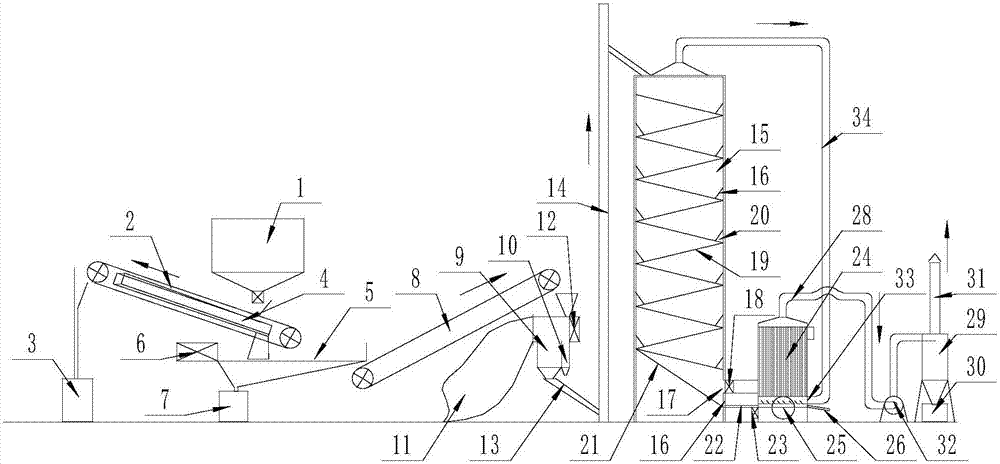

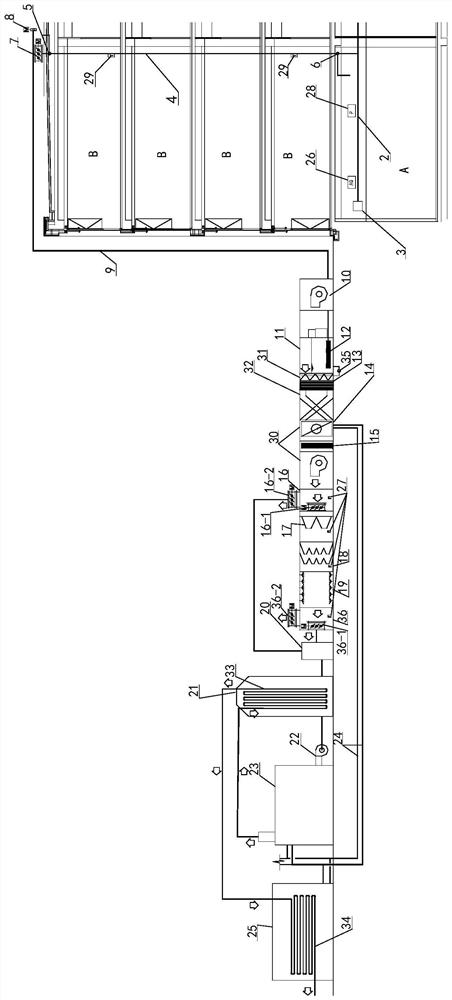

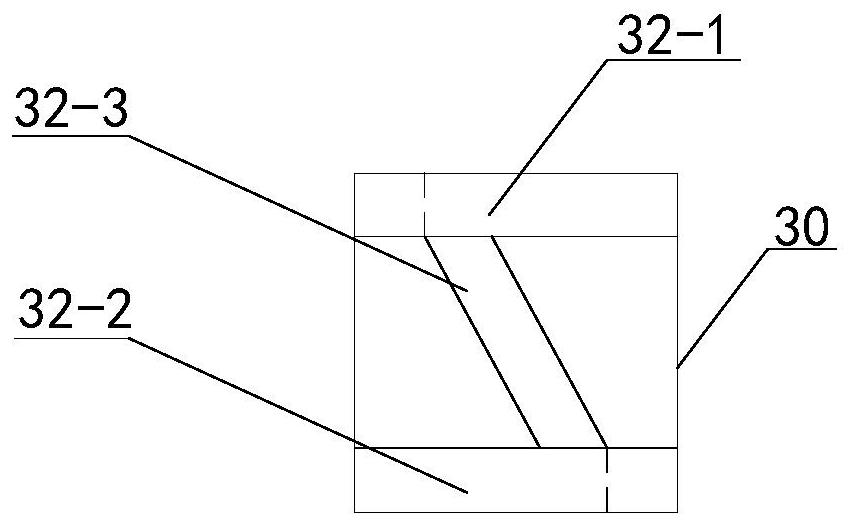

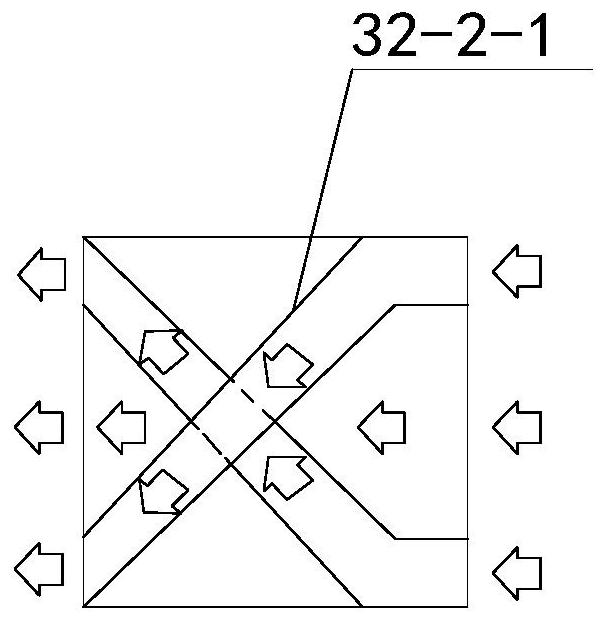

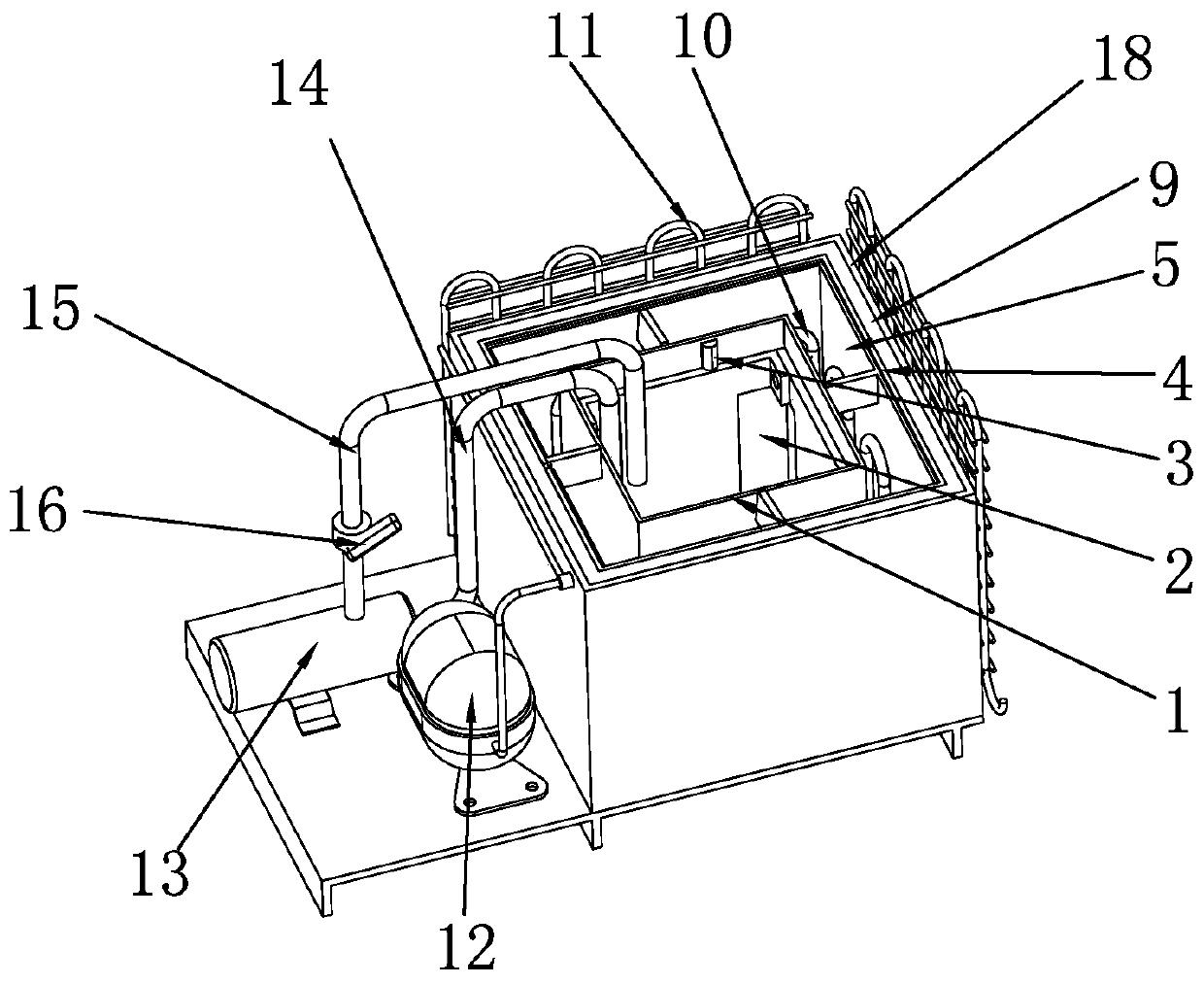

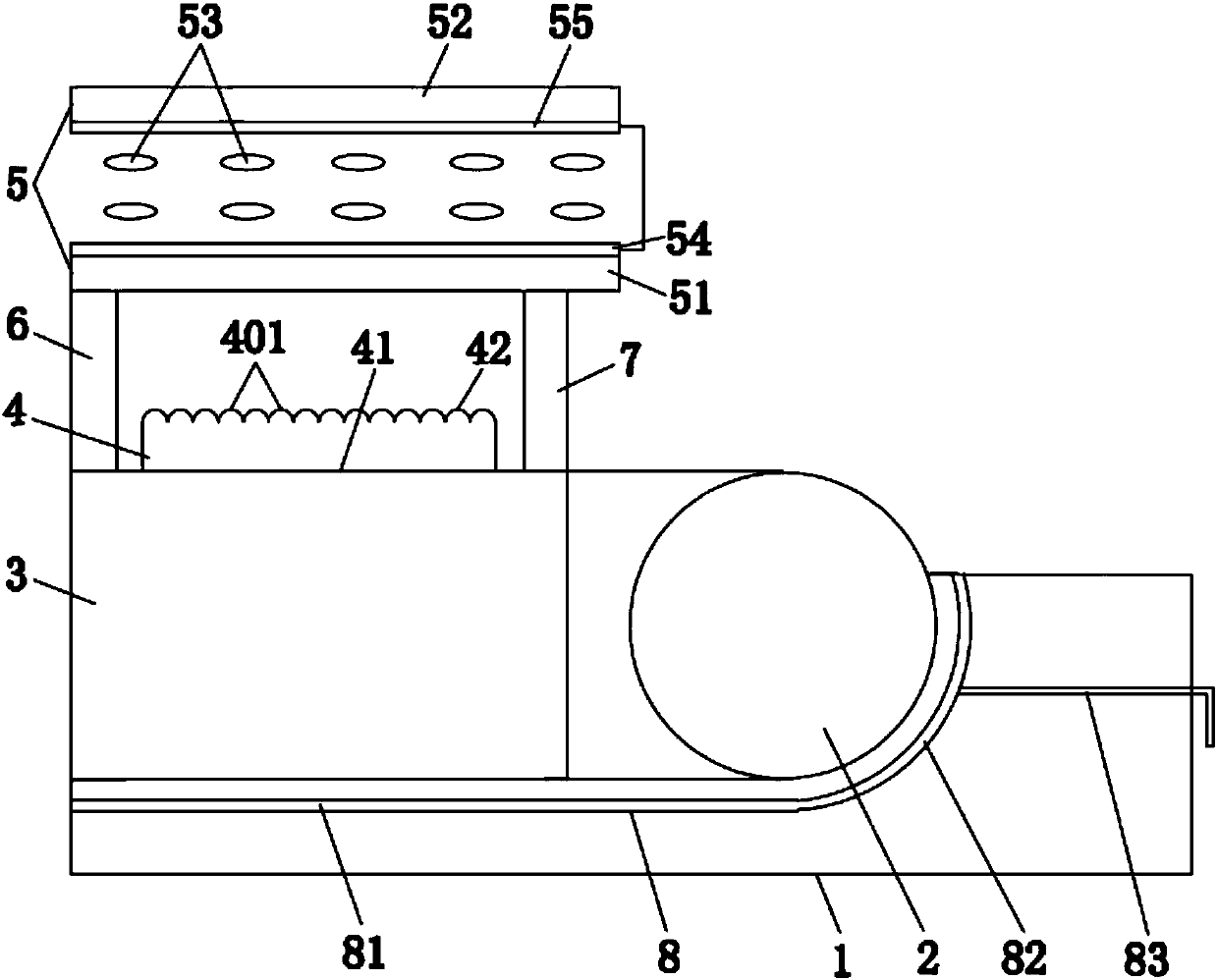

Energy-saving environmental-friendly efficient tower type grain impurity and dust removing and drying system device

The invention discloses an energy-saving environmental-friendly efficient tower type grain impurity and dust removing and drying system device which comprises a stock bin. A dust removing mechanism is arranged at the lower portion of the stock bin. The dust removing mechanism comprises an inclined conveying belt type coarse drying device, a reciprocating type horizontal sieve device and a winnowing type impurity and dust removing device. The output end of the dust removing mechanism is connected with a drying mechanism, and the drying mechanism comprises a hot wind drying device and a cold wind drying device. The energy-saving environmental-friendly efficient tower type grain impurity and dust removing and drying system device has the beneficial effects of saving the manpower resource, improving working efficiency, and being good in practicality.

Owner:刘硕

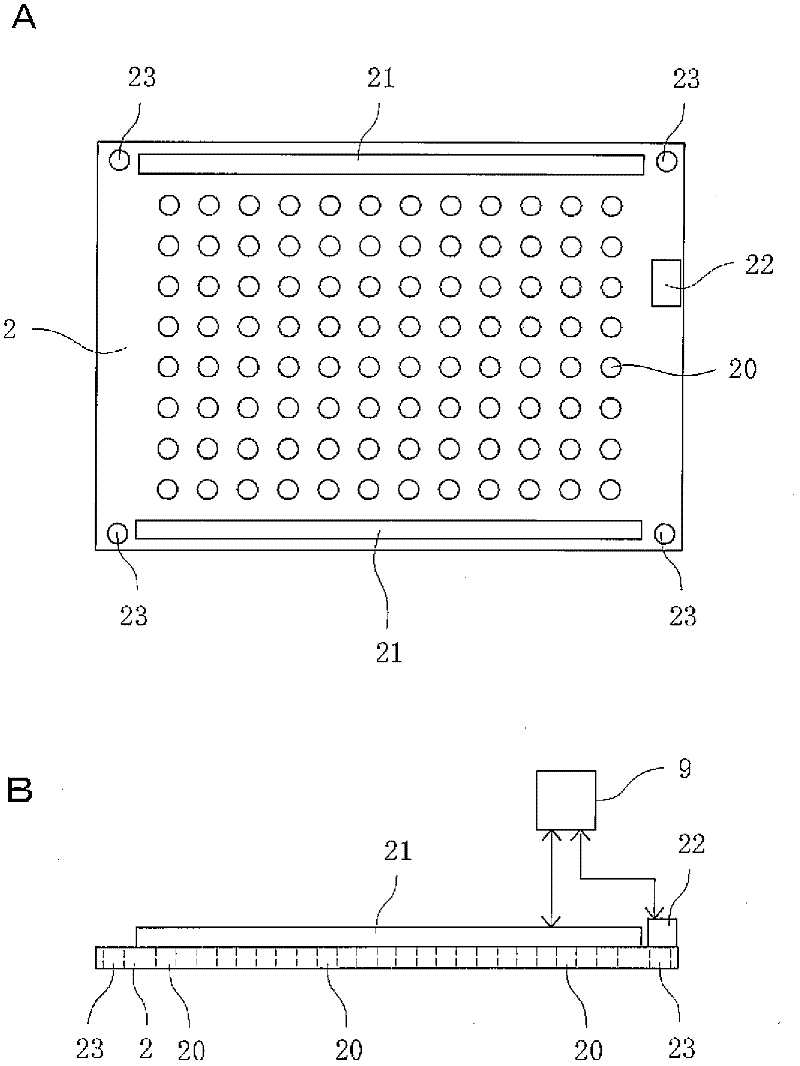

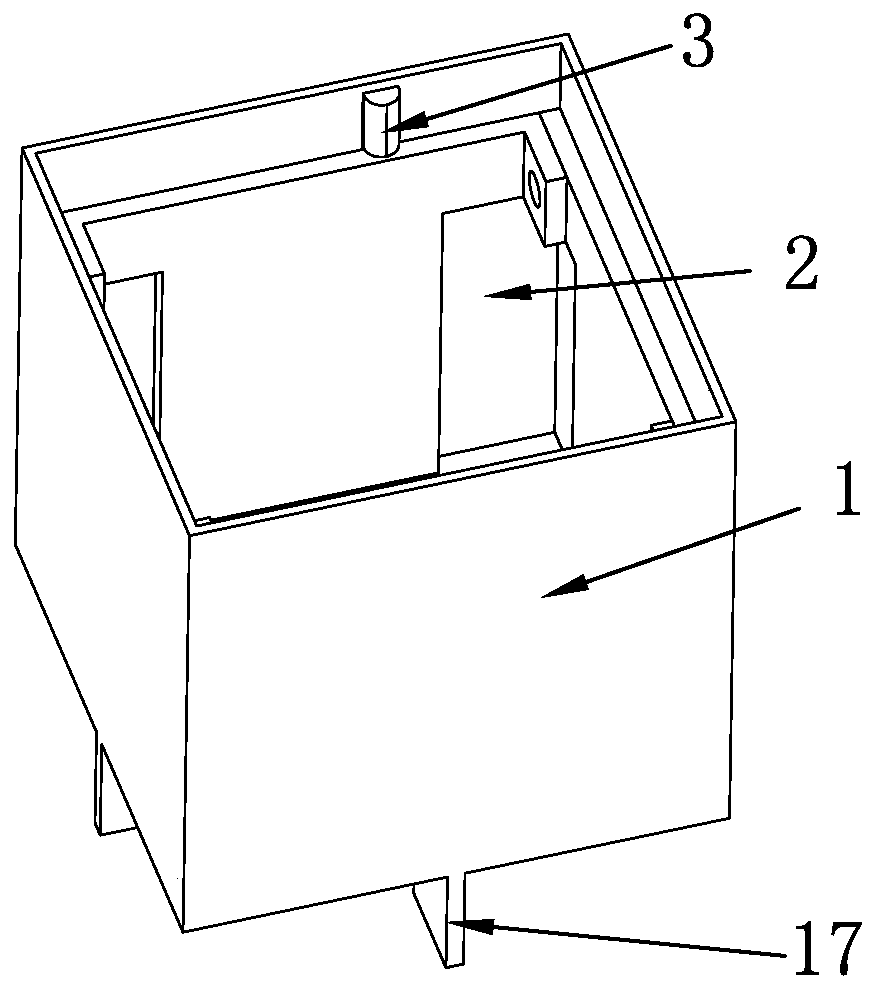

Temperature cycling device

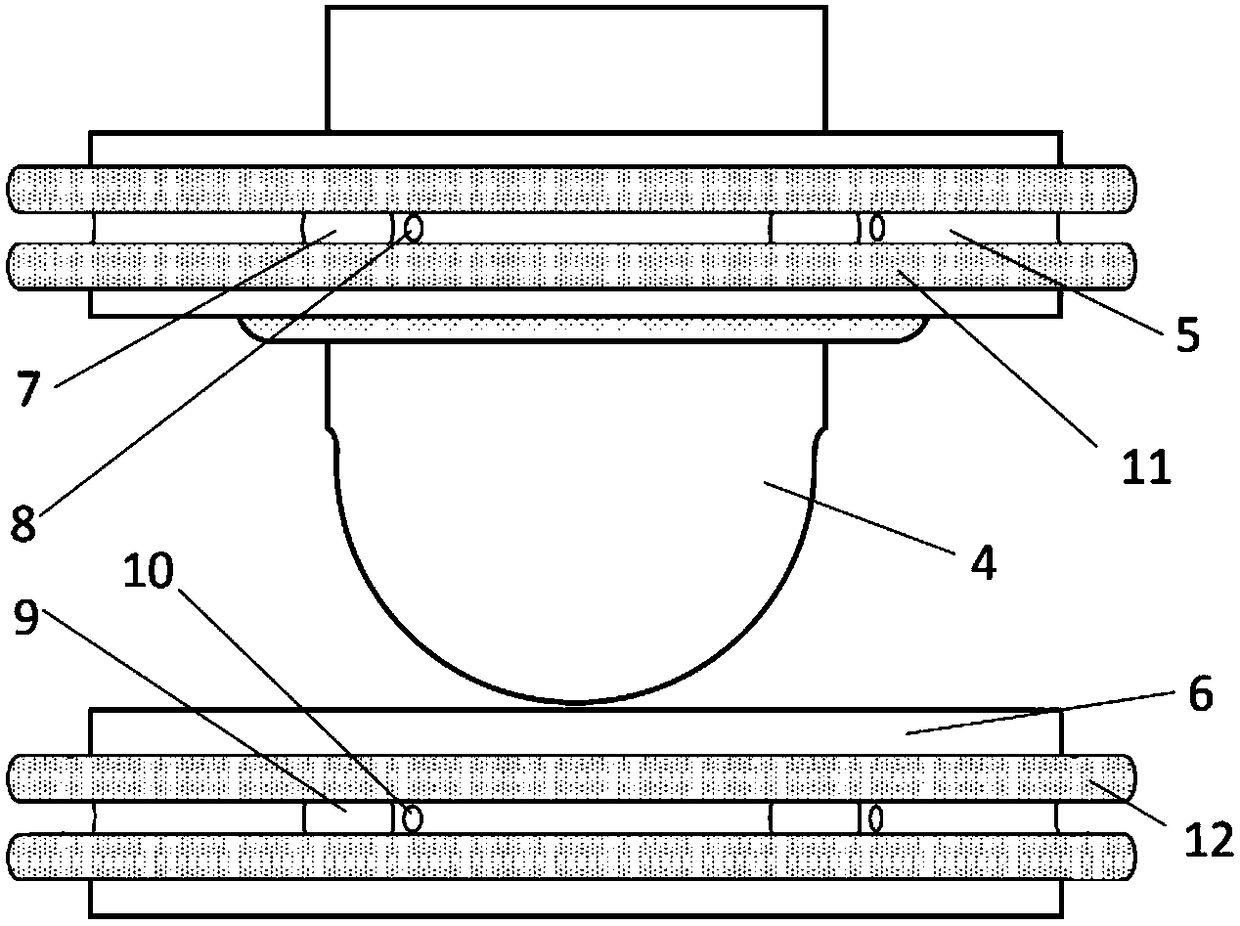

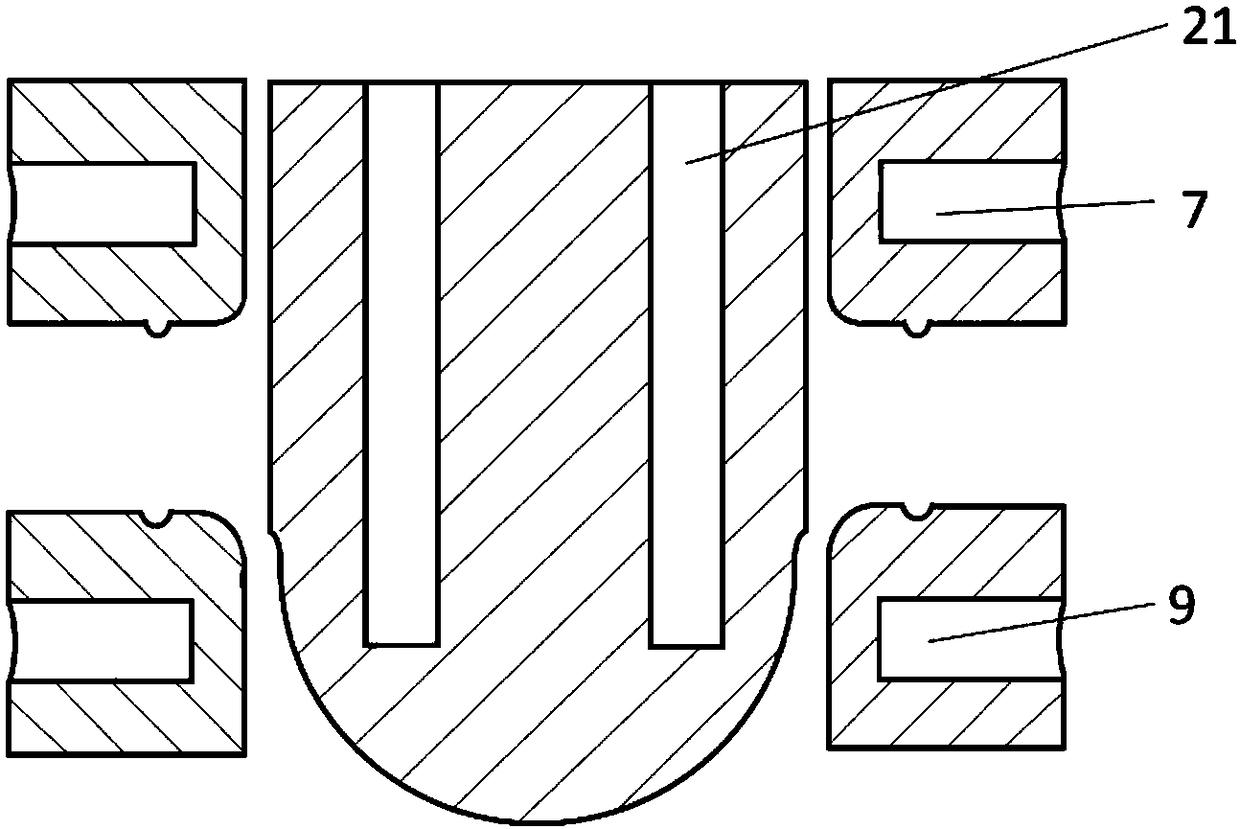

InactiveCN102471746AAvoid condensationAvoid uneven temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlBiological studies

The invention provides a temperature cycling device which is useful in performing the reaction of a biological sample used, for example, in the field of a molecular biological study, and particularly the amplification of nucleic acid. Specifically disclosed is a temperature cycling device for incubating a reaction solution (5), the device [1] being provided with a heat block (1) for holding and heating a reaction container (4) that accommodates the reaction solution (5), the heat block (1) being configured by two layers of a lower heat block (3) and an upper heat block (2), the device [2] being further provided with a temperature control means for controlling the temperature of the lower heat block (3) and the upper heat block (2) independently of each other, and maintaining the temperature of the upper heat block (2) higher than the temperature of the lower heat block (3); when the reaction solution (5) is incubated. As a result, water and other components in the reaction solution (5) do not coagulate in the reaction container (4), and temperature variations depending on the installation position of the reaction container (4) do not occur, thereby enabling the performance of a PCR and other enzyme reactions with good reproducibility.

