Patents

Literature

43results about How to "Improve shear performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Room-temperature cured high-temperature-resistant epoxy resin plugging material and preparation method thereof

InactiveCN104726047AHigh tensile strengthImprove shear performancePolyureas/polyurethane adhesivesEpoxy resin adhesivesExtensibilityAccelerant

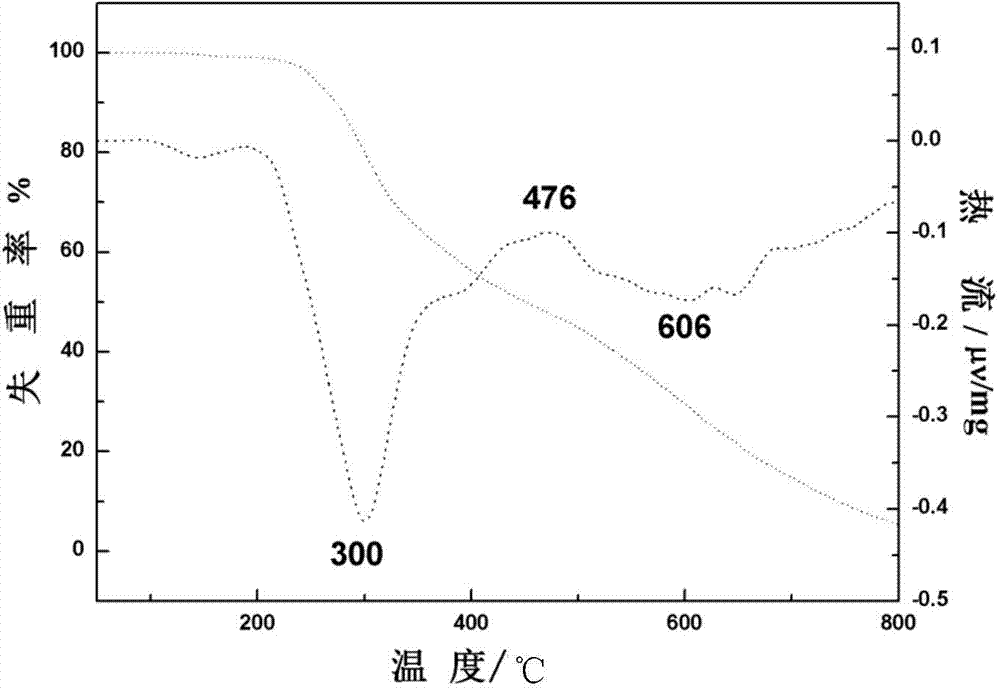

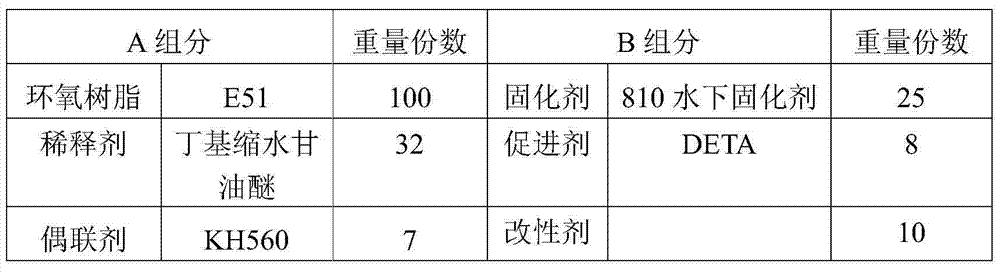

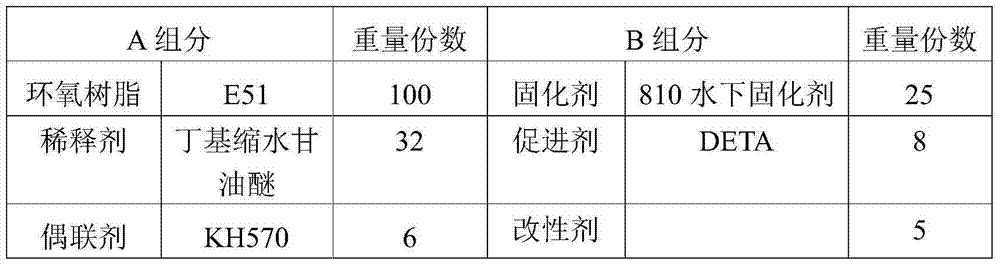

The invention discloses a room-temperature cured high-temperature-resistant epoxy resin plugging material and a preparation method thereof, and belongs to the technical field of material preparation. The plugging material is composed of a part A and a part B, wherein the part A comprises epoxy resin, a diluent, a coupling agent, and packing; the part B comprises a curing agent, an accelerant, and a modifying agent, and the modifying agent is a polyurethane prepolymer prepared by reacting isocyanate with polyether polyol. The preparation method comprises the following steps: uniformly mixing the epoxy resin with the reactive diluent and the coupling agent so as to obtain the part A; uniformly mixing the curing agent with the compound accelerant, adding the modifying agent, and uniformly stirring, so that the part B is obtained; and when in use, pouting the part B into the part A, uniformly mixing at room temperature, and curing the obtained product to plug a position required to be plugged. The plugging material prepared according to the invention is simple in preparation process, strong in operability, wide in application, good in shearing property and high in tensile strength at high temperature, short in curing time at room temperature, and good in extensibility and toughness, and the maximum thermal decomposition temperature can reach 275 DEG C.

Owner:JILIN UNIV

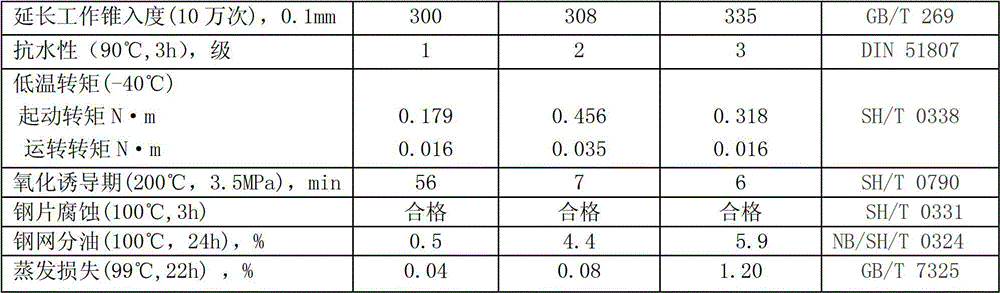

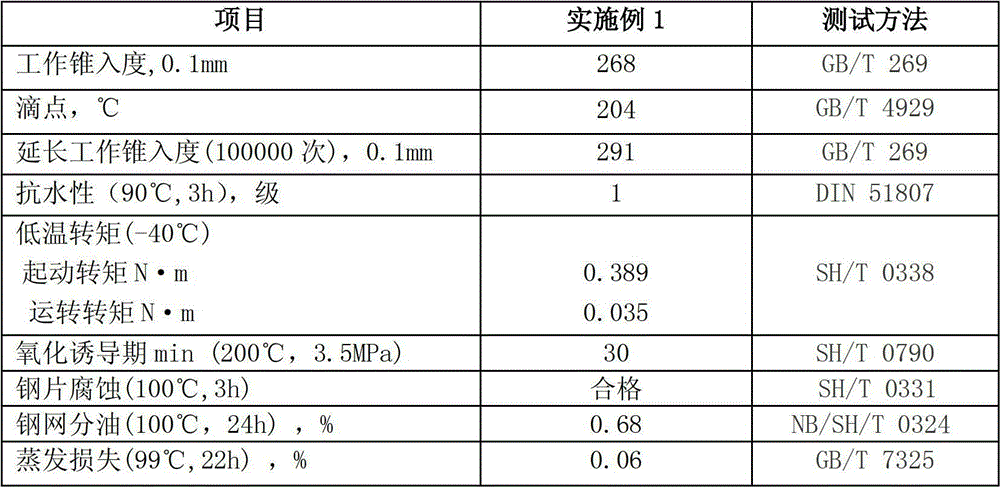

Lubricating grease composition for automobile glass lifter and preparation method of lubricating grease composition

ActiveCN102876434AOutstanding water resistanceOutstanding shear performanceLubricant compositionAntioxidantEvaporation

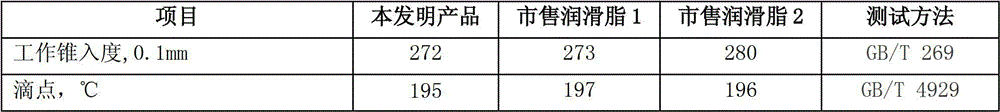

The invention provides a lubricating grease composition for an automobile glass lifter and a preparation method of the lubricating grease composition. The lubricating grease for the automobile glass lifter comprises the following ingredients in percentage by weight: 87 to 91.5 percent of basic oil, 7.5 to 12 percent of thickening agents, 0.5 percent of antioxidants, 0.03 percent of anti-rust agents and 0.5 percent of structure improving agents. The unique mixed thickening agent type is adopted, so the water-resistance and shearing performance of the lubricating grease are excellent, good low-temperature and viscosity-temperature performance is given to the lubricating agent through the proper basic oil type and mixture ratio, and the wide temperature use requirement being minus 40 DEG C to 70 DEG C of the automobile glass lifter accessories can be perfectly met. The prepared lubricating grease has the characteristics that the water resistance and the oxidation resistance are excellent, the oil rate is low, the evaporation loss is small, the shearing stability is high, the high-low temperature performance and the anti-corrosion protection effect are good, and the like, the use requirements of the automobile glass lifter can be perfectly met, and the use temperature range of the lubricating grease is minus 40 DEG C to 130 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

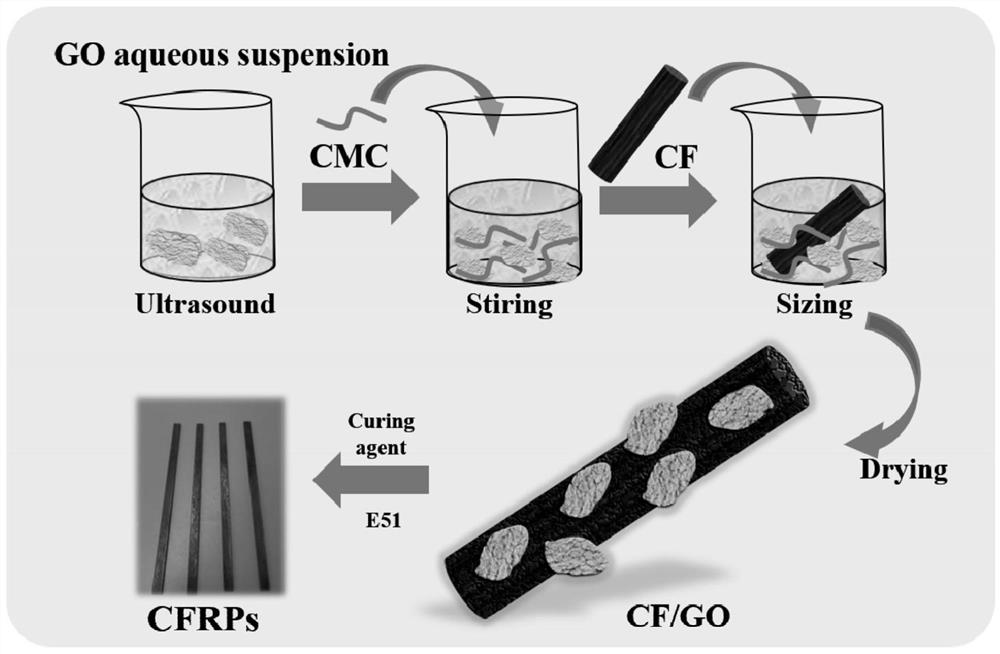

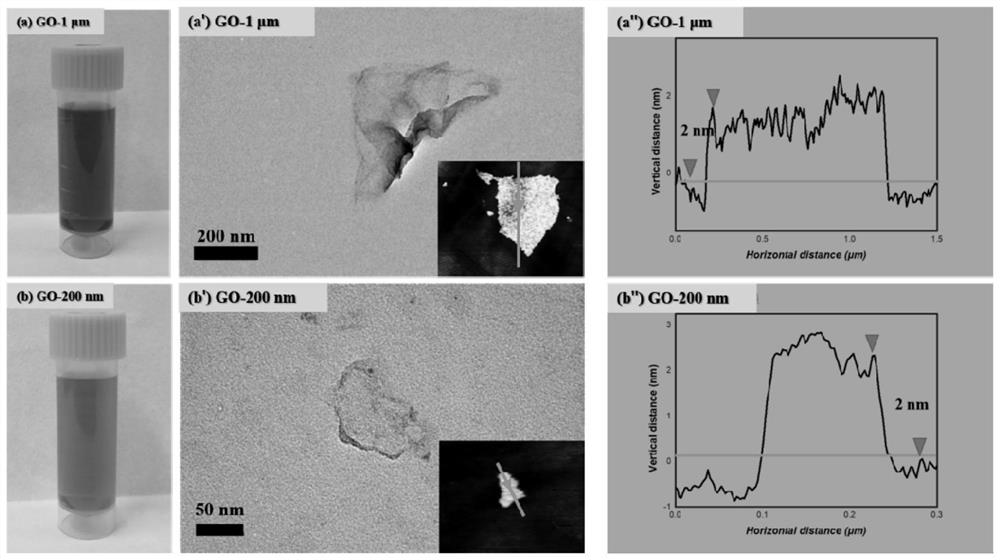

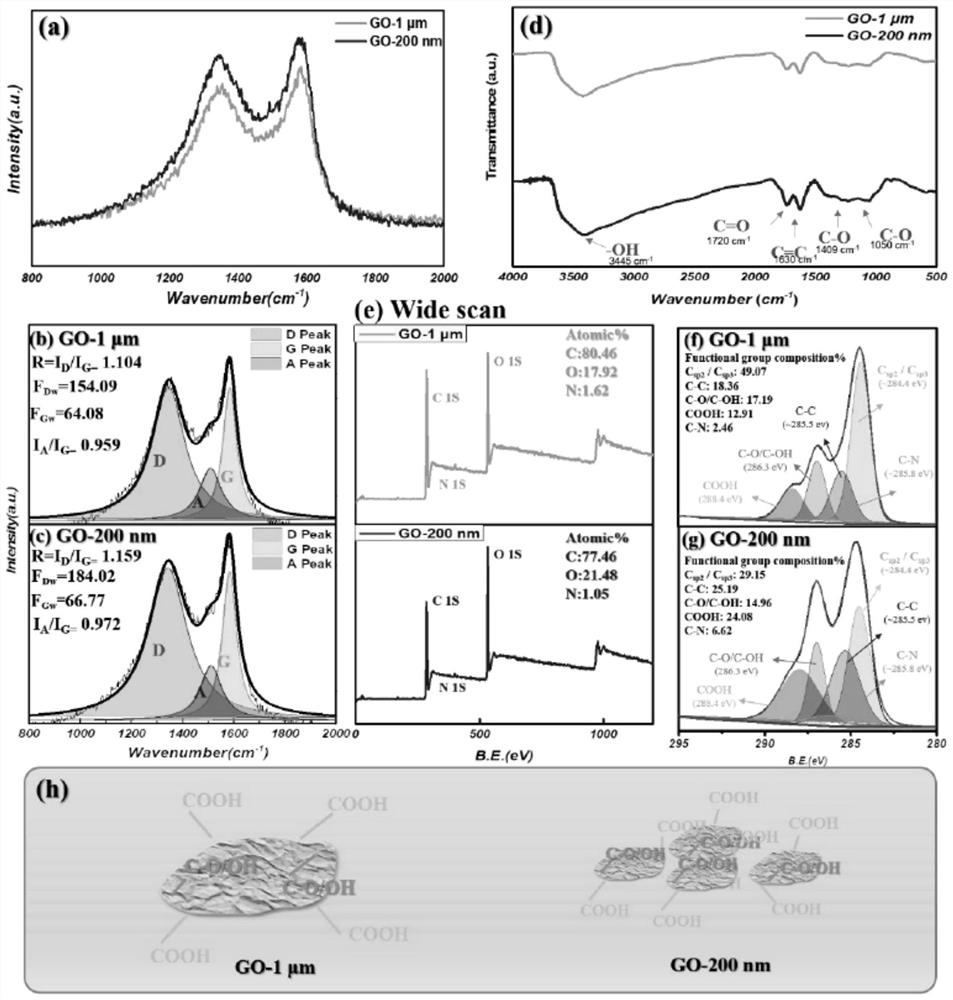

Method for improving interface performance of resin matrix and carbon fibers

ActiveCN113293605AImprove interface performanceSimple preparation processCarbon fibresModified carbonInterlaminar shear

The invention discloses a method for improving the interface performance of a resin matrix and carbon fibers, and belongs to the field of composite materials. Graphene oxide is adopted to modify the surface interface of the carbon fibers, so that a carbon fiber reinforced resin matrix composite material with high interface shear strength and interlayer shear strength is obtained. The carbon fiber reinforced resin-based composite material is prepared from graphene oxide modified carbon fibers, a resin matrix and a curing agent as raw materials, and the graphene oxide modified carbon fibers are obtained from graphene oxide modified carbon fibers with the transverse size of 50-50000 nm. The method has outstanding advantages in the aspect of enhancing the interface performance of the carbon fiber composite material, can meet the high-temperature forming requirement of high-heat-resistance resin, and has important application prospects in preparation of various high-performance resin-based composite materials. The graphene oxide modified carbon fiber reinforced resin matrix composite material is excellent in interlaminar shear performance and can be applied to the fields of aerospace, rail transit, automobiles, energy sources, ships and the like.

