Side light type backlight module and its operation method

The technology of a backlight module and operation method is applied in the field of side-light backlight module and its operation, and can solve problems such as temperature unevenness, light guide plate warping, difference in power density and heat dissipation capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the description of the present invention more detailed and complete, reference may be made to the attached drawings and various embodiments described below, and the same numbers in the drawings represent the same or similar elements. On the other hand, well-known elements and steps have not been described in the embodiments in order to avoid unnecessary limitations of the invention.

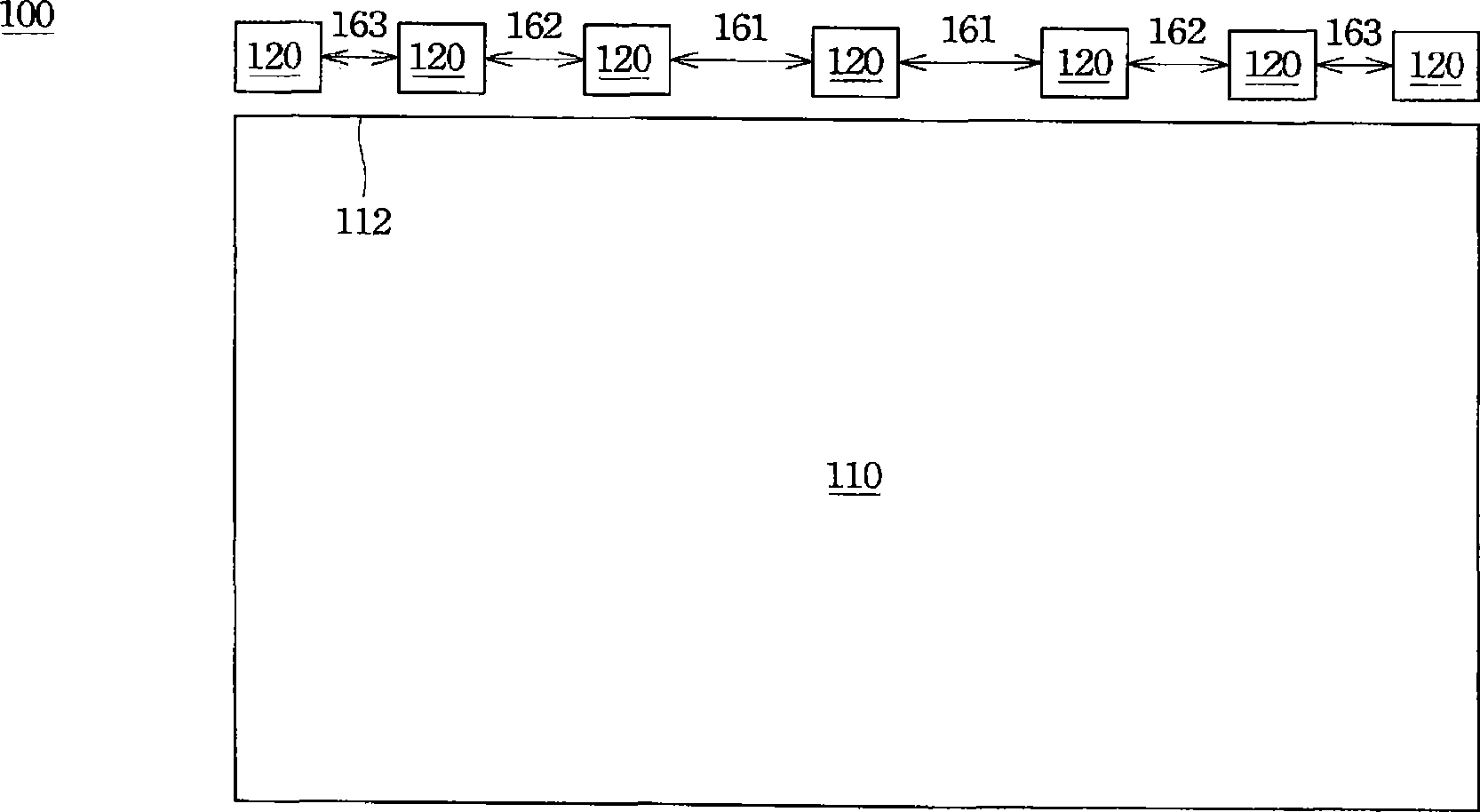

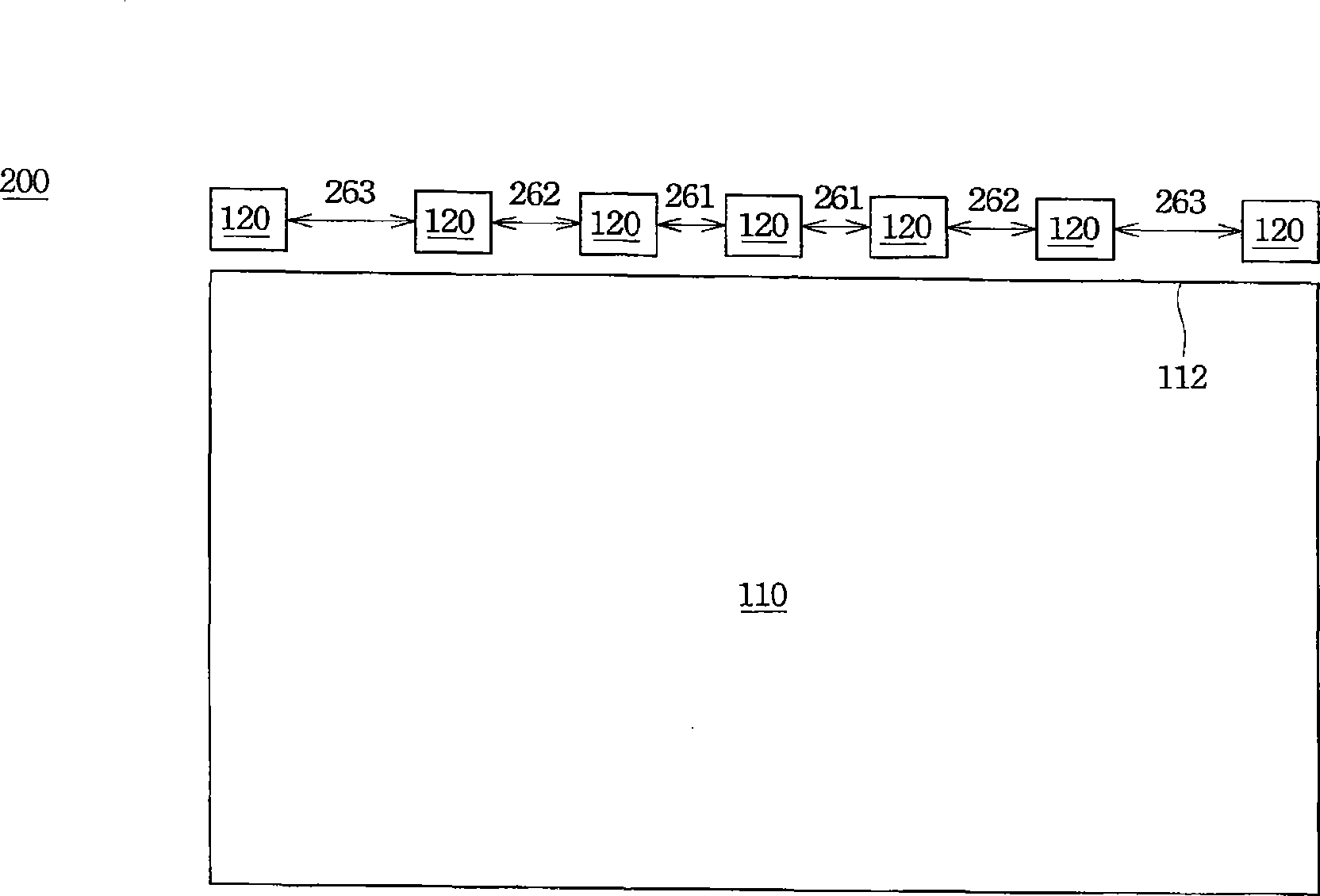

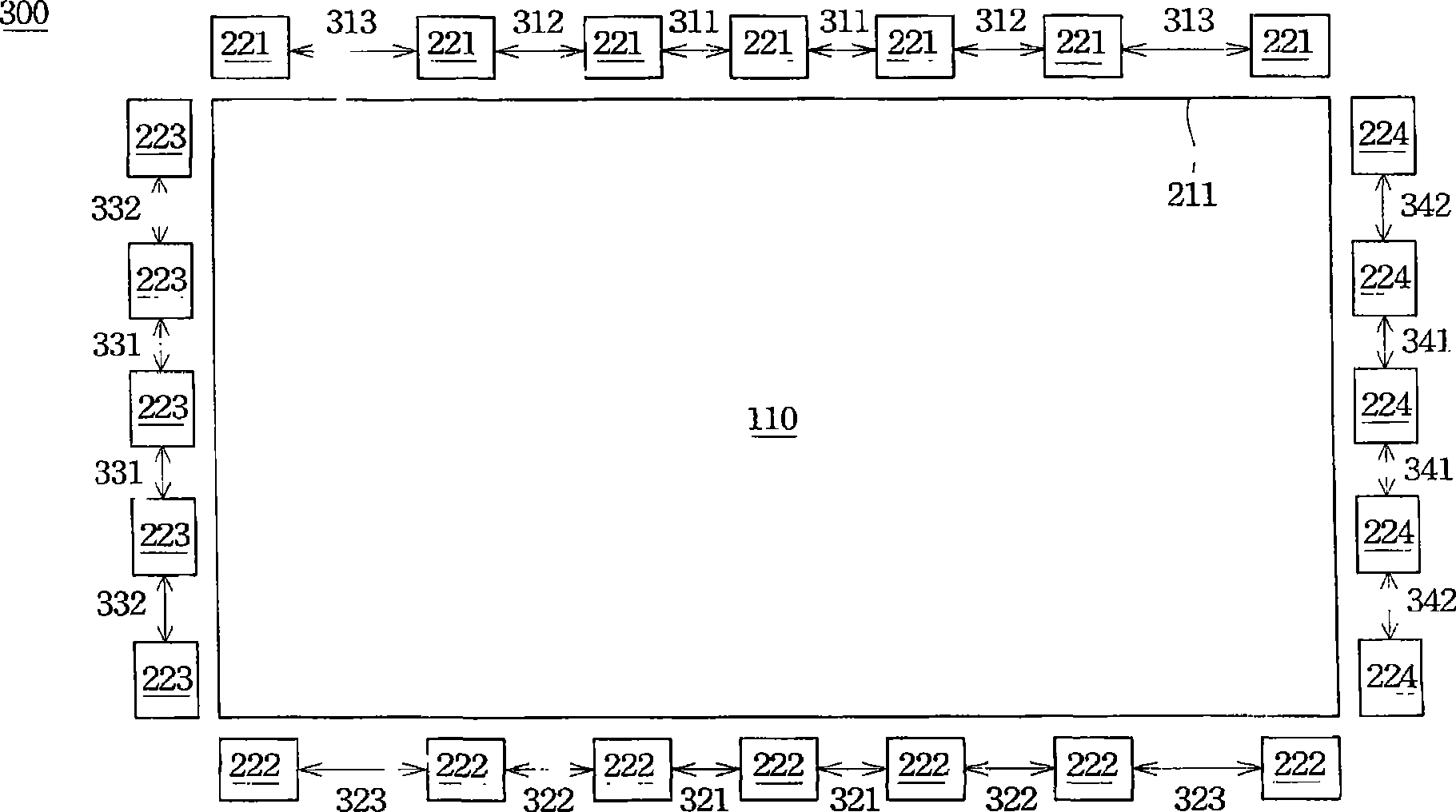

[0046] One embodiment of the present invention is an edge-lit backlight module. The side-light backlight module can be widely used in displays, or in other similar technical links. The following will match Figure 1 to Figure 3 The implementation of the edge-lit backlight module will be described in detail.

[0047] Generally speaking, for a side-lit backlight module with light incident from one side, a plurality of LED light sources on the light incident side of the light guide plate are arranged with a pitch. However, this will cause temperature unevenness on the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com