Owner:宝生物工程有限公司

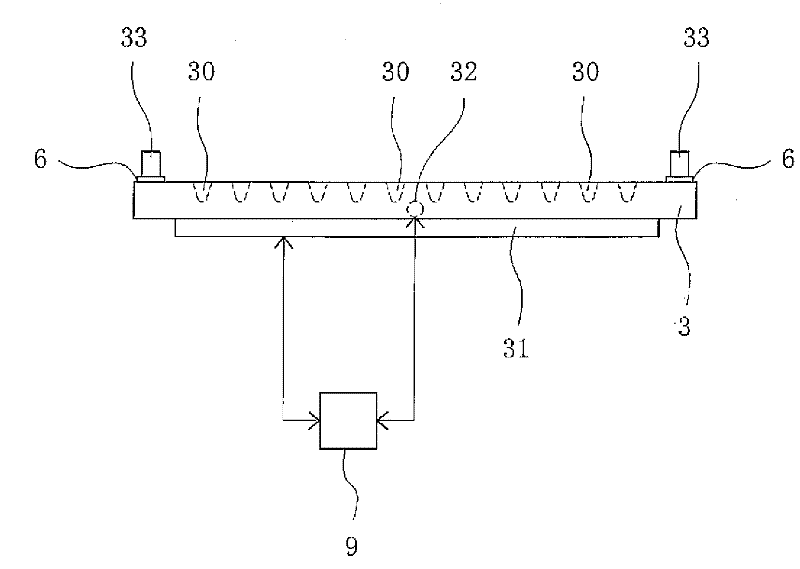

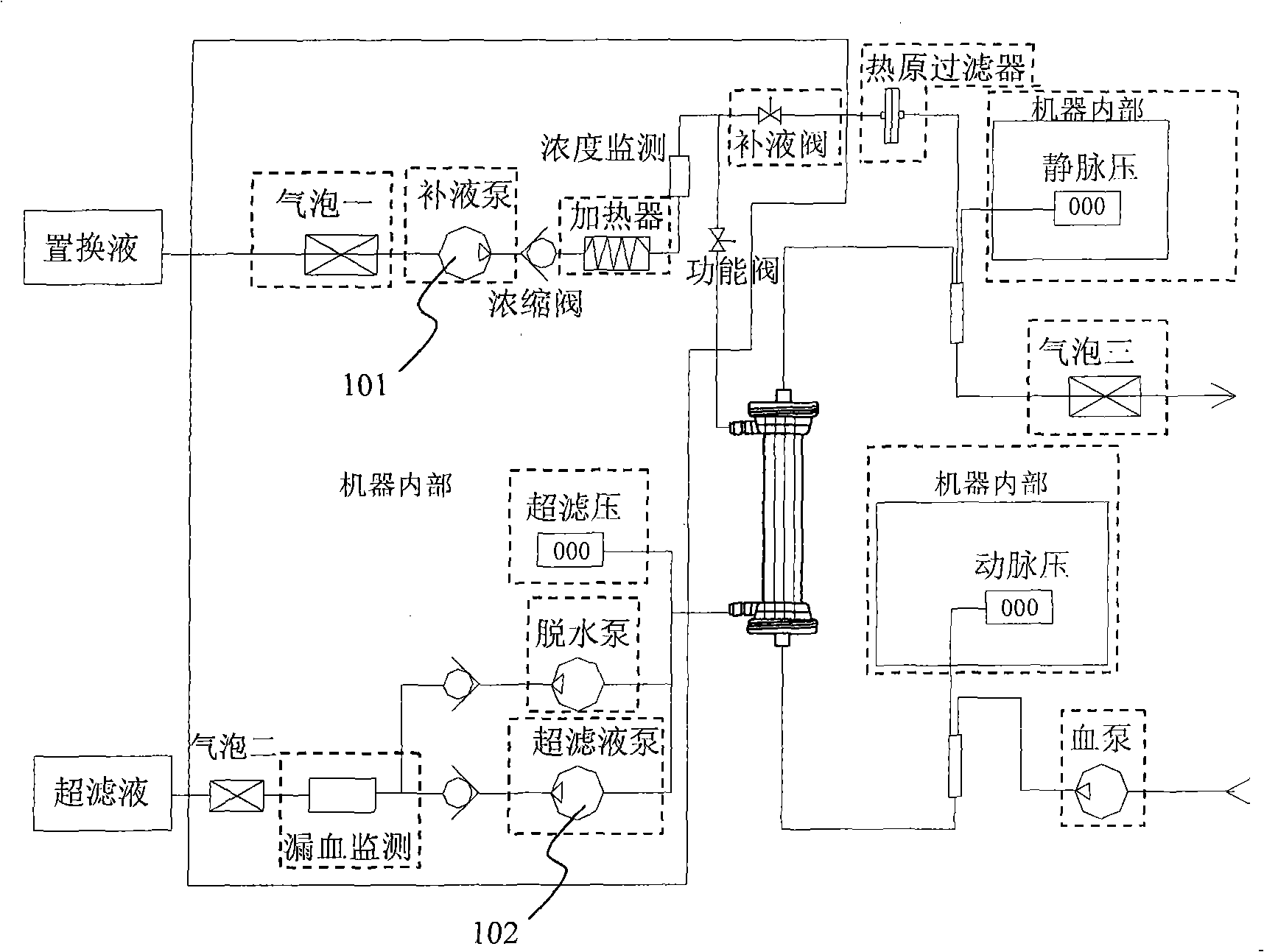

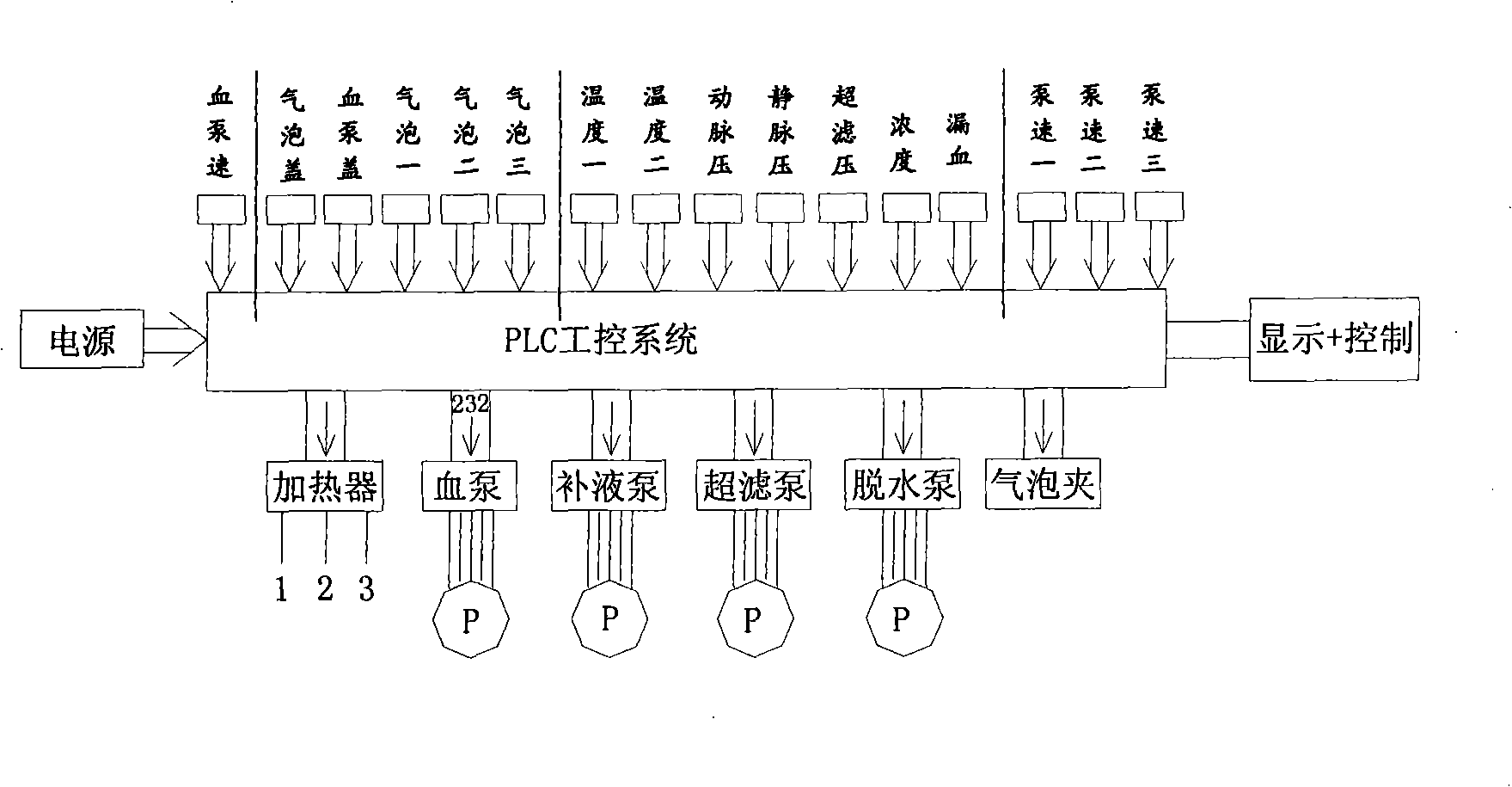

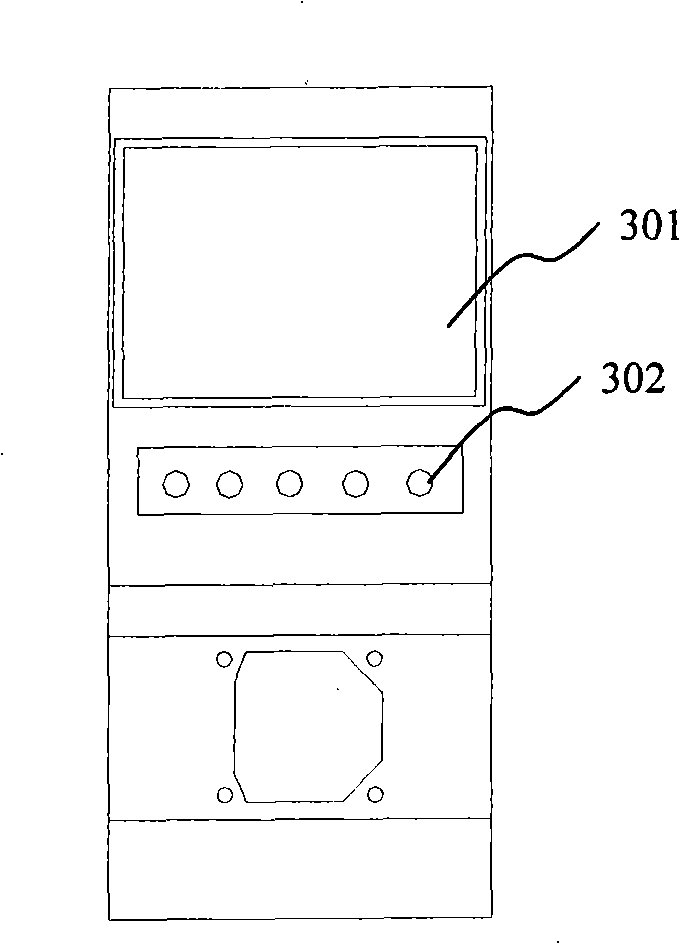

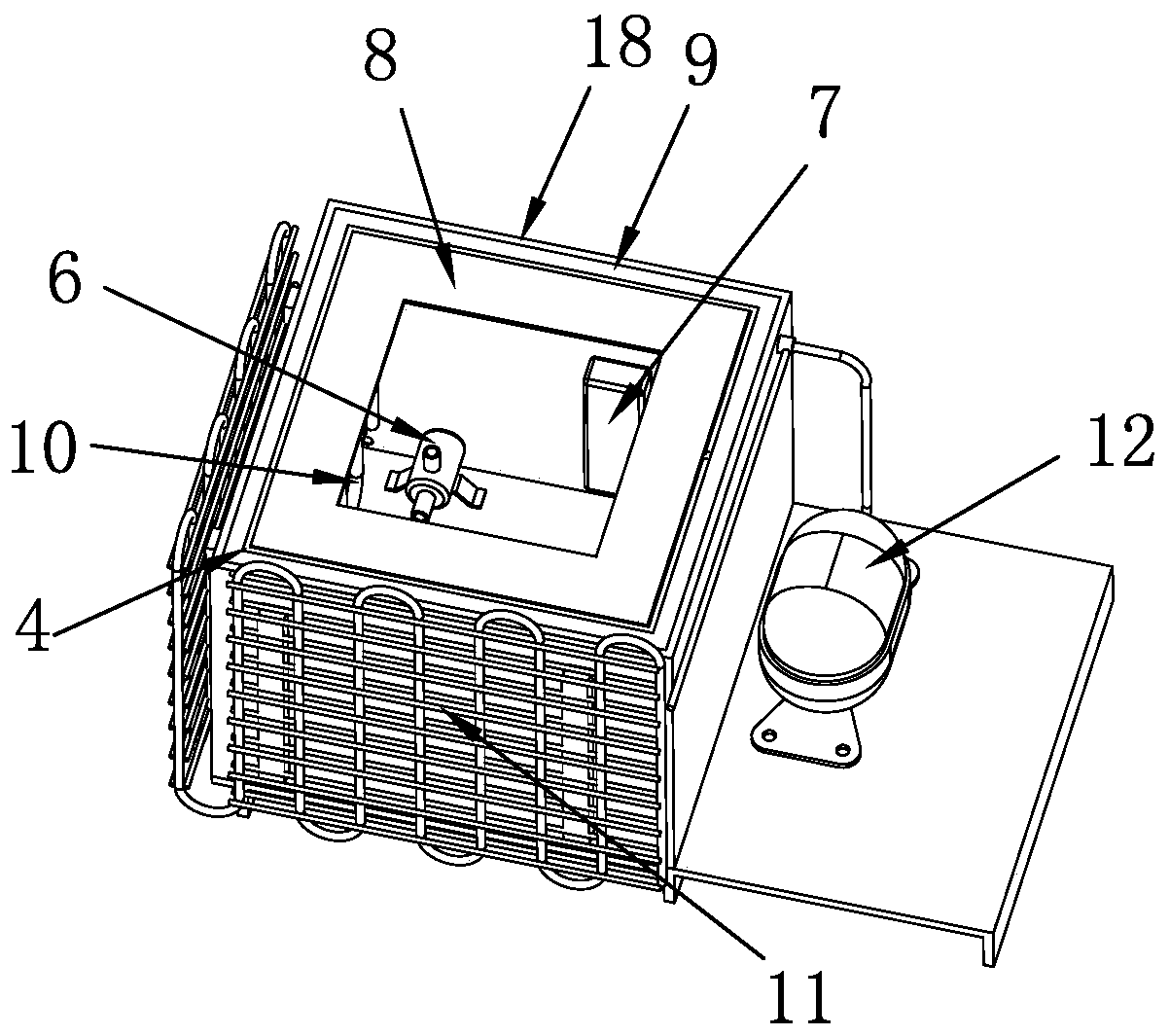

Portable equipment for continuous renal replacement therapy and blood purification method

InactiveCN101347644AGuaranteed measurement accuracyAvoid uneven temperatureDialysis systemsEngineeringBlood purification

The invention provides a portable and continuous kidney replacing therapy apparatus and a method for purifying blood. The therapy apparatus comprises a blood channel, a displacement liquid channel and an ultrafiltrate channel. The apparatus also comprises a first displacement pump, a second displacement pump and a controller, wherein, the first displacement pump is arranged in the displacement liquid channel, and liquid of fixed volume can be output per revolution; the second displacement pump is arranged in the ultrafiltrate channel, and liquid of fixed volume can be output per revolution; the controller calculates the input flow of the displacement liquid channel and the output flow of the ultrafiltrate channel in a volume metering method, controls the rotational speed of the first displacement pump and the second displacement pump and maintains the balance of the input flow and the output flow. The therapy apparatus of the invention can be used in the environments of turbulence, rocking and vibration, and the like, such as on the sea, and can be suitable for corrosion of salt-fog on the sea and a plurality of external power supplies.

Owner:BEIJING MEDER MEDICAL SCI & TECH

High-pollution building space exhaust disinfection and purification system and method

PendingCN111878927AReduce virus contentImprove disinfection effectDucting arrangementsMechanical apparatusVentilation tubeInsulation layer

The invention provides a high-pollution building space exhaust disinfection and purification system and method. The system comprises a pollution region negative pressure metal ventilation pipe, and any position of the pollution region negative pressure metal ventilation pipe is communicated to the inlet end of a high-resistance ventilation pipeline with a heat insulation and insulation layer. Theoutlet end of the high-resistance ventilation pipeline with the heat insulation and insulation layer is connected to the inlet end of an outdoor negative pressure metal ventilation pipe through an electric backflow prevention valve, and the outlet end of the outdoor negative pressure metal ventilation pipe is connected to an extraction opening of an efficient frequency conversion draught fan. A plurality of virus killing devices are sequentially arranged at the rear end of the efficient variable-frequency draught fan. By means of the system and method, air possibly containing viruses in a high-pollution building space is subjected to high-temperature disinfection and sterilization through an electric heating pipeline, then the air subjected to high-temperature disinfection and sterilization is guided to an outdoor multi-virus disinfection and sterilization device through the negative pressure pipeline to conduct diversified thorough disinfection and sterilization on the introduced air,and the viruses in the air in the high-pollution building space can be thoroughly removed.