Owner:SICHUAN UNIV

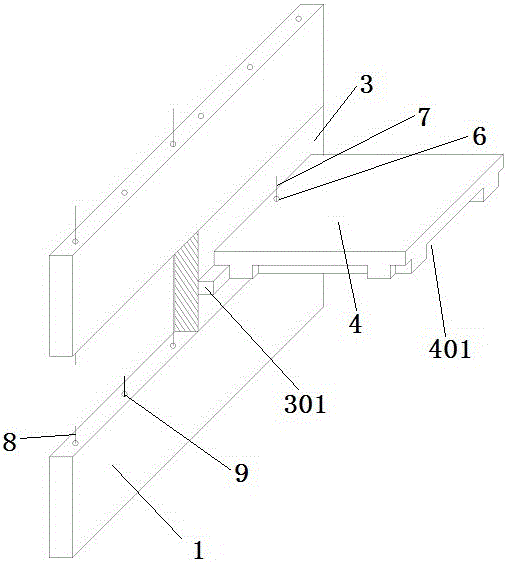

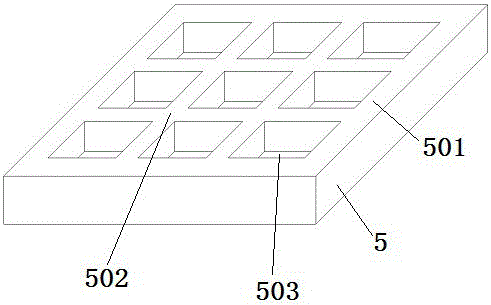

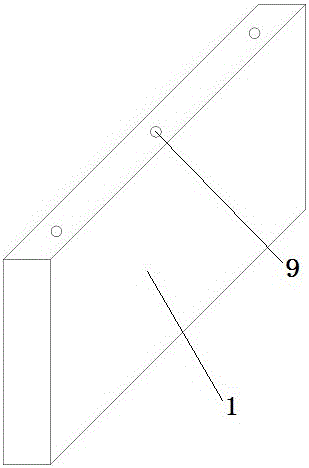

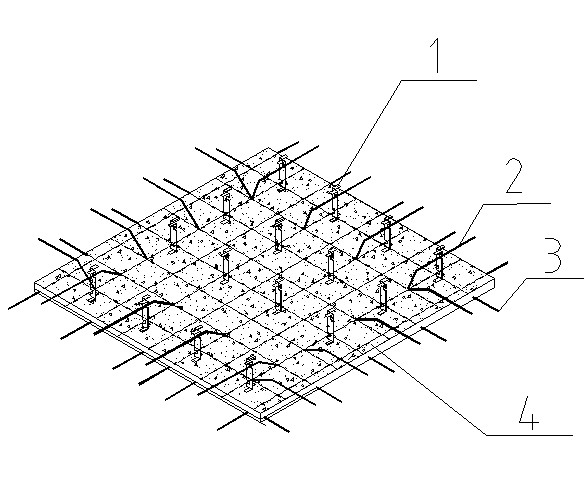

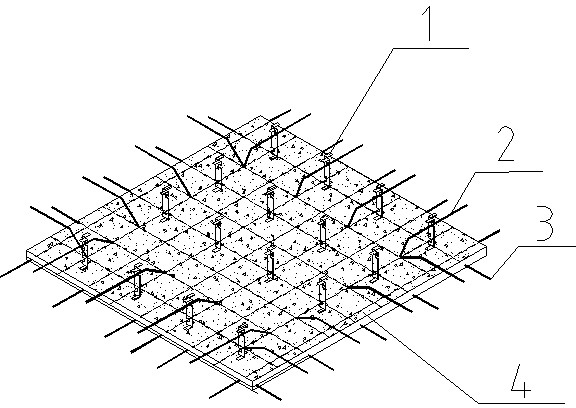

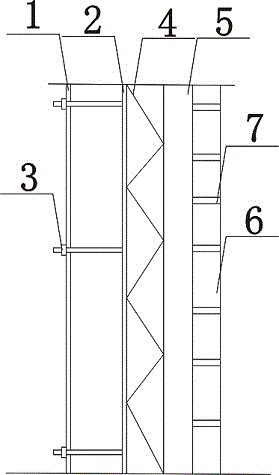

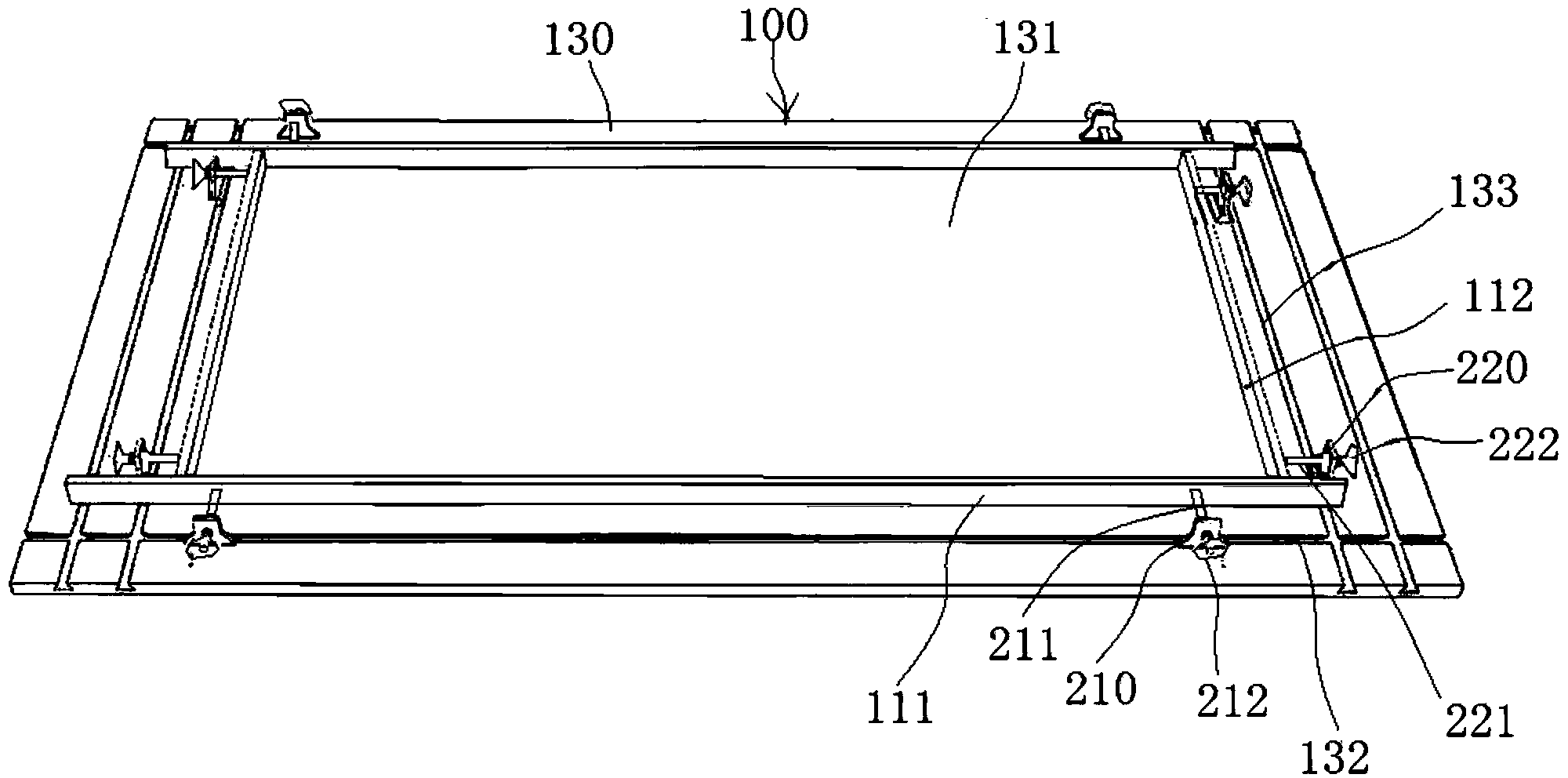

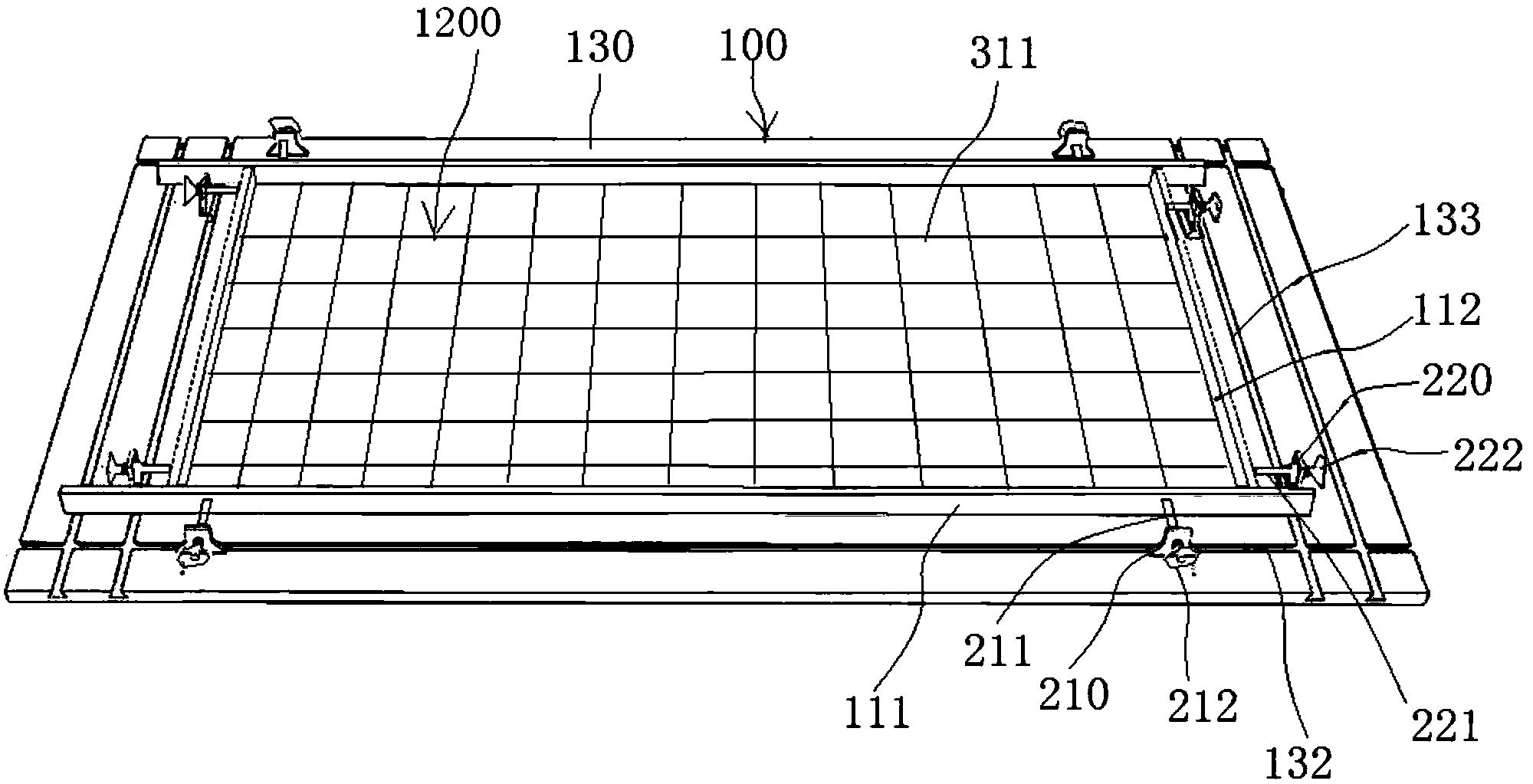

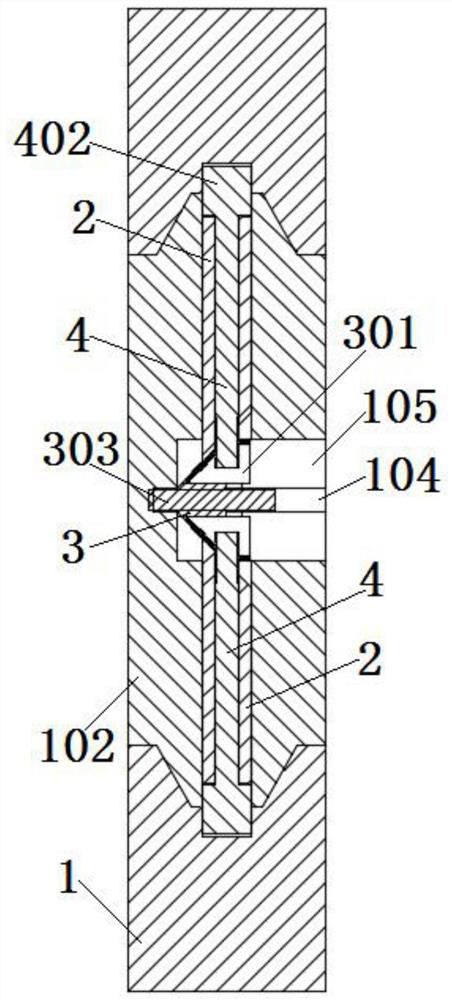

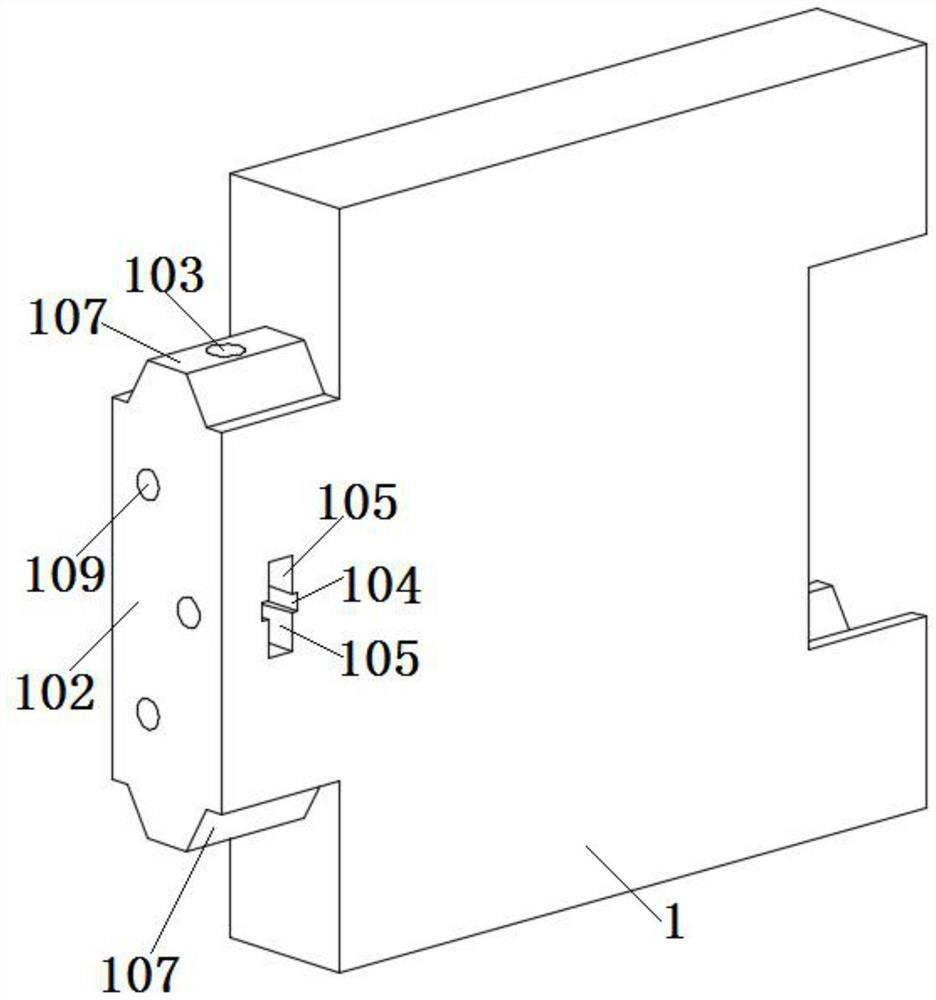

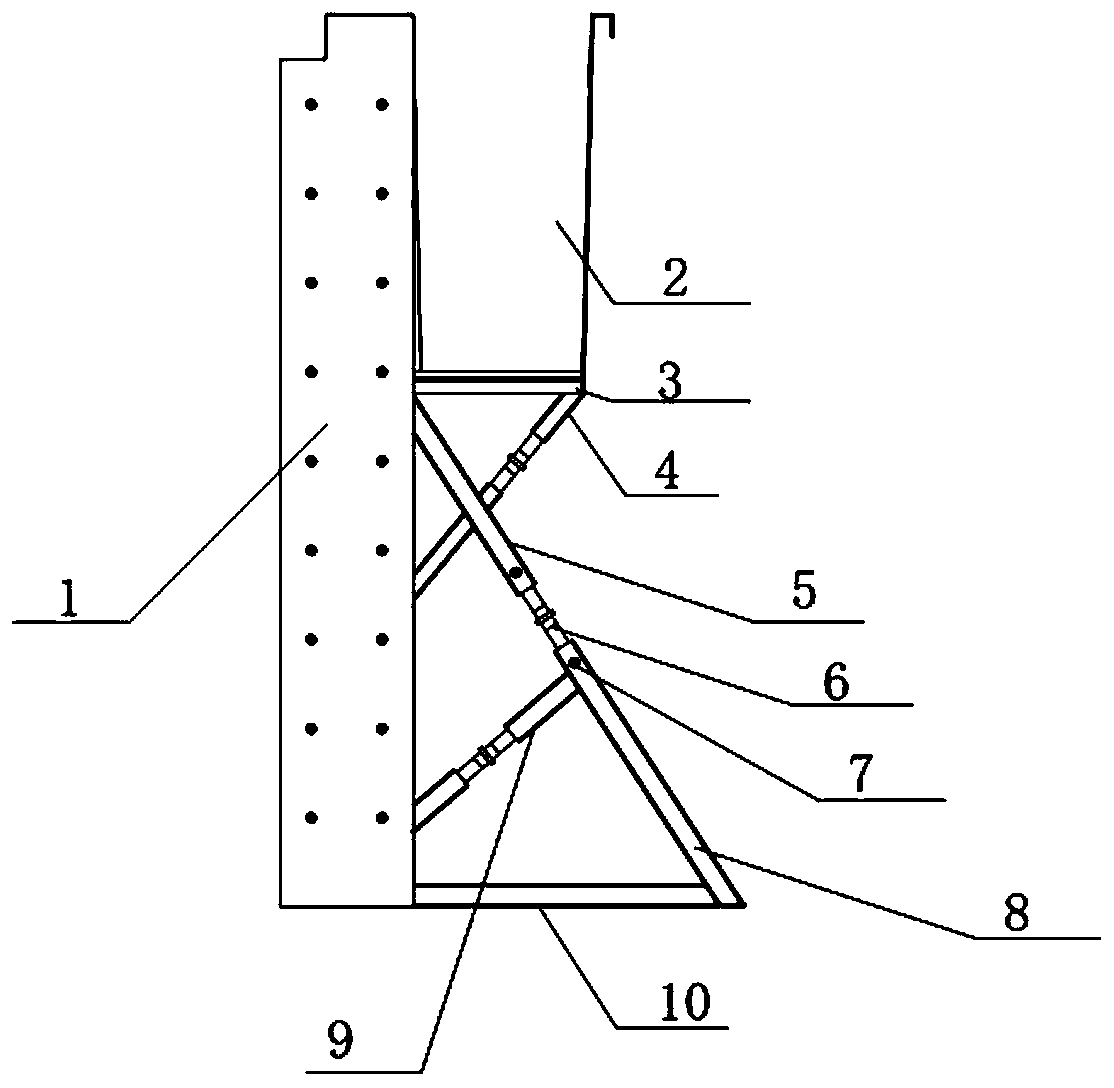

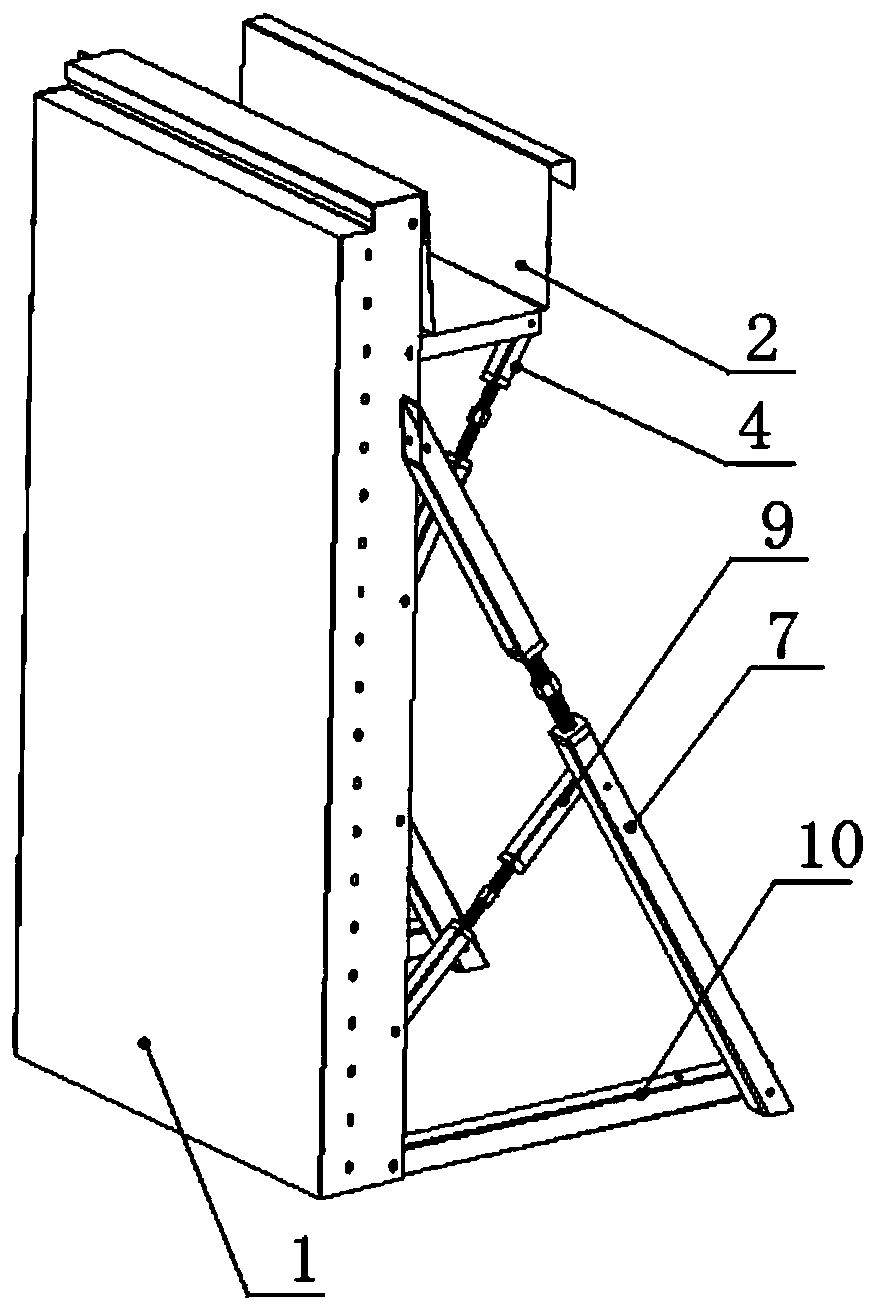

Multilayer architectural structure adopting prefabricated panel and construction method thereof

InactiveCN106381923AStable structureReduce processing difficultyBuilding constructionsFloor slabBrick

The invention discloses a prefabricated panel used for a multilayer architectural structure, a multilayer architectural wallboard adopting the prefabricated panel, a multilayer architectural floor adopting the prefabricated panel, the multilayer architectural structure adopting the prefabricated panel and a construction method for the multilayer architectural structure adopting the prefabricated panel. On the basis of the prefabricated panel for industrial production, the material can be used for manufacturing the wallboard and the floor; and meanwhile, a new architectural structure is adopted and the wallboard is connected with the floor in a manner of matching of a bracket and a blocking slot, so that the construction cost of the multilayer building is lowered under the condition of guaranteeing the building strength and controlling the cost; the problems of a large amount of site construction, higher construction cost and slow construction progress caused by adopting the brick-concrete structure can be solved; the prefabricated panel has the advantages of stable structure, low processing difficulty, low production cost and benefit in industrial production; the modularized structure is adopted, so that the construction cost is low; the structure is stable and the horizontal shearing resistance is excellent.

Owner:SICHUAN INSITITUTE OF BUILDING RES

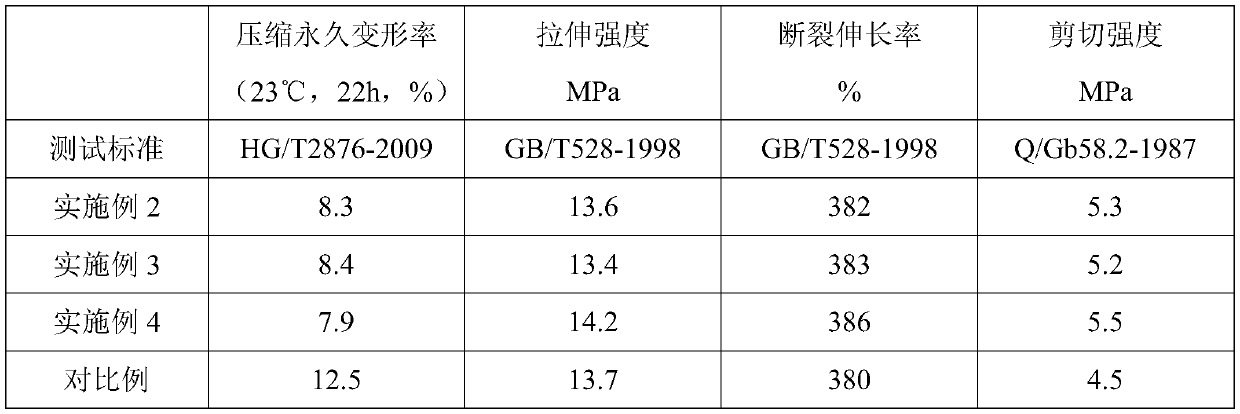

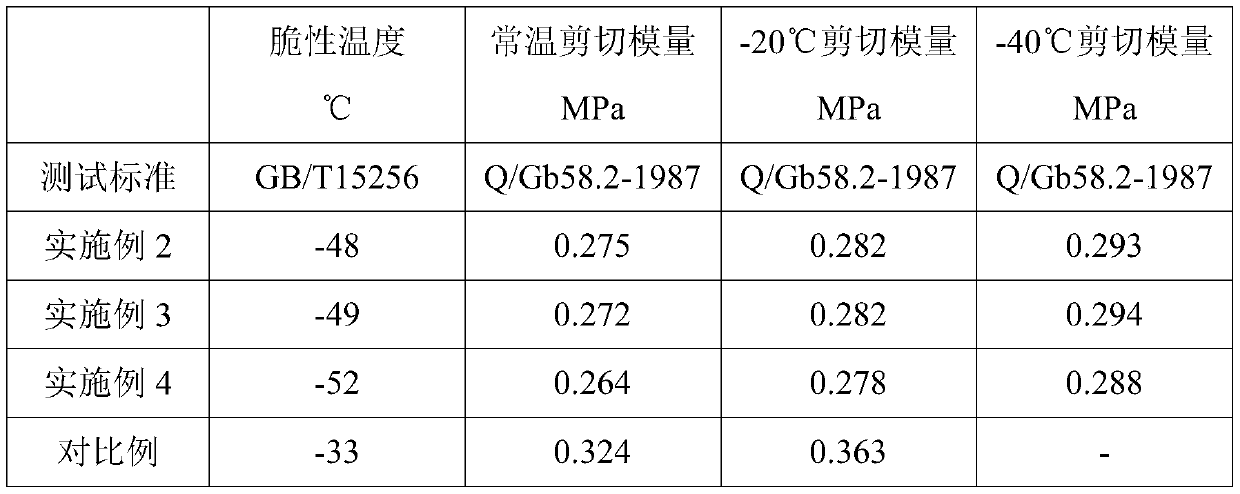

Graphene cold-resistant rubber polymer composition and preparation method thereof

The invention discloses a graphene cold-resistant rubber polymer composition. The graphene cold-resistant rubber polymer composition prepared from the following raw materials in parts by weight: 60-68parts of natural rubber, 8-12 parts of polybutadiene rubber, 23-29 parts of low-pressure polyethylene, 13-17 parts of polyphenylene ether, 4-6 parts of oxidized polyethylene, 3-4.5 parts of a flow additive, 2.6-3.4 parts of grapheme, 5-8 parts of silane coupling agent modified white carbon black, 3-5 parts of fumed silica, 2-3 parts of a foaming agent, 1.4-1.8 parts of activated zinc oxide, 1.6-1.9 parts of a bridging agent, 1.5-2.2 parts of a cross-linking agent, 3-5 parts of an antioxidant and 3-5 parts of a heat stabilizer. The graphene cold-resistant rubber polymer composition is low in compression permanent deformation rate, good in resilience, high in tensile strength, high in elongation at break, excellent in shear performance, good in comprehensive performance, excellent in processing performance, good in apparent quality, most importantly, low in brittleness temperature and good in low temperature resistance, can be used in a long term in the range of normal temperature to -40 DEG C, and is excellent in cold resistance.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

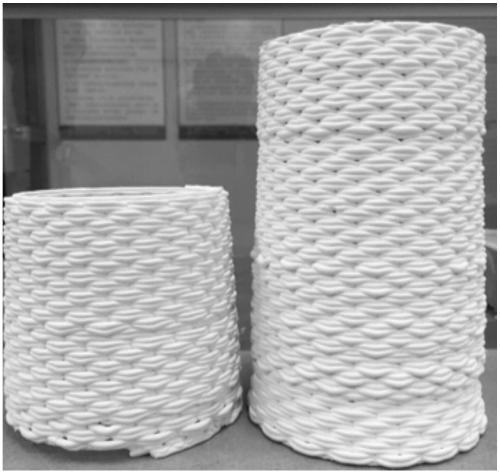

Manufacturing method for environment-friendly fiber reinforced plastic (FRP) iron wire compound type anchor rod

InactiveCN105252689ASimple production processGood flexibilityCoatingsBulkheads/pilesFiberGlass fiber

