A titanium tube numerical control differential temperature heating bending forming mold and method

A technology of differential temperature heating and bending forming, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem of difficult-to-form titanium alloy tube CNC heating and bending forming, which is not conducive to improving the bending and forming quality/forming limit, temperature It can improve the quality of bending, avoid temperature unevenness, and improve the forming limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

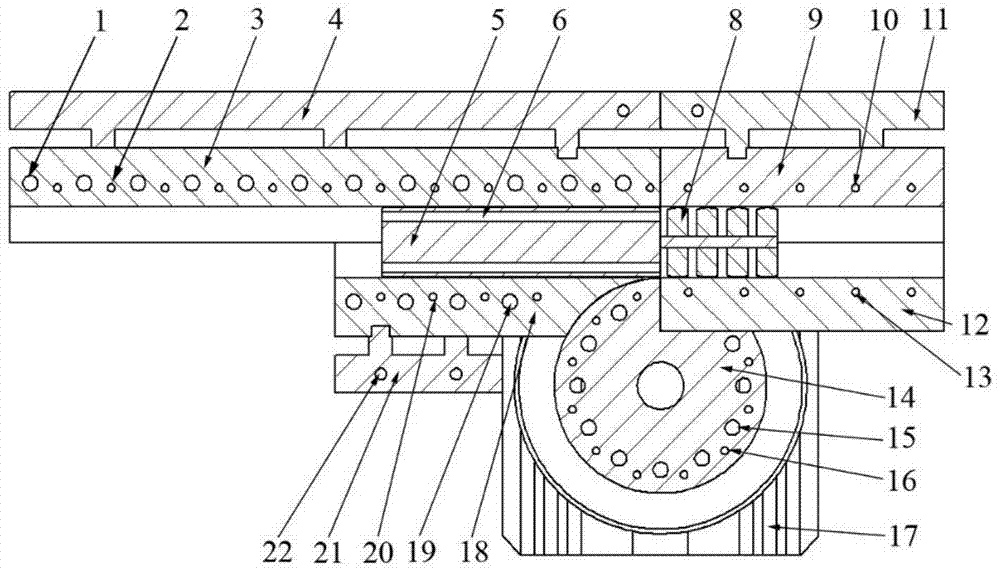

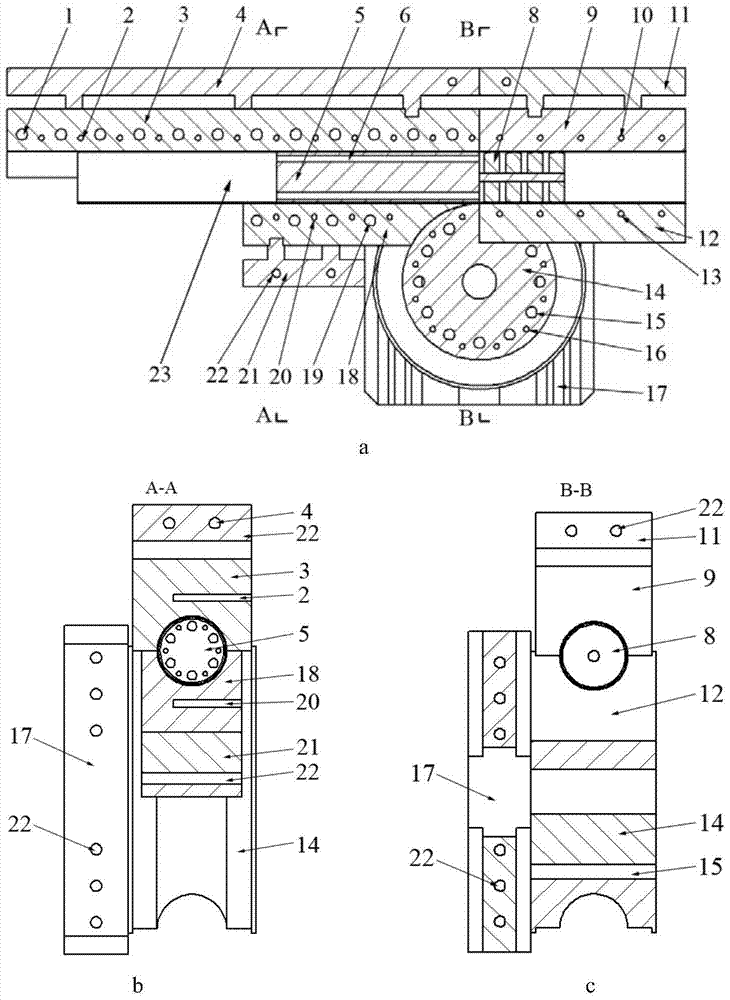

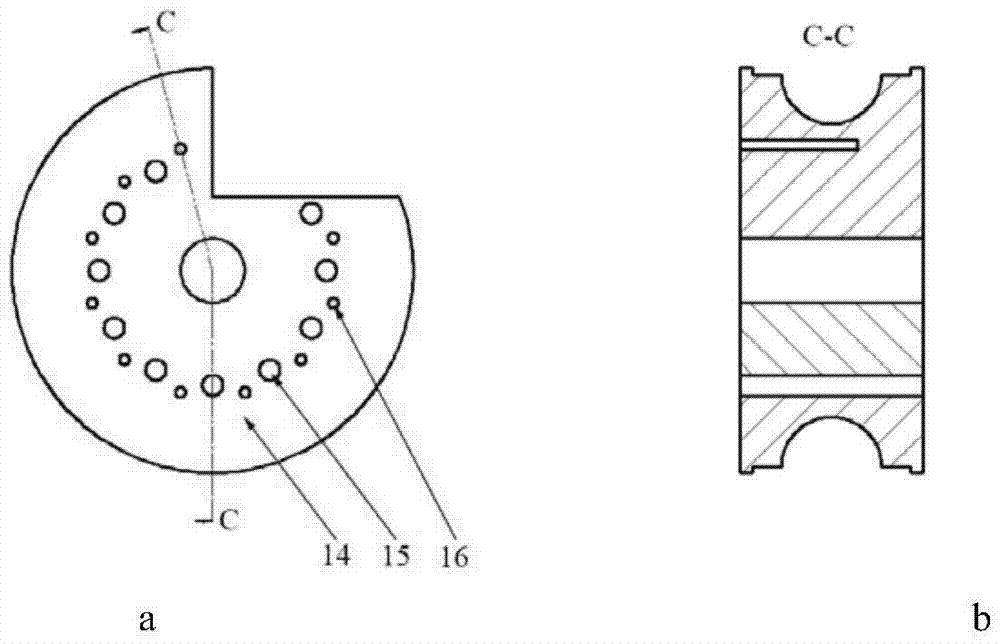

[0050] This embodiment is a titanium tube numerically controlled differential temperature heating bending forming die.

[0051] The titanium tube numerical control heating bending forming mold proposed by the present invention includes a pressure mold 3, a clamping mold 9, an insert 12, a bending mold 14, an anti-wrinkle mold 18, a core mold, a pressure mold heat insulation plate 4, and a clamping mold heat insulation Plate 11, bending mold heat insulation board 17 and anti-wrinkle mold heat insulation board 21; the core mold includes mandrel 5 and core ball 8. In this embodiment, heating holes and temperature measuring holes are respectively added on the pressure mold 3, the bending mold 14, the mandrel 5 and the anti-wrinkle mold 18, and the temperature measuring holes are added on the clamping mold 9 and the insert 12, so as to meet the requirements of titanium Tube CNC heating bending requirements. In the present invention, cooling holes 22 are added to the heat insulatio...

Embodiment 2

[0072] This embodiment is a method of bending and forming a titanium tube by using the mold described in the first embodiment to heat and bend it.