Owner:CHINA RAILWAY CONSTR GROUP +1

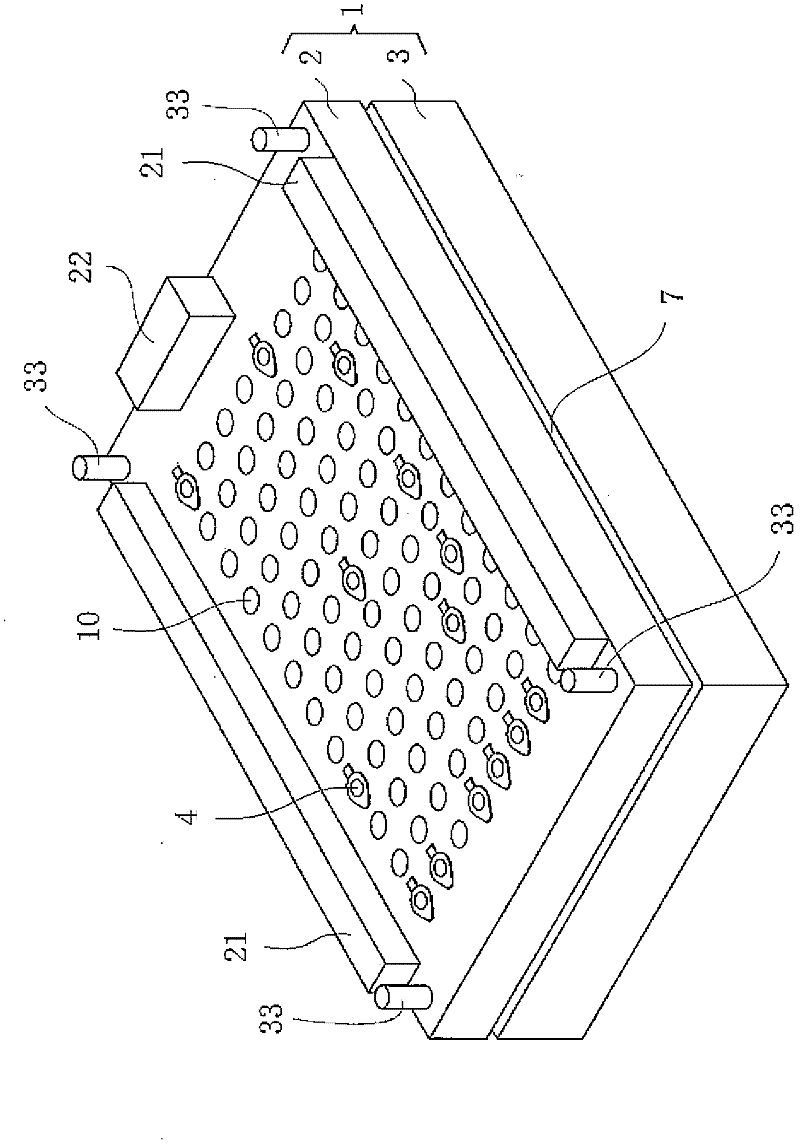

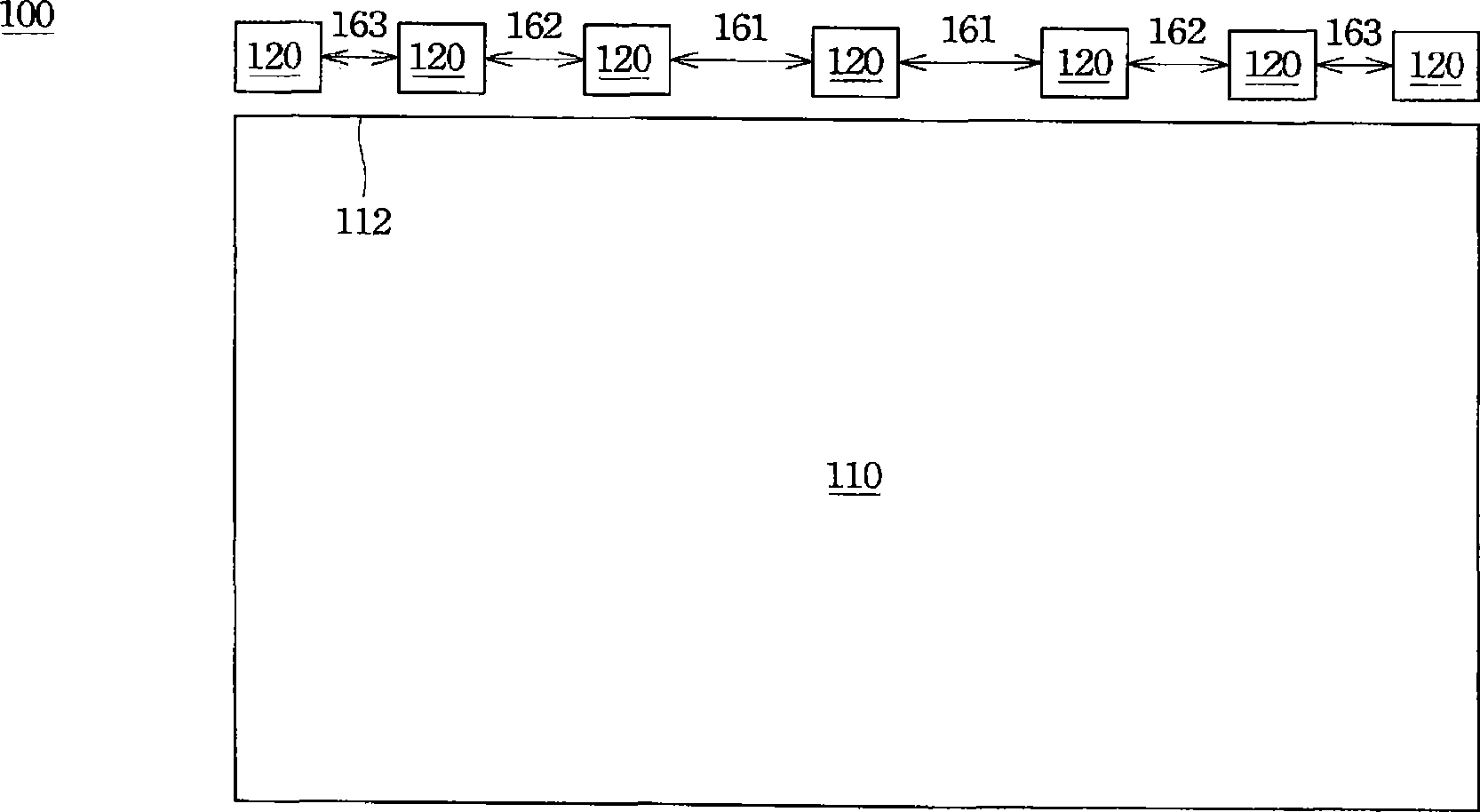

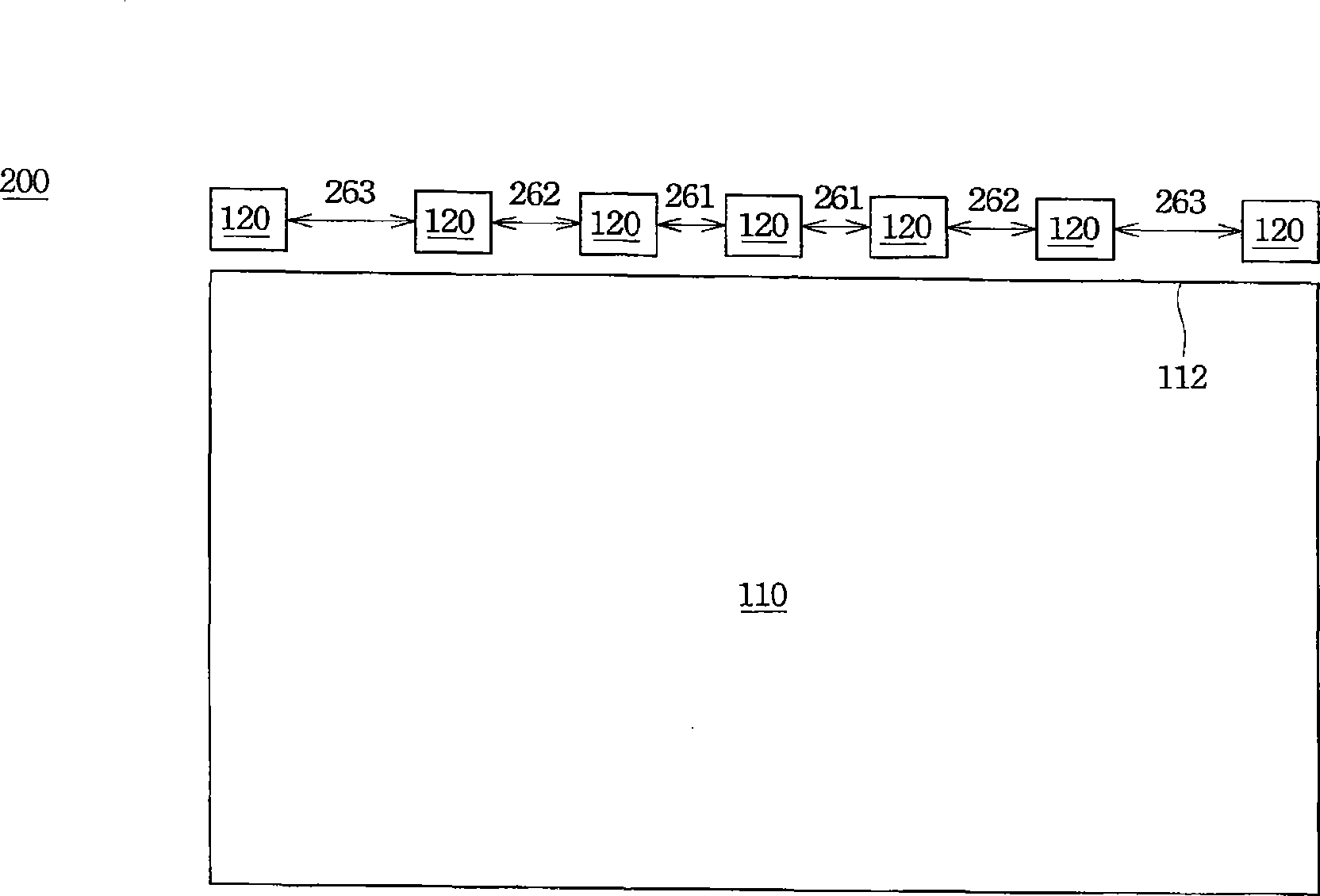

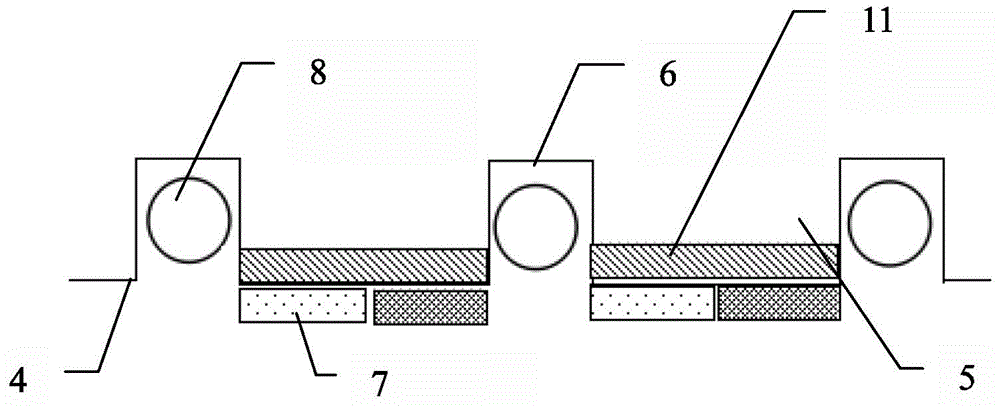

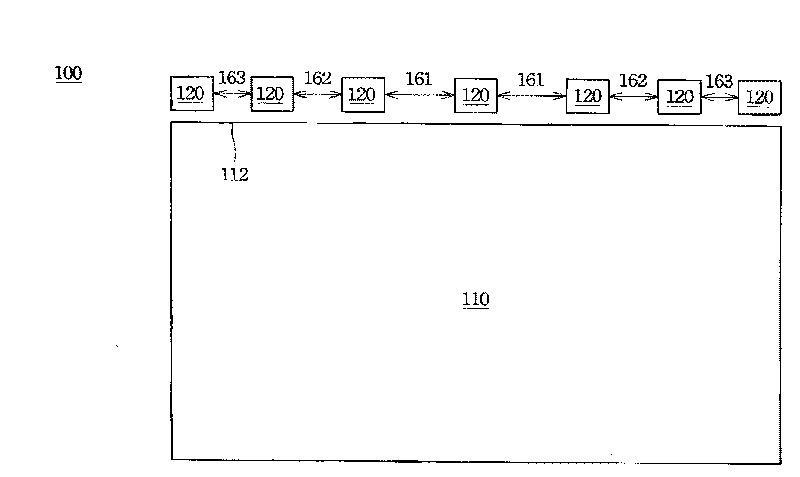

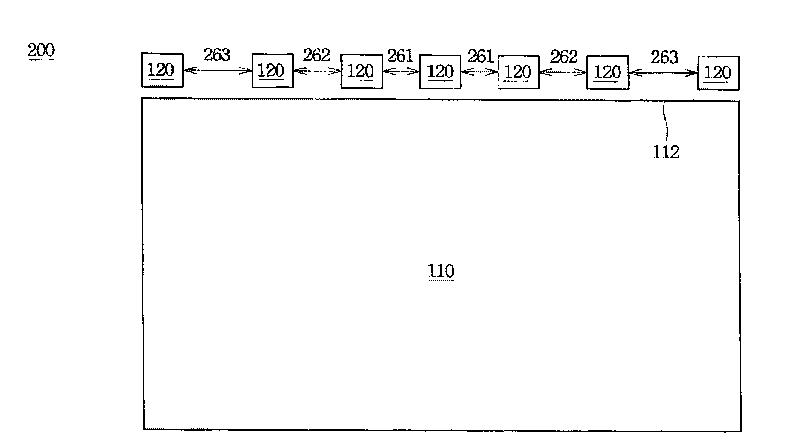

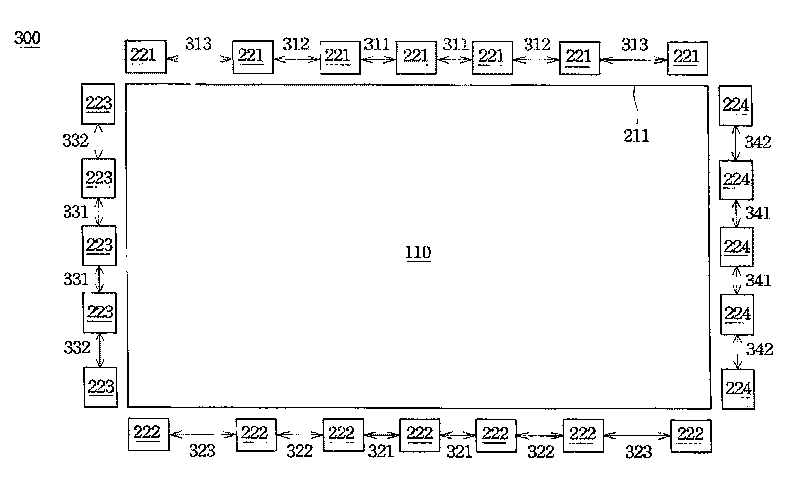

Side light type backlight module and its operation method

ActiveCN101368687AAvoid warpingAvoid uneven temperaturePlanar light sourcesMechanical apparatusLight-emitting diodePhysics

Disclosed are a sidelight type backlight module and the operation method thereof; wherein, the sidelight type backlight module comprises a light guide plate and a plurality of LED light sources. The light guide plate includes a light input lateral side and a light output surface. The LED light sources are arranged on the light input lateral side; an interval is maintained between each two adjacent LED light sources; wherein, the LED light sources are arranged with unequal intervals. The sidelight type backlight module can prevent the uneven temperature problem, have no influence on the optical quality and prevent the warping phenomenon of the light guide plate.

Owner:AU OPTRONICS CORP

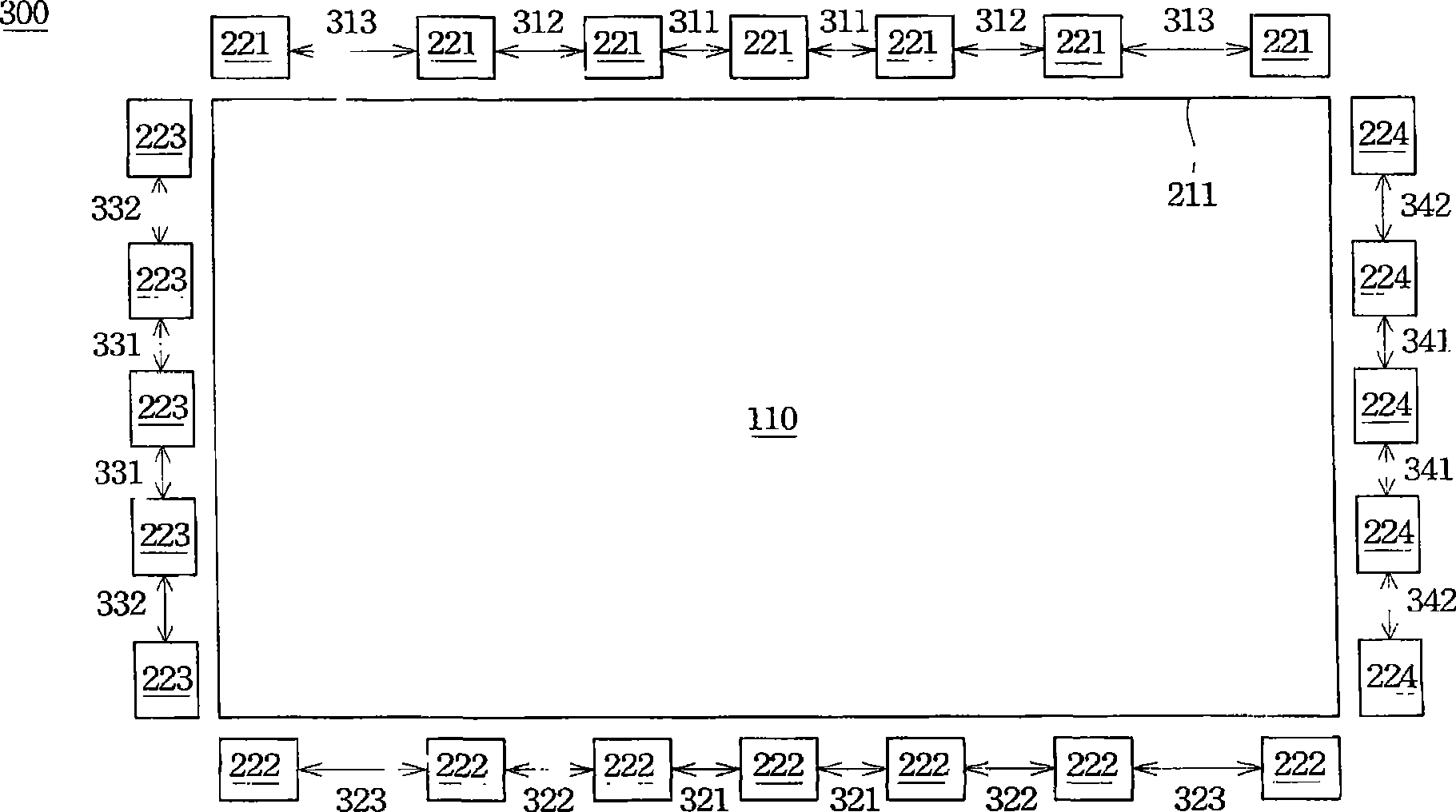

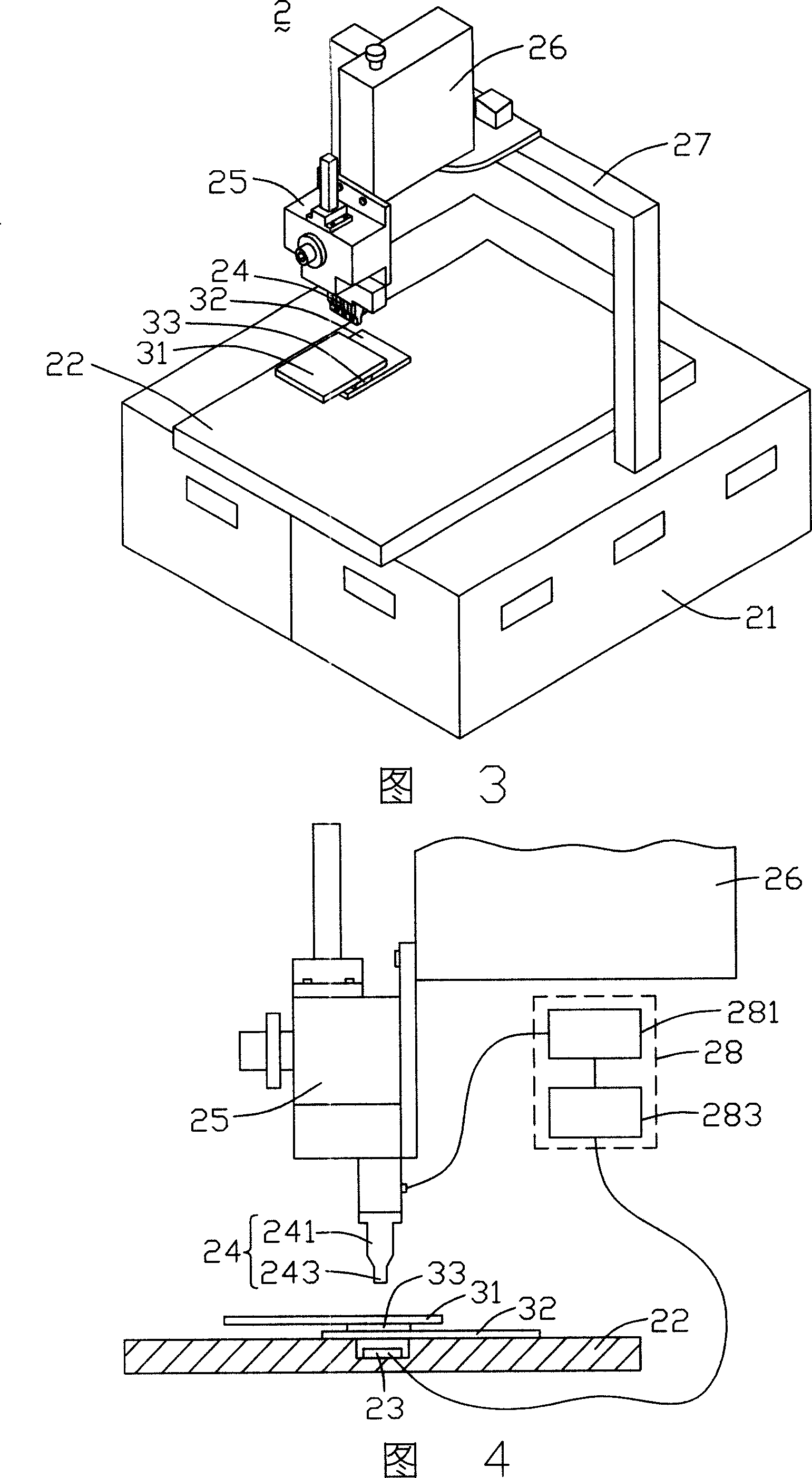

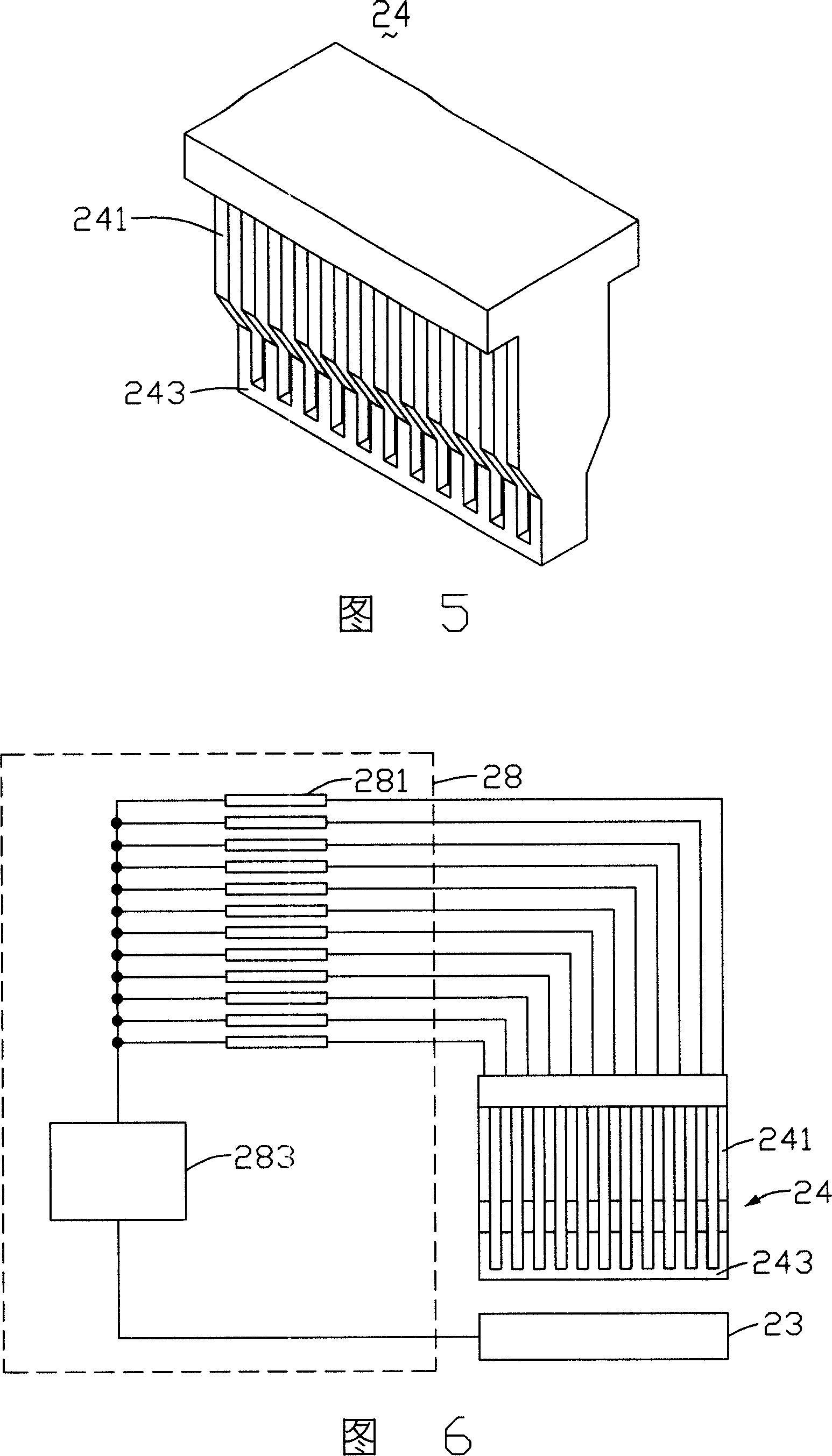

Hot press device and hot press method using the same

InactiveCN101125386AAvoid uneven temperatureImprove lamination qualityPrinted circuit assemblingHeating appliancesElectricityHot press

The present invention relates to a hot-pressing device used for electrically and mechanically connecting for the two electronic components waiting for pressing and a hot-pressing method by adopting the hot-pressing device. The hot-pressing device comprises a control unit and a hot-pressing contract electrically connected with thereof, wherein, the hot-pressing contract comprises a plurality of heating noumena, and the control unit respectively controls each heating noumenon to work. The hot-pressing device ensures the even temperature on the surface of the pressing position of the electronic components waiting for pressing by controlling the working of a plurality of heating noumena by the control unit, and avoids that: the disproportionation of heat transmission and releasing causes the temperature uneven in the pressing position, thereby causing the impact to pressing quality.