The invention provides a manufacturing method for an environment-friendly fiber reinforced plastic (FRP) iron wire compound type anchor rod. The method includes the steps that unsaturated polyester resin, polyurethane, glass fibers and release agents are added into a resin adhesive fluid bath, mixed and stirred evenly; then vacuumizing defoaming is carried out; iron wire coils with the diameter being 0.4-0.6 mm and FRP are twisted through a twisting support and then rotated to form the twist degree of 10-30 degrees, and afterwards are pulled into the resin adhesive fluid bath to be impregnated; twisted and impregnated FRP iron wire composite materials continue to be pulled into a conical sleeve to be combined into a bundle and preformed; finally, the FRP iron wire composite materials combined into the bundle continue to be pulled into a hot pressing die to be subjected to die forming at the temperature of 160 DEG C-180 DEG C; a guide cap is manufactured; a wire stringing ring is machined; a fastening ring is machined; and an anchorage pier is manufactured. The defects that existing steel bar and steel strand anchor rods are easy to corrode and glass fiber reinforced plastic anchor rods are insufficient in tightening force are overcome through the environment-friendly FRP iron wire compound type anchor rod, and the environment-friendly FRP iron wire compound type anchor rod is light, high in strength, resistant to corrosion and especially suitable for construction sites where the requirement for safety performance is high.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

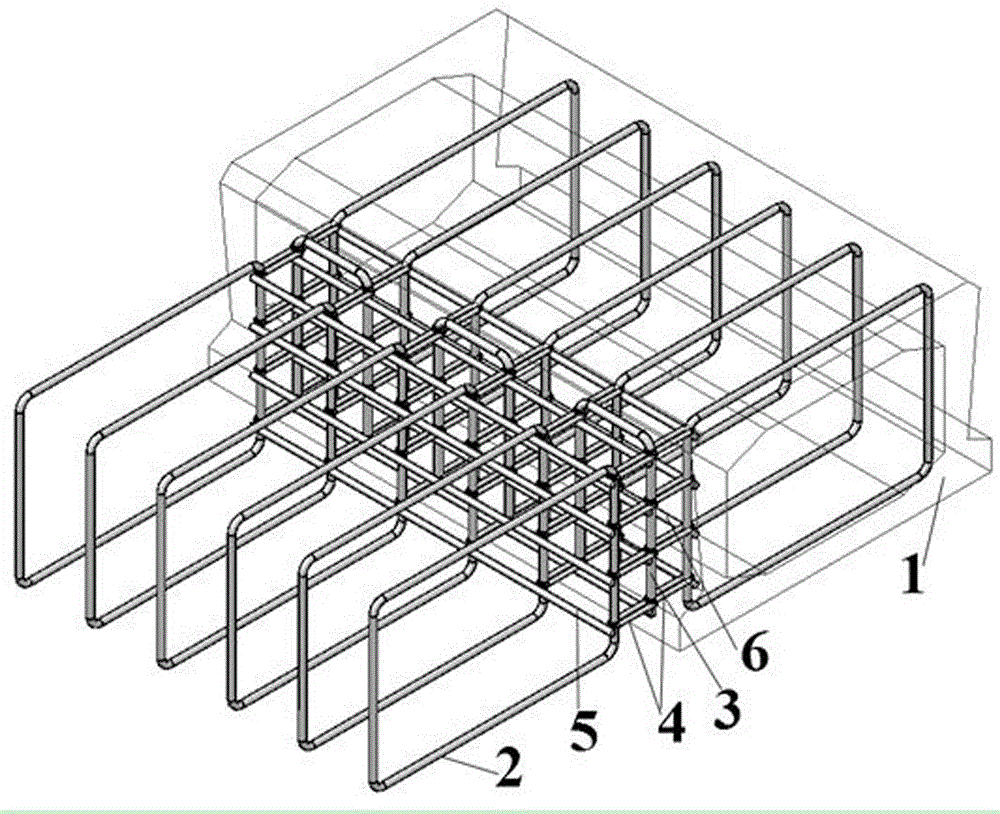

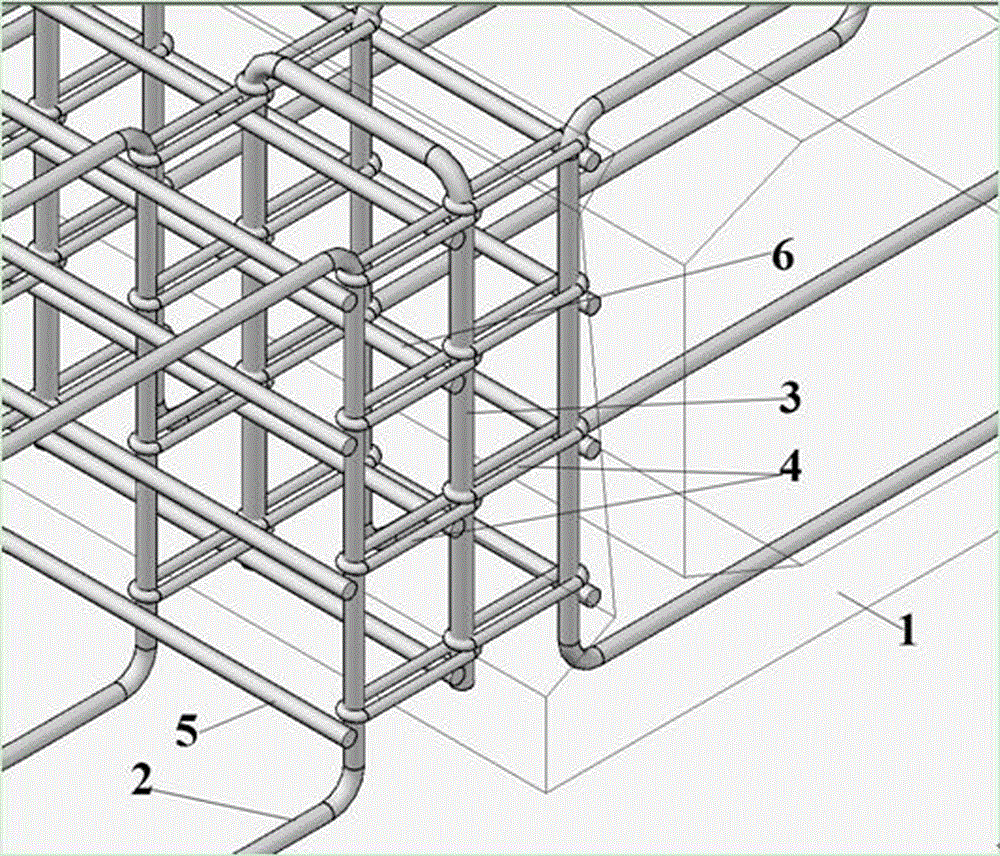

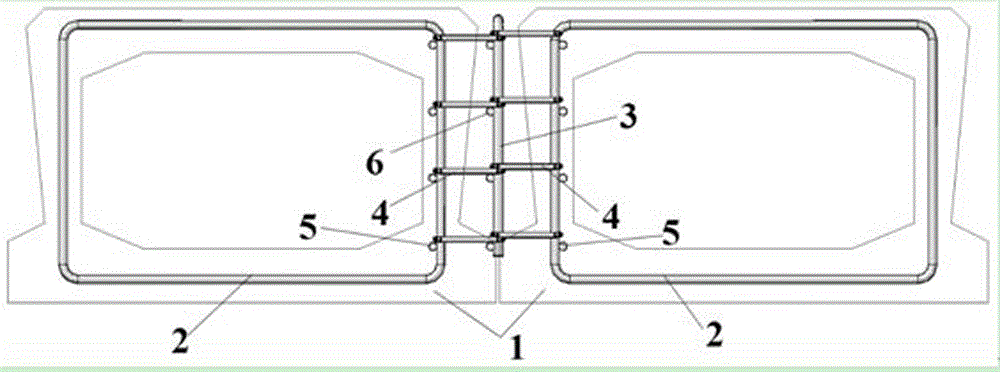

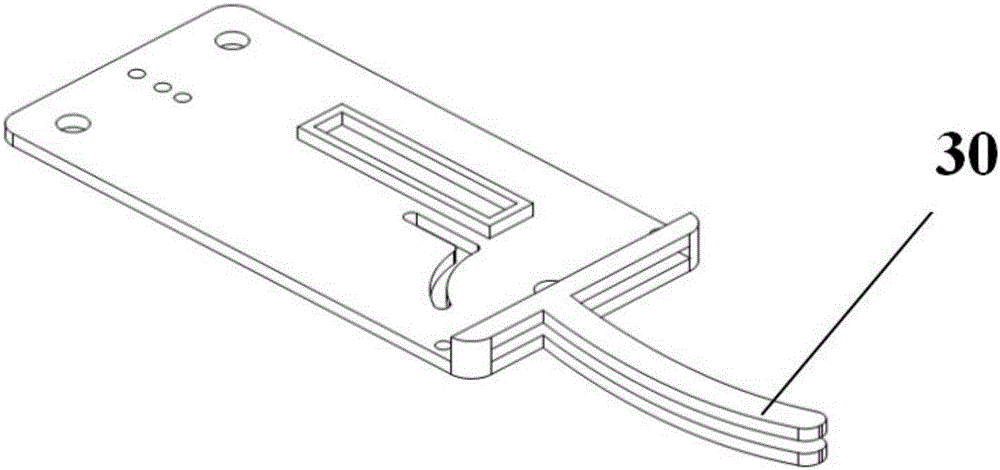

Hinge joint reinforcement bar structure for concrete hollow slab bridge

ActiveCN105648899AImprove shear performanceImprove shear resistanceBridge structural detailsBridge erection/assemblyRebarShear resistance

The invention belongs to the technical field of bridge structures, particularly relates to a hinge joint reinforcement bar structure for a concrete hollow slab bridge and mainly aims to provide a novel hinge joint reinforcement bar form of an assembled concrete slab bridge to solve the problems of insufficient anchoring length of a hinge joint tensile reinforcement bar in a hollow slab and a hinge joint by means of a novel reinforcement bar pin joint structure and to improve the tension resistance of the hinge joint. The hinge joint reinforcement bar structure for the concrete hollow slab bridge comprises hollow slab bodies and hollow slab reinforcement stirrups arranged in the hollow slab bodies, wherein a plurality of U-shaped hinge joint pin joint reinforcement bars are arranged between adjacent hollow slab bodies, a plurality of closed and annular hinge joint tensile reinforcement bars are arranged between each hinge joint pin joint reinforcement bar and each of the hollow slab reinforcement stirrups on two sides of the hinge joint pin joint reinforcement bar, and hollow slab longitudinal reinforcement bars and hinge joint longitudinal reinforcement bars are arranged between the inside of each hollow slab reinforcement stirrup and the corresponding hinge joint pin joint reinforcement bar. The construction is simple and convenient, the shear resistance and the bending resistance capability of the hinge joint connection position are effectively improved, and the service life of the bridge is prolonged.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Anti-shear self restoring pier joint

InactiveCN106869011AImprove shear performancePostpone submissionBridge structural detailsRebarEngineering

The invention discloses an anti-shear self restoring pier joint comprising a pier, a base, an unbonded prestressed steel bar, a plurality of anti-shear components and a plurality of reserved ductile steel bars, wherein the pier and the anti-shear components are positioned on the base; the anti-shear components are positioned around the pier; the upper end of the unbonded prestressed steel bar is connected with the pier and the lower end of the unbonded prestressed steel bar is connected with the base; and the upper end of each reserved ductile steel bar is connected with the pier and the lower end of each reserved ductile steel bar is connected with the base. The anti-shear self restoring pier joint facilitates the anti-shearing and anti-collision of the pier and can effectively improve the safety redundancy of the pier.

Owner:CHANGAN UNIV

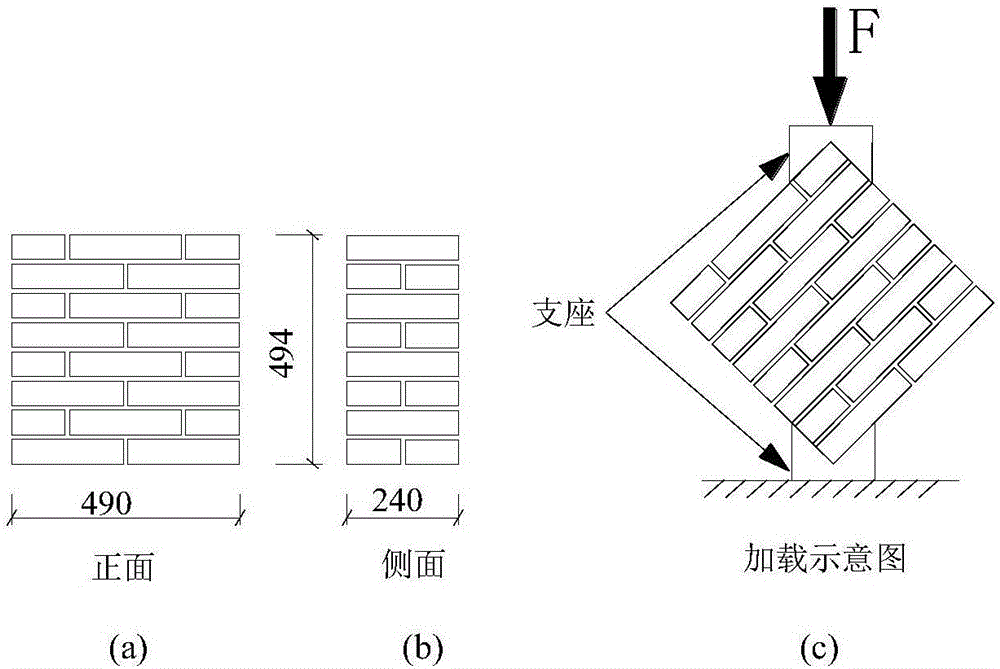

Manufacturing method of brick wall with high shear resistance and shock resistance

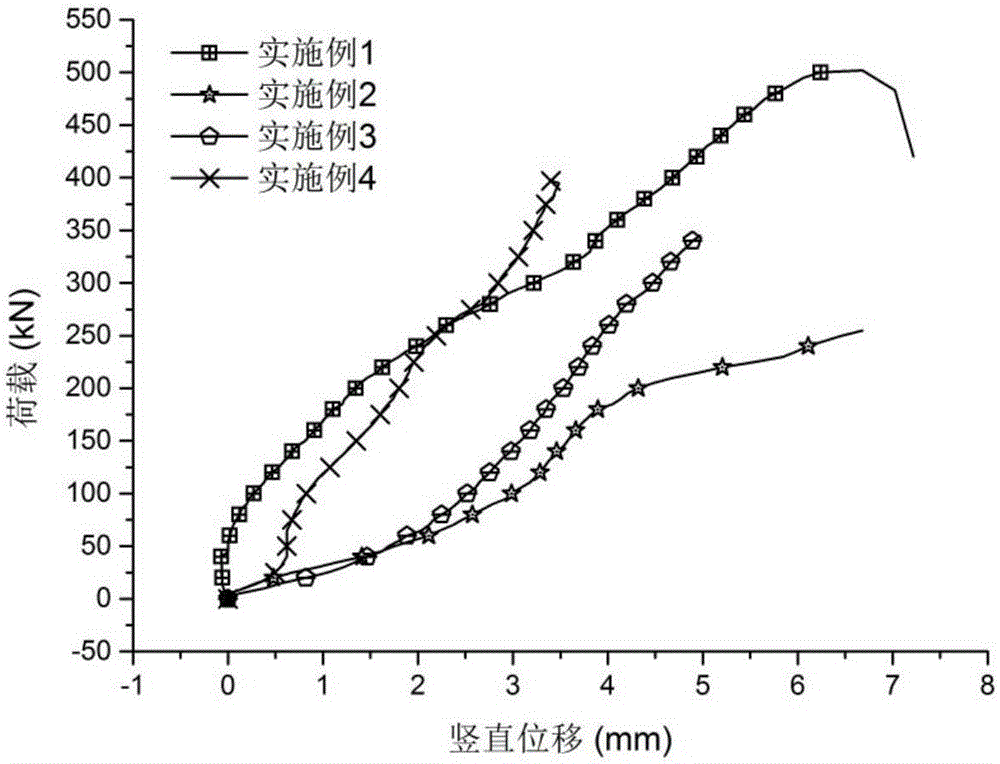

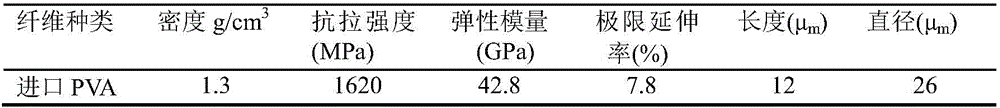

InactiveCN106592815AImproved shear performanceImprove shear performanceWallsDuctilityPolyvinyl alcohol

The invention provides a manufacturing method of a brick wall with high shear resistance and shock resistance. The manufacturing method comprises the following steps that bricks are taken out, polyvinyl alcohol fiber reinforced cement-based composite materials serve as masonry mortar, and a three-one bircklaying method is adopted for bricklaying; after bricklaying is completed, plastering is conducted on the both sides of a wall body, and plastering mortar is high ductility materials, wherein the high ductility materials are prepared from water, binding materials, silica sand and fibers, the mass ratio of the water to the binding materials, the silica sand and the fibers is 1:2.44:(0.8-1):0.038, the binding materials are cement and fly ash, and the fly ash accounts for 40%-50% of the total amount of the binding materials; and after plastering is conducted, water is sprayed onto the wall body for curing in one to seven days, and then the brick wall is obtained after the wall body is cured for 28 days under the outdoor environment condition. According to the manufacturing method of the brick wall with high shear resistance and shock resistance, the shear resistance of the brick wall can be remarkably improved, and the shock resistance can also be greatly improved.

Owner:HEBEI UNIV OF TECH

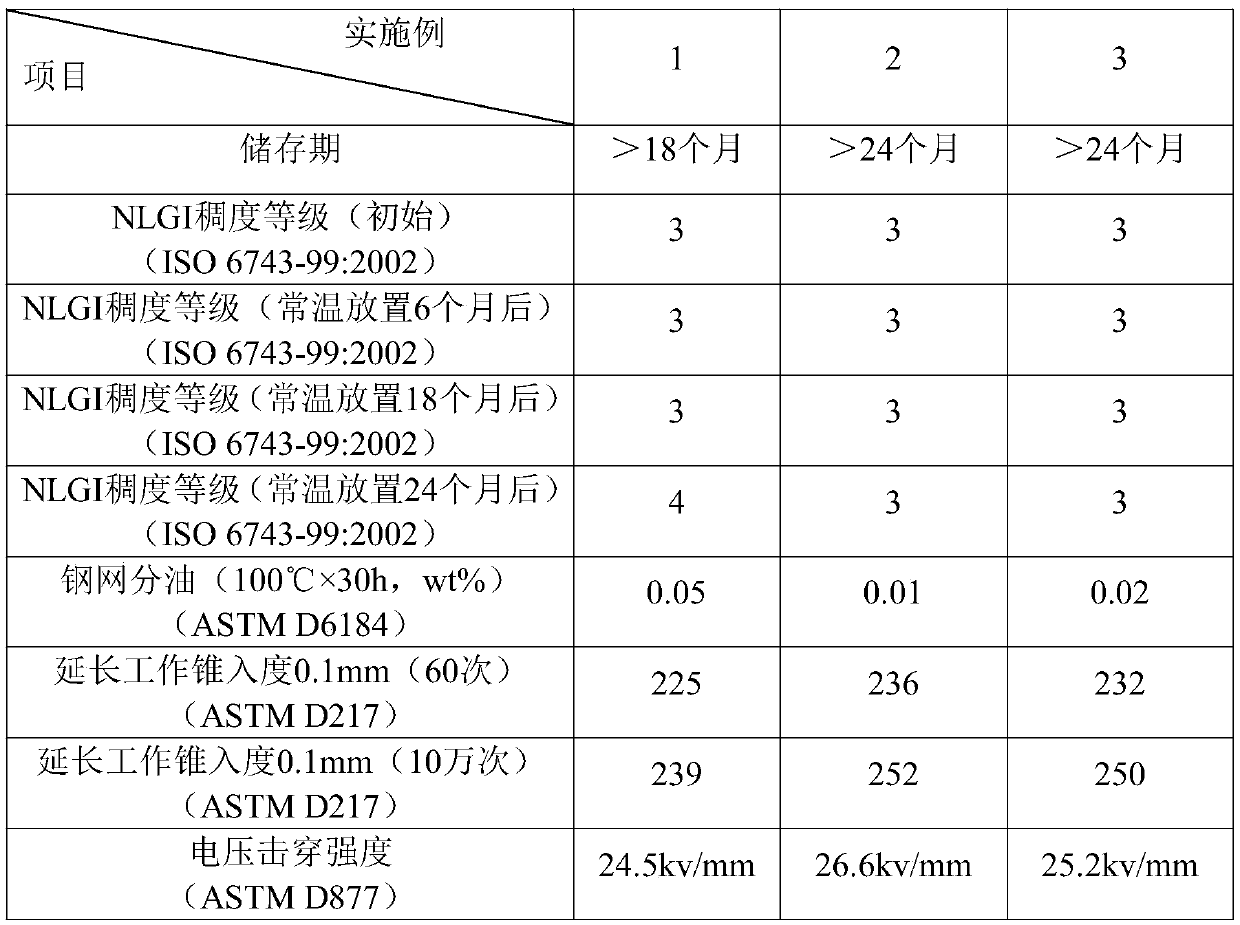

High-performance insulation lubricating grease and preparation method thereof

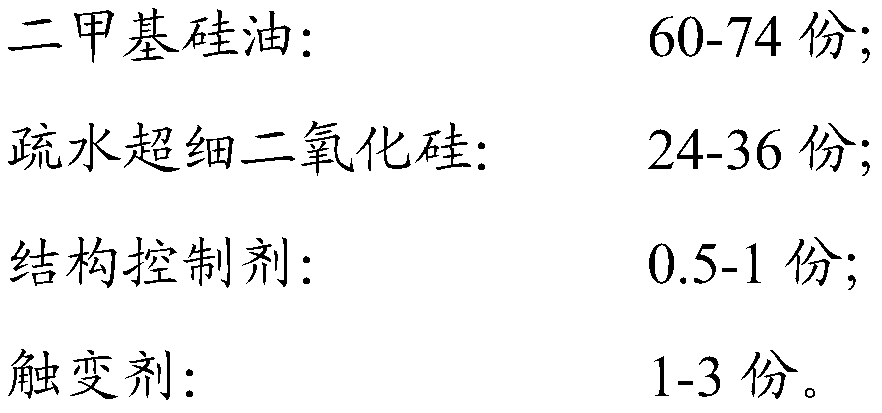

ActiveCN109797027AEasy to removeImprove insulation performanceLubricant compositionEngineeringColloid

The invention discloses a high-performance insulation lubricating grease and a preparation method thereof. The high-performance insulation lubricating grease comprises, by weight, 60-74 parts of silicone oil, 24-36 parts of hydrophobic ultra-fine silica, 0.5-1 part of a constitution controller and 1-3 parts of a thixotropic agent. The preparation comprises the steps that the silicone oil and the hydrophobic ultra-fine silica are mixed and processed at a low temperature in a kneader, high-temperature vacuum processing is conducted, the constitution controller and the thixotropic agent are addedafter the temperature is decreased, and the high-performance insulation lubricating oil is obtained after the mixture is ground by a three-roller grinding machine. The prepared high-performance insulation lubricating grease has the advantages that the storage period is 18 months or above, the lubricating grease does not thin, bleed and structuralize, and the colloidal stability and shearing stability are excellent.

