Fiber reinforced plastic (FRP) pultruded profile for bridge, forming equipment and preparation method

A technology of pultrusion profiles and forming equipment, which is applied in bridge construction, bridges, bridge parts, etc., can solve problems such as prone to accidents and insufficient shear strength, so as to improve mechanical properties and weather resistance, improve surface effects, The effect of reducing spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

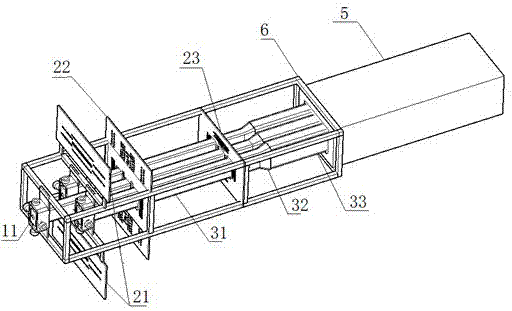

[0047] The third technical solution of the present invention is to provide a preparation method for forming the FRP pultrusion profile for the bridge of the present invention using the FRP pultrusion molding machine for the above-mentioned bridge, including the following steps:

[0048] 1) Prepare the glue solution and place it in the above-mentioned glue solution impregnation device;

[0049] 2) Select the fiber pultrusion yarn and fiber fabric, and install them on the above-mentioned creel and the above-mentioned felt guide respectively;

[0050] After passing through the fiber pultruded yarn of the creel and the fiber fabric drawn out through the felt guide, the fiber material and the fiber fabric are jointly immersed in the dipping tank under the action of the above-mentioned traction device;

[0051] 3) After step 2), the fiber pultruded yarn and fiber fabric after impregnation pass through the preforming mold to remove excess resin and air bubbles, and then enter the cav...

example 1

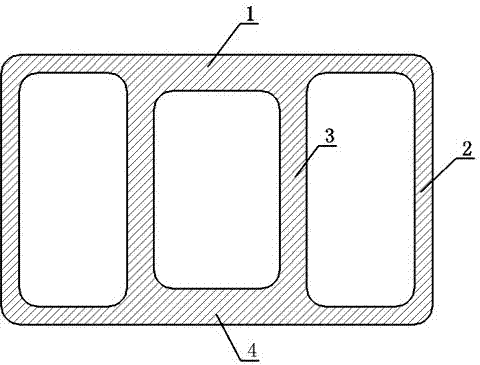

[0063] The FRP pultruded profile for the bridge of the present invention is a cuboid, the length is determined according to the design of the bridge, the width is 220mm, and the height is 130mm. 10mm, the width of the top plate 1 and the bottom plate 4 is 220mm, the height of the side wall web 2 is 110mm, and the thickness is 10mm, the height of the middle web 3 is 90mm, and the thickness is 15mm, in the 2 side wall webs 2 to 2 middle webs The thickness of the top plate 1 and the bottom plate 4 on the outer side of 3 are both 10mm; the thickness of the top plate 1 and the bottom plate 4 between the two middle webs 3 are both 20mm; the top plate 1 and the bottom plate 4 are symmetrical along the horizontal center line of the profile, and the profile is three Cavity structure, the width of the middle cavity along the profile is 60mm, the height along the profile is 90mm, the cavity size on both sides is the same, the width along the profile is 55mm, the height along the profile i...

example 2

[0065] The FRP pultruded profile for bridges of the present invention is a cuboid, the length is determined according to the design of the bridge, the width is 235mm, and the height is 145mm. 14mm, the width of the top plate 1 and the bottom plate 4 is 235mm, the height of the side wall web 2 is 123mm, and the thickness is 11mm, the height of the middle web 3 is 103mm, and the thickness is 16mm, in the 2 side wall webs 2 to 2 middle webs The thickness of the top plate 1 and the bottom plate 4 on the outer side of 3 are both 11 mm; the thickness of the top plate 1 and the bottom plate 4 between the two middle webs 3 are both 21 mm; the top plate 1 and the bottom plate 4 are symmetrical along the horizontal center line of the profile, and the profile is three Cavity structure, the width of the middle cavity along the profile is 67mm, the height along the profile is 103mm, the cavity size on both sides is the same, the width along the profile is 57mm, and the height along the prof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com