Owner:INNOCOM TECH SHENZHEN +1

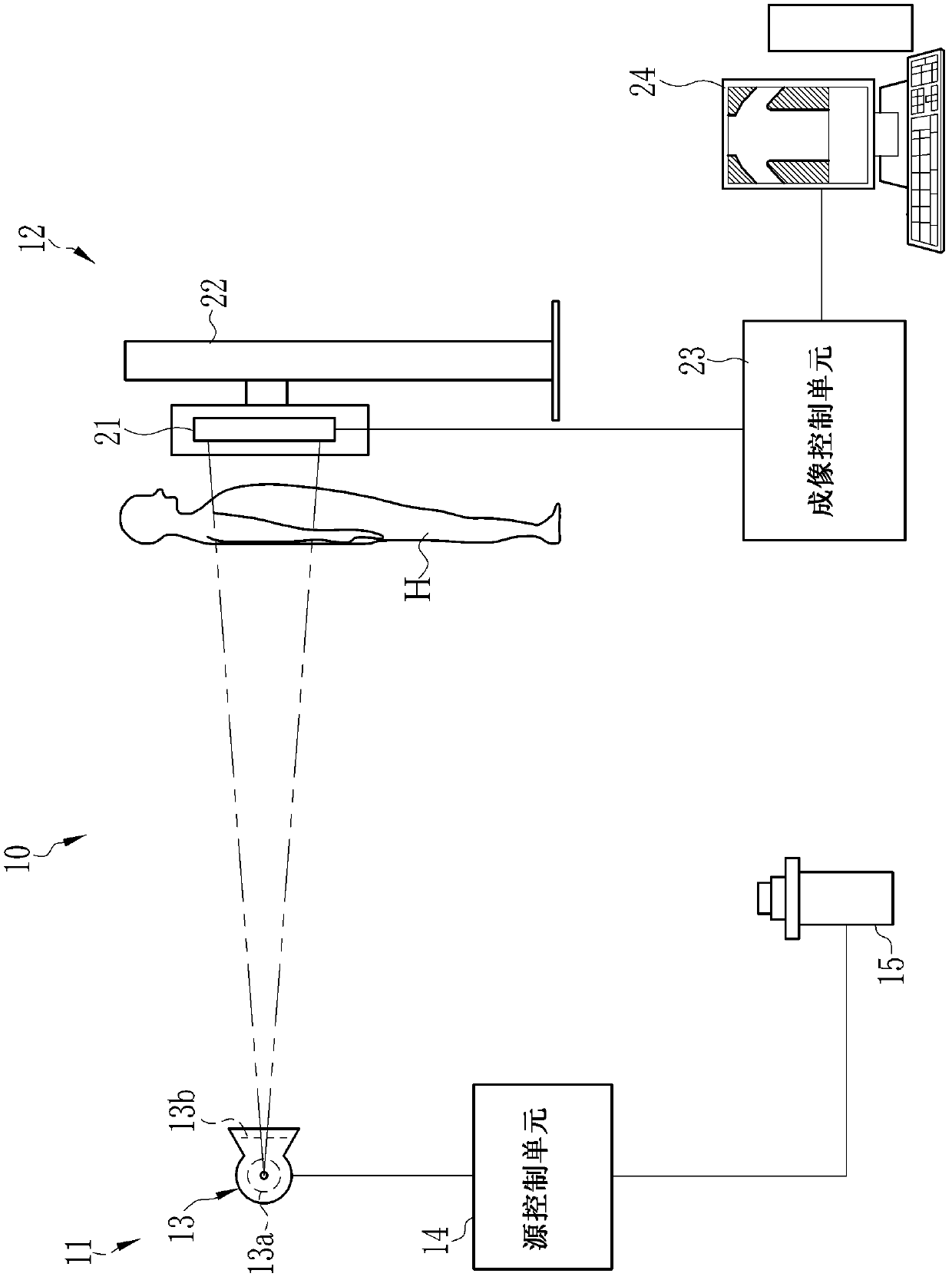

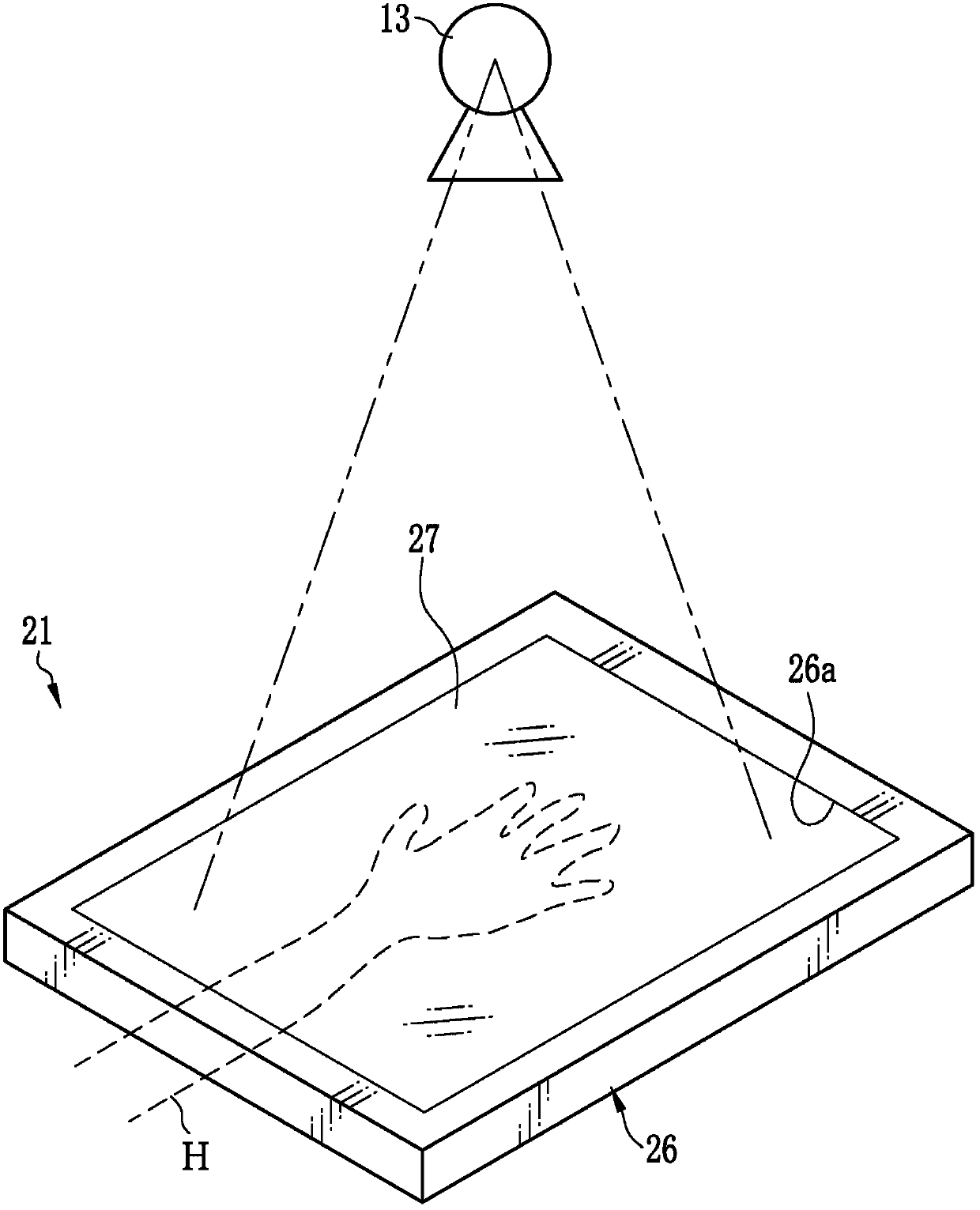

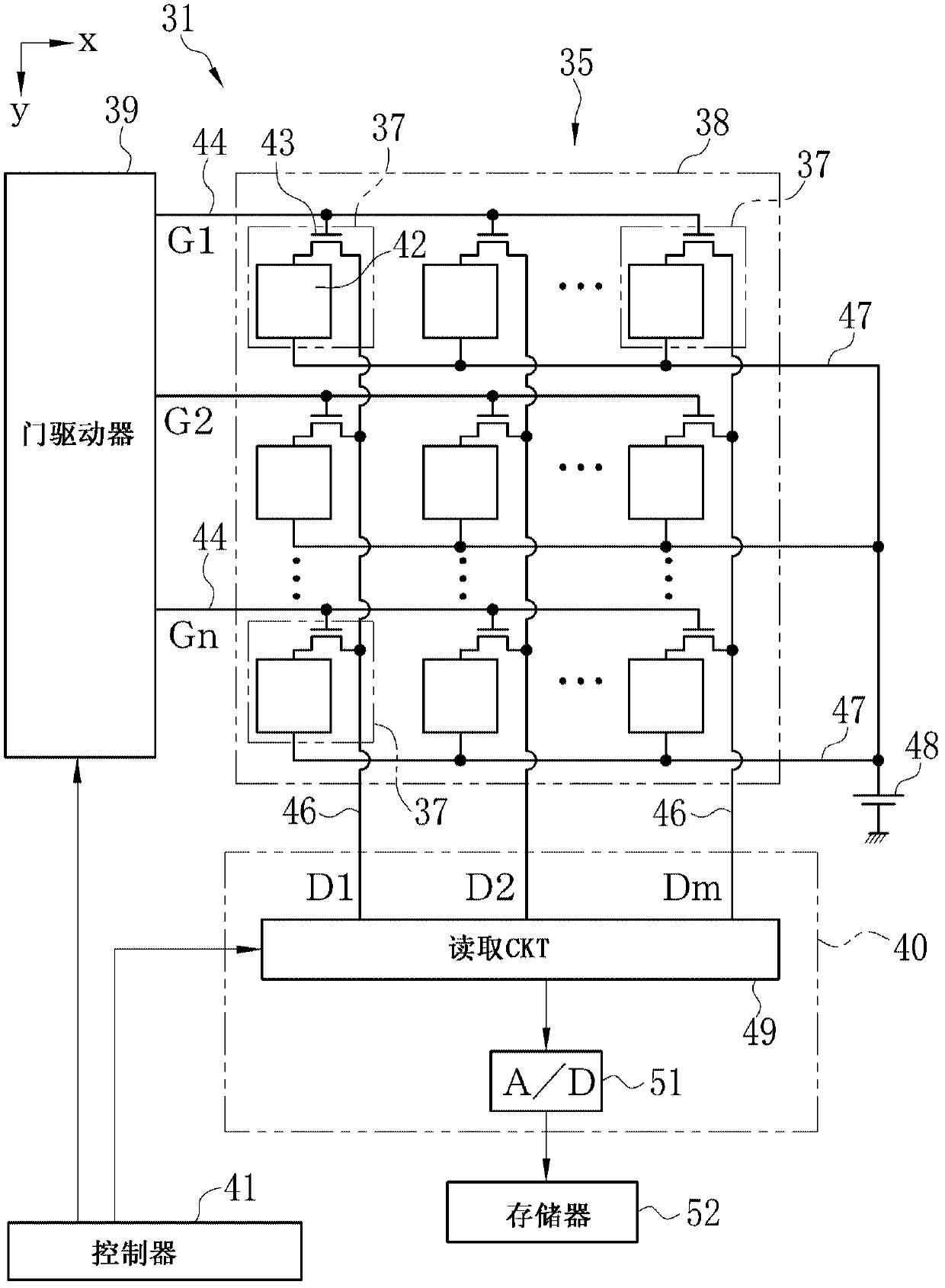

Electronic cassette for radiation imaging

ActiveCN102579064AGuaranteed image qualityAvoid uneven temperatureRadiation intensity measurementRadiation diagnosticsWindow openingImage detection

An electronic cassette for radiation imaging has an image detection device for forming an image of an object irradiated with radiation. The image detection device includes a housing. A window opening is formed in the housing, for receiving the radiation. A scintillator is contained in the housing, for converting the radiation from the window opening into light. A detection panel is contained in the housing, disposed between the scintillator and window opening, for converting the light into a signal. A radio transparent plate of a quadrilateral shape is disposed to close the window opening, is radio transparent to the radiation, has at least high and low thermal conductivity sheets arranged in a direction of entry of the radiation into the housing, the radio transparent plate being so anisotropic that thermal conductivity is higher in a longitudinal direction of the quadrilateral shape than in a transverse direction of the quadrilateral shape.

Owner:FUJIFILM CORP

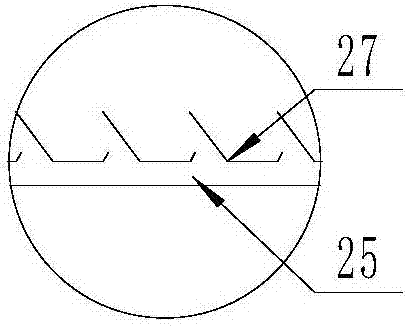

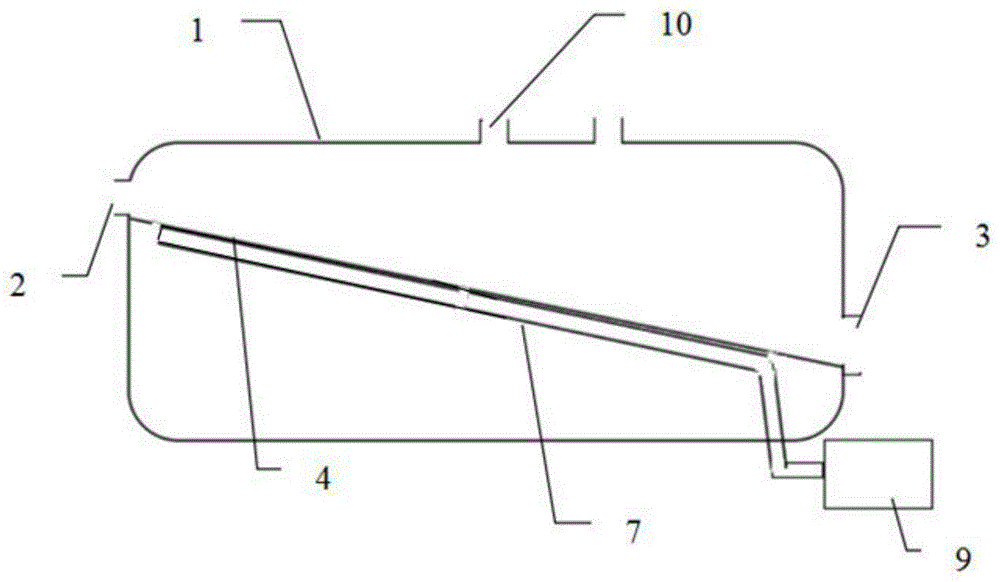

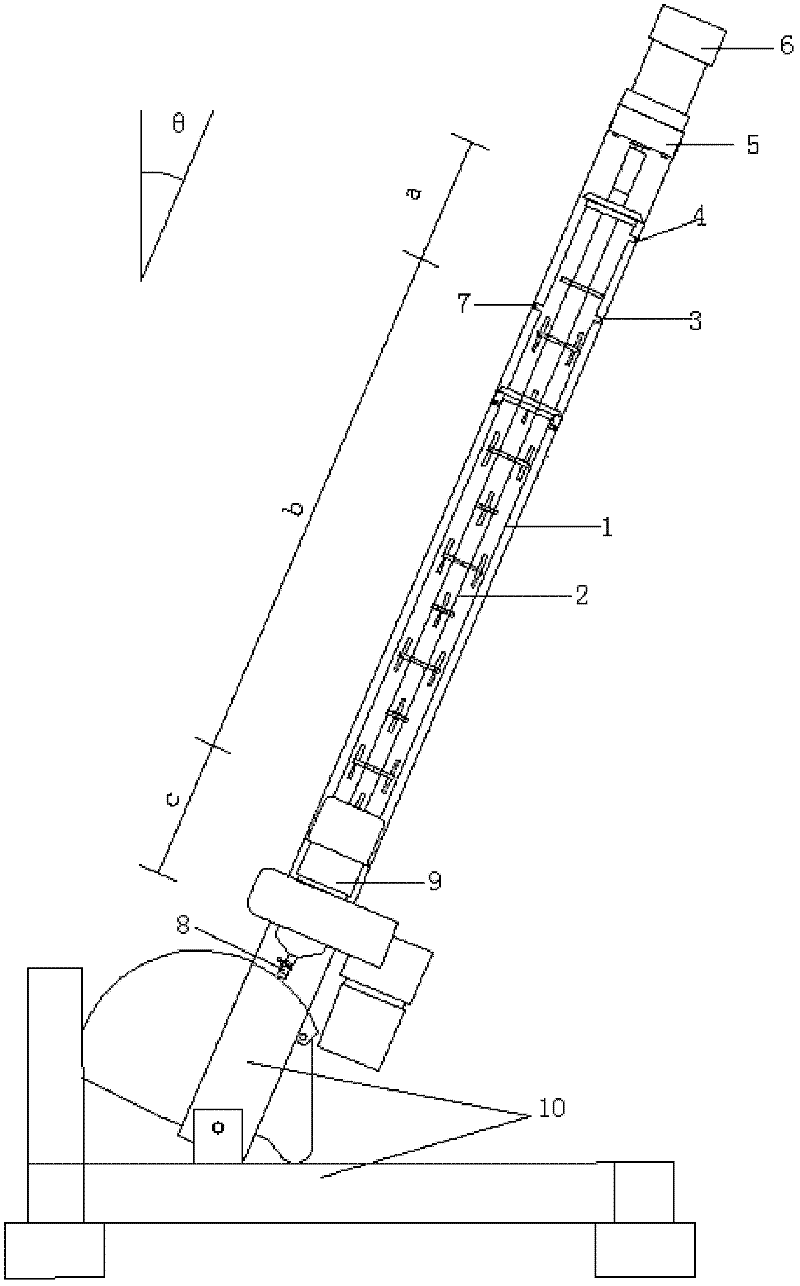

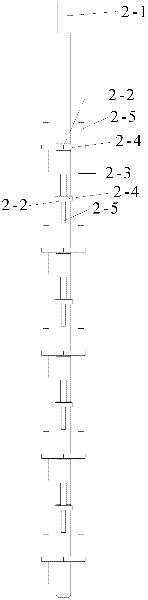

High-temperature disinfecting and drying device for livestock and poultry manure

InactiveCN104667333AAvoid uneven temperatureImprove efficiencySludge treatment by de-watering/drying/thickeningMedical waste disposalFecesPoultry manure

The invention discloses a high-temperature disinfecting and drying device for livestock and poultry manure. A heating pipeline is arranged at the lower part of an obliquely placed support plate and set as a two-way steam circulating system, so that two ends of the support plate can reach the disinfection temperature, and the high-temperature disinfection effect and efficiency of the livestock and poultry manure are improved. Besides, the support plate is set as a curved surface formed by arranging a plurality of grooves and hollow bosses in a staggered manner, air inlet pipes are arranged in the hollow bosses, a plurality of holes are formed in the hollow bosses and side walls of the air inlet pipes, the livestock and poultry manure enters the grooves from feed ports and then is subjected to high-temperature disinfection when sliding downwards along walls of the grooves, and meanwhile, the air inlet pipes blow hot drying air towards the livestock and poultry manure via the holes of the hollow bosses, so that the livestock and poultry manure is dried to a certain extent.

Owner:曾泽华 +1

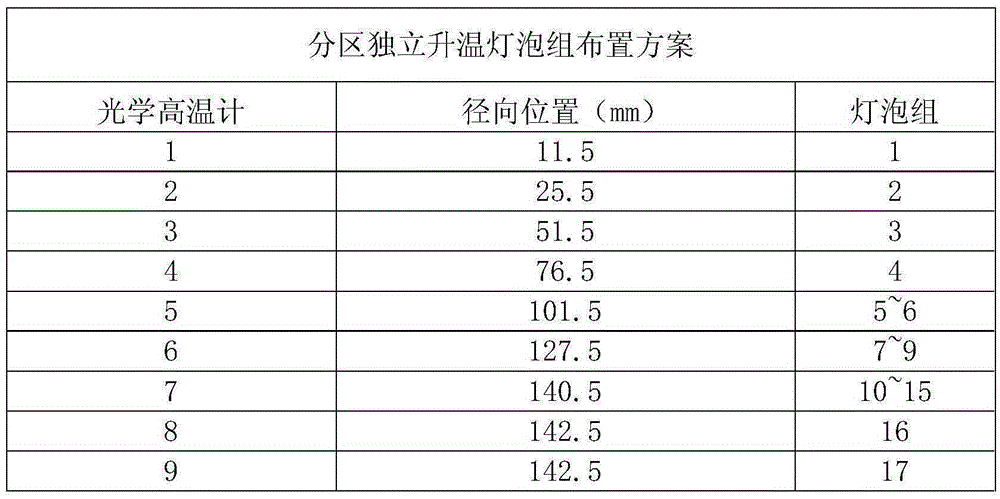

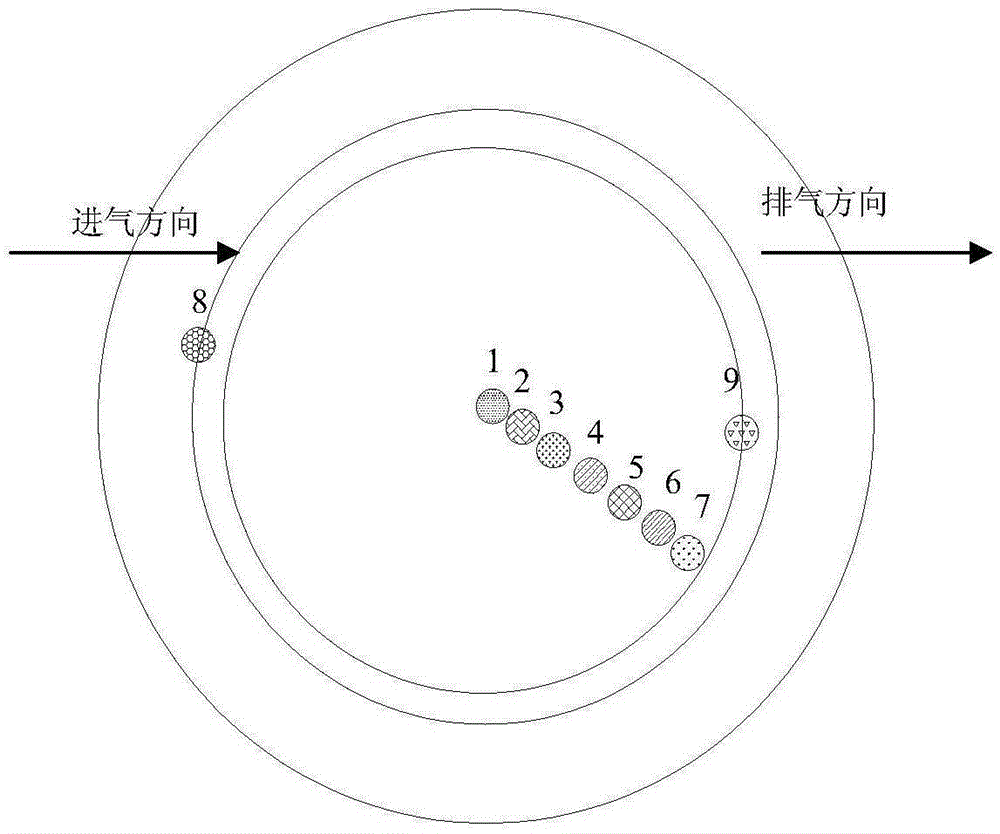

Reaction chamber temperature zone control system

InactiveCN105390421ASolve the problem of uneven heating caused by uneven thicknessImprove uniformitySemiconductor/solid-state device manufacturingTemperature controlControl system

The invention relates to the technical field of semiconductor devices, particularly to a reaction chamber temperature zone control system. A sealed reaction chamber is divided into a plurality of zones; thermometers can sense the temperatures of different zones in the sealed reaction chamber; a temperature controller is connected to the thermometers; the temperature controller is internally provided with temperature control software; the temperature control software calculates temperature compensations of the corresponding zones in the sealed reaction chamber, sensed by the thermometers, and heats the zones, corresponding to the temperature compensations, in the sealed reaction chamber according to the temperature compensations. According to the technical scheme of the invention, the sealed reaction chamber is divided into the plurality of zones, the temperature compensations of the zones can be calculated respectively, and the corresponding zones can be heated according to the temperature compensations, in such a way that the problems that a gas inlet port and a gas exhaust port of the sealed reaction chamber and other zones of the sealed reaction chamber have different temperatures after being heated, and uneven heating of a silicon chip depositing material is due to uneven thickness of the silicon chip depositing material, can be solved; and the uniformity and the stability of a hot-working technology effect can be improved, and the purpose of controlling the temperature can be effectively achieved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

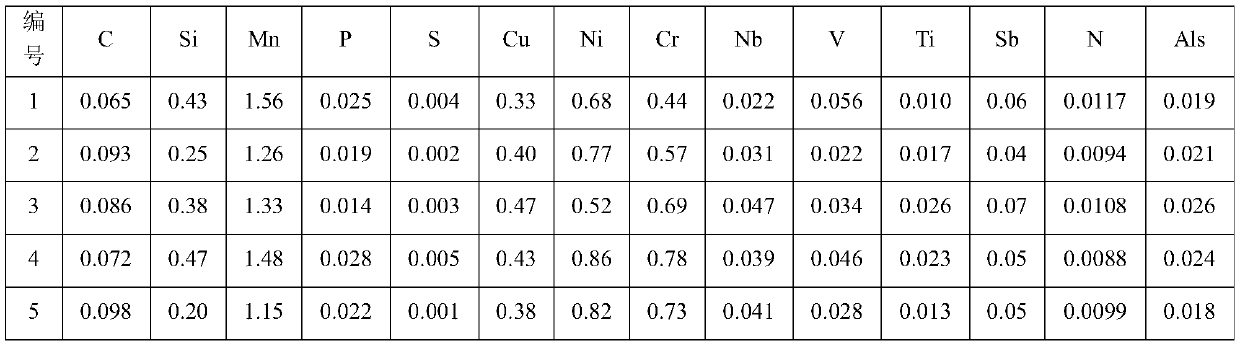

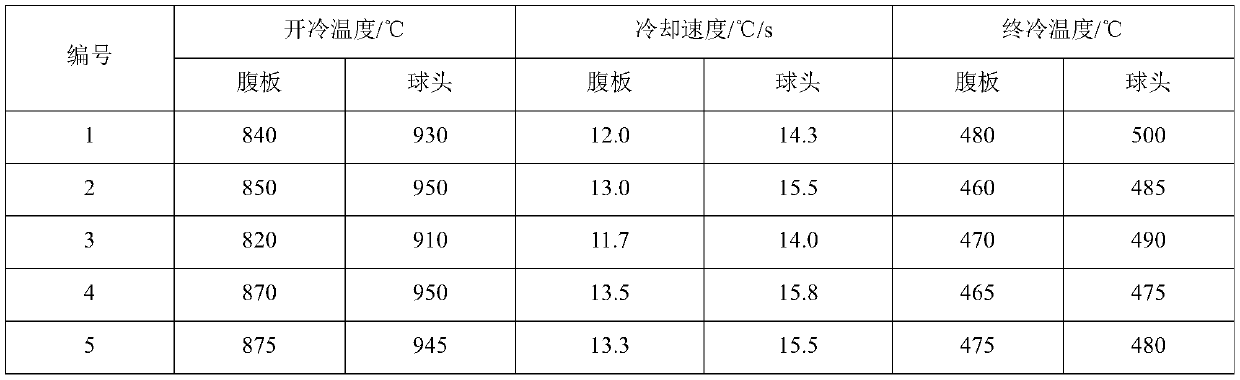

High-strength corrosion-resistant flat-bulb steel and production method thereof

ActiveCN110863146AAvoid uneven temperatureImprove the uniformity of the mechanical properties of the sectionChemical compositionProcess design

The invention relates to high-strength corrosion-resistant flat-bulb steel and a production method thereof. The high-strength corrosion-resistant flat-bulb steel comprises the following chemical components of, in percentage by weight, 0.050%-0.100% of C, 0.10%-0.50% of Si, 1.10%-1.60% of Mn, 0.010%-0.030% of P, less than or equal to 0.005% of S, 0.30%-0.50% of Cu, 0.40%-0. 90% of Ni, 0.40%-0.80% of Cr, 0.010%-0.050% of Nb, 0.010%-0.060% of V, 0.007%-0.030% of Ti, 0.03%-0.08% of Sb, 0.0080%-0.0120% of N, 0.015%-0.030% of Als and the balance Fe and unavoidable impurities. The high-strength corrosion-resistant flat-bulb steel is reasonable in chemical components and process design, and finished products have excellent mechanical property and corrosion resistance.