Owner:东莞市港田高分子材料有限公司

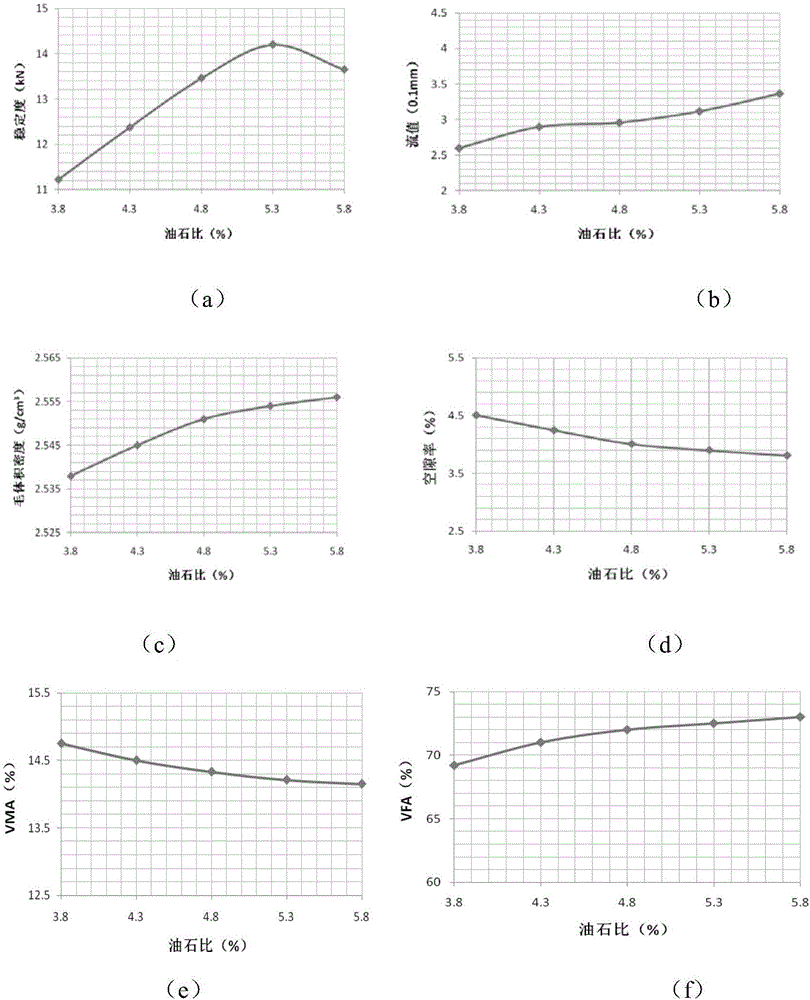

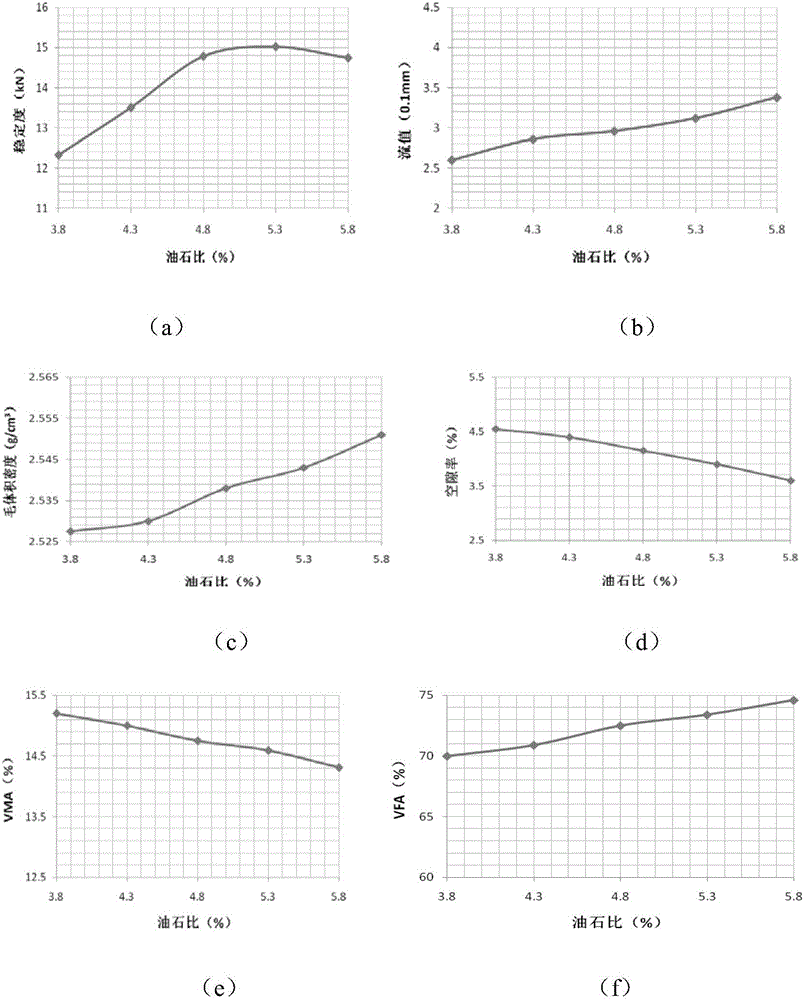

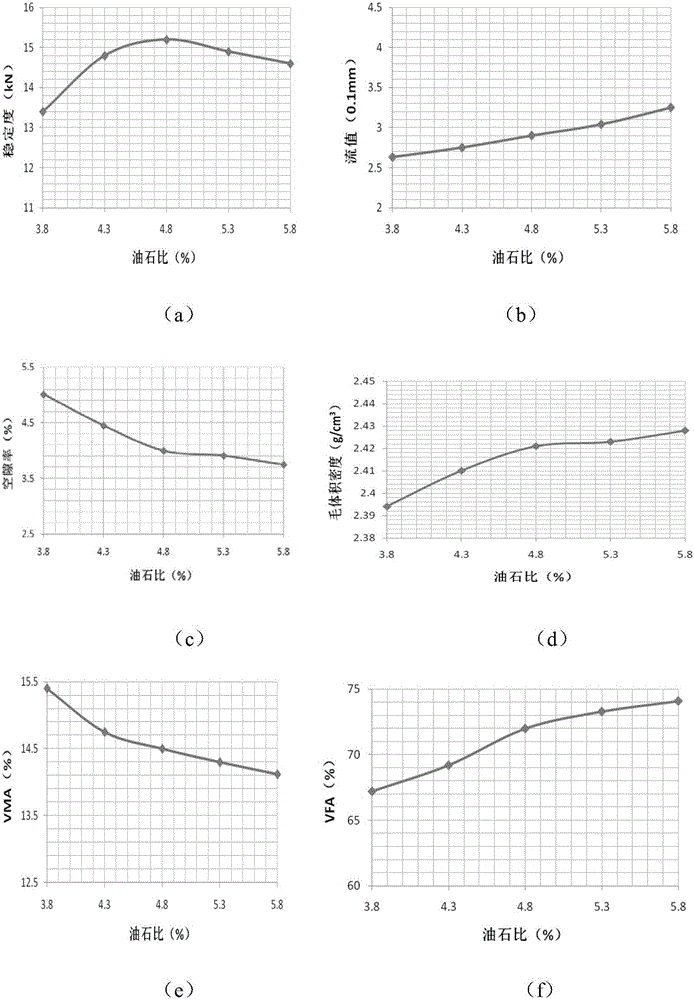

CPC-AC composite pavement fiber asphalt mixture and preparation method thereof

The invention discloses a road pavement construction material and a mineral aggregate grading design method thereof, and particularly relates to a CPC-AC composite pavement fiber asphalt mixture and a mineral aggregate grading design method based on shear resistance. The mixture is prepared from, by weight, 100 parts of mineral aggregates, 3-6 parts of asphalt and 0-0.3 part of fiber which is glass fiber, the grading design method is a multi-stage interlocking method and a vibration compaction method, the grading types of the mineral aggregates are multi-stage interlocking AC-13 and AC-16 types and vibration compaction AC-13 and AC-16 types. The fiber asphalt mixture fully utilizes the excellent characteristics of the glass fiber, the shear resistance and permeation resistance capacity under dynamic water pressure of an asphalt concrete surface course can be effectively improved, the multi-stage interlocking method and the vibration compaction method are adopted for comparing and designing mineral aggregates, and the special requirements of a composite pavement on the shear resistance of the asphalt mixture are fully met.

Owner:CHANGAN UNIV

Cement-based polystyrene material and insulation board production process based thereon

InactiveCN104119046AMeet fire resistance requirementsImprove fire resistancePolymer scienceThermal insulation

The invention discloses a cement-based polystyrene material, which comprises the following components: (1) according to a dry powder ratio (by mass percentage): 65-85 of portland cement; 10-25 of fly ash; 0.15-0.25 of polypropylene fiber; 0.2-0.4 of a concrete admixture; and 0.15-0.25 of an emulsion; and (2) the volume ratio of the dry powder to expanded polystyrene particles being 1:4-1:6. The production process for preparation of a composite insulation board based on the cement-based polystyrene material includes the steps of proportioning, stirring, molding transportation, curing and molding packaging, and a final product can be obtained thereby. The composite insulation board obtained on the basis of the formula and the preparation process has the advantages of high fire resistance, high thermal insulation, high strength, light weight, high bonding strength, and no toxicity or harm, etc.

Owner:江苏省苏安能节能建材科技有限公司

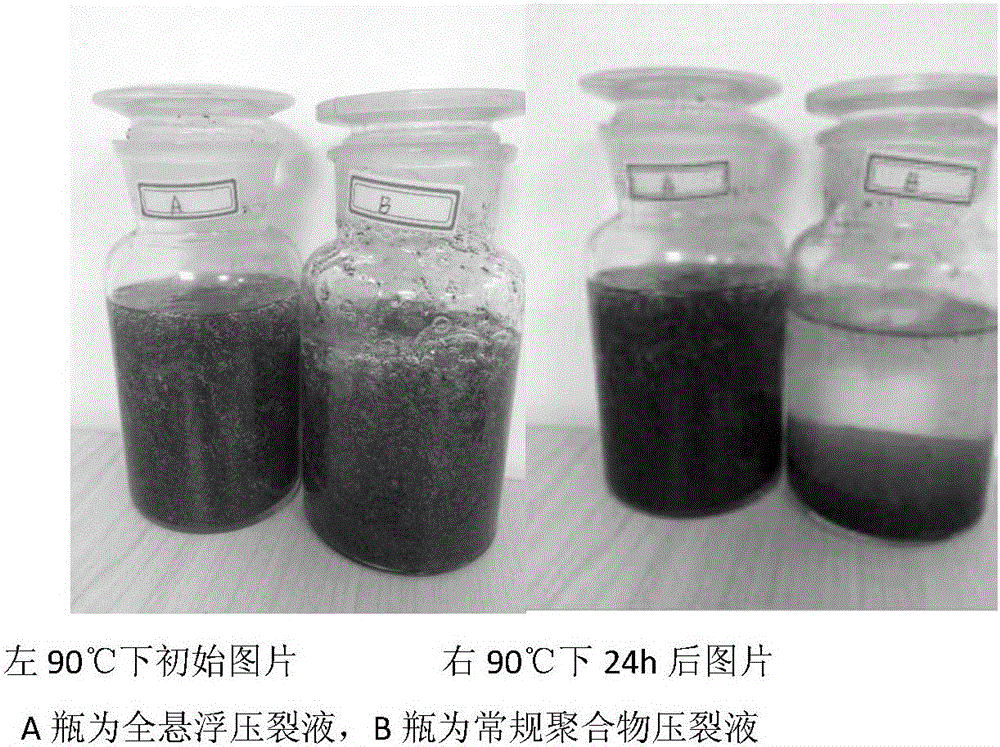

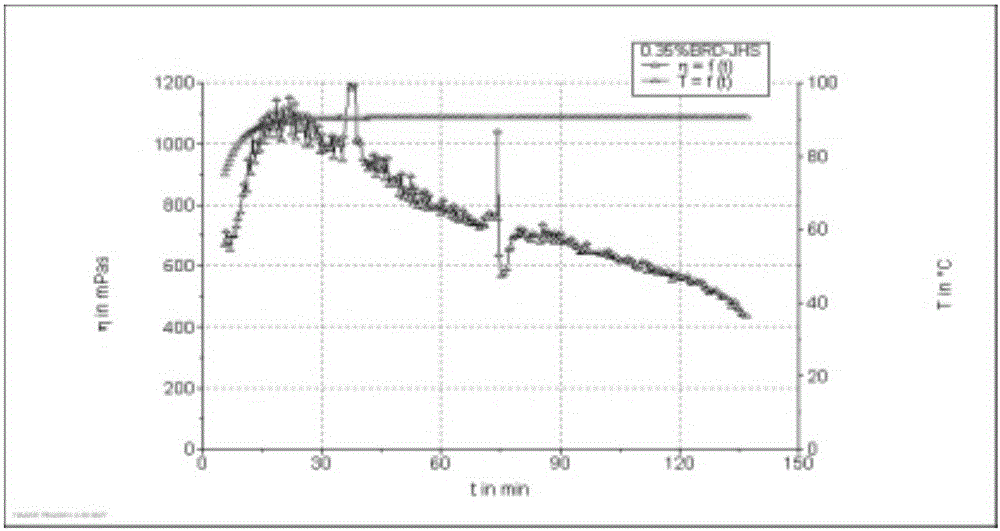

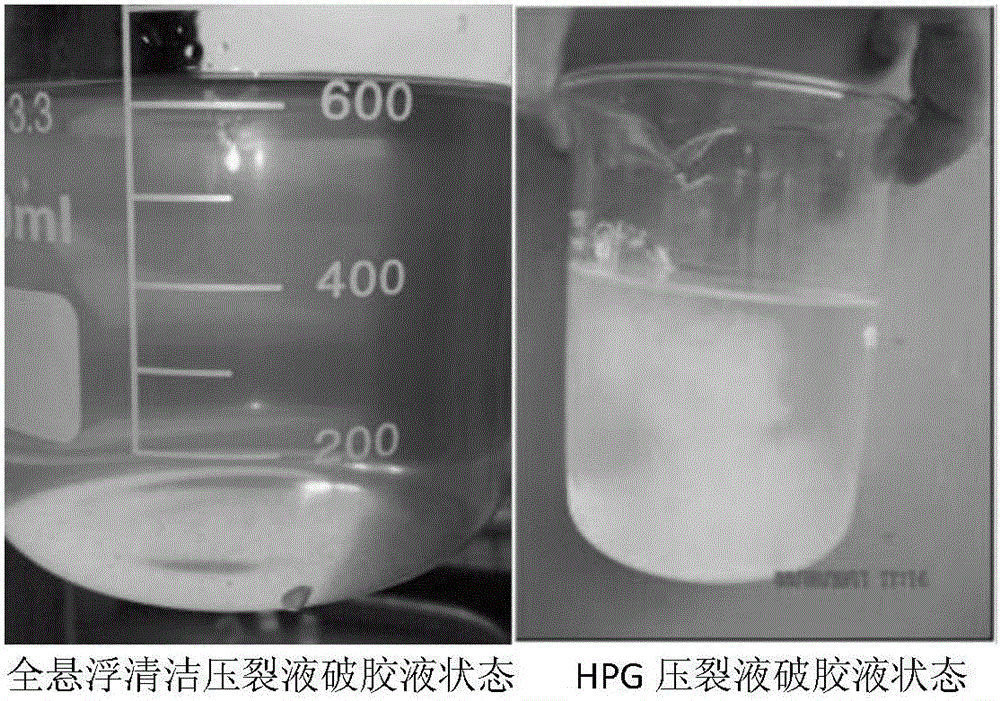

Full-suspension cleaning polymer fracturing fluid and preparation method thereof

InactiveCN105778883AHigh viscosityLiquid performance does not degradeFluid removalDrilling compositionCompound aCross-link

The invention discloses full-suspension cleaning polymer fracturing fluid and a preparation method thereof. The fracturing fluid is prepared from the following components in percentage by weight: polyacrylamide polymers, a cross-linking agent A, a cross-linking agent B, a proppant, an anti-swelling agent, a cleanup additive, a gel breaker and water, and the pH value is 5-7. The preparation method comprises the following steps: compounding a polymer solution of which the concentration is 0.2-0.5%, adding 0.1-0.4% of the cleanup additive, adding the cross-linking agent A and the cross-linking agent B, and performing uniform stirring. The fracturing fluid disclosed by the invention can be widely applied to sand fracturing of various oil and gas wells, and mainly aims to solve the problems that the sand settling speed of the conventional fracturing fluid system under a high temperature and dynamic shear state is high and the proppant is difficult to transport; compared with the conventional fracturing fluid system, the fracturing fluid system has the most significant characteristic that under the condition of simulated formation temperature and dynamic shear, the sedimentation speed of the proppant is basically zero, so that the dosage of the proppant and the dosage of liquid can be greatly reduced, the spreading profile of the proppant is improved, the effective fracture length is increased, and the oil and gas production is increased.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

Reinforced concrete laminated slab

InactiveCN102635184AStrengthen connectionImprove shear performanceFloorsBuilding reinforcementsRebarReinforced concrete

The invention discloses a reinforced concrete laminated slab consisting of plate bottom steel bars, bent-up steel bars, limiting stoppers and a prefabrication layer. The reinforced-concrete laminated slab is characterized in that each limiting stopper is I-shaped and consists of an upper limiting surface, a lower limiting surface and a connector between the upper and lower limiting surfaces, the lower limiting surfaces of the limiting stoppers are positioned in the prefabrication layer, and the half parts of the bent-up steel bars are arranged in the prefabrication layer. As the laminated slab fully utilizes the functions of materials, the common stress on an adjoining face between the prefabrication layer and a cast-in-situ layer of the laminated slab is ensured, and the shearing performance of the part of the laminated slab, close to a support, is improved.

Owner:CHINA MCC17 GRP

Method for preparing duplex metal composite material through solid-liquid compounding and drawing combination of solid steel

InactiveCN105537859AImprove physical and mechanical propertiesImprove shear performanceExtrusion control devicesGas protectionZinc

The invention discloses a method for preparing a duplex metal composite material through solid-liquid compounding and drawing combination of solid steel. The method includes the steps that a duplex metal drawing blank is prepared through solid-liquid composite casting; and the duplex metal composite material is prepared through drawing. The method is characterized in that a process method of solid-liquid connection after protection of a surface zinc layer is used, a series of problems that air holes, burnthrough, too-thick intermediate compound layers and the like are prone to occurrence when steel and other materials are connected in a traditional welding method are solved, and the problem that the lower surface of the steel at a high temperature is prone to forming an oxidation film so that metallurgical bonding between the steel and the other materials can be blocked is solved; and then molding in a drawing method is carried out, intermediate compounds formed on an interface in the solid-liquid compounding process are crushed, and therefore the mechanical property and the physical property of the duplex metal composite material and a base material are improved. According to the method, gas protection is not needed, the composite technology is simple, the process condition is wide, operation is easy, the requirement for process equipment is simple, the interface bonding intensity is high, and the electric conduction property and the heat-conducting property are good.

