Intelligentized manipulator for manufacturing ball roughs and placing ball roughs into oil pan

A technology of manipulators and blanks, which is applied to the utensils used for frying things in oil, oil/fat baking, household appliances, etc. It can solve the problems of affecting the quality of meatballs, low work efficiency, and high labor intensity, so as to avoid uneven temperature , Improve work efficiency and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

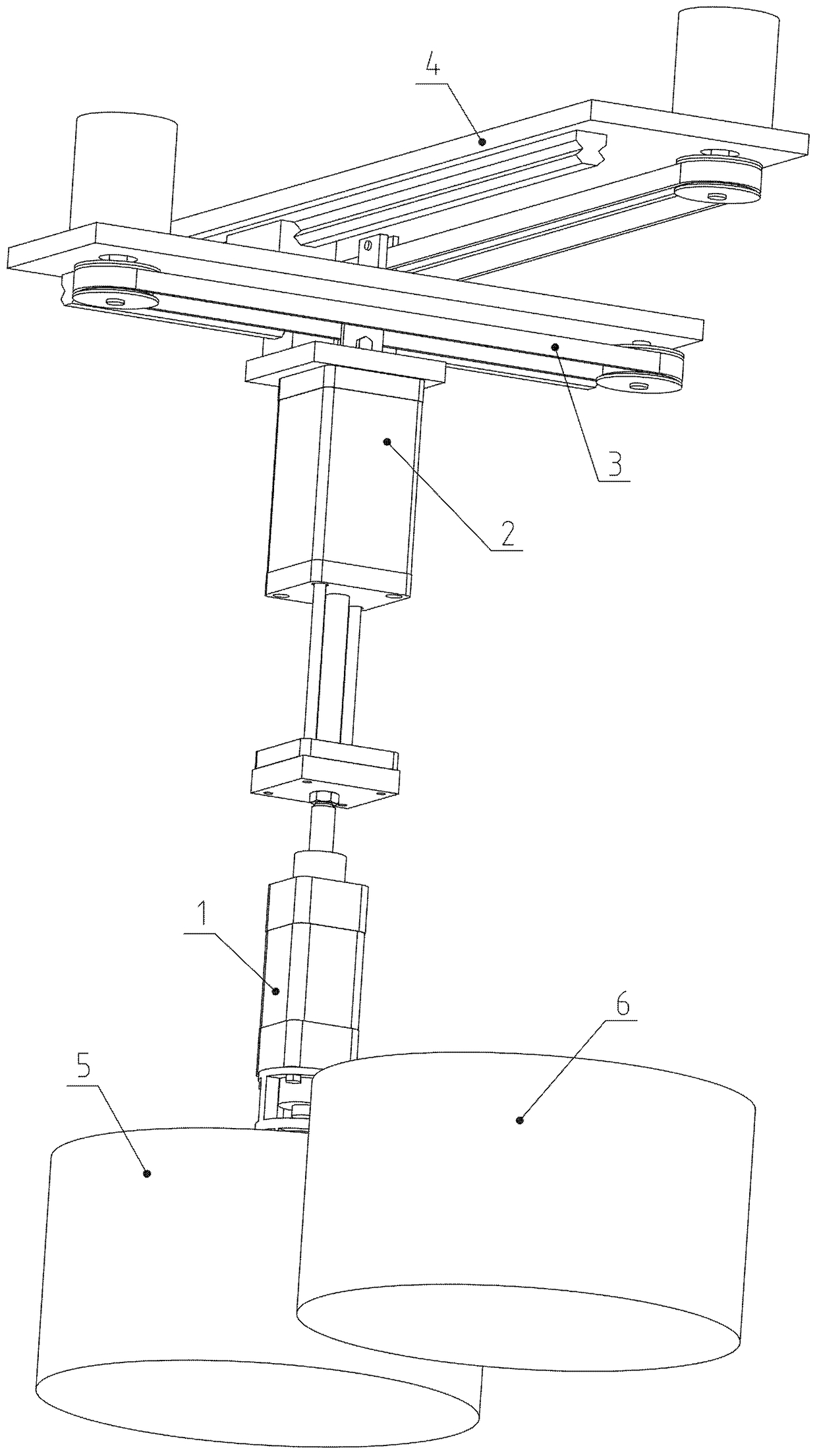

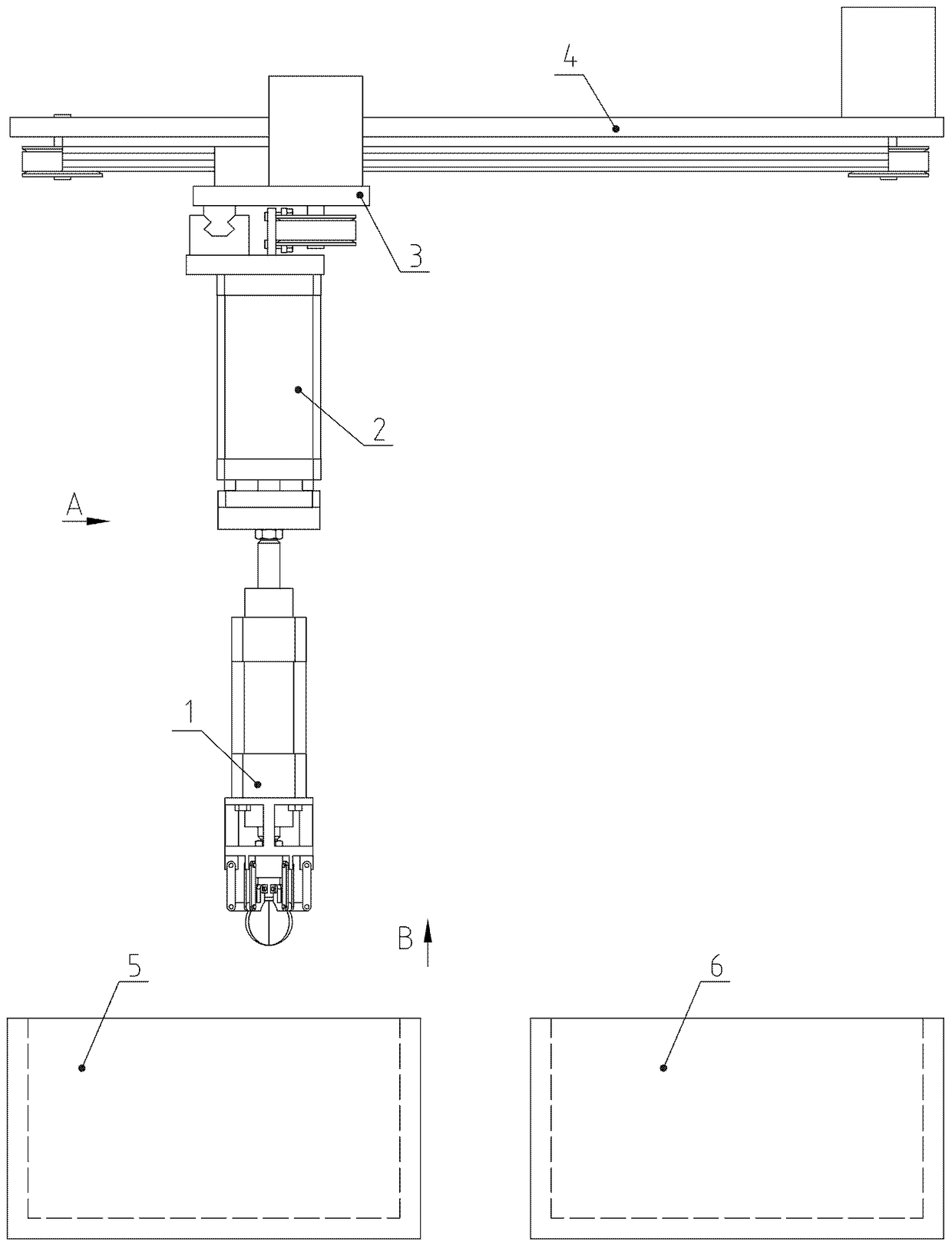