Owner:ANGANG STEEL CO LTD

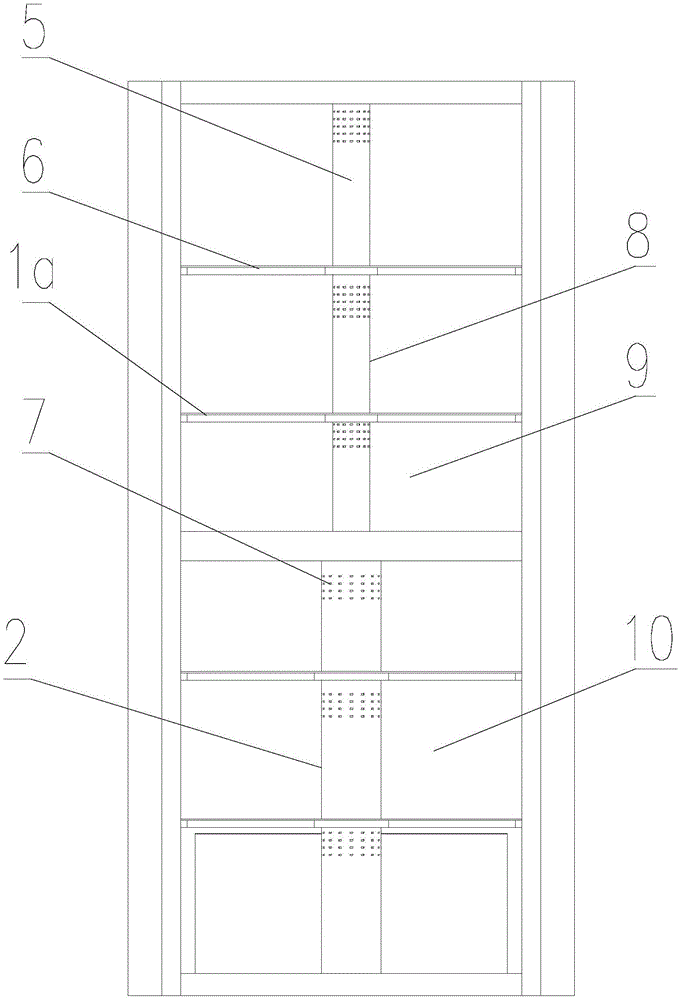

Crystallization tower for purifying phosphoric acid

ActiveCN102580345AHigh removal rateFully meet the requirements of sweating mechanismCrystallization separationPhosphorus compoundsPhosphoric acidEngineering

The invention relates to a crystallization tower for purifying phosphoric acid. The crystallization tower comprises a tower body, one stirrer, a heater and a driving mechanism, wherein the tower body is divided into a cooling crystallization section, a separating purification section and a crystal melting section; the cooling crystallization section is arranged at the upper part of the tower body; the crystal melting section is arranged at the lower part of the tower body; the separating purification section is arranged between the cooling crystallization section and the crystal melting section; a feeding hole and a coolant inlet are arranged at the lower part of the cooling crystallization section of the tower body; the coolant inlet is arranged above the feeding hole; the upper part of the cooling crystallization section of the tower body is provided with a raffinate and coolant discharge hole; the bottom of the crystal melting section of the tower body is provided with a purified phosphoric acid outlet; the main body part of the stirrer is arranged in the tower body; one end of the stirrer extends out of the tower body and is connected with a speed reducer of the driving mechanism; and the heater is arranged on the tower body and is positioned on the crystal melting section of the tower body.

Owner:SICHUAN UNIV

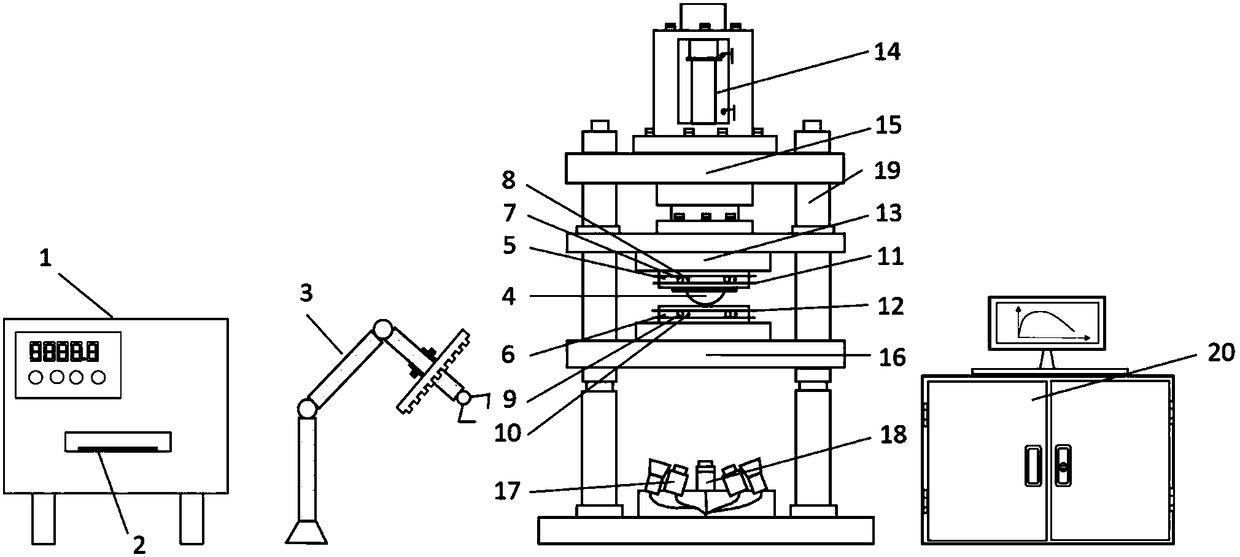

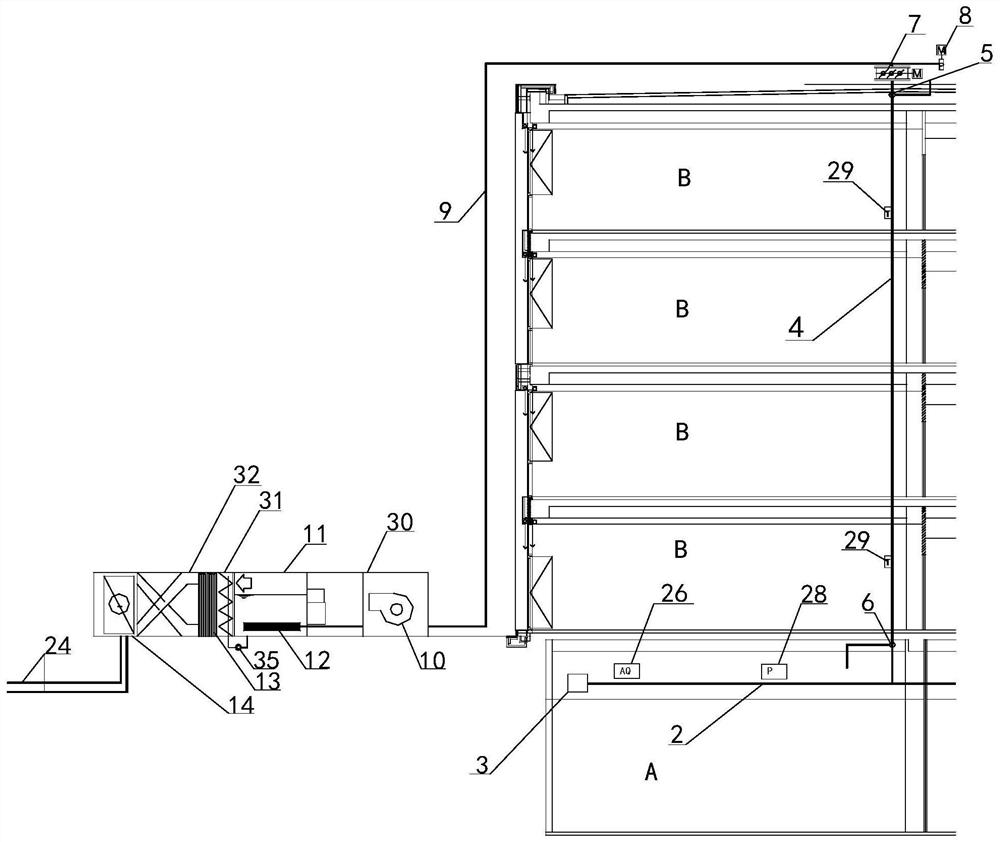

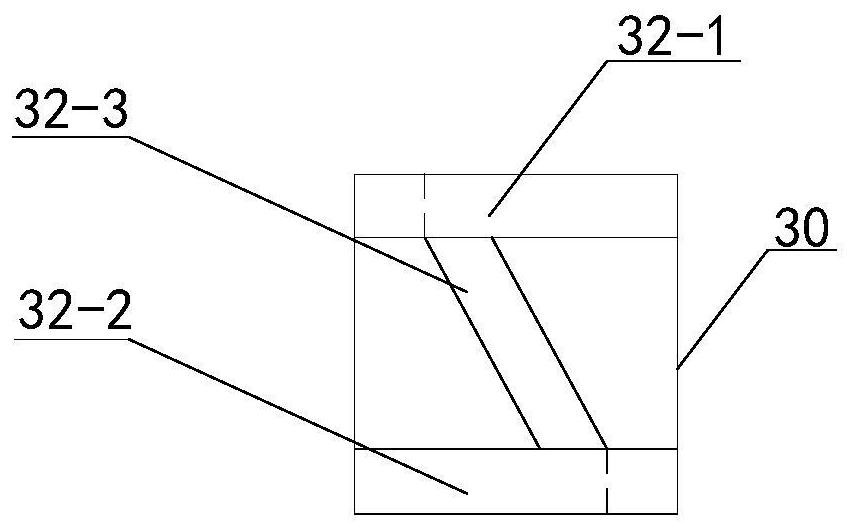

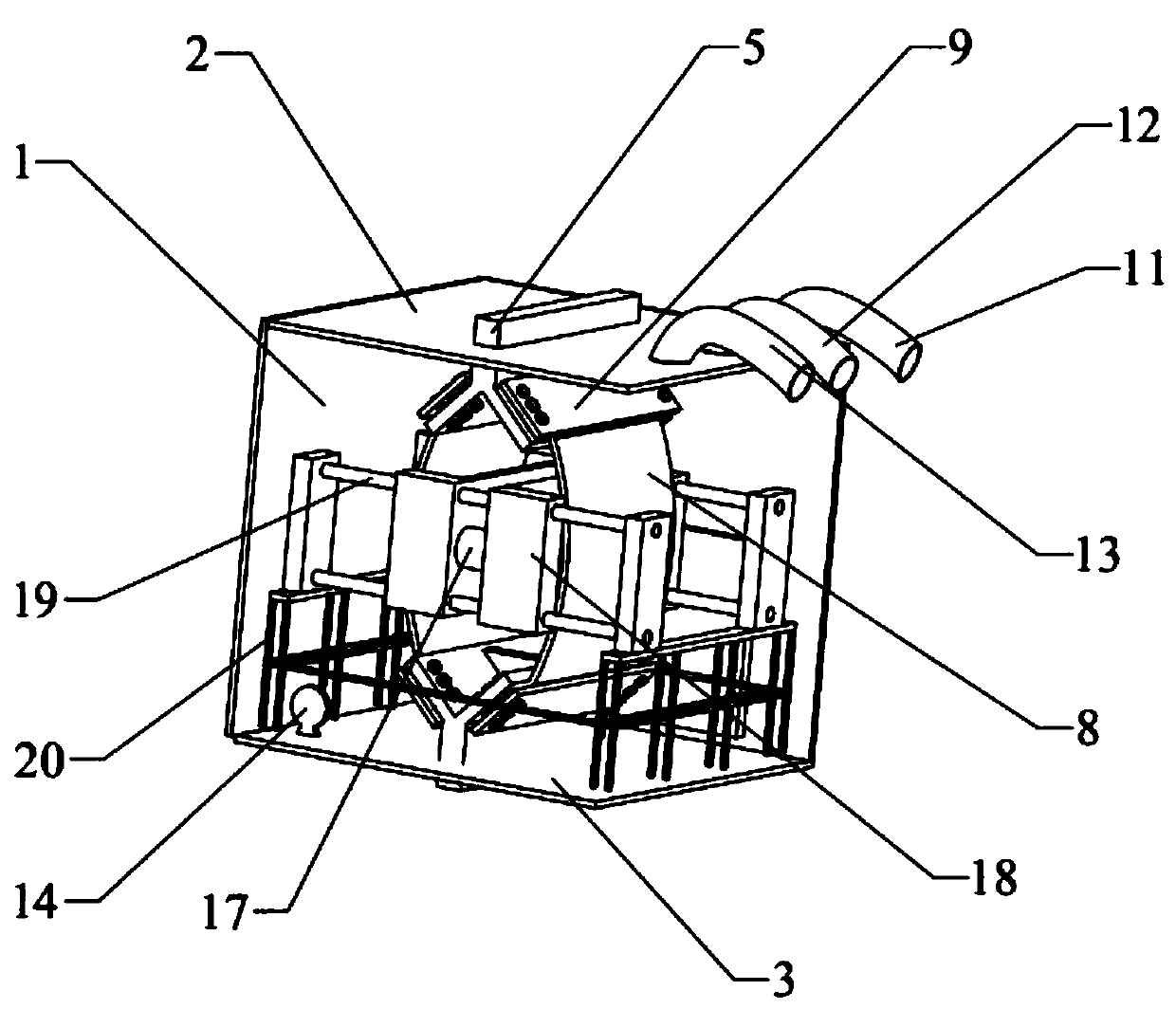

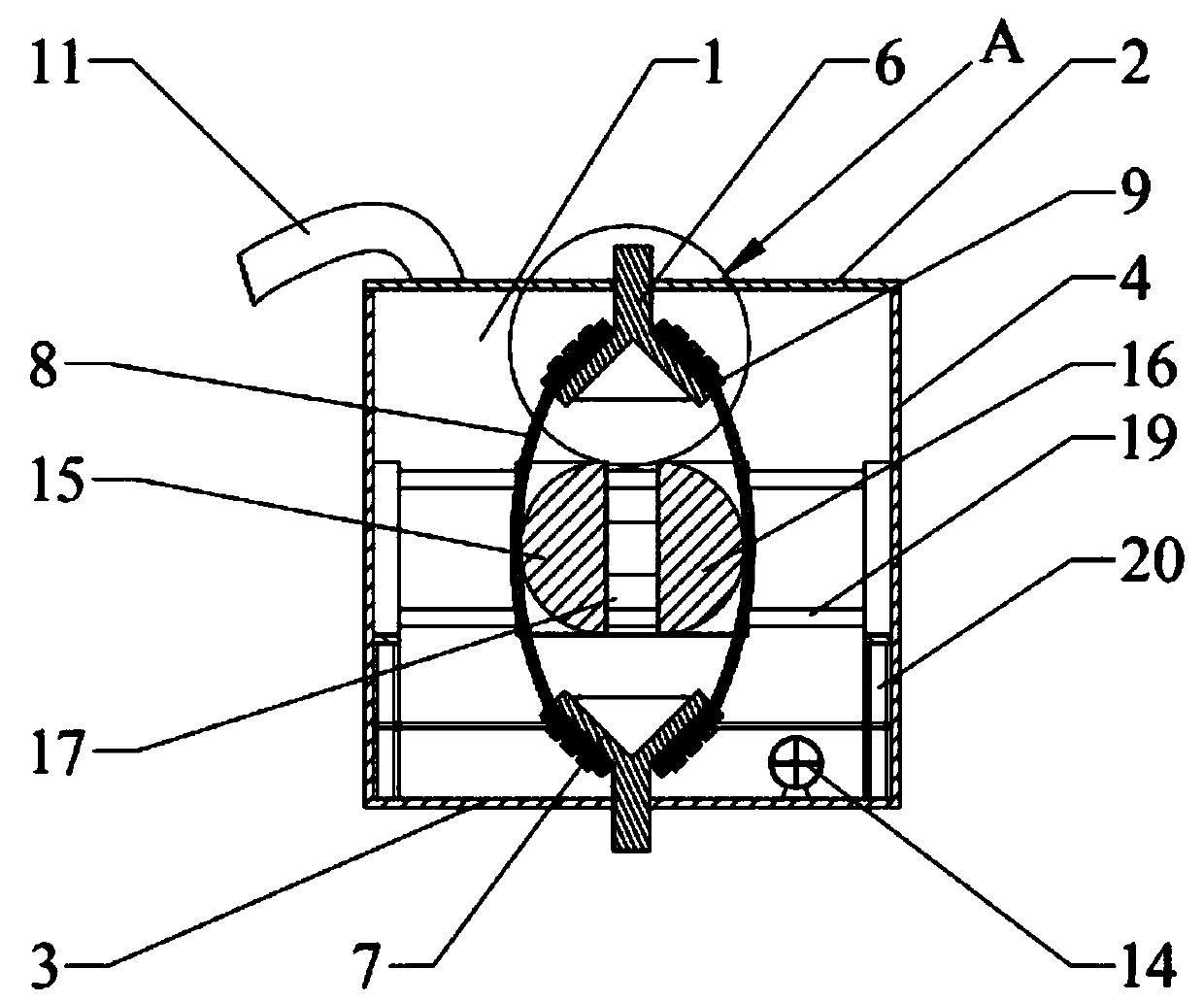

High-temperature high-speed metal sheet hot stamping forming limit testing device and method

PendingCN108279177AImprove heating efficiencySave energyStrength propertiesIncreasing energy efficiencyForming limit diagramHot stamping

The invention provides a high-temperature high-speed metal sheet hot stamping forming limit testing device and a high-temperature high-speed metal sheet hot stamping forming limit testing method. Thehigh-temperature high-speed metal sheet hot stamping forming limit testing device comprises a high-frequency induction heating box, a robotic arm, a stamping structure, a supporting structure, an optical strain measuring device, an infrared thermometer and a control device, wherein the stamping structure comprises a hemispherical stamping head, a blank pressing ring and a concave mould; a high-power stamping head heating rod and a stamping head temperature sensor are arranged inside the hemispherical stamping head; high-frequency induction coils are arranged on the peripheries of the blank pressing ring and the concave mould; high-power heating rods and temperature sensors are arranged inside the blank pressing ring and the concave mould; the supporting structure comprises an upper mould frame and a lower mould frame which are connected through guide posts; a stamping head hydraulic cylinder and a blank pressing ring hydraulic cylinder are mounted on the upper mould frame; the hemispherical stamping head is connected with the stamping head hydraulic cylinder through a connecting rod; the blank pressing ring is connected with the blank pressing ring hydraulic cylinder; the concave mould is fixedly mounted on the lower mould frame. Through the high-temperature high-speed metal sheet hot stamping forming limit testing device and the high-temperature high-speed metal sheet hot stamping forming limit testing method, a high-temperature and high-speed metal sheet forming limit diagram which fully meets the actual industrial hot stamping technological flow can be established, a covered working condition range is wide, the applicability is strong, optimization of a hot stamping technology can be effectively guided and the research and development cycle of a product is shortened.