Owner:SHANGHAI JIAO TONG UNIV

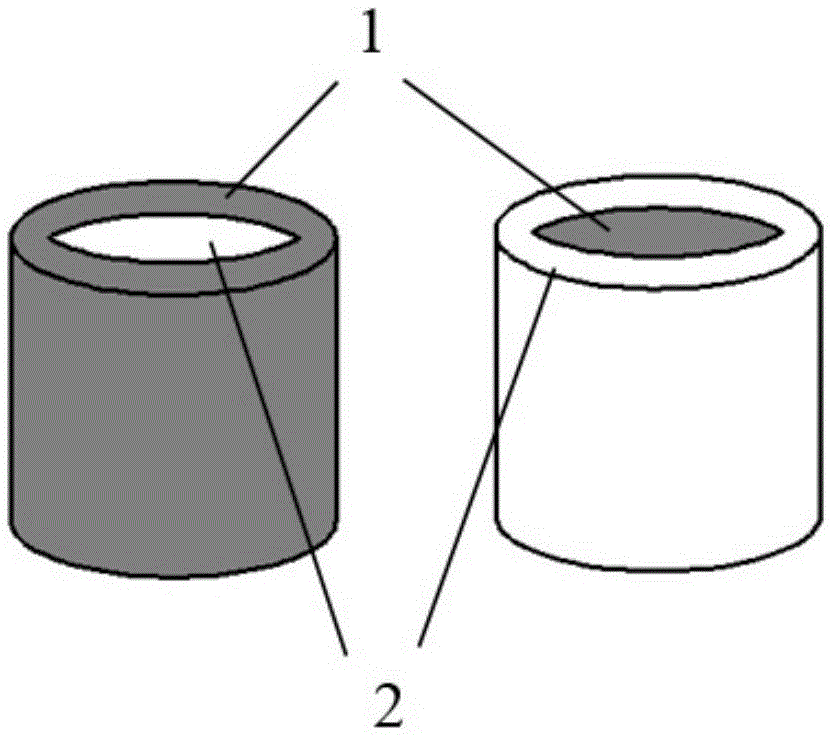

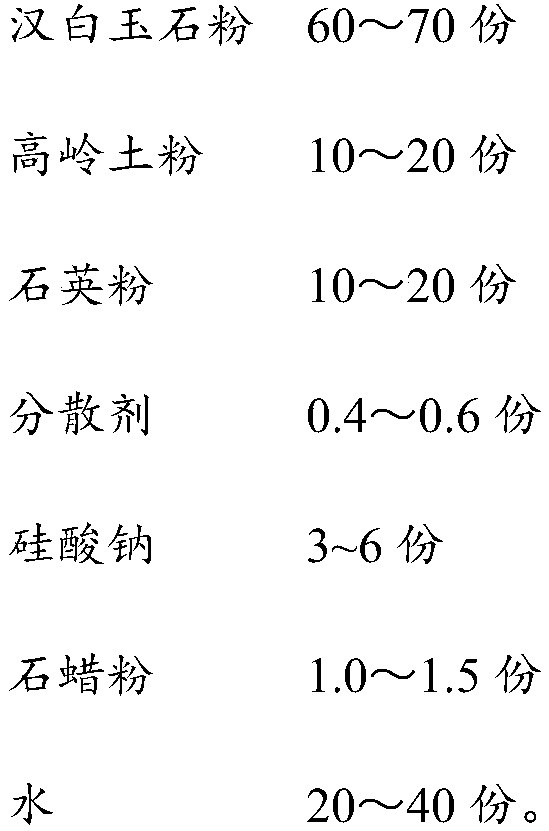

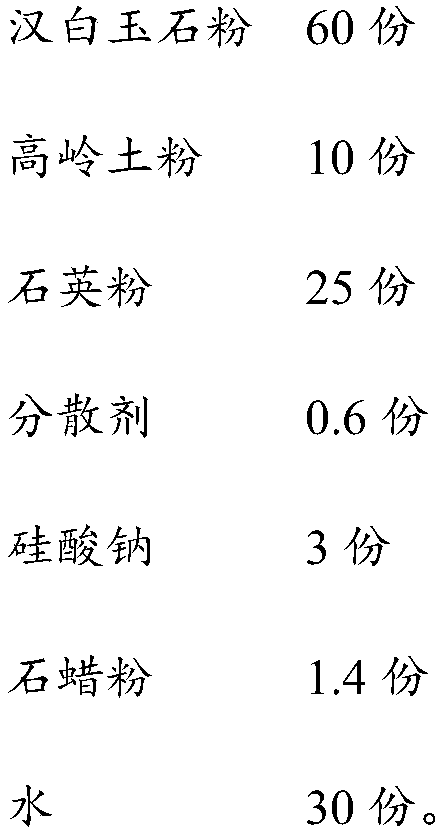

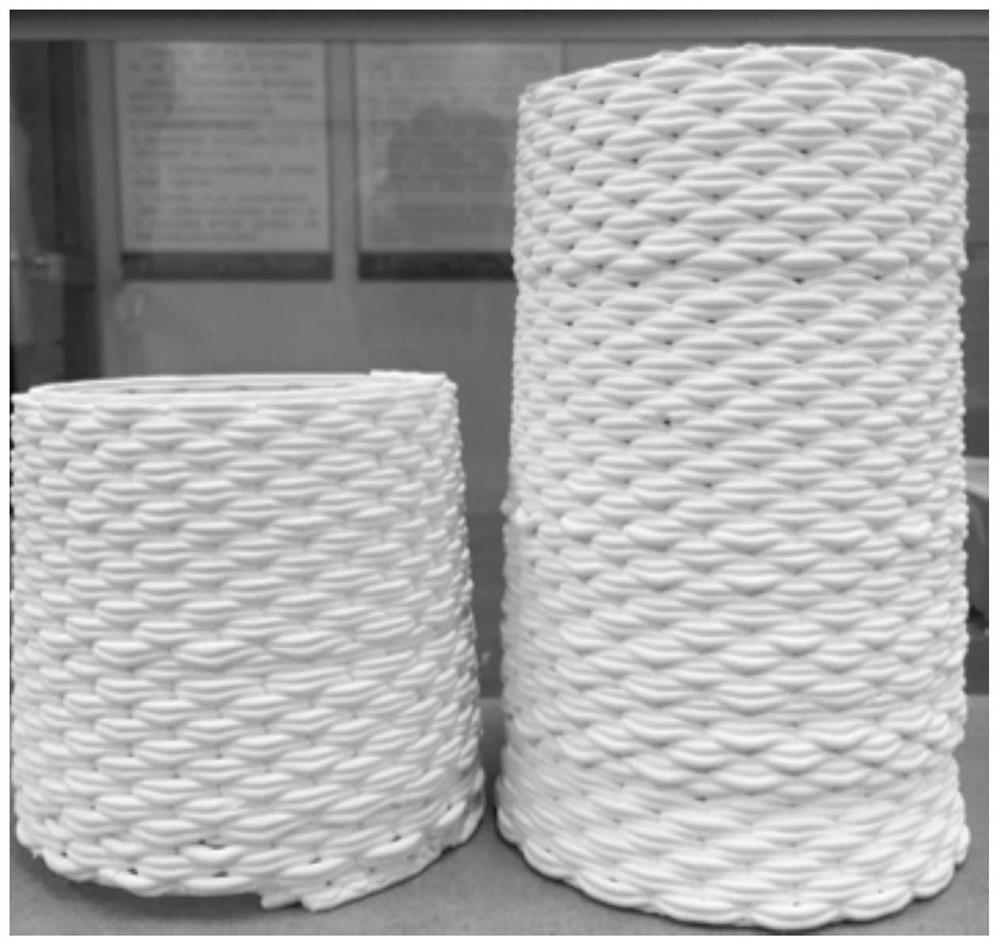

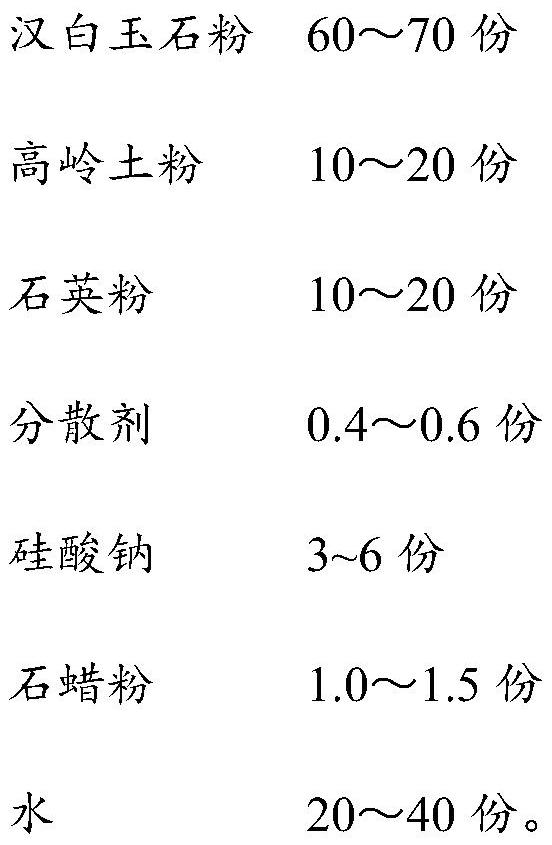

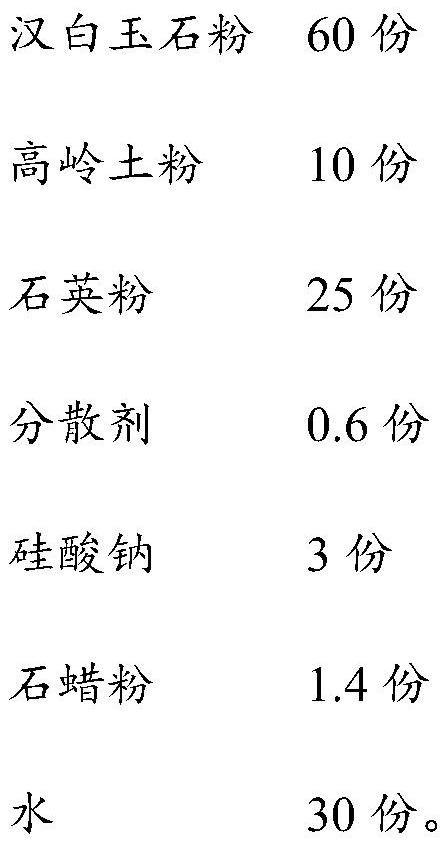

Slurry used for extrusion type 3D white marble powder printing and preparation method thereof

ActiveCN109534767AMeet the needs of extrusion 3D printingImprove shear performanceAdditive manufacturing apparatusRoom temperatureSlurry

Slurry used for extrusion type 3D white marble powder printing and a preparation method thereof are disclosed. The slurry has a high solid content and good shearing performance, and is suitable for anextrusion type 3D printing process. At room temperature, the slurry is gradually dried and cured in a 3D printing process, thereby obtaining a molded part of higher precision without collapsing.