[0073] What this embodiment adopts is the CP-3 pipe material whose specification is Φ76.2×t1.0668, that is, the pure titanium pipe whose pipe diameter D is 76.2 mm and whose wall thickness t is 1.0668 mm. The D / t of the pure titanium pipe is 71.4 , Bending radius R = 1.5D. The equipment used in this embodiment is W27YPC-159 CNC pipe bender.

[0074] The specific implementation process includes the following steps:

[0075] The first step is the heat insulation of the mold and the pipe bender. Place the pressure mold heat insulation board 4 between the assembly surface of the pressure mold 3 and the machine tool connection surface, place the anti-wrinkle mold heat insulation board 21 between the anti-wrinkle mold 18 and the machine tool connection surface, and connect the bending mold 14 assembly surface with the machine tool Pl...

Embodiment 3

[0095] What this embodiment adopts is the TC4 pipe with specification of Φ60×t1, that is, the titanium alloy pipe with diameter D of 60mm and wall thickness t of 1mm. The titanium alloy pipe has D / t=60 and bending radius R=3D.

[0096] The specific implementation process includes the following steps:

[0097] The first step is the heat insulation of the mold and the pipe bender. Place the pressure mold heat insulation board 4 between the assembly surface of the pressure mold 3 and the machine tool connection surface, place the anti-wrinkle mold heat insulation board 21 between the anti-wrinkle mold 18 and the machine tool connection surface, and connect the bending mold 14 assembly surface with the machine tool Place the bending mold heat insulation board 17 between the surfaces, and place the clamping mold heat insulation board 11 between the assembly surface of the clamping mold 9 and the connecting surface of the machine tool; on the upper and lower surfaces of the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com