Owner:DALIAN UNIV OF TECH

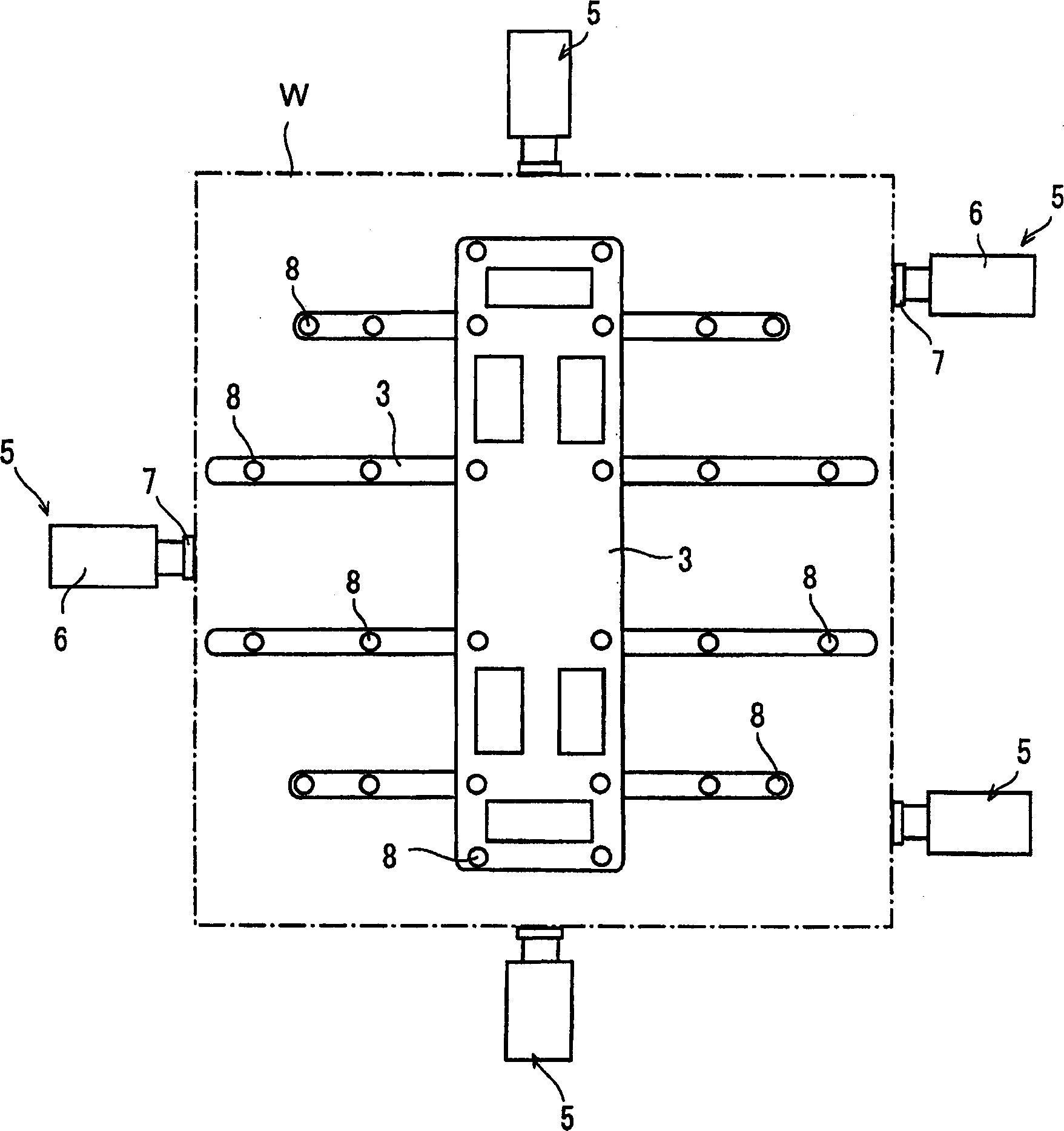

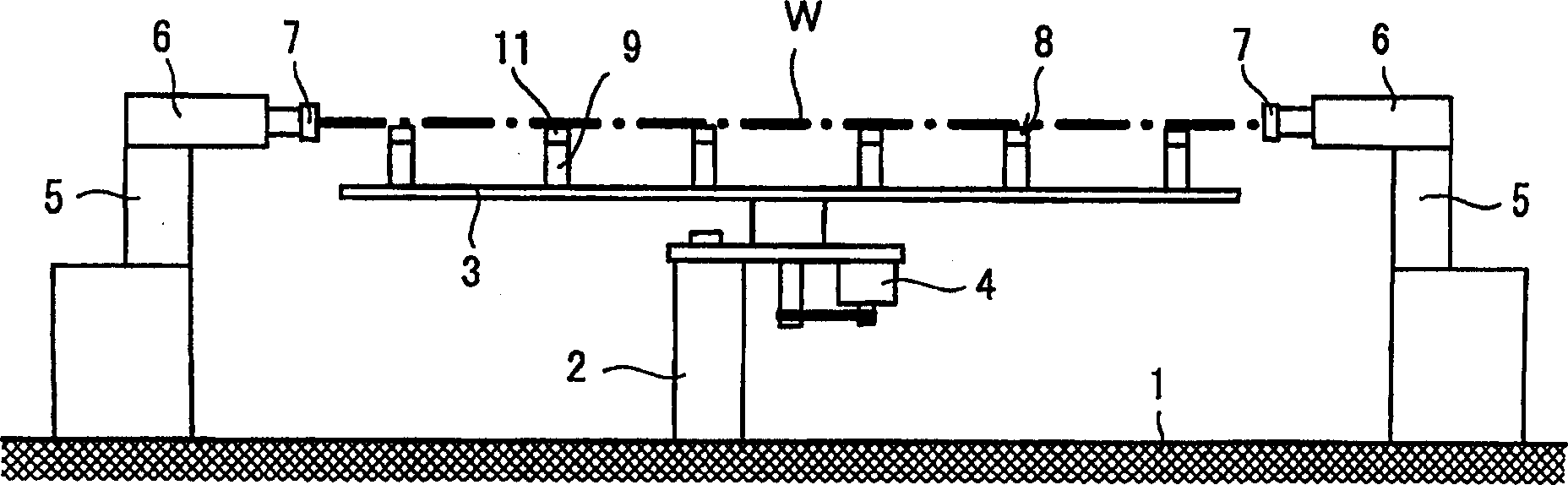

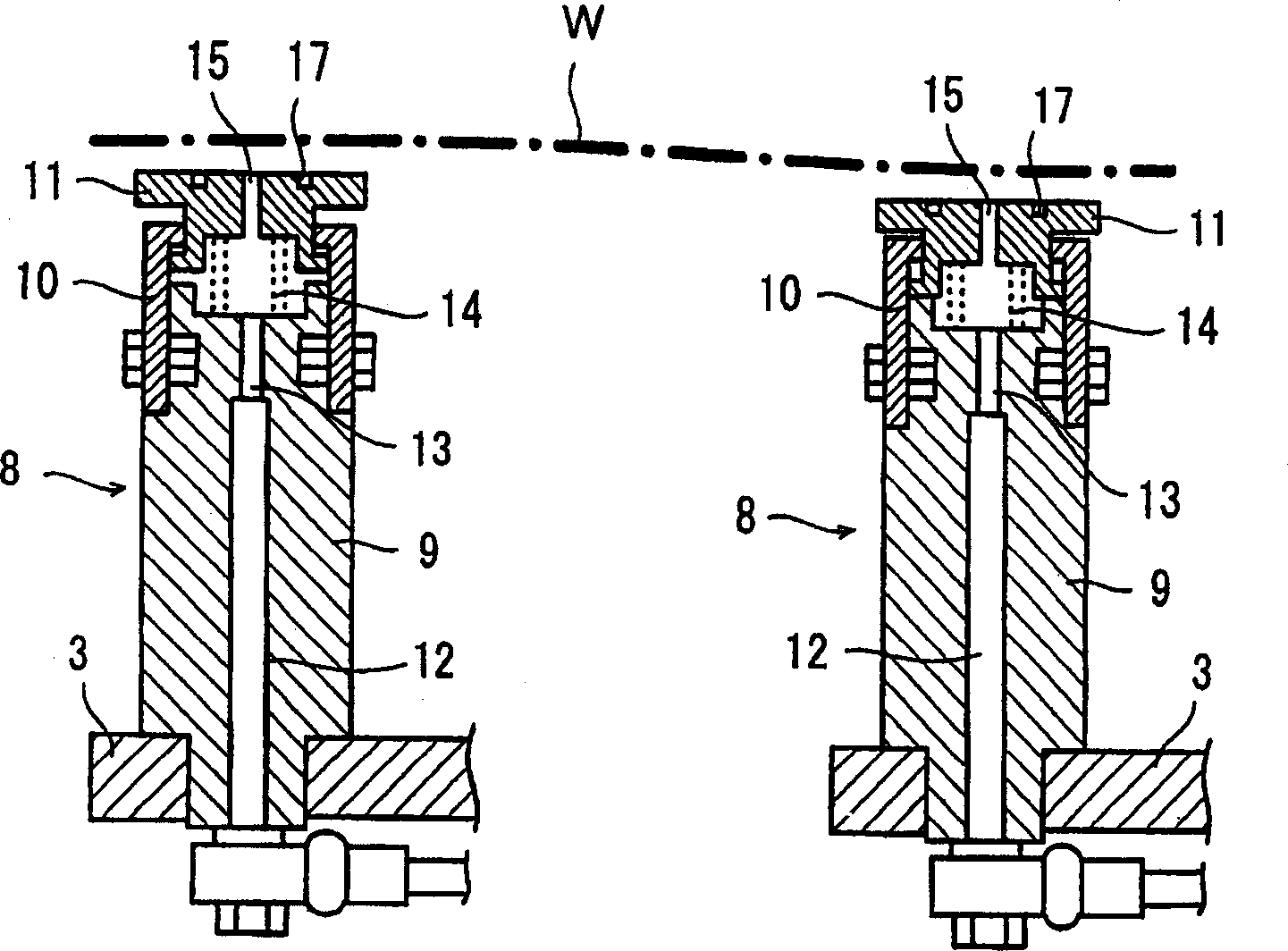

Orientation equipment

ActiveCN1812073APrevent saggingAvoid uneven temperatureSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringCompressed air

The present invention provides a positioning device which can accurately position a substrate without damaging it even if the substrate is made large. In a state where a slide member 6 is retreated, a cylinder unit 2 is operated to raise a supporting member 3, and a substrate W is received by the upper surface of the reception part 11 of a lifting member 8. Next, the cylinder unit 2 is operated to lower the supporting member 3 until the substrate W is on the same level of the slide member 6 of an alignment member 5, and a valve is changed over to connect the piping 12 of the lifting member 8 to a compressed air source. An air is allowed to be jetted from grooves 16 and 17 on the upper surface of the reception part 11 of the lifting member 8, so as to lift the substrate W from the upper surface of the reception part 11, move forward the slide member 6 of the alignment member 5, and bring a pusher 7 into contact with the edge of the substrate W for positioning.

Owner:TOKYO OHKA KOGYO CO LTD +1

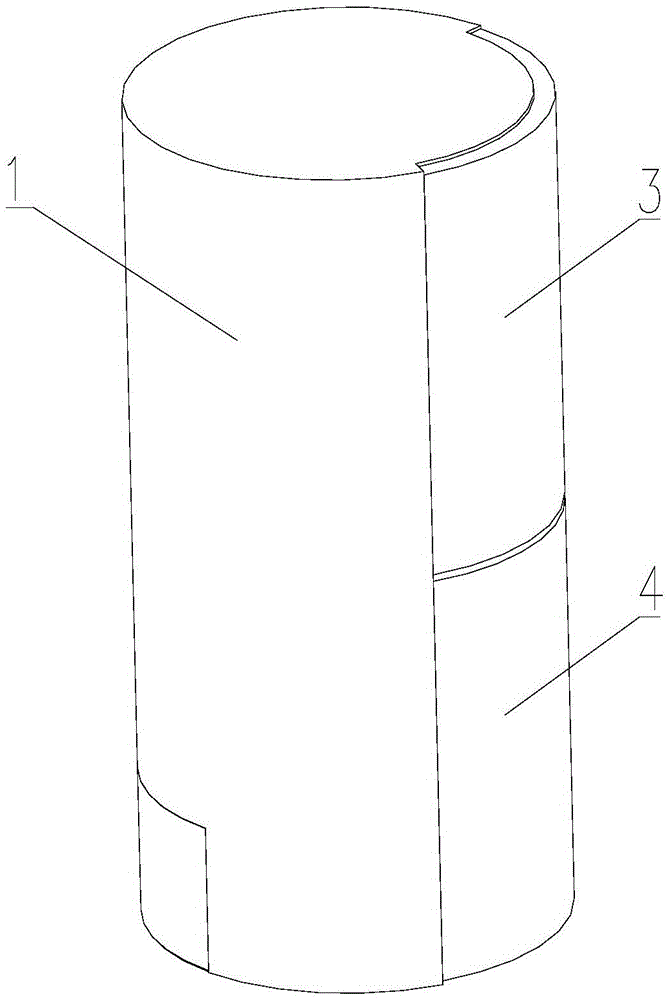

Cylindrical refrigerator

ActiveCN105627671ABeautiful shapeUniform air supplyLighting and heating apparatusDomestic refrigeratorsEngineeringCold store

The invention discloses a cylindrical refrigerator. The cylindrical refrigerator comprises a refrigerator body, an opening is formed in one side of the refrigerator body, and a door body is arranged on the opening; the cross section of the refrigerator body is in an optimal arc shape, and the section shape of the door body is in an inferior arc shape; when the door body is closed, a cylindrical whole structure is jointly formed by the refrigerator body and the door body; and the refrigerator body comprises a cold storage chamber and a freezing chamber which are vertically arranged; the center of the cold storage chamber and the center of the freezing chamber are each provided with a vertical stand column, and a disc shelf is rotatably arranged on the stand columns; and a plurality of air outlets are formed in the stand columns in the circumferential direction, and a lighting device is arranged around the stand columns. Compared with the prior art, the cylindrical refrigerator has the following advantages that the cylindrical refrigerator can achieve 360-degree air supplying, 360-degree lighting and 360-degree rotation of the shelf.

Owner:CHANGHONG MEILING CO LTD

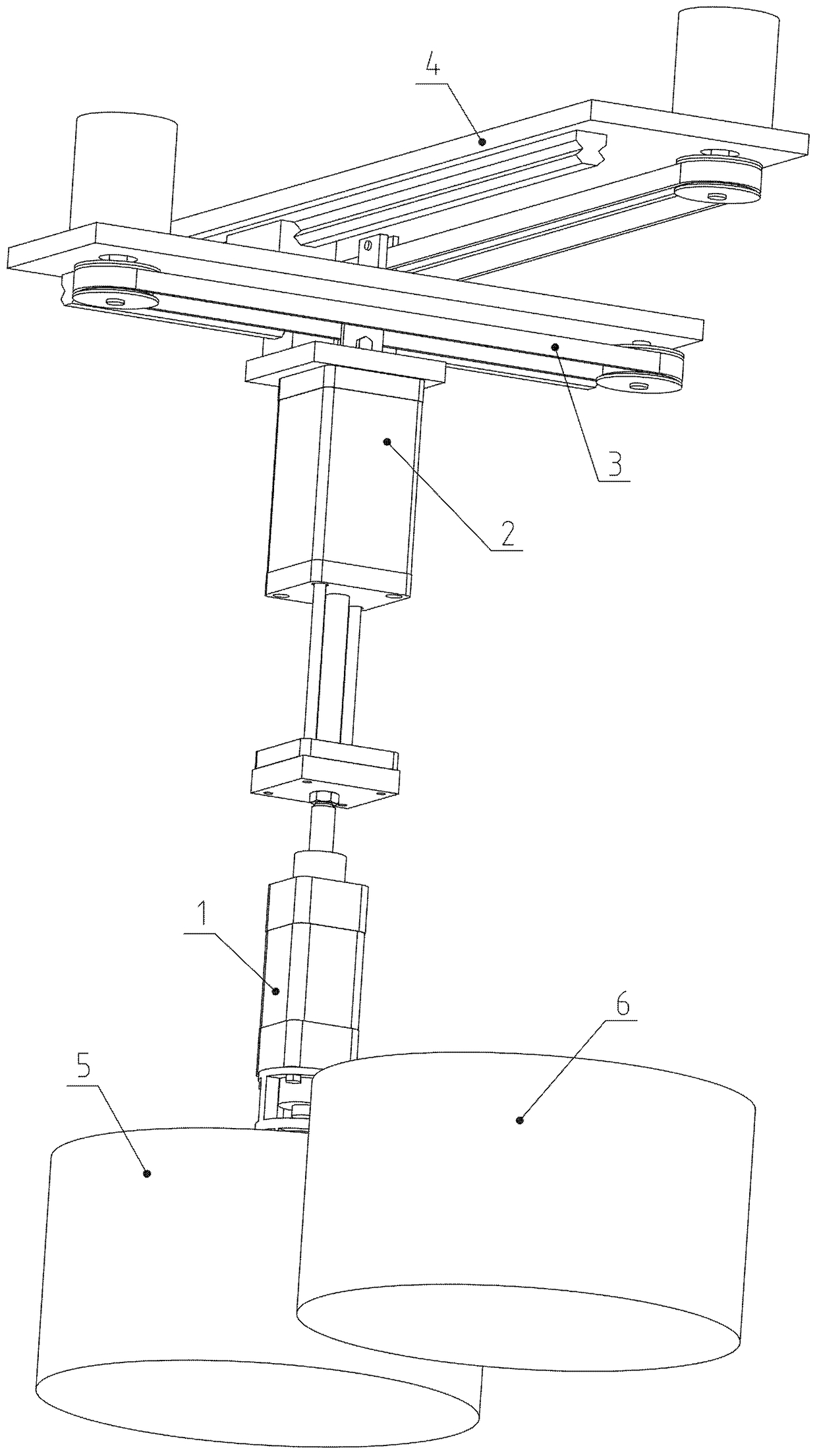

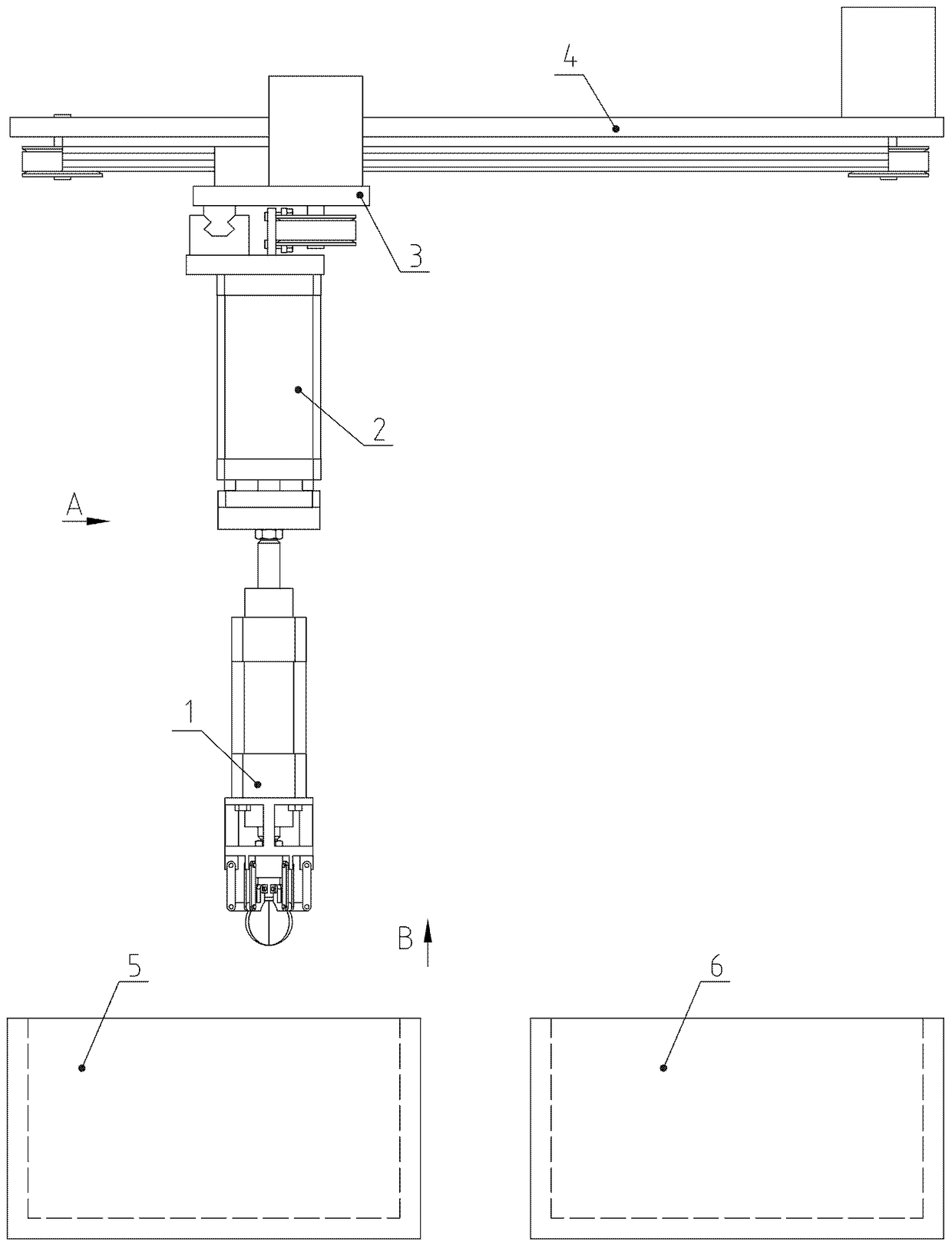

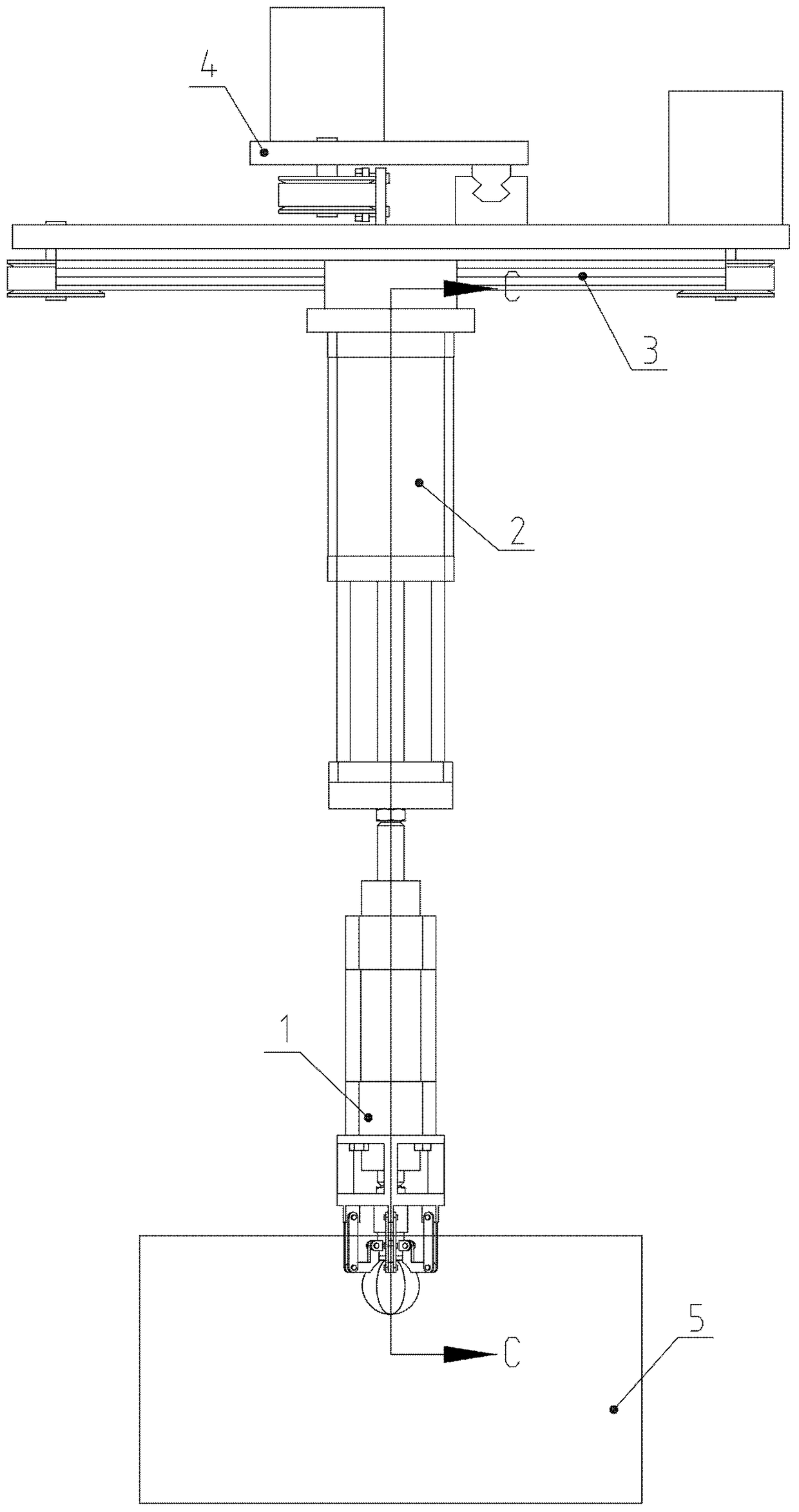

Intelligentized manipulator for manufacturing ball roughs and placing ball roughs into oil pan

InactiveCN109044124AAvoid uneven temperatureAvoid normal workOil/fat bakingDeep fat fryersEngineeringManipulator

The invention belongs to the technical field of cooking machinery, and relates to an intelligentized manipulator for manufacturing ball roughs and placing the ball roughs into an oil pan. A double-shaft cylinder body drives a manipulator bracket to push a connecting rod downward, the connecting rod pushes a sectioning assembly to swing downward to gather together, multiple side inner arc surfacesand top inner arc surfaces are enclosed together to form a hollow sphere, the hollow sphere is filled with paste to form the ball roughs. A lifting cylinder drives a manipulator assembly to lift upward, and a longitudinal movement servo motor drags the manipulator assembly right above the oil pan; a transverse movement servo motor drags the manipulator assembly to a certain specific position rightabove the oil pan, the lifting cylinder drives the manipulator assembly to descend, and the double-shaft cylinder body drives the sectioning assembly to put the ball roughs down separately. The intelligentized manipulator for manufacturing the ball roughs and placing the ball roughs into the oil pan has the advantages that the manipulator grabs the paste and places the ball roughs intelligently,the evenness of the temperature of oil is effectively kept, the manipulator operates intelligently and automatically, it is avoided that workers work near the oil pan, the work efficiency is improved,the labor intensity is reduced, and the dangerousness is reduced.

Owner:杜宗英

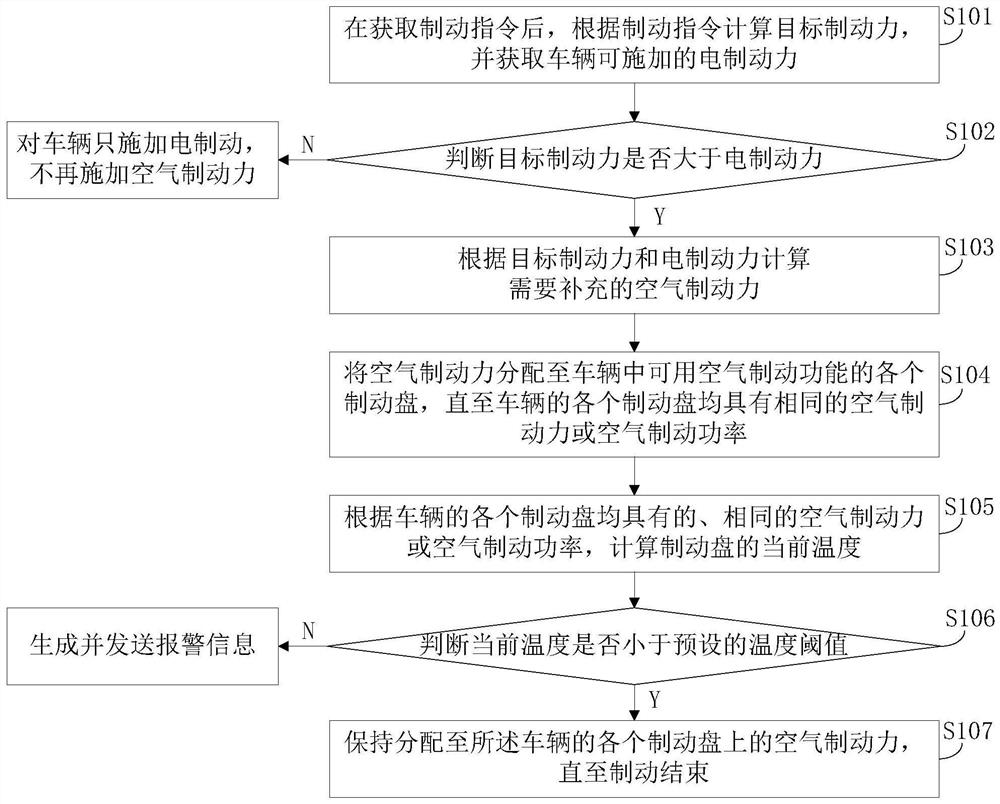

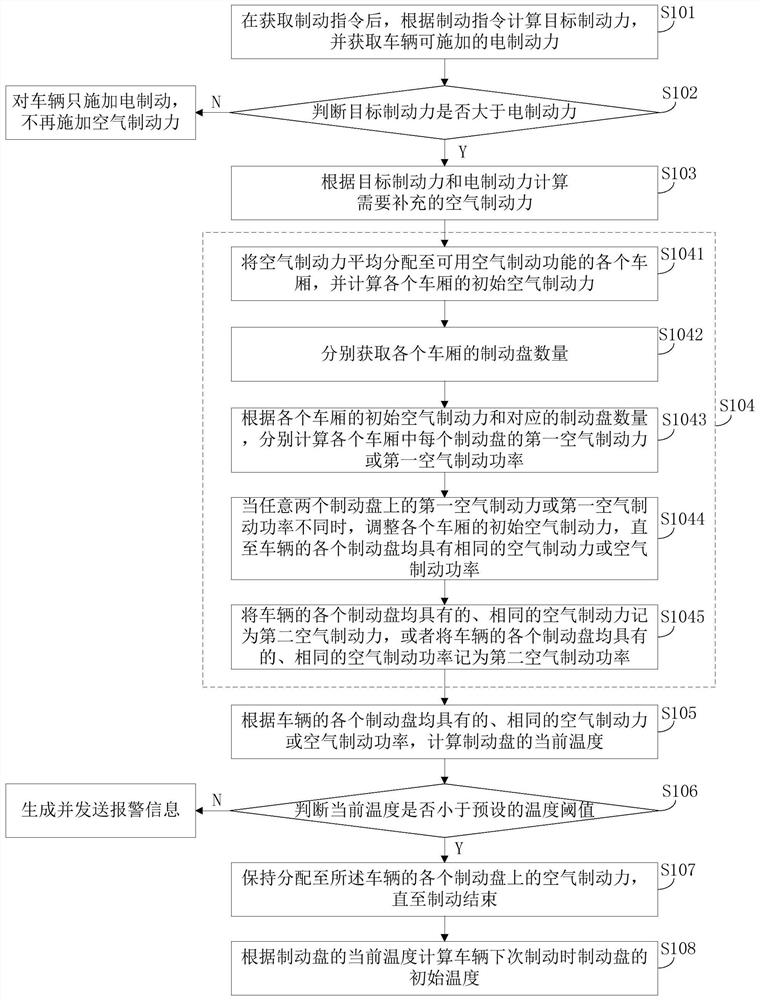

Vehicle braking force distribution method, terminal equipment and storage medium

ActiveCN112124275AAvoid uneven temperatureImprove braking reliabilityBraking action transmissionAutomatic controlAir brake

The invention is suitable for the technical field of automatic control, and provides a vehicle braking force distribution method, terminal equipment and a storage medium. The method comprises the steps: calculating a target braking force according to a braking instruction, and obtaining an electric braking force which can be applied by a vehicle; when the target braking force is larger than the electric braking force, calculating the air braking force needing to be supplemented according to the target braking force and the electric braking force; distributing the air braking force to each brake disc with an available air braking function in the vehicle until each brake disc of the vehicle has the same air braking force or air braking power; calculating the current temperature of the brakediscs; and when the current temperature is smaller than the preset temperature threshold value, keeping the air braking force distributed to all the brake discs of the vehicle till braking is finished. The temperature of the brake discs is indirectly monitored by monitoring the air brake force or the air brake power of the brake discs, so that the temperature of the brake discs is prevented from being too high, and the brake reliability of the brake discs is enhanced.