Owner:HUAQIAO UNIVERSITY

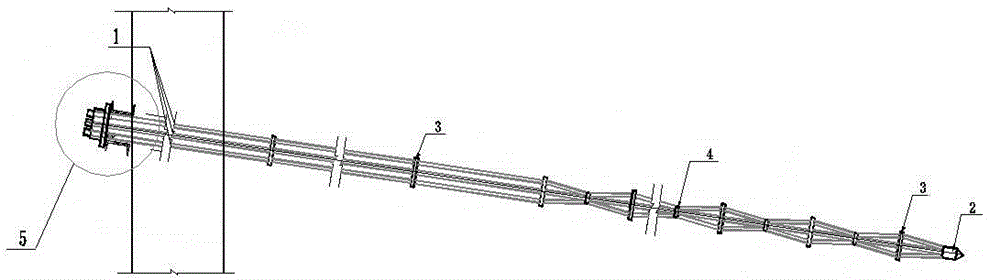

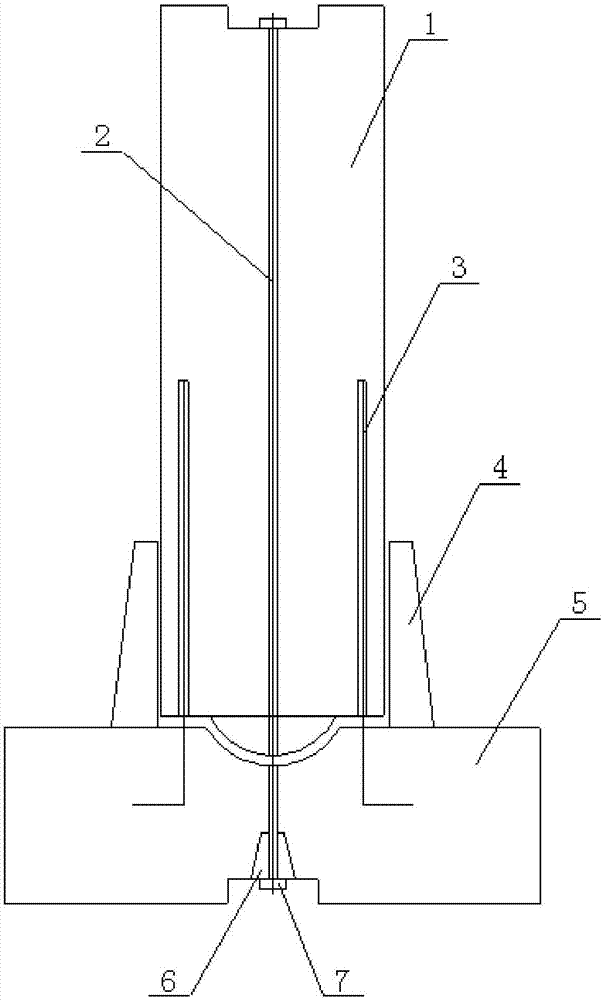

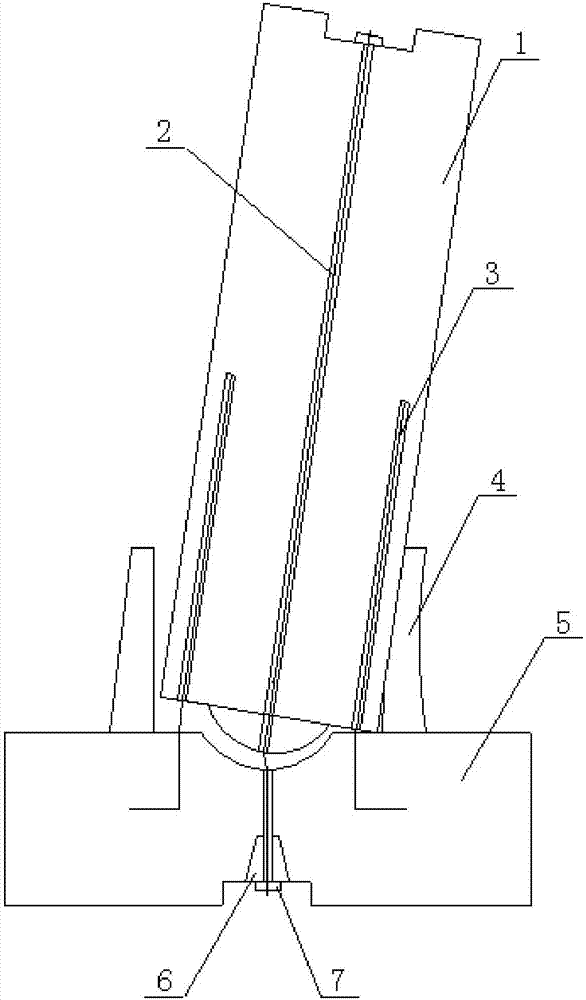

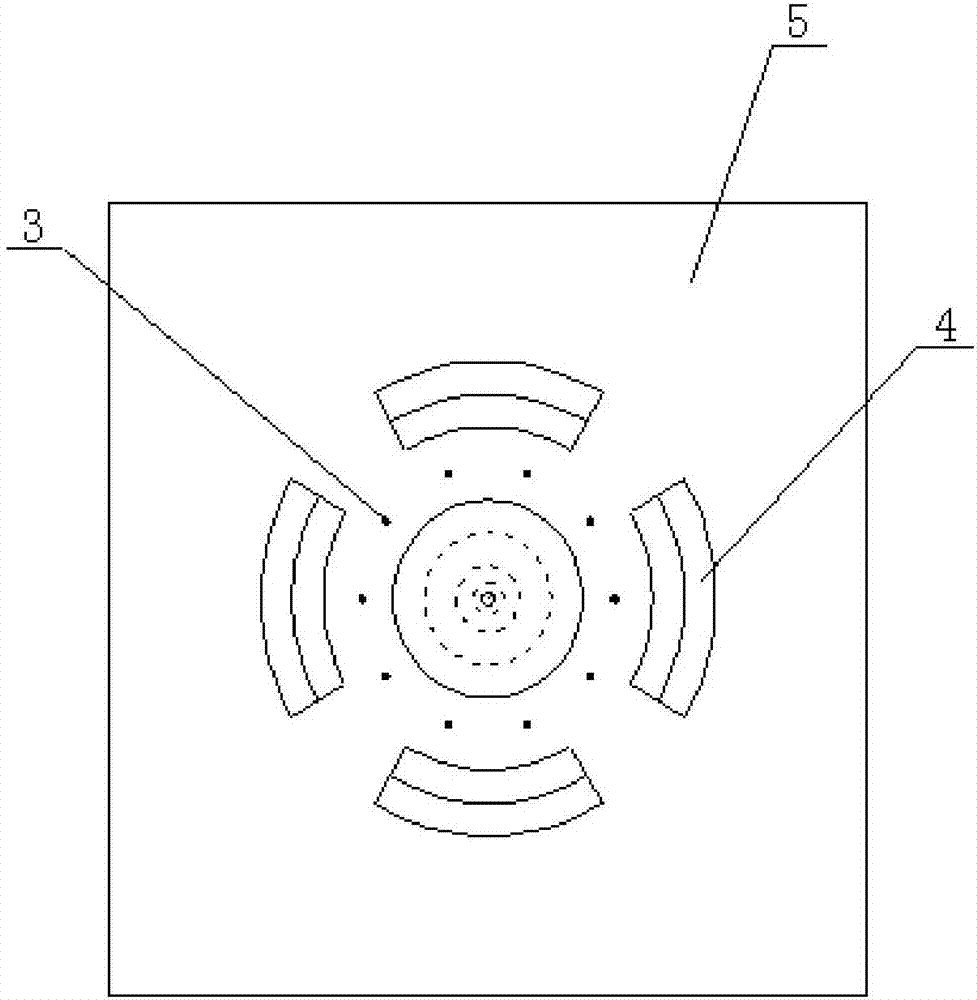

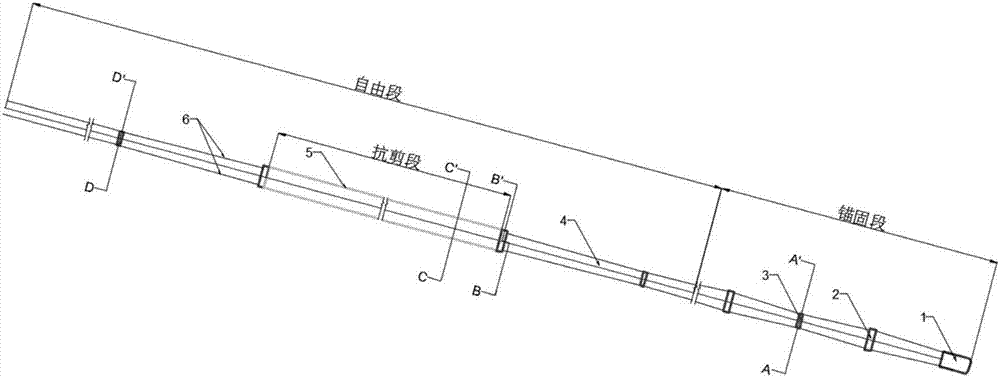

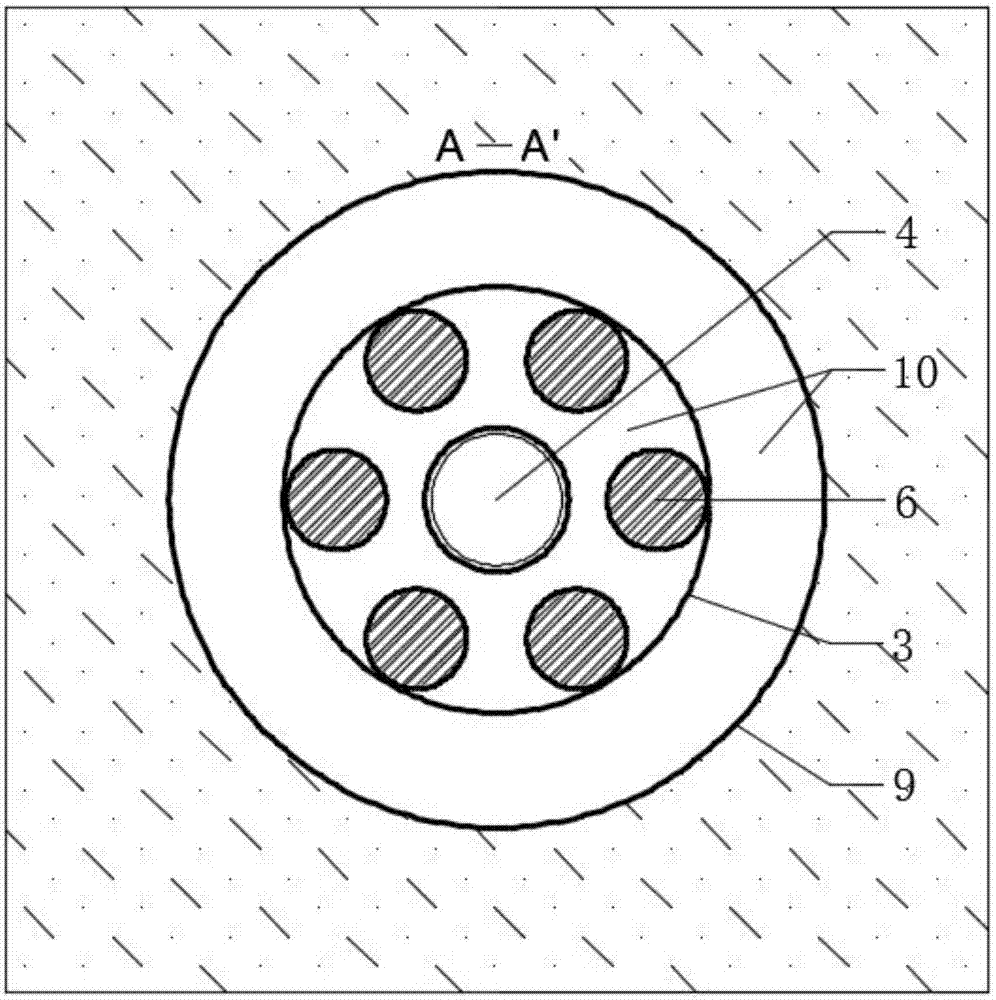

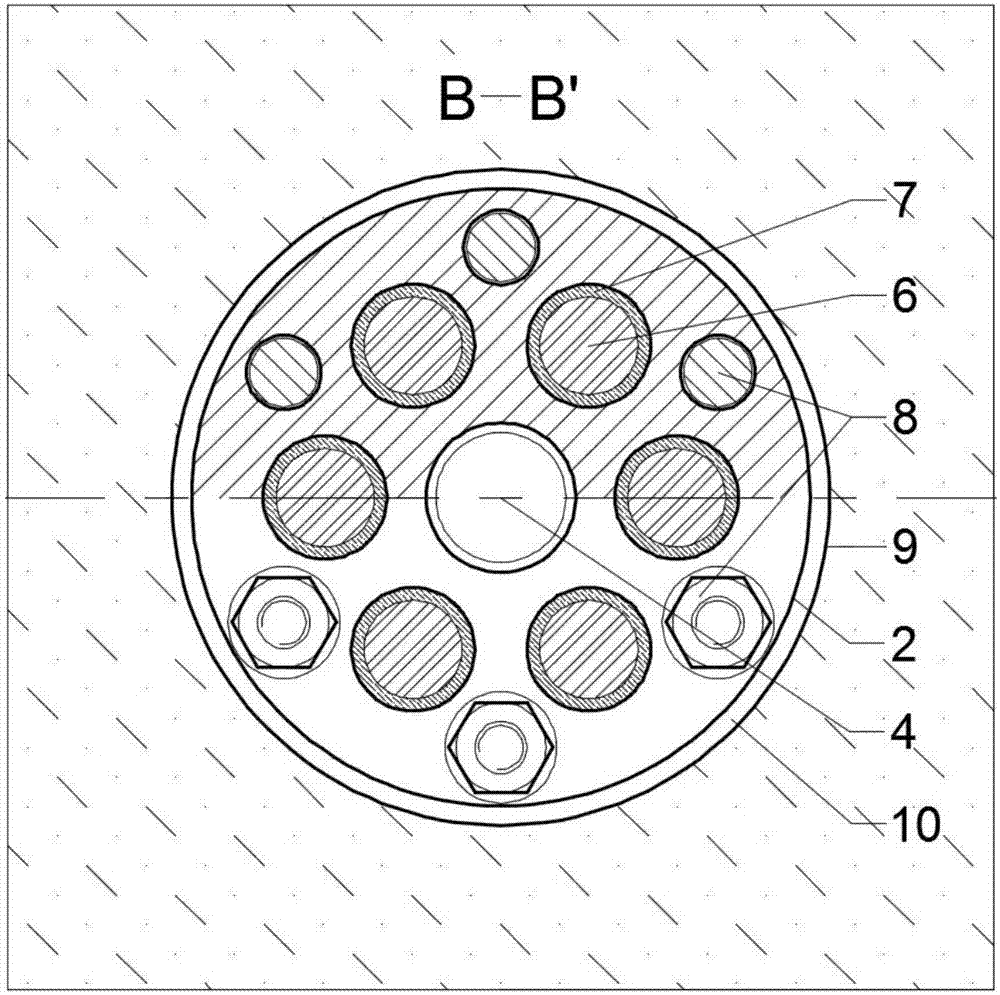

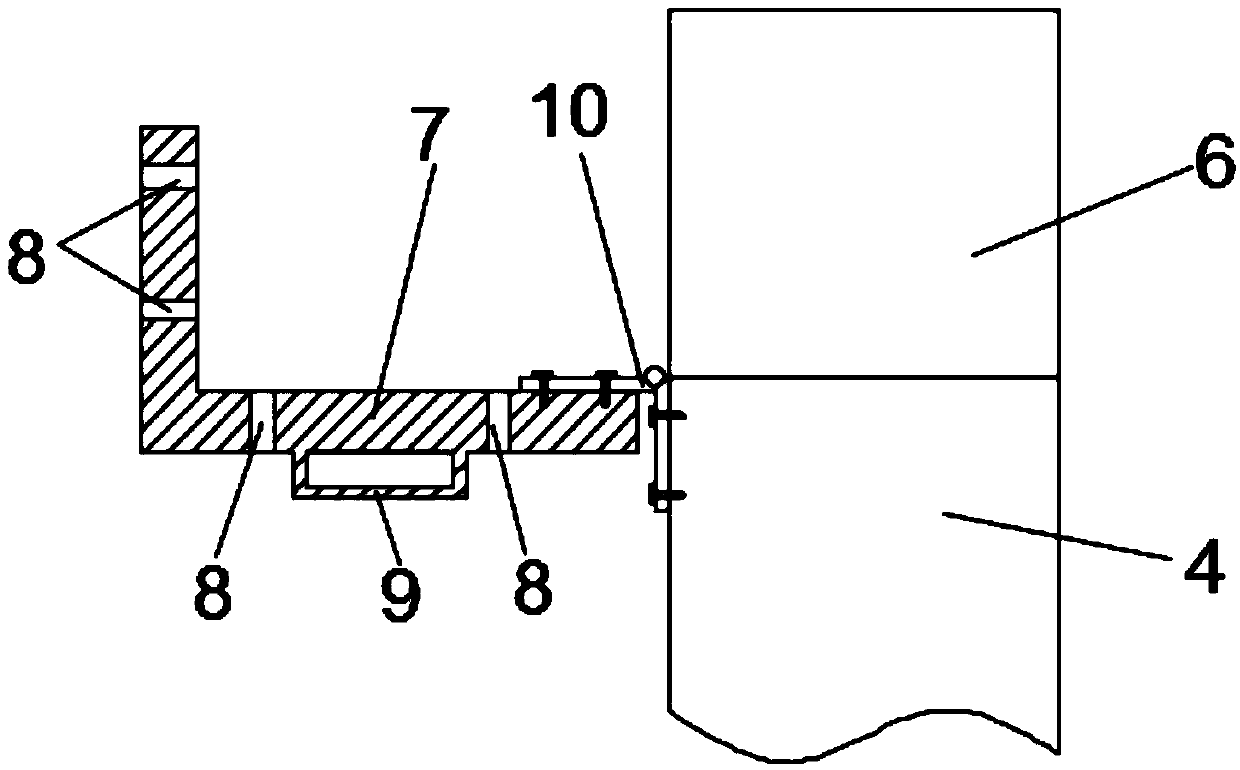

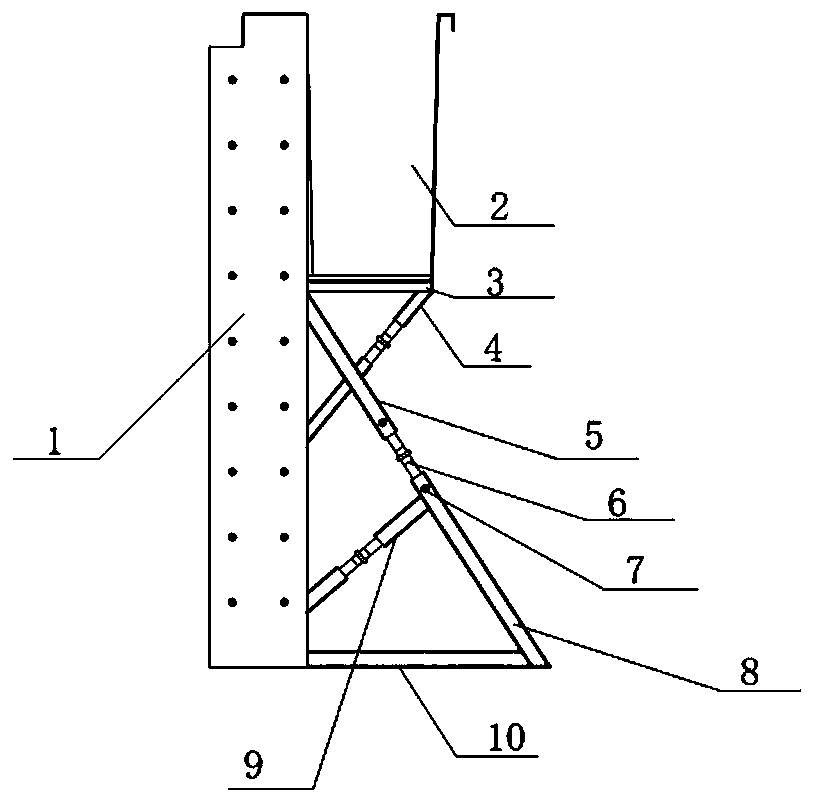

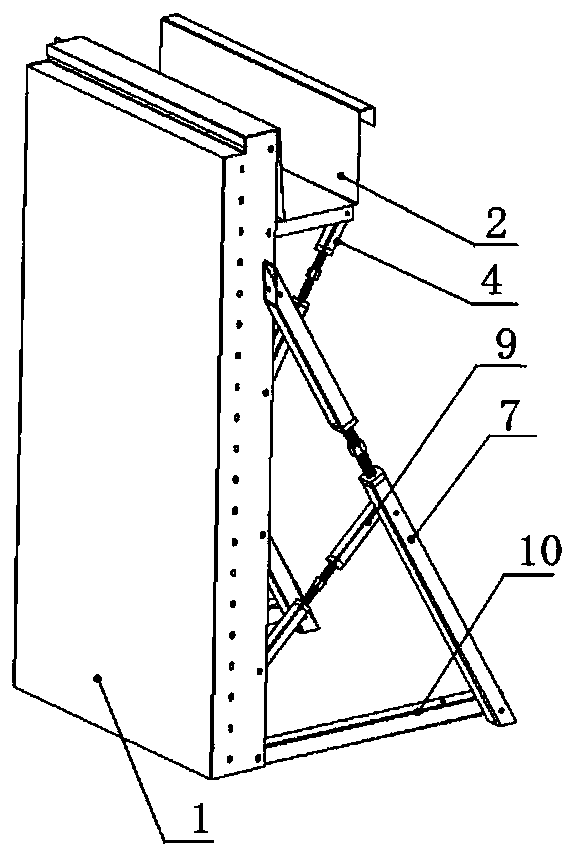

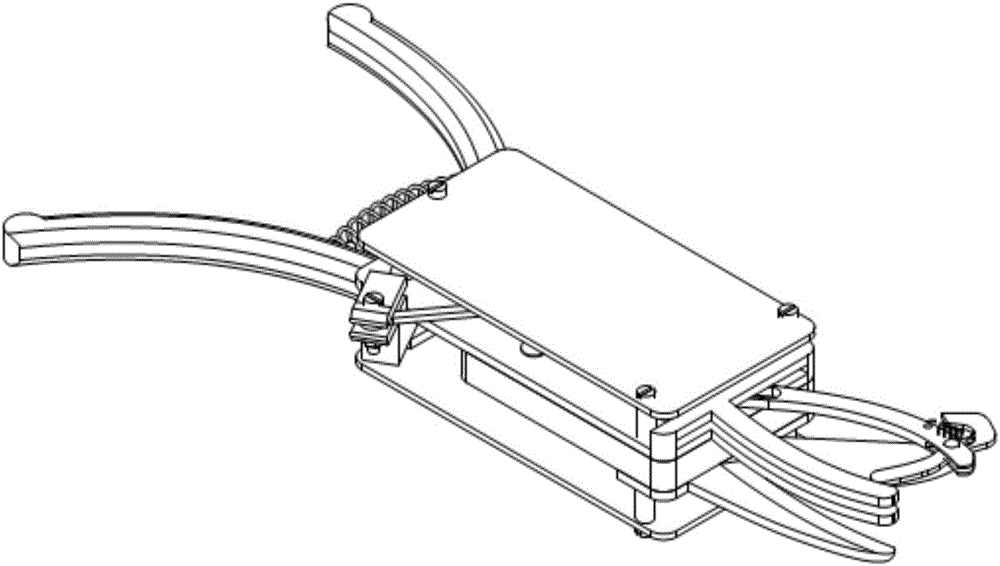

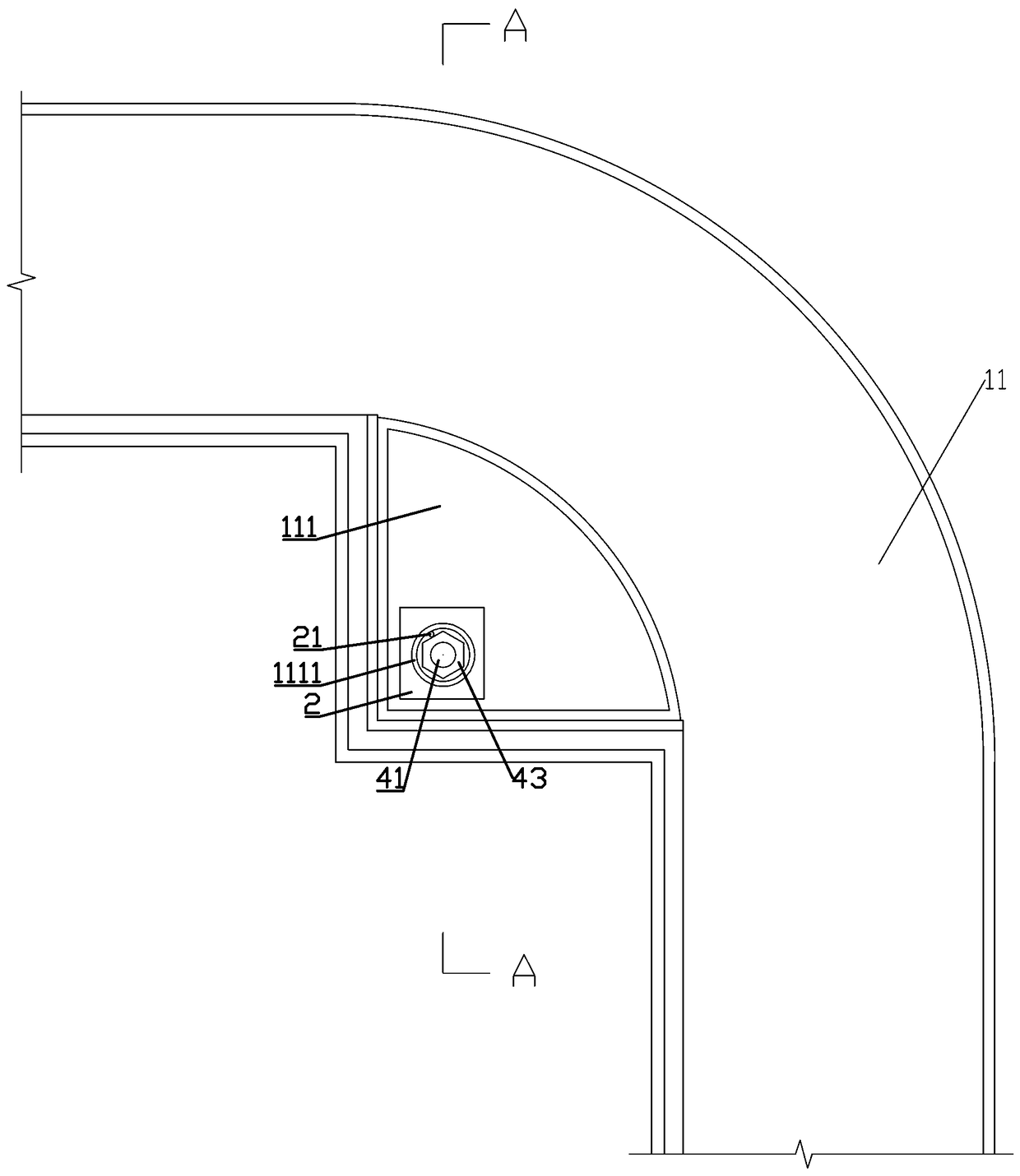

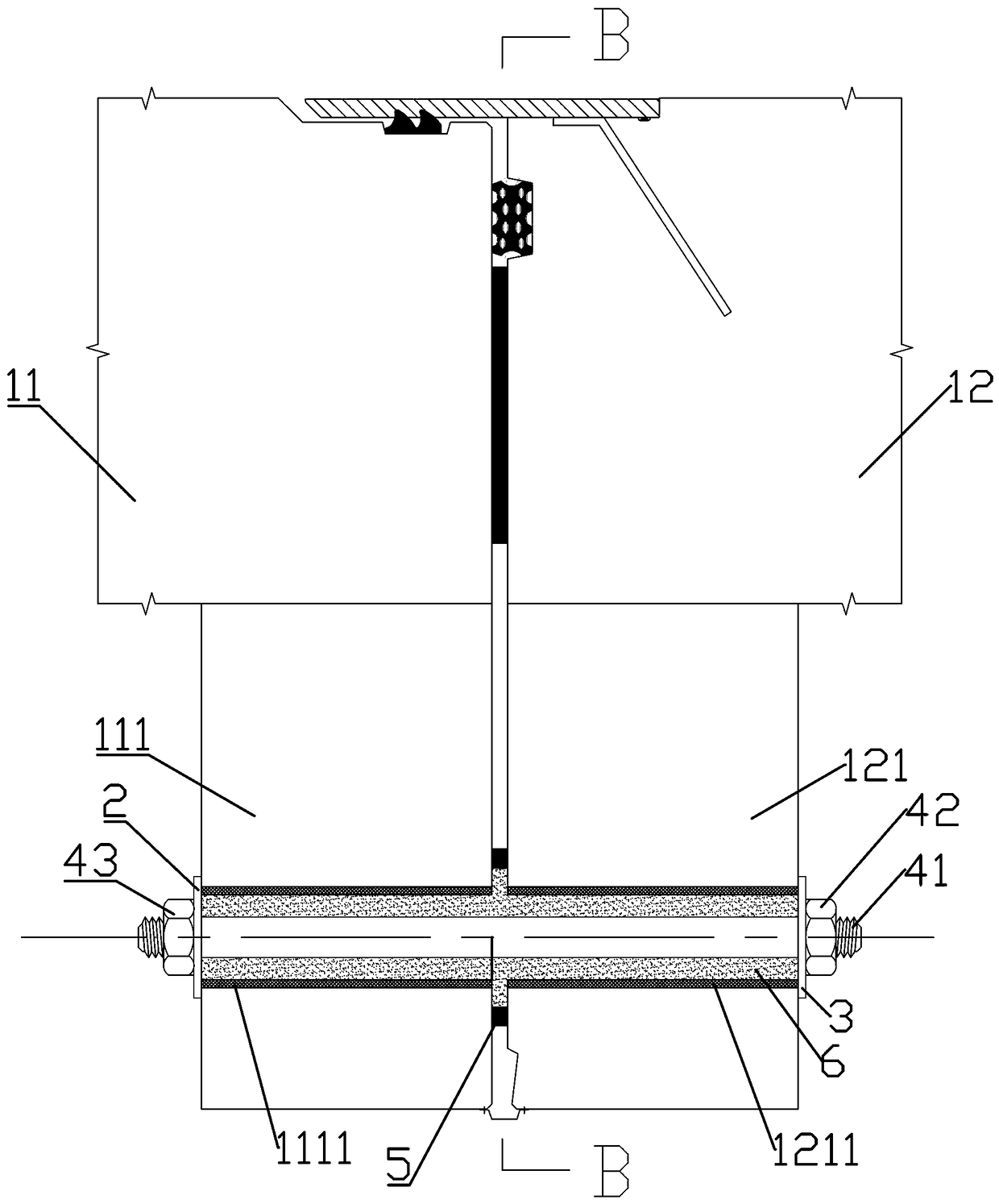

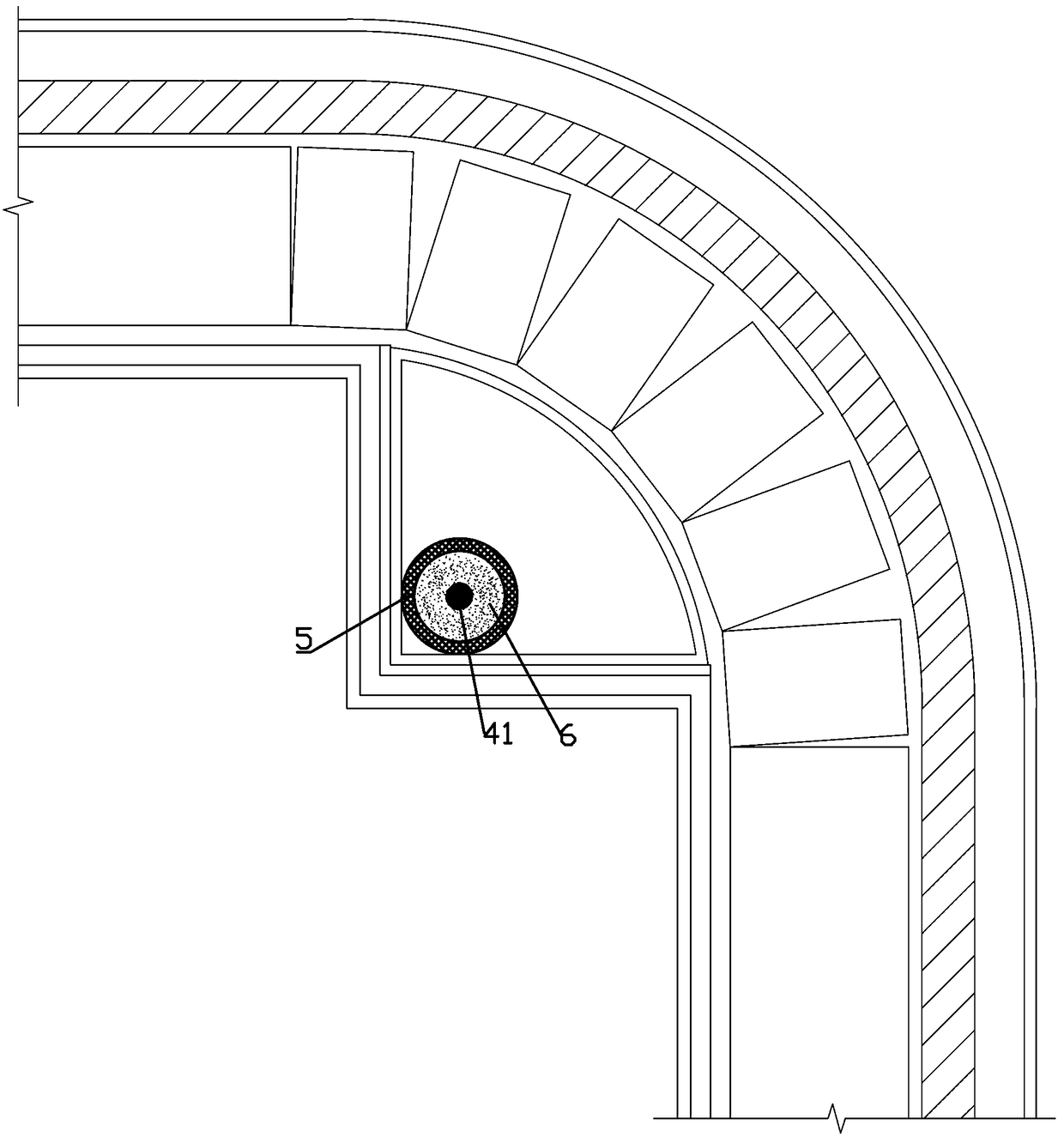

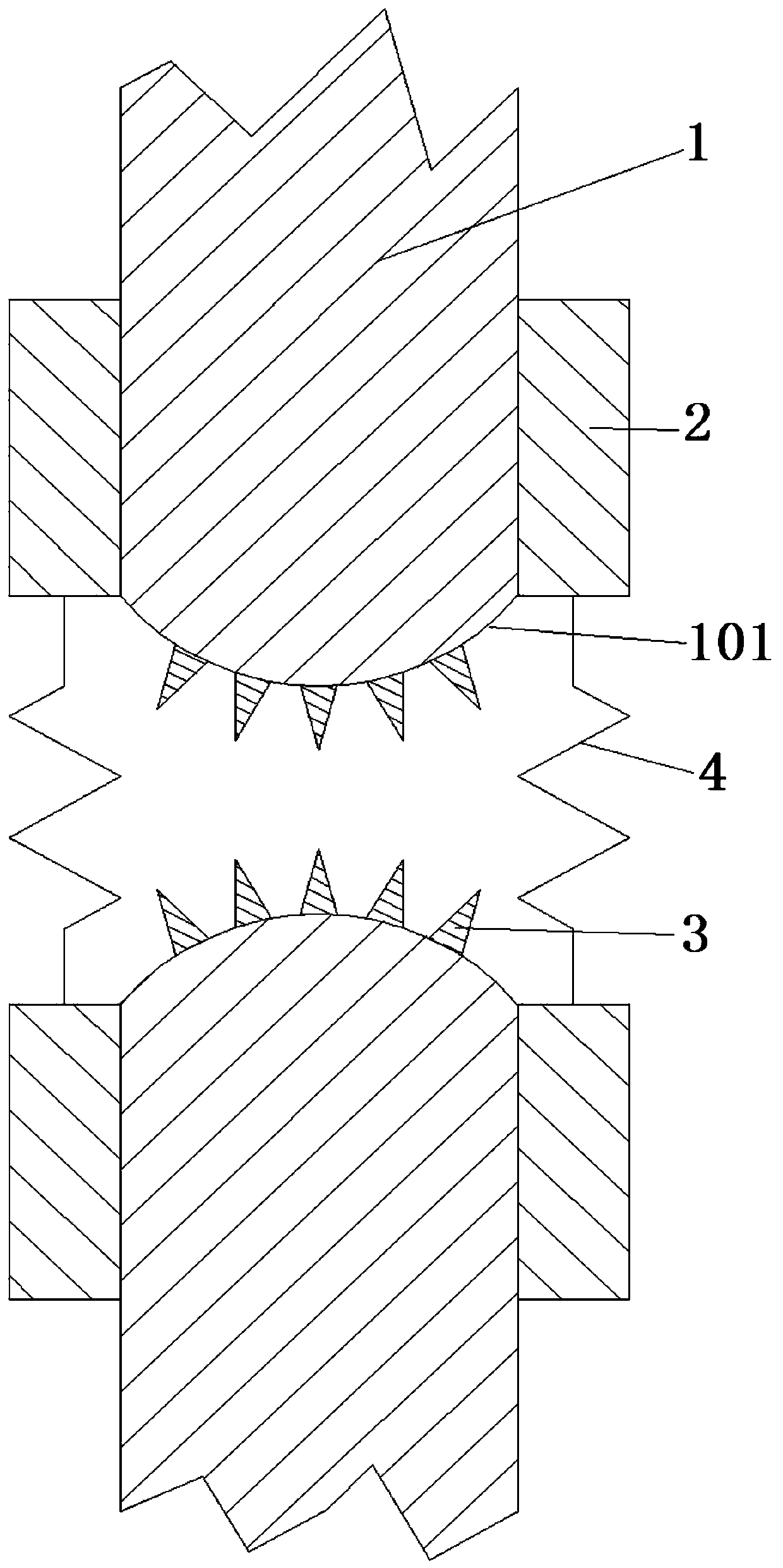

Compound prestressed anchor cable capable of improving anti-shear performance of anchorage structure

InactiveCN106917407AImprove shear performanceOvercoming anchor cable failureExcavationsBulkheads/pilesPre stressShear capacity

The invention provides a compound prestressed anchor cable capable of improving anti-shear performance of an anchorage structure, and belongs to the technical field of rock mass reinforcing. The anchor cable comprises a guiding cap, steel strands, a tensioner ring, a tightening ring, a sleeve and a grouting pipe; the sleeve is arranged nearby a sliding face or a potential sliding face, thus, the anti-shear effect of the anchorage structure can be effectively improved, and the defect that deformation is severe and even a slope is instable and is damaged due to the fact that a traditional prestressed anchor cable is short of the anti-shear capacity is overcome. Compared with the traditional prestressed anchor cable, according to the compound prestressed anchor cable, the arrangement distance between anchor cables can be increased, and meanwhile, the number of the anchor cables is decreased, so that related materials, time and fund investment are saved. The compound prestressed anchor cable capable of improving the anti-shear performance of the anchorage structure has the prominent advantages that the process is simple, operability is high, resources are saved, and the position of the anti-shear structure is controllable.

Owner:UNIV OF SCI & TECH BEIJING +1

Anti-seepage shear wall

InactiveCN105952029AImprove the decorative effectStable structureCovering/liningsWallsSurface layerSteel bar

The invention discloses an anti-seepage shear wall. The anti-seepage shear wall comprises a wall surface structure, the outer side of the wall surface structure is provided with a decorative surface layer which is connected with the wall surface structure through detachable structures, and the inner side of the wall surface structure is provided with a shear structure; the outer side of the shear structure is connected to the wall surface structure in a sealing mode, the inner side of the shear structure is connected with a reinforcing board which is connected with the shear structure through a built-in fixing part, the inner side of the reinforcing board is provided with an anti-seepage material layer which is connected to the reinforcing board in a sealing mode, and reinforcing steel bar holes are formed in the reinforcing board and are horizontally formed. According to the anti-seepage shear wall, the decorative effect is good, the self structure is firm, deformation is not prone to generate, the decorative surface layer is convenient to replace, the good shear resistance is achieved, the anti-seepage capacity is high, the replacement and maintenance frequency is decreased, and the service life of the shear wall is greatly prolonged.