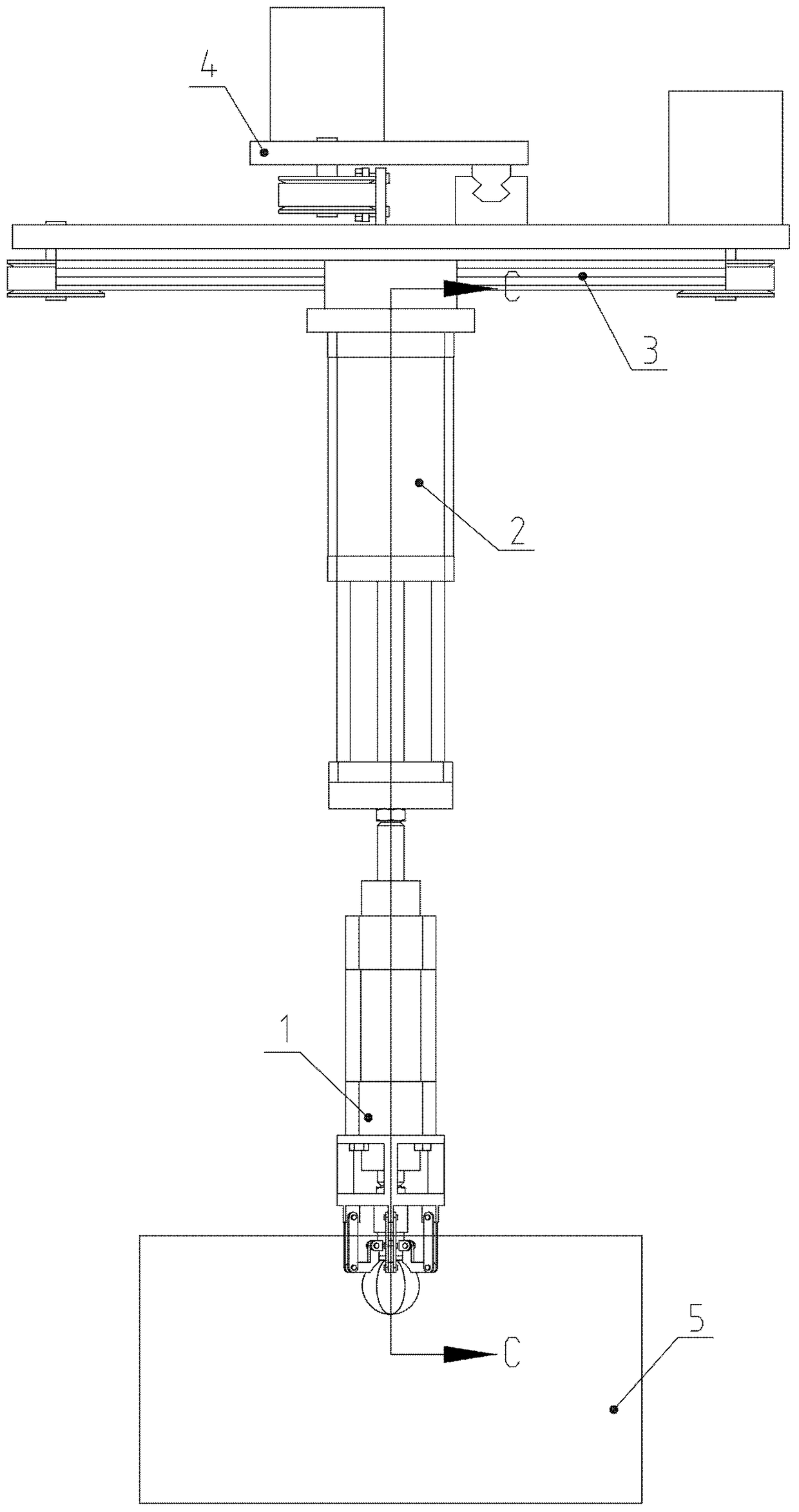

[0047] Example: see Figure 1 to Figure 16 .

[0048] A manipulator for making intelligent meatball blanks and placing them in an oil pan, including a manipulator assembly 1, a lateral movement support assembly 2, a longitudinal movement support assembly 3 and a fixed support plate assembly 4;

[0049] The manipulator assembly 1 includes a biaxial cylinder 11, a manipulator bracket 12, six connecting rods 13, a central shaft assembly 14 and six split assemblies 15;

[0050] Biaxial cylinder 11 comprises biaxial cylinder block 111 and biaxial piston assembly 112; The extended piston lower shaft 1122; the biaxial cylinder body 111 translates up and down relative to the piston upper shaft 1121 and the piston lower shaft 1122;

[0051] The upper end of the manipulator support 12 is fixedly connected with the lower end of the biaxial cylinder block 111, and the lower end of the manipulator support 12 is provided with six connection holes 121 on the connecting rods; uniform circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com