Owner:CRRC TANGSHAN CO LTD

Aluminum alloy electrolytic oxidation film forming device

InactiveCN110983403AAvoid uneven temperatureIncrease the rate of heatingCellsAnodisationChemistryMetallurgy

The invention discloses an aluminum alloy electrolytic oxidation film forming device. The aluminum alloy electrolytic oxidation film forming device comprises an oxidation device and a temperature control device; the oxidation device comprises an oxidation tank; a temperature sensor is arranged in the oxidation tank; the oxidation device further comprises an oxidation tank liquid circulation device; the temperature control device comprises a temperature control tank, the oxidation tank is placed in the temperature control tank, a temperature control room is formed between the oxidation tank andthe temperature control tank; a heating device is arranged in the temperature control room, and a cooling device is arranged outside the temperature control tank; and the temperature sensor, the heating device and the cooling device are all electrically connected to a controller. According to the aluminum alloy electrolytic oxidation film forming device, precise control of the oxidation temperature can be realized, different oxidation temperatures can be controlled according to different stages of oxidation film forming, and the oxidation tank liquid circulation device further improves the temperature uniformity of oxidation liquid; and the whole oxidation film forming is carried out under a single temperature or variable temperature conditions of multiple temperatures, the quality of film forming is improved, and the experiment and production requirements of oxidation film forming are met.

Owner:高瑞安 +1

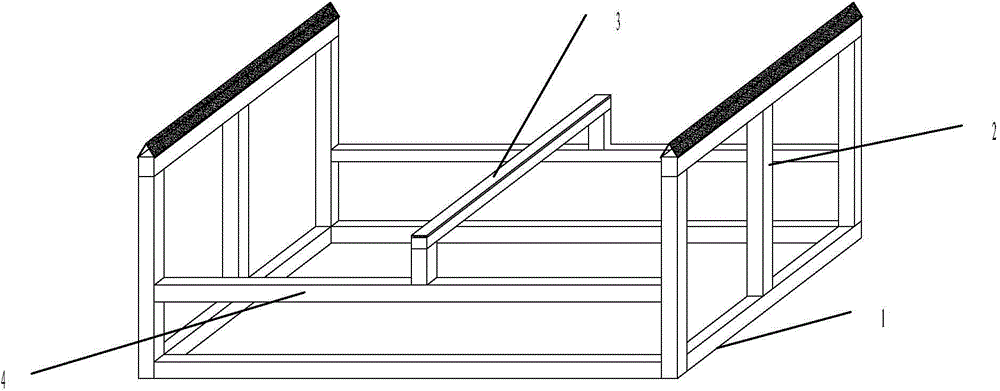

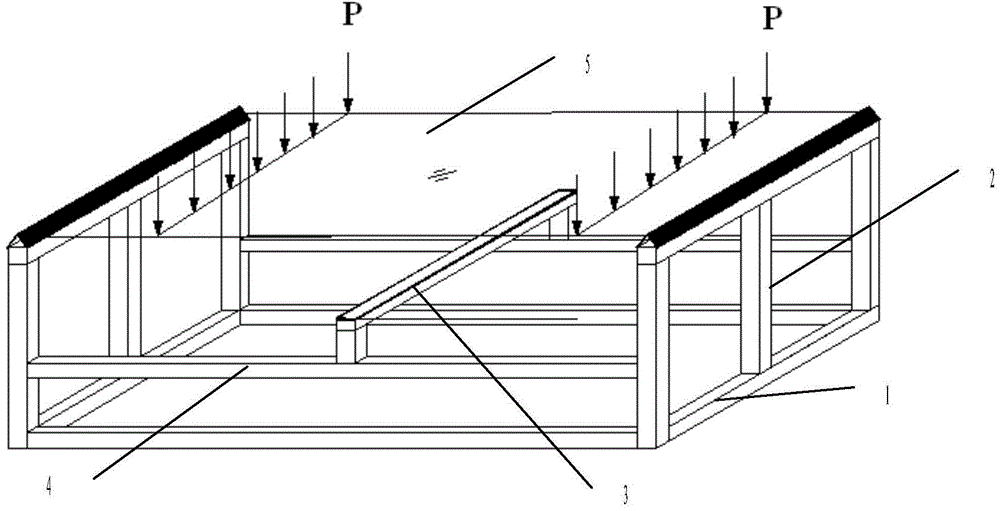

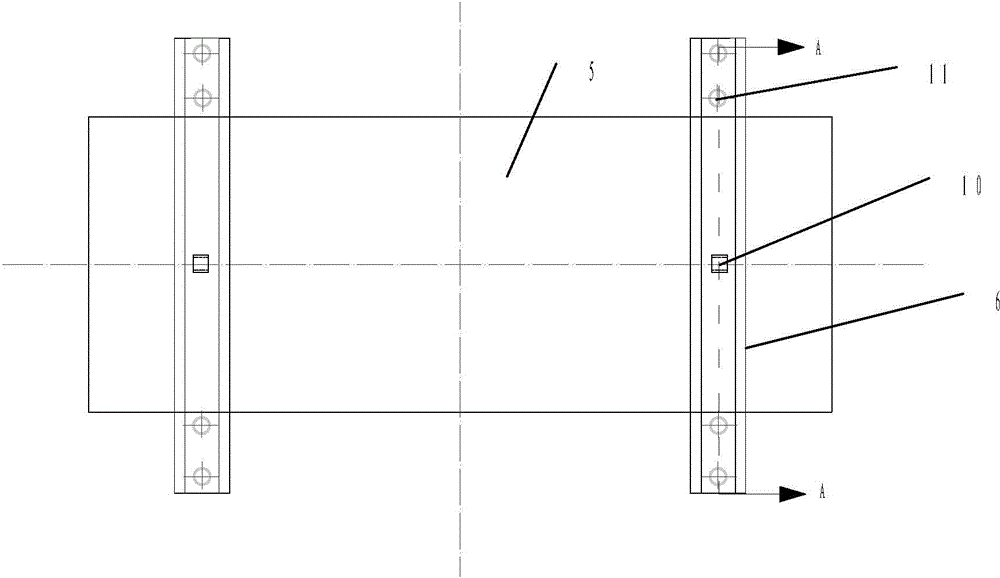

Symmetrical concentrated force and uniformly distributed load coupling bending forming device and application thereof

The invention provides a symmetrical concentrated force and uniformly distributed load coupling bending forming device. The device comprises a die frame and a concentrated force loading unit, an integral body of the die frame is in a hollow structure, and comprises a pedestal, a bracing frame and a spacing beam. The concentrated force loading unit comprises an upper fixing device and a lower fixing device, the upper fixing device comprises an upper fixing channel steel and a first high temperature resistance glass wool which are arranged in order, the lower fixing device comprises a second high temperature resistance glass wool and a lower fixed slot steel which are arranged in order, a hook ring is arranged at central section of the lower fixed slot steel, the upper fixing device and the lower fixing device are fixedly connected through a fixing bolt; the upper fixing device and the lower fixing device are fixed by employing the slot steel, the slot steel has stronger intensity and less bearing deformation. According to the invention, a condenser is prepared by coupling symmetrical concentrated force and uniformly distributed load and then performing thermal forming, the surface curve of the prepared condenser is the composite curve formed under coupling effect of symmetrical concentrated force and uniformly distributed load, and its curve is the segmented high order curve.

Owner:SOUTHEAST UNIV

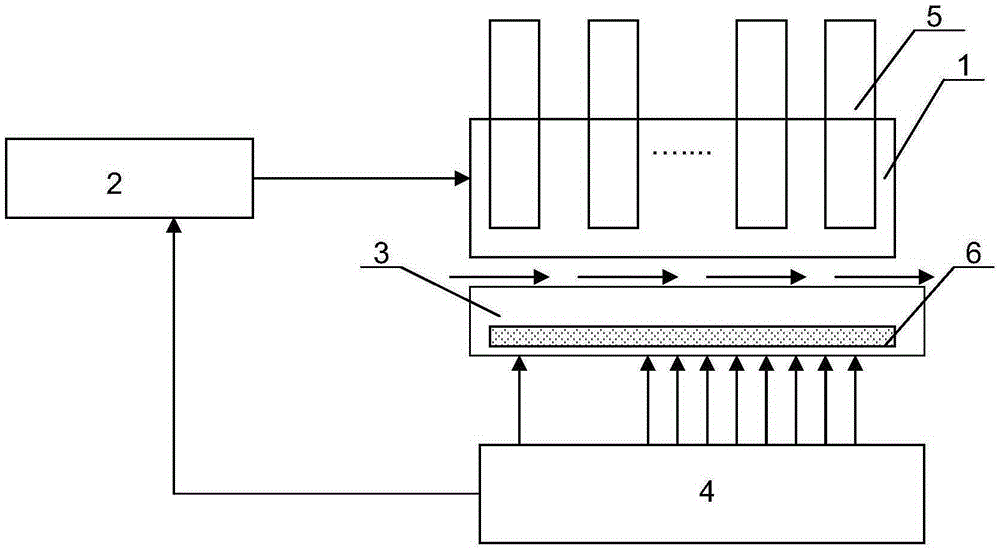

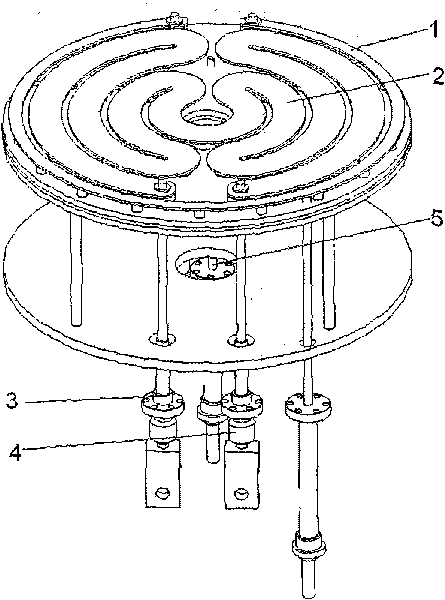

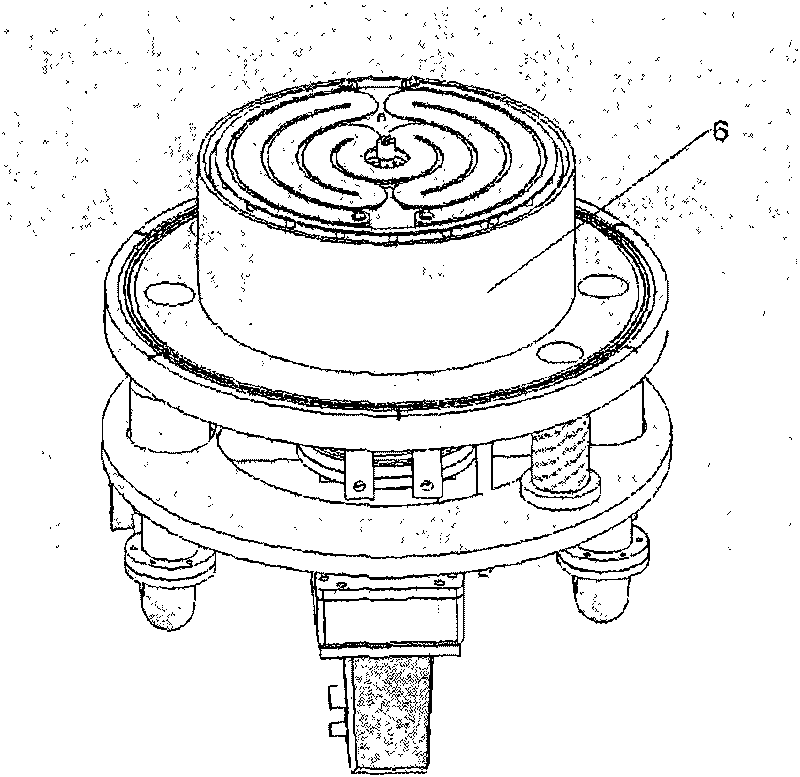

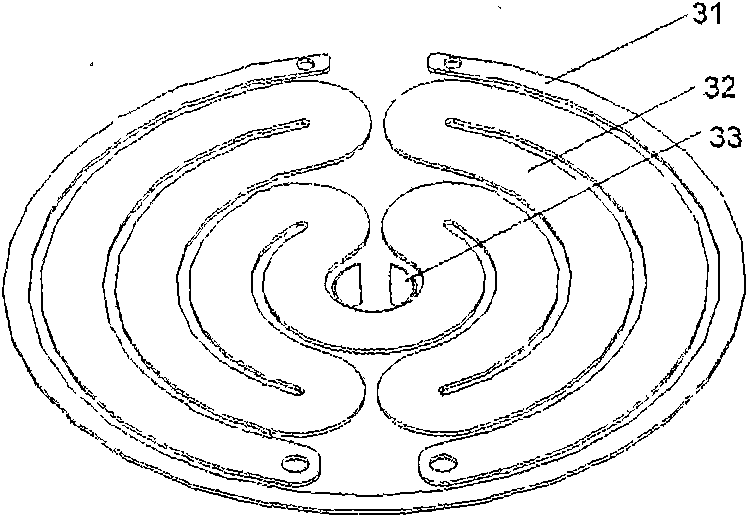

Heating device for metallorganic chemical deposition equipment

InactiveCN101736311AQuality improvementUniform and controllable heating temperature in large areaChemical vapor deposition coatingTemperature controlEpitaxial material

The invention discloses a heating device for metallorganic chemical deposition equipment, which comprises: at least two sections of furnace wires which are arranged on the same heating plane and are connected to respective electrodes; a thermo detector which is arranged below the at least two sections of furnace wires and close to the heating plane and is used for detecting the heating temperatures of the two sections of furnace wires; and a temperature controller which, according to the temperatures detected by the thermo detector, controls the heating powers applied to the sections of furnace wire to control the heating temperatures of the at least two sections of furnace wires respectively so as to homogenize the heating temperatures of the at least two sections of furnace wires. In the heating device for the metallorganic chemical deposition equipment, multi-section furnace wire heating is adopted, the independent control of the heating power of each section of furnace wire and / or the design of the shape and size of the furnace realize homogeneous and controllable large-area heating temperatures, so the quality of an epitaxial material is improved. In addition, a cold water electrode and a heater shield are adopted to further improve heating stability and safety.

Owner:广东省中科宏微半导体设备有限公司

Thermal distributed tobacco curing barn

PendingCN111920075AImprove baking efficiencyImprove roast qualityTobacco preparationCold airEnvironmental engineering

The invention discloses a thermal distributed tobacco curing barn. A plurality of groups of carbon crystal plates are arranged at the bottom and the top of a curing barn body; the upper side of the back surface of the curing barn body is provided with a number of dehumidifying fans, and a cold air door is arranged on the lower side of the back surface of the curing barn body; a first tobacco hanging frame is arranged in the middle of the curing barn body, a second tobacco hanging frame is arranged on the inner walls of the two sides of the curing barn body, and a temperature sensor, a humiditysensor and the carbon crystal plates are electrically connected with a control cabinet through wires. According to the invention, a traditional hot air chamber is cancelled; the plurality of groups of carbon crystal plates are arranged at the bottom and the top of the curing barn body; heat radiation and weak convection are transmitted to the outside; heat radiation is mainly carried out throughfar infrared radiation, after the far infrared radiation is absorbed by tobacco leaves, intense molecular resonance of moisture in the tobacco leaves is caused, the molecular resonance generates heat,the temperature in the tobacco leaves is promoted to rise, the purpose of synchronously drying the moisture in the tobacco leaves and surface moisture is achieved, the tobacco leaf baking efficiencyand quality are improved, and environmental pollution is avoided.

Owner:SHANDONG LINYI TOBACCO

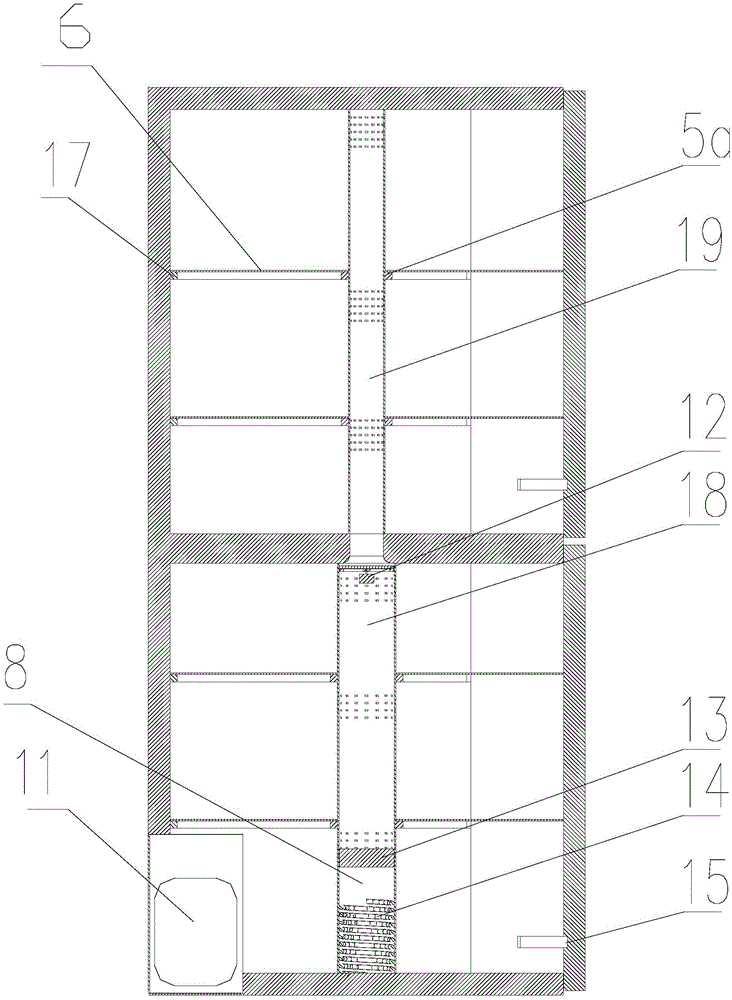

Steam curing device of slag unburned bricks

The invention belongs to the technical field of building materials machinery and discloses a steam curing device of slag unburned bricks. The steam curing device comprises a steam curing reaction tank and a steam output device, wherein the steam curing reaction tank comprises a base, a raw brick bracket, a cover body, a gas inlet pipeline and a gas discharge pipeline; the raw brick bracket is arranged on the base, gas inlet holes are arranged in the base and connected with the gas inlet pipeline, the cover body covers the base, a gas discharge hole is connected is arranged on the cover body and connected with the gas discharge pipeline, and the gas inlet pipeline and the gas discharge pipeline are connected with the steam output device respectively. The water steam uniformly disperses, the temperature and the humidity in the steam curing reaction tank are proper, the heat loss is less, the usage amount of steam is small, and the quality of the cured slag unburned bricks is furthermore improved.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

A titanium tube numerical control differential temperature heating bending forming mold and method

ActiveCN105537342BIncrease temperatureImprove heating efficiencyShaping toolsNumerical controlTitanium alloy

Owner:NORTHWESTERN POLYTECHNICAL UNIV

System and method for exhausted air sterilization and aeration and comprehensive heating disinfection of highly-contaminated building space

PendingCN111895550AReduce virus contentImprove disinfection effectDucting arrangementsMechanical apparatusVentilation tubeThermal insulation

The invention provides a system and method for exhausted air sterilization and aeration and comprehensive heating disinfection of a highly-contaminated building space. The system comprises a contaminated area negative pressure metal ventilation pipe, any position thereon communicates with an inlet end of a high-resistance thermal-insulation-layer-carried ventilation pipeline, an outlet end of thehigh-resistance thermal-insulation-layer-carried ventilation pipeline is connected to an inlet end of an outdoor negative pressure metal ventilation pipe through an electric anti-backflow valve, and an outlet end of the outdoor negative pressure metal ventilation pipe is connected with an exhaust port of a high-efficiency variable-frequency fan. Various virus killing devices are sequentially disposed at the rear end of the high-efficiency variable-frequency fan. The system disinfects the air that may contain viruses in the highly-contaminated building space at high temperature through an electric heating pipeline and then guides the air that is disinfected at high temperature to the various outdoor virus killing devices through negative pressure pipelines to diversely and thoroughly disinfect the guided air, thereby thoroughly removing viruses in the air in the highly-contaminated building space.

Owner:CHINA RAILWAY CONSTR GROUP +1

Method for operating side-lighting type backlight module

ActiveCN101730338AAvoid warpingAvoid uneven temperaturePlanar light sourcesMechanical apparatusLight guideEffect light

The invention discloses a method for operating a side-lighting type backlight module. The side-lighting type backlight module comprises a light guide plate and a plurality of light-emitting diode light sources, wherein the light guide plate is provided with a light-incidence side surface, and the plurality of light-emitting diode light sources are arranged on the light-incidence side surface. The operating method is characterized by driving the plurality of light-emitting diode light sources so that the light-emitting diode light sources have different powers. The invention can solve the problem of nonuniform temperature, and prevent the warping phenomenon of light guide plate without influencing the optical quality.