Owner:CHENGDU XUNDE SCI & TECH

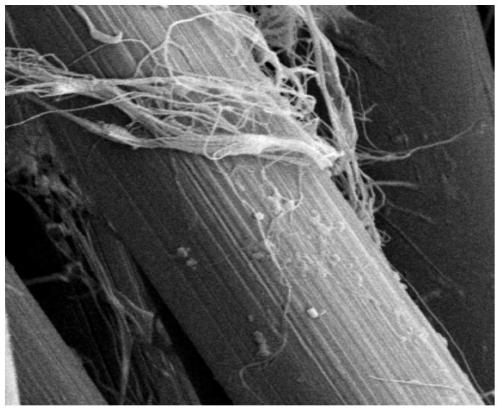

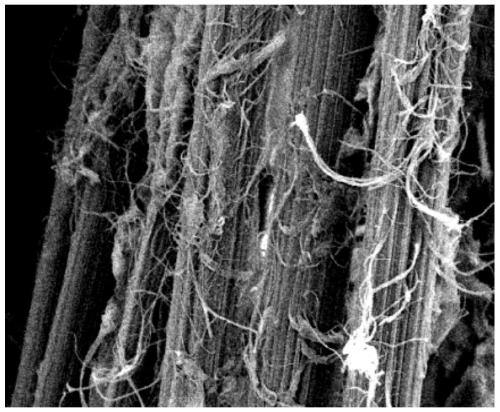

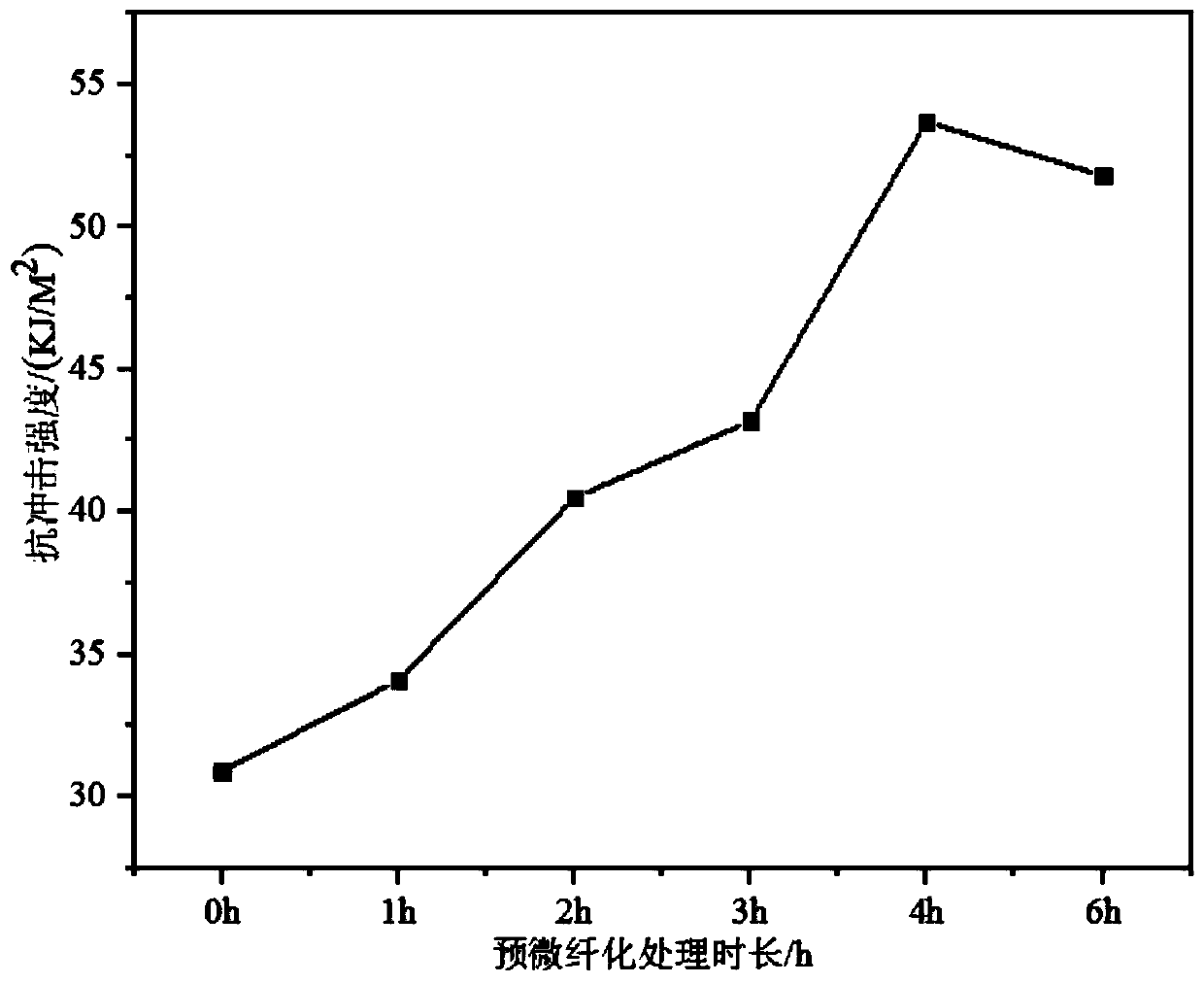

Preparation method of microfibrillated fiber reinforced composite material

InactiveCN111533930AImprove interface adhesionImprove interface performanceResin matrixFiber-reinforced composite

The invention discloses a preparation method of a microfibrillated fiber reinforced composite material, belongs to the field of material preparation, and aims to solve the problems of weak shearing performance and impact resistance of the existing fiber reinforced polymer matrix composite material. The method comprises the following steps: 1, cleaning and drying fibers; 2, swelling the fibers anddimethyl sulfoxide, and drying to obtain microfibrillated fibers; and 3, dipping the microfibrillated fibers into resin for ultrasonic treatment, taking out the microfibrillated fibers, and curing themicrofibrillated fibers by using a mixture of resin and a curing agent. The fibers are subjected to microfibrillating treatment so that the microscopic surface area of the fibers is increased, and the resin impregnation efficiency is improved; the interface adhesive force of the fiber and the resin matrix is effectively improved, and the interface performance is improved; the prepared composite material is uniform in matrix, high in density, more excellent in shearing performance and excellent in impact resistance. The method is applied to the field of fiber reinforced composite material preparation.

Owner:HARBIN INST OF TECH

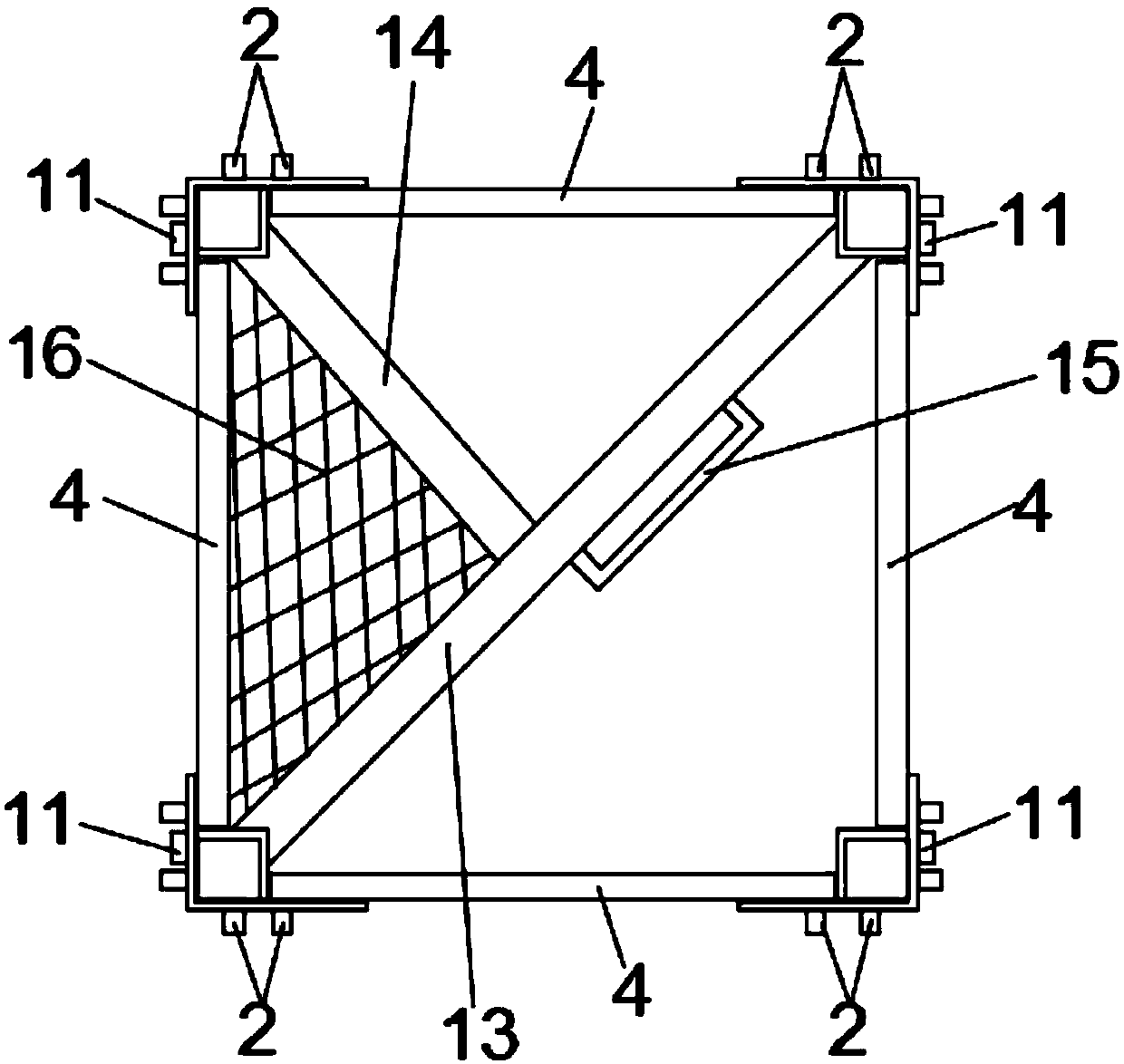

Tower crane standard joint high in shear resistance

The invention discloses a tower crane standard joint high in shear resistance. The tower crane standard joint comprises four main chord members, a plurality of steps are fixedly arranged on the main chord members, the upper ends of the four main chord members are fixedly connected through four upper-layer cross beams, the middle portions of the four main chord members are fixedly connected throughfour middle-layer cross beams, and the lower ends of the four main chord members are fixedly connected through four lower-layer cross beams. Upper connecting sleeves and lower connecting sleeves arefixedly arranged at the upper ends and the lower ends of the main chord members respectively. Buckling plates are hinged to the inner sides of the four upper-layer cross beams, buckling grooves buckled to the lower-layer cross beams are formed in the buckling plates, and positioning holes which correspond to one another are formed in the buckling plates and the lower-layer cross beams. Pin shaftsor positioning bolts are inserted into the positioning holes so that the buckling plates and the lower-layer cross beams can be fixed. Through the use of the buckling plates, the inclined pulling force on the main chord members can be exerted on the buckling plates, so that the stress condition of the bolts at the connecting sleeves is reduced, the shear resistance of the standard joint is improved, and the connection firmness between standard joints is enhanced.

Owner:江苏久和机械有限公司

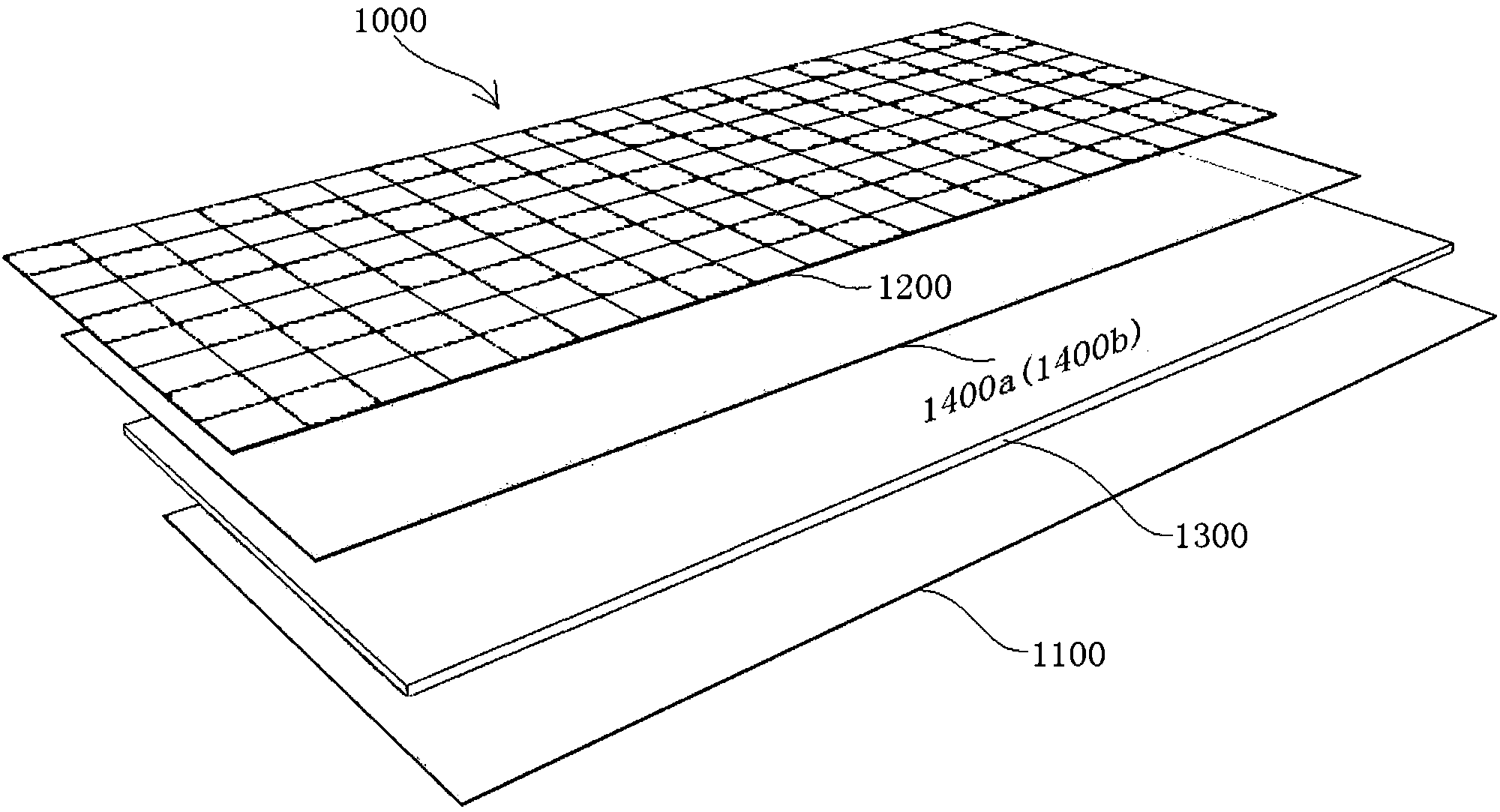

Calcium silicon wall ground decoration module and manufacturing method thereof

The invention discloses a calcium silicon wall ground decoration module which comprises a metal base plate and a decoration surface layer compounded on the surface of the metal base plate. A calcium silicon plate is arranged between the decoration surface layer and the metal base plate, and the decoration surface layer, the calcium silicon plate and the metal base plate are compounded together in a bonding mode through adhesive. The manufacturing method includes the following steps: a. mould installation; b. decoration surface layer laying; c. adhesive coating; d. calcium silicon plate bonding; e. base plate bonding; f. solidifying. The module and the method have the advantage that the moisture-proof calcium silicon plate is added between the decoration surface layer and the metal base plate, the strength of the decoration module is improved, anti-bending performance, anti-folding performance and anti-shearing performance are improved, the decoration module is not easy to moisten and deform and low in price, the decoration module can be quickly manufactured in a factory, and working efficiency is greatly improved.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

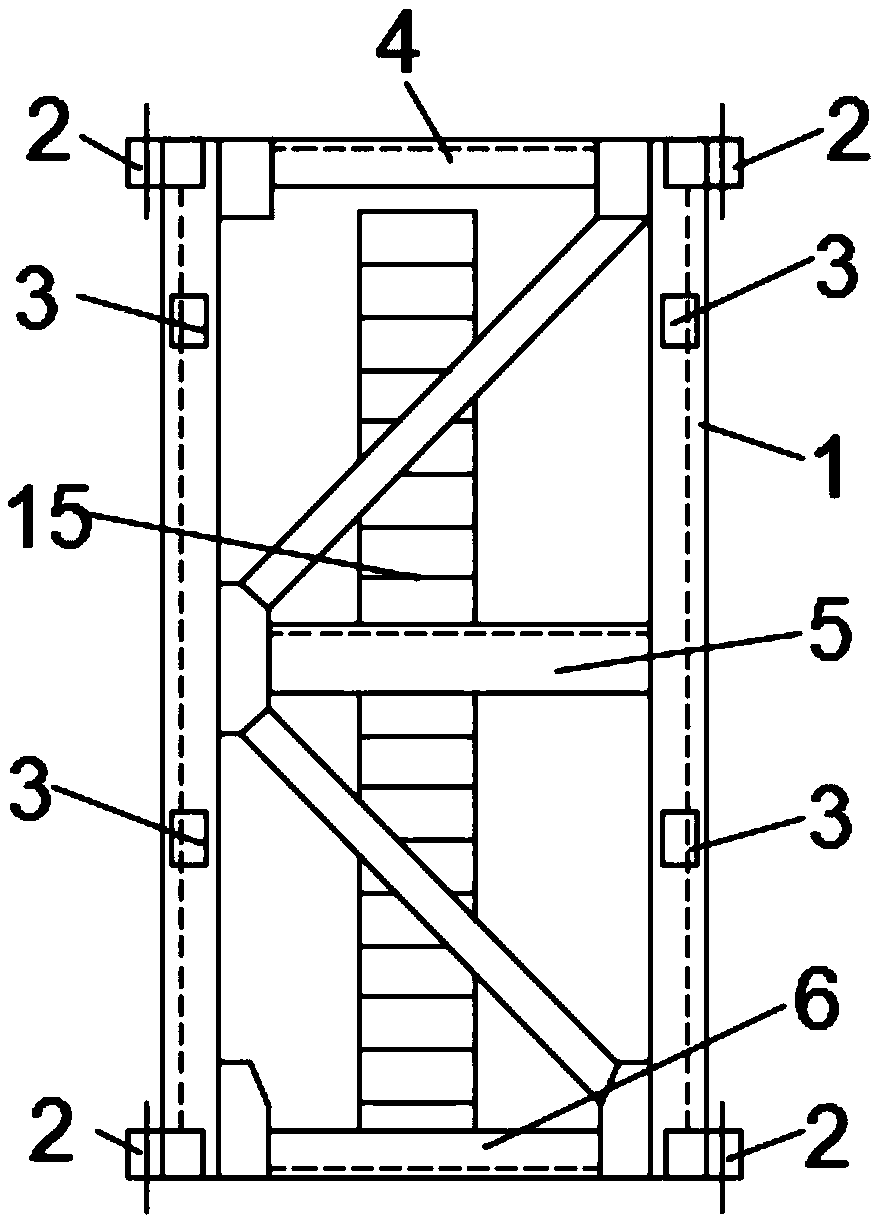

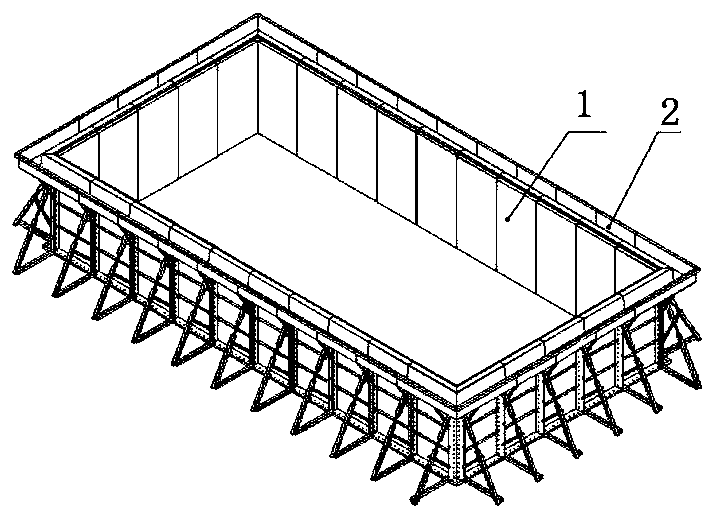

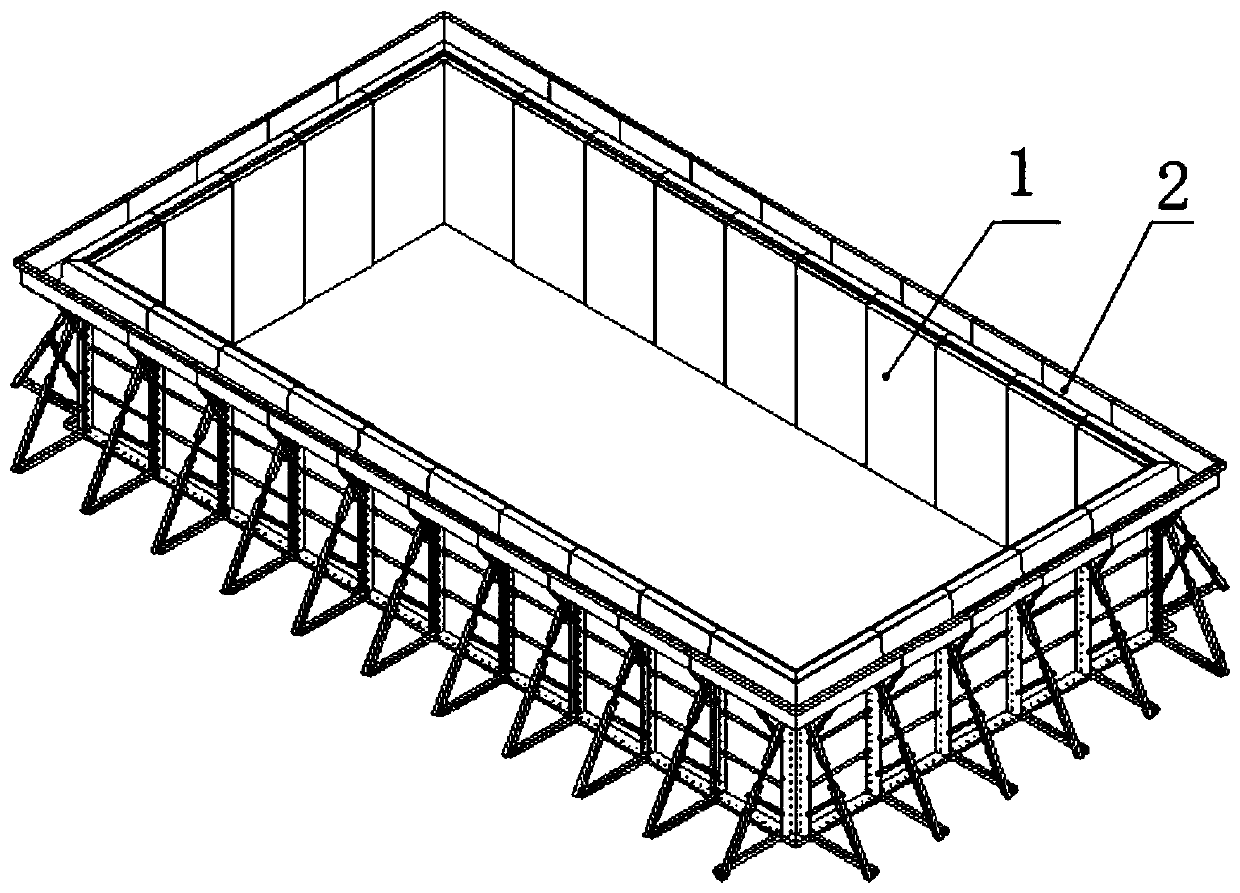

Modular integrated swimming pool system

ActiveCN111395816AGuaranteed stabilityAvoid deformationPipe supportsDomestic plumbingWater treatment systemMarine engineering

The invention discloses a modular integrated swimming pool system, and belongs to the technical field of swimming pool construction. The problems that the swimming pool construction time is long, a lot of manpower and material resources are consumed, an existing pipeline installation structure is unstable, the seismic effect is poor, a water treatment system is poor in flexibility, the on-site construction of rooms for auxiliary facilities is difficult, and the quality is difficult to guarantee in the prior art are solved. The modular integrated swimming pool system includes a modular-swimming-pool-type pool body, a water treatment system and a pipeline system; the modular-swimming-pool-type pool body includes a pool body frame structure, a pool body modular part and a pool floor; and thepool body modular part is connected to the pool body frame structure to form the side wall of the modular-swimming-pool-type pool body. The modular integrated swimming pool system is large in site adaptability, simple in installation method and low in labor cost.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