Owner:AU OPTRONICS CORP

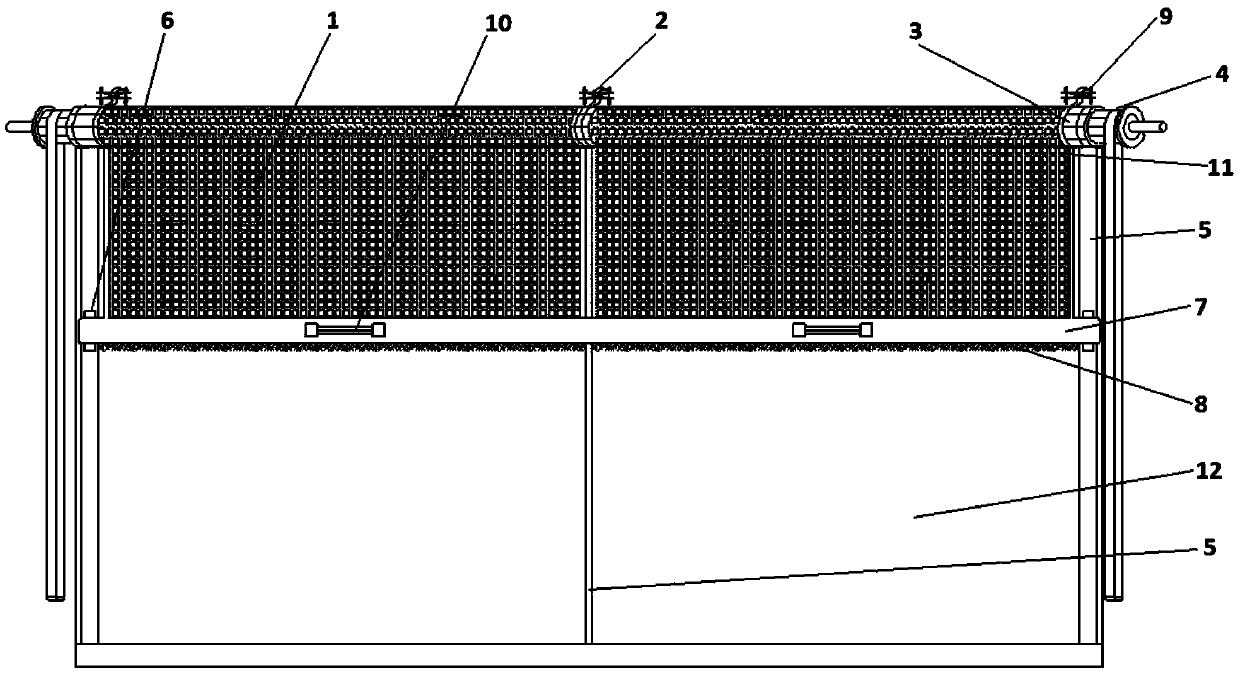

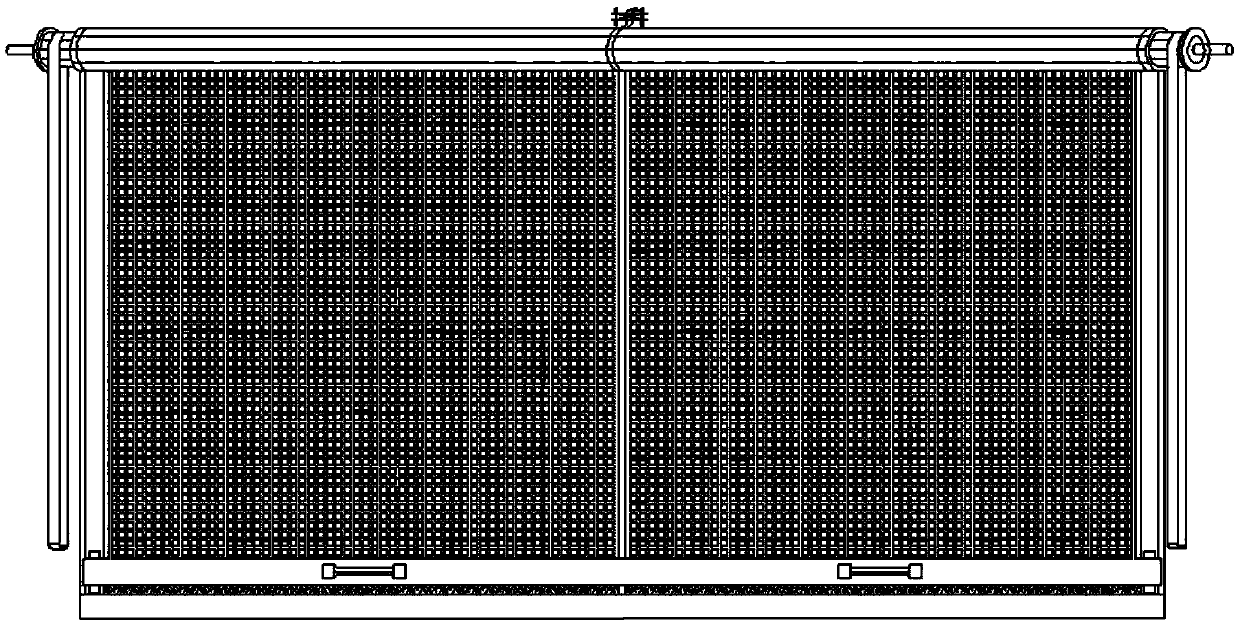

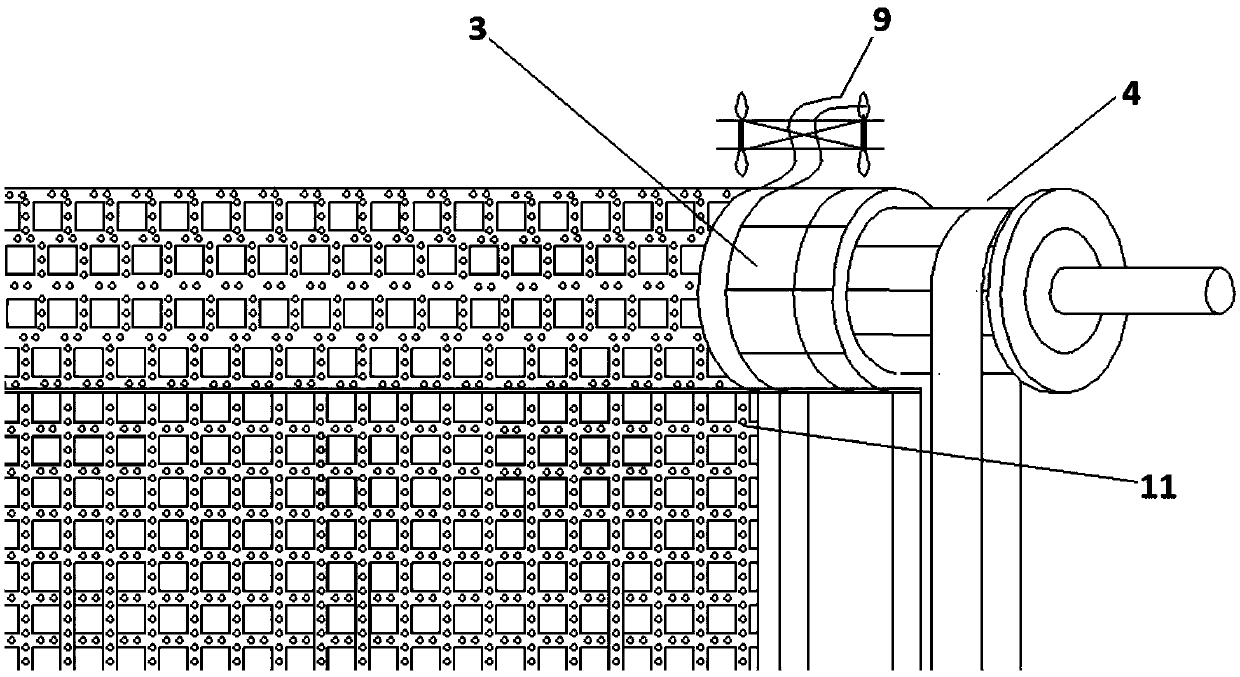

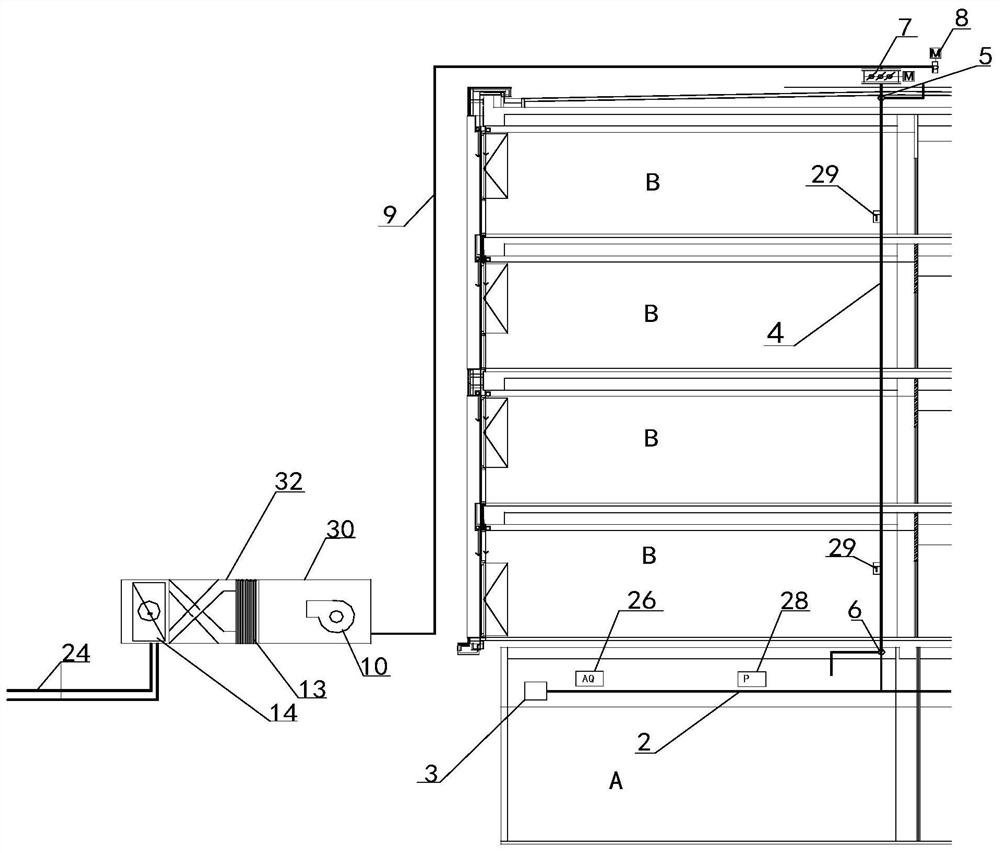

A multifunctional curtain device and a control method for a passenger car

The invention belongs to the technical field of curtains and discloses a bus multifunctional curtain device and a control method. The curtain device comprises a curtain with a net-shaped hose structure, the curtain of the net-shaped hose structure is provided with uniformly distributed small holes on one side facing the vehicle, and the net-shaped hose is communicated with an air conditioning ventilation system. The mesh hose structure further comprises an intercommunicating heat preservation hose which is uniformly arranged and does not have small holes, and the heat preservation hose is communicated with the heat preservation liquid tank. The bottom end of the curtain is fixedly connected with a cleaning brush at the left end or the right end, and the bristles of the cleaning brush facethe window. The curtain of the mesh hose structure is provided with an independent non-perforated pipeline, one end of the pipeline is communicated with an air-conditioning condensing water pipe, andthe other end is communicated with a passage through which a cleaning brush penetrates the back. The cleaning brush is provided with a water vapor atomizing device capable of atomizing and ejecting the condensed water. Mesh hose structure is used to connect ventilation, condensate and heat preservation liquid to realize the combination of multiple functions.

Owner:GREE ELECTRIC APPLIANCES INC

High-contamination exhaust multi-disinfecting-killing system and method

PendingCN111895551AShorten survival timeReduce the risk of residual virusDucting arrangementsMechanical apparatusContamination zoneEnvironmental engineering

The invention provides a high-contamination exhaust multi-disinfecting-killing system and method. The system comprises a contaminated area negative-pressure metal vent pipe, any position on the contaminated area negative-pressure metal vent pipe communicates to the inlet end of a high-resistance tape heat insulating and insulating layer vent pipeline, the outlet end of the high-resistance tape heat insulating and insulating layer vent pipeline is connected to the inlet end of an outdoor negative-pressure metal vent pipe through an electric anti-backflow valve, and the outlet end of the outdoornegative-pressure metal vent pipe is connected to an exhaust port of an efficient variable-frequency fan. Multiple virus disinfecting and killing devices are sequentially arranged at the rear end ofthe efficient variable-frequency fan. Firstly, air probably containing viruses in high-contamination building spaces is disinfected and killed at high temperature through an electric heating pipeline,then the air disinfected and killed at high temperature is exhausted to the outdoor multi-virus disinfecting and killing devices through a negative-pressure pipeline, the introduced air is completelydisinfected and killed diversely, and therefore the viruses in the air of the high-contamination building spaces can be completely removed.

Owner:CHINA RAILWAY CONSTR GROUP +1

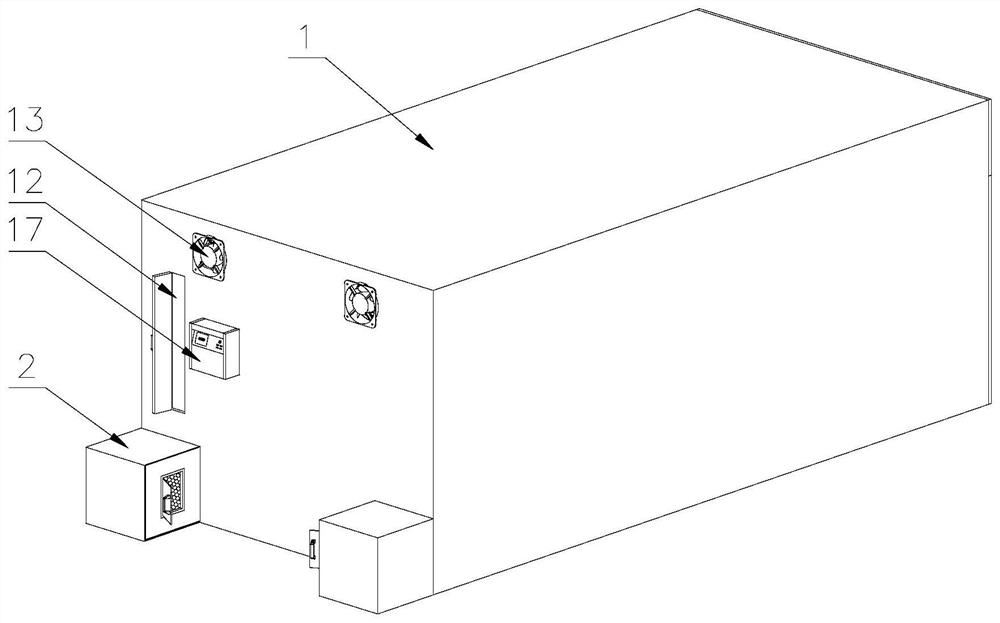

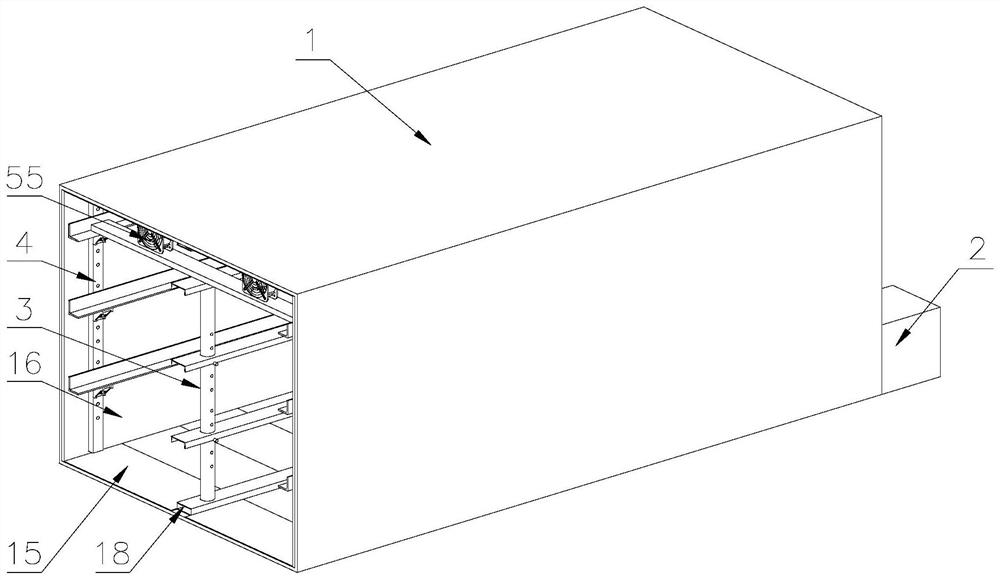

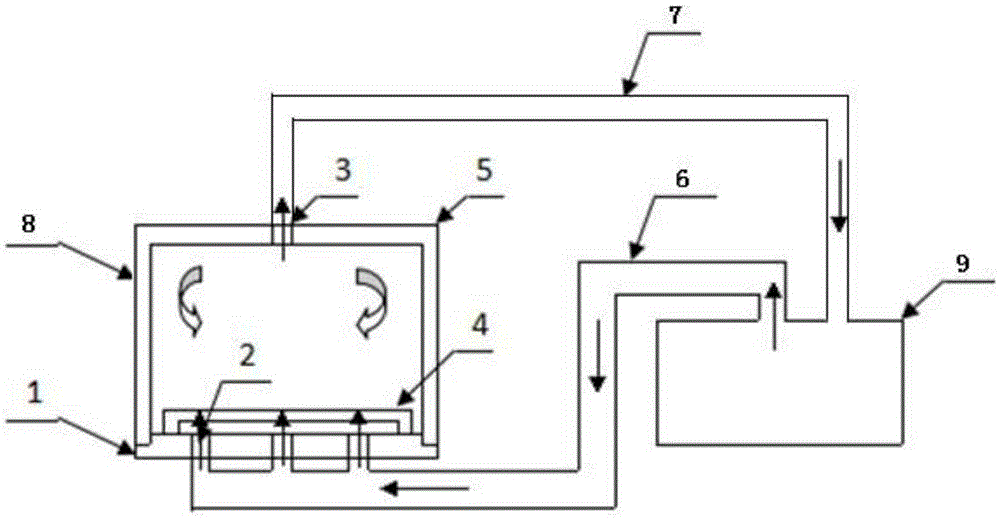

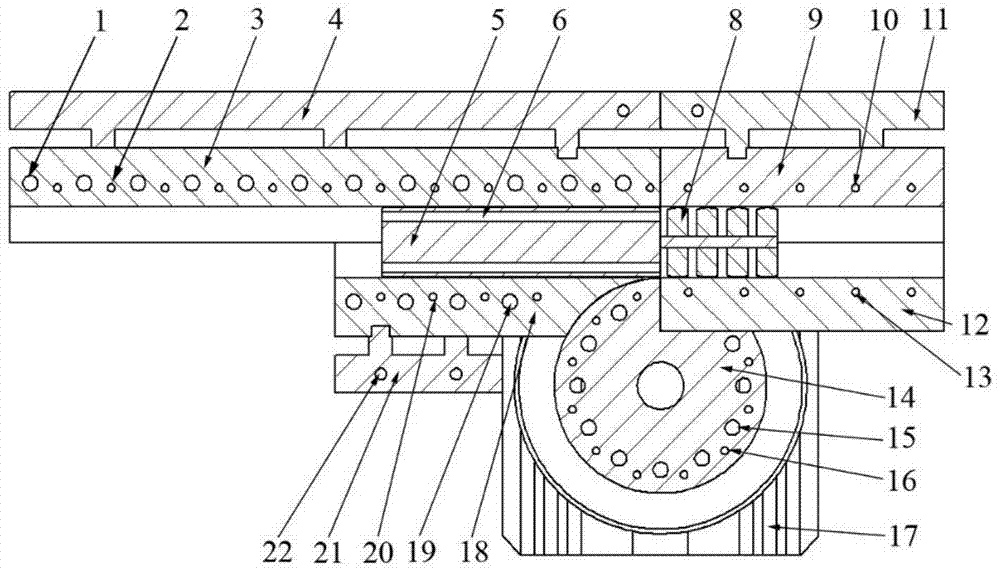

Tooth-shaped belt environment test box

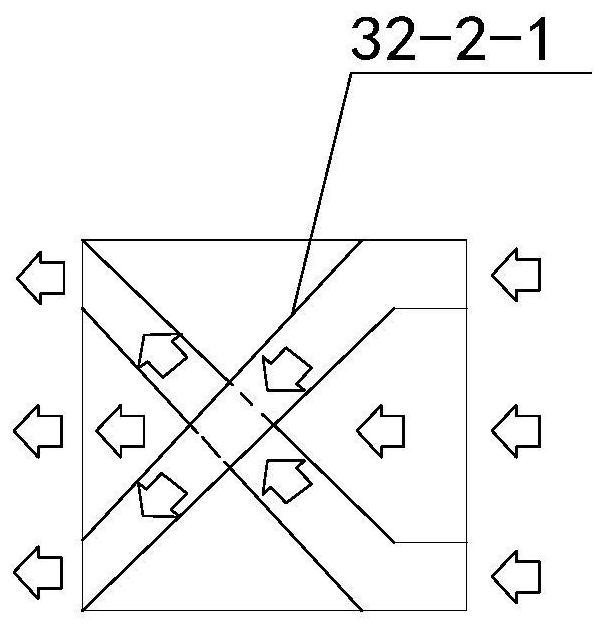

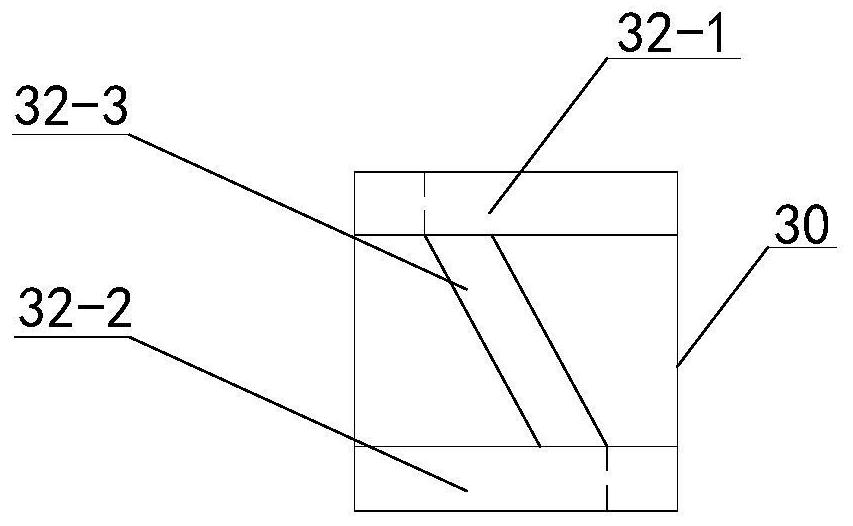

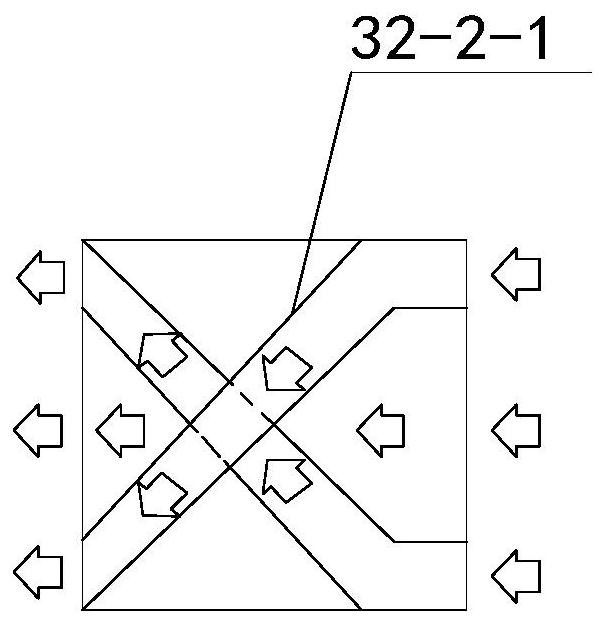

PendingCN110194312APlay the role of self-centeringAvoid uneven temperatureShock-sensitive articlesInternal fittingsEngineeringTime cost

The invention provides a tooth-shaped belt environment test box. The tooth-shaped belt environment test box is used in cooperation with a fatigue test machine to test the fatigue life of a tooth-shaped belt, and the tooth-shaped belt environment test box comprises a box body. The box body comprises a top plate, a bottom plate and side plates arranged between the top plate and the bottom plate; a pair of herringbone plates opened towards the interior of the box body are symmetrically arranged on the top plate and the bottom plate, each herringbone plate comprises a vertical plate which penetrates through the top plate / bottom plate and extends into the outside of the box body and a pair of inclined plates symmetrically arranged on one end of the vertical plate, the inclined plates are provided with pressing plates used for fixing the tooth-shaped belt to be tested, the vertical plates are connected with the fatigue test machine to adjust the interval between the two vertical plates, a heating plate is arranged in the box body, and a humidity channel, a salt mist channel and an airflow channel which communicate with the exterior are formed in the box body. The test box has the beneficial effects that when the fatigue test is carried out, the influences of the environment factors of the temperature, the humidity, the salt mist and the like on the tooth-shaped belt fatigue life canbe considered, the device can test two tooth-shaped belts at the same time, and time cost is reduced.

Owner:HEBEI UNIV OF TECH

Touch liquid crystal display device avoiding residual images

InactiveCN107643619ASimple structureReduce manufacturing costOptical light guidesNon-linear opticsLiquid-crystal displayLiquid state

The invention relates to the technical field of liquid crystal display devices, in particular to a touch liquid crystal display device avoiding residual images. The touch liquid crystal display deviceavoiding the residual images comprises a liquid crystal display panel and a backlight module, wherein the liquid crystal display panel comprises a first substrate, a second substrate opposite to thefirst substrate and a liquid crystal layer arranged between the first substrate and the second substrate; a first liquid metal layer is arranged on one face, facing the liquid crystal layer, of the first substrate, a second liquid metal layer is arranged on one face, facing the liquid crystal layer, of the second substrate, and the first liquid metal layer is electrically connected with the secondliquid metal layer; the backlight module comprises a back frame, a backlight source arranged in the back frame and composed of a plurality of light sources in an arranged mode, a light guiding platearranged on one side of the backlight source and a diffusion plate arranged on the light guiding plate; the liquid crystal display panel is arranged on one side of the diffusion plate. By means of thetouch liquid crystal display device, it can be avoided that an additional electric field for driving liquid crystals is abnormal, and occurrence of the residual image phenomenon is thus avoided.

Owner:星星显示科技(东莞)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com