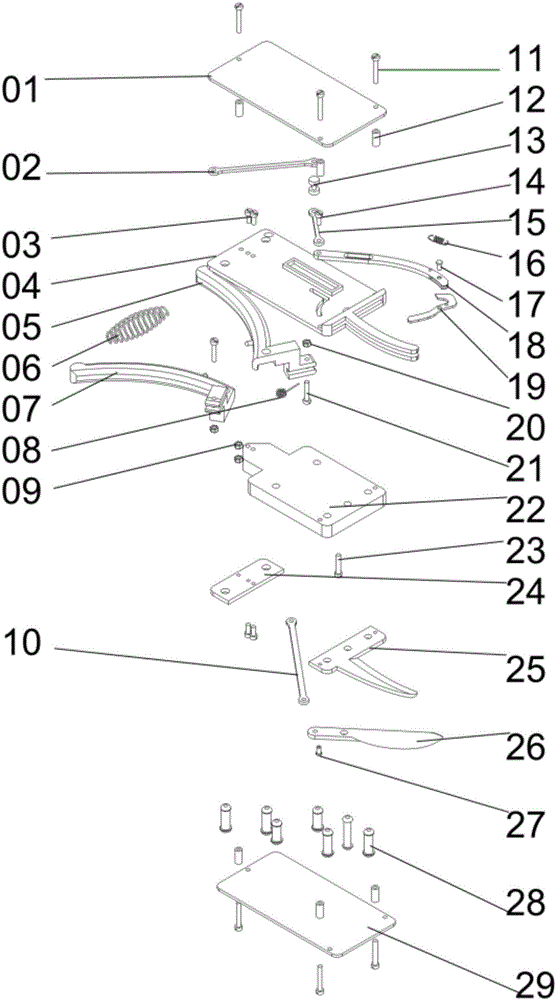

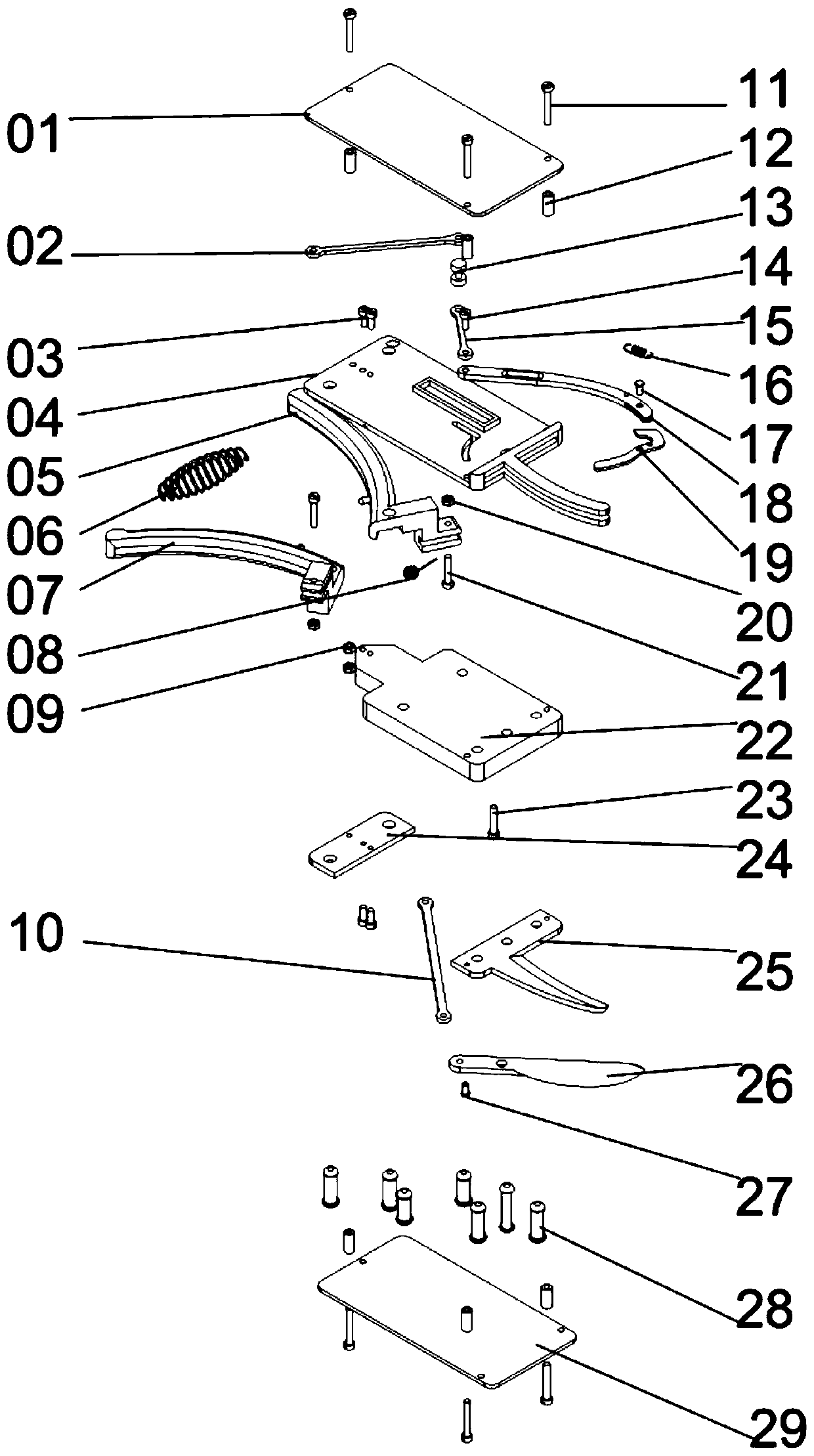

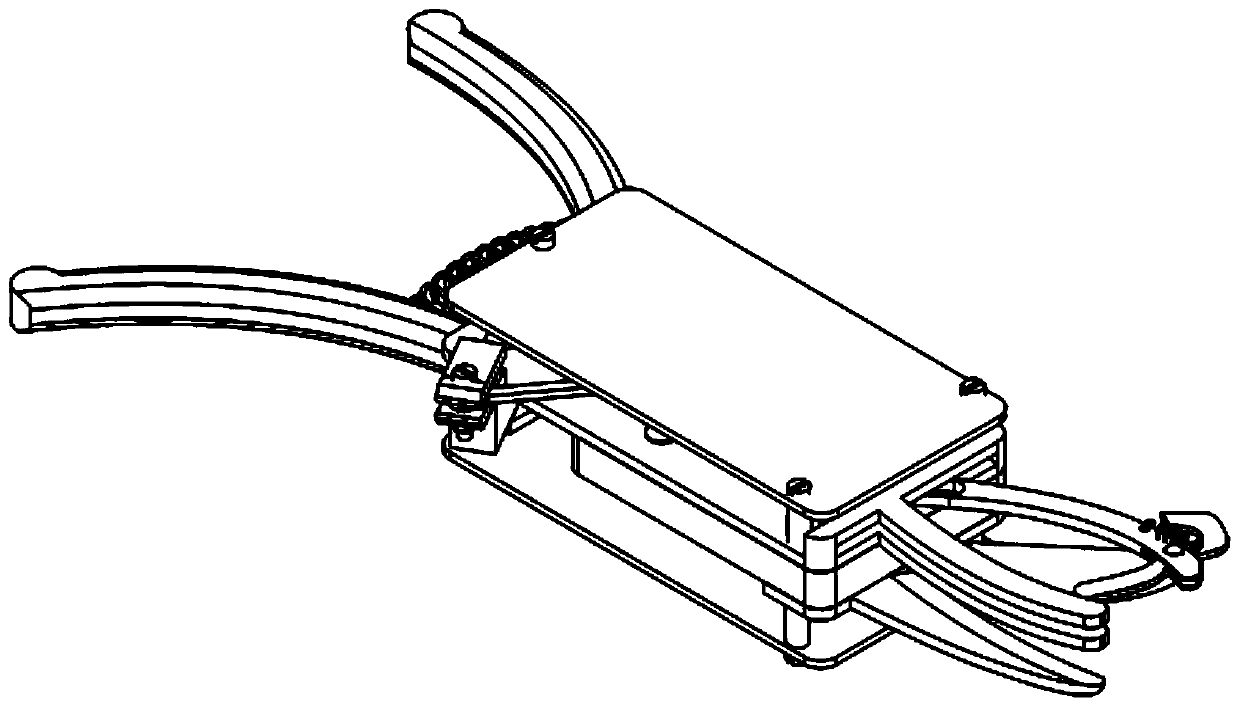

Bionic self-clamping fruit tree scissors

ActiveCN106718152AWith differential clamping trimming functionDifferential realizationSecateursCuttersFruit treeEngineering

The invention discloses a pair of bionic self-clamping fruit tree scissors. A fixed blade, an intermediate plate and a branch clamping plate are fixed sequentially; a movable blade is connected with the outer side of the fixed blade; movable clamps are connected with the outer side of the branch clamping plate; a handle I and a handle II are fixed between the branch clamping plate and a blade laminate; a spindle-shaped spring is fixed between the handle I and the handle II; a twisting spring is fixed between the handle I and an intermediate plate layer; the movable blade is hinged to the handle I via a connecting rod II; a connecting rod I is connected with the handle II; a connecting rod III is connected with the connecting rod I via a circular slide block screw; the movable clamp I is riveted to the connecting rod III; the movable clamp II is riveted to the tail end of the movable clamp I; and a return spring is mounted between the movable clamp I and the movable clamp II. The pair of scissors simulates a clamping action of fingers of human during pruning, adopts a design structure of picking fruits or twigs by a single hand, can achieve a differential clamping trimming function, clamps the fruits while the twigs are cut off by the fruit tree scissor blades, and achieves single-hand fruit picking and branch pruning.

Owner:JILIN UNIV

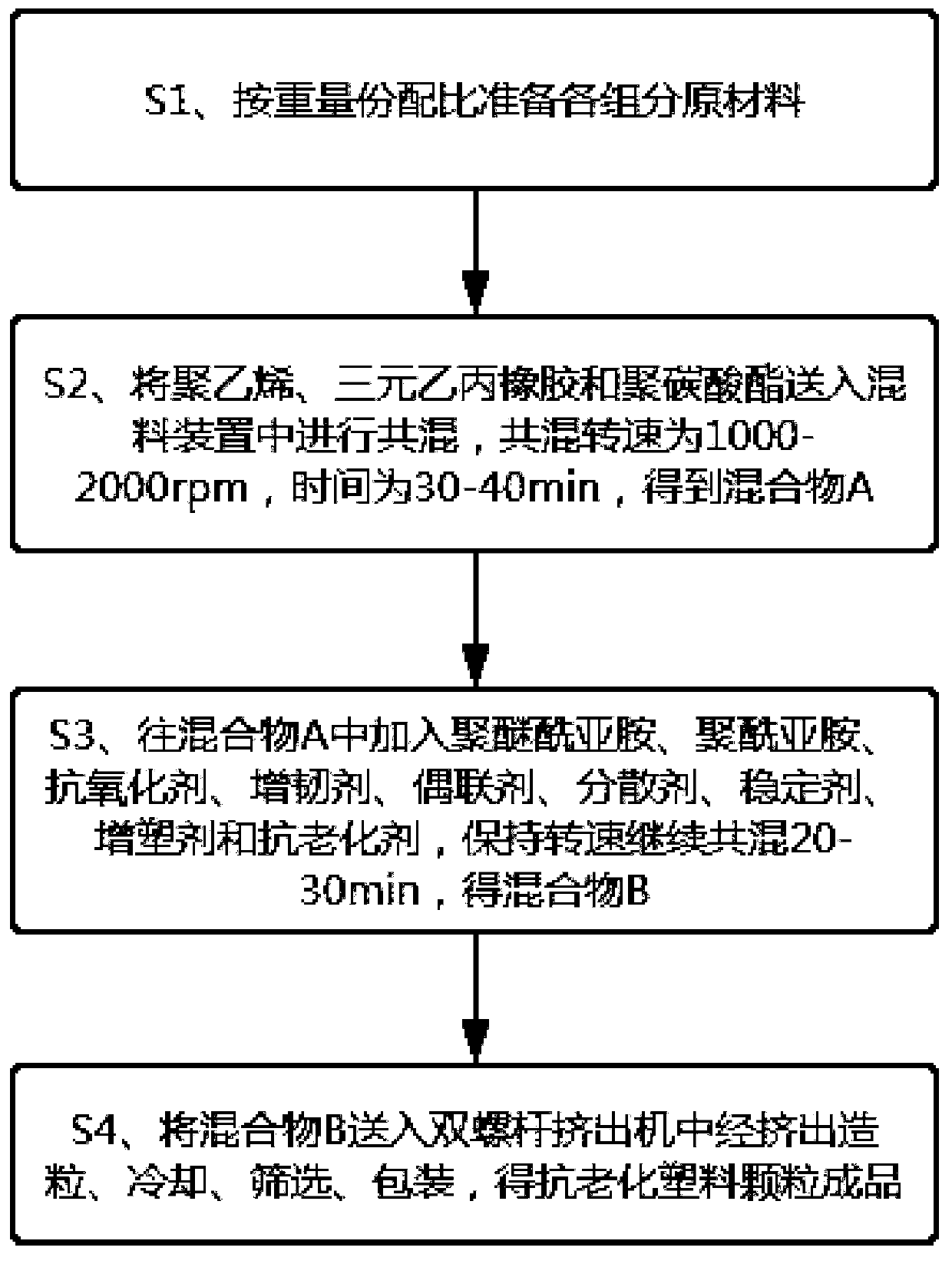

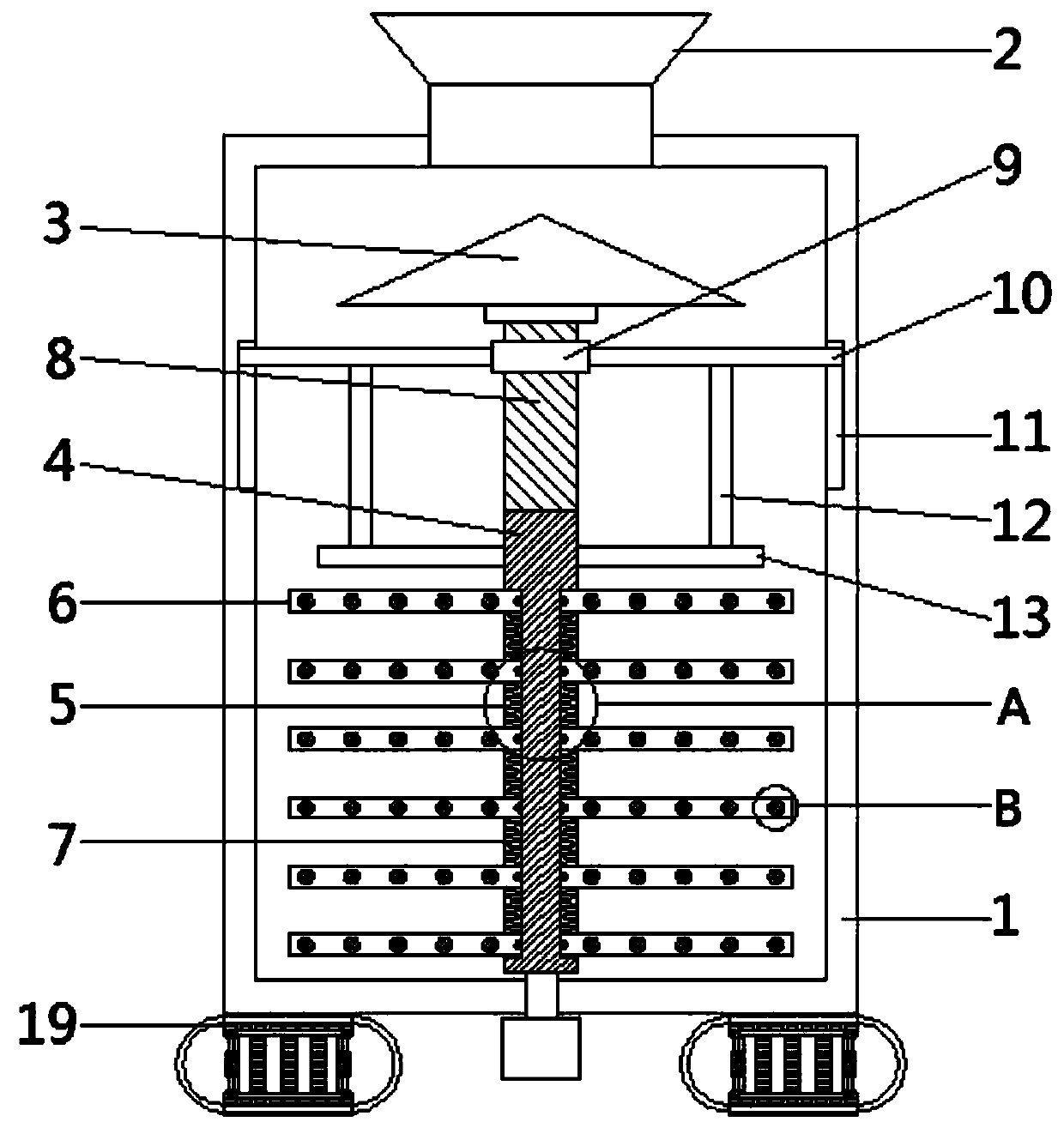

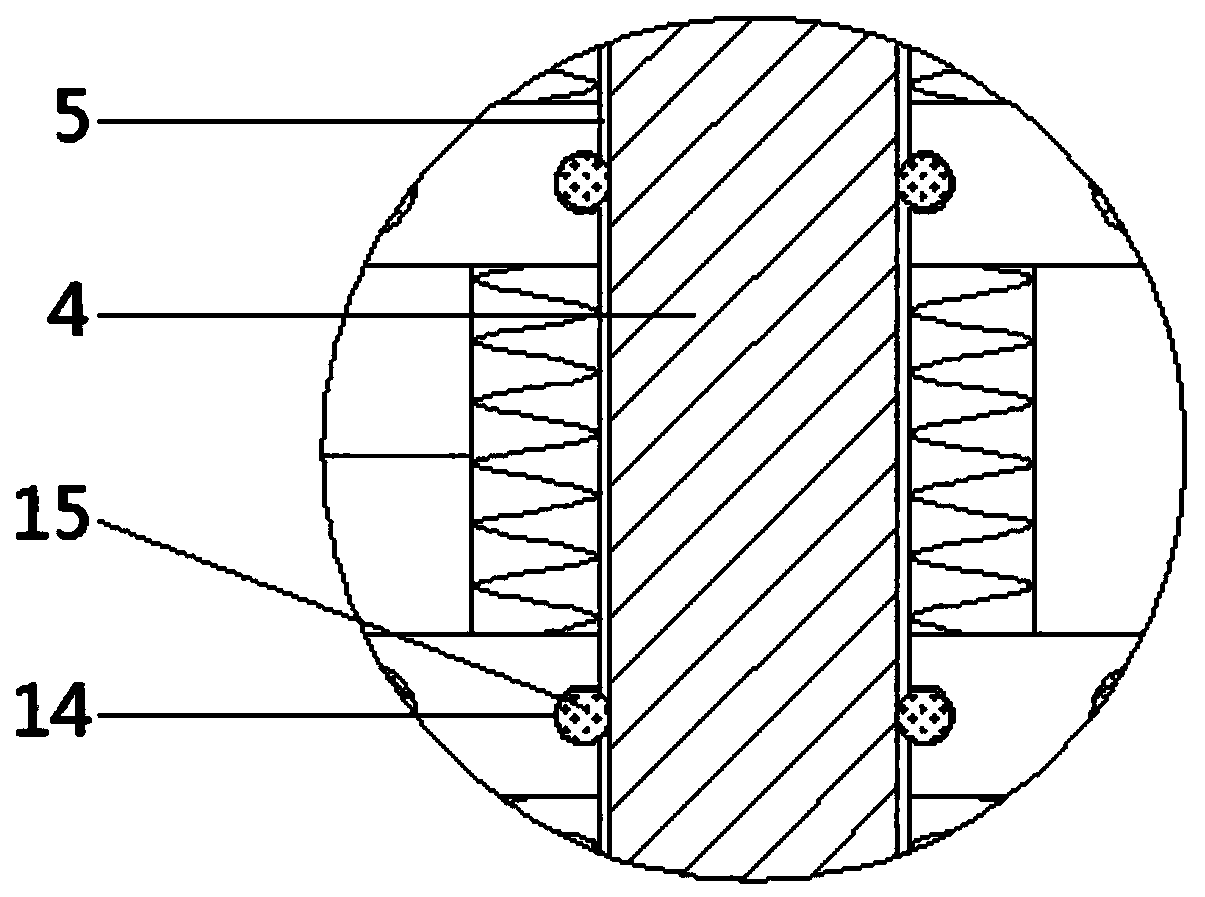

Anti-aging plastic particles and preparation method thereof

The invention discloses an anti-aging plastic particle and a preparation method thereof and belongs to the technical field of plastic processing. The anti-aging plastic particle comprises polyethylene, ethylene propylene diene monomer, polycarbonate, polyetherimide, polyimide, an antioxidant, a flexibilizer, a stabilizer, a plasticizer, an anti-aging agent and the like. The preparation method comprises the steps of material preparation, blending, extrusion granulation, cooling, packaging and the like. According to the invention, polyethylene, ethylene propylene diene monomer and polycarbonateare adopted as raw materials to prepare the plastic particles; so that the tensile strength is high, the resilience force is high, and the flame-retardant performance is excellent; the anti-aging plastic particle disclosed by the invention has the advantages of simple preparation process, low production cost, suitability for mass production, high temperature resistance, dimensional stability, highstrength resistance, wide long-term use temperature range, excellent mechanical property and good fireproof property.

Owner:江苏百兴管业科技有限公司

An assembled and combined partition wall structure

ActiveCN111997229BImprove shear performanceImprove connection accuracyWallsClassical mechanicsEngineering

The invention discloses an assembled and combined partition wall structure, which relates to the technical field of construction engineering. The invention comprises a wall; the opposite sides of the wall are respectively provided with connecting notches and connecting blocks; the top and bottom surfaces of the connecting notches are provided with threaded blind holes; the upper surface of the connecting blocks is provided with through holes and symmetrically provided with connecting The side of the wall is provided with a chute opening; the slide slot is slidingly connected with a slider; the upper and lower surfaces of the slider are fixed side by side with wedge-shaped plates; the side of a wedge-shaped plate is evenly distributed with teeth; the lower end surface of the connecting rod is suitable for the slope of the wedge-shaped plate. Matching; the connecting rod is provided with a rotating rod; the lower end of the rotating rod is evenly distributed with tooth grooves; the upper end of the rotating rod is fixed with a connecting column connected with the threaded blind hole. The invention realizes the axial movement of the connecting rod by using the wedge-shaped plate on the slider, and uses the teeth of the wedge-shaped plate to drive the rotating rod to rotate, so that the connecting column is connected with the threaded blind hole, which solves the problem of the existing wall connection accuracy and shear resistance. Poor power performance and inconvenient connection.

Owner:安徽地平线建筑设计有限公司

A bionic self-clamping fruit wood shears

ActiveCN106718152BWith differential clamping trimming functionDifferential realizationSecateursCuttersFruit treeTwig

The invention discloses a pair of bionic self-clamping fruit tree scissors. A fixed blade, an intermediate plate and a branch clamping plate are fixed sequentially; a movable blade is connected with the outer side of the fixed blade; movable clamps are connected with the outer side of the branch clamping plate; a handle I and a handle II are fixed between the branch clamping plate and a blade laminate; a spindle-shaped spring is fixed between the handle I and the handle II; a twisting spring is fixed between the handle I and an intermediate plate layer; the movable blade is hinged to the handle I via a connecting rod II; a connecting rod I is connected with the handle II; a connecting rod III is connected with the connecting rod I via a circular slide block screw; the movable clamp I is riveted to the connecting rod III; the movable clamp II is riveted to the tail end of the movable clamp I; and a return spring is mounted between the movable clamp I and the movable clamp II. The pair of scissors simulates a clamping action of fingers of human during pruning, adopts a design structure of picking fruits or twigs by a single hand, can achieve a differential clamping trimming function, clamps the fruits while the twigs are cut off by the fruit tree scissor blades, and achieves single-hand fruit picking and branch pruning.

Owner:JILIN UNIV

Multi-opening multi-pipe-section large-section tunnel, construction method, pipe section connection structure and connection method

PendingCN109162729AImprove shear performancePrevent rustUnderground chambersTunnel liningWhole bodyEngineering

The invention discloses a pipe section connection method and connection structure of a large-section tunnel for a pipe-jacking construction method. The structure comprises two adjacent pipe sections longitudinally connected to each other and a connection part. Upper parts of two sides of inner walls of the pipe sections are provided with tensioning portions with tensioning holes, and an elastic water stop ring for sealingly connecting the two tensioning holes is arranged between the two pipe sections. The connecting part comprises a rigid rod body and two cushion blocks which are provided withholes for grouting. The two pipe sections are fixed together through the connection part passing through the tensioning holes, and a pouring sealing body is arranged in the tensioning holes and the elastic water stop ring. The connection structure has the advantages of convenience in installation, little possibility of rust and good shear resistance. The invention also comprises a multi-pipe-section large-section tunnel constructed by using the pipe-jacking construction method, a side of the large-section tunnel is provided with a side outlet, the tensioning portions corresponding to the pipesections are connected to be a whole body through the above pipe section connection structure of the large-section tunnel, the construction efficiency is high, the cost is low, the settlement is balanced, and the maintenance cost is low.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Slurry for extruding 3D white marble powder printing and preparation method thereof

ActiveCN109534767BMeet the needs of extrusion 3D printingImprove shear performanceAdditive manufacturing apparatusSlurrySolid content

The invention discloses an extrusion type 3D white marble powder printing slurry and a preparation method thereof. The slurry of the invention has high solid content and good shear performance, and is suitable for extrusion 3D printing technology. At room temperature, it can gradually dry and solidify during the 3D printing process, so as to obtain high-precision molded parts without collapse.

Owner:HUAQIAO UNIVERSITY

Shear force connection structure for lightning receptors

The invention discloses a shearing force resistant connection structure for an air-termination system. The shearing force resistant connection structure comprises two lightning receiving rods opposite to each other, wherein opposite surfaces of the two lightning receiving rods opposite to each other are arc-shaped, connection blocks are also arranged at outer surfaces of side surfaces at ends of the opposite surfaces of the lightning receiving rods, and the two lightning receiving rods are connected by a spring between the connection blocks. By dividing an integrated lightning receiving rod into the two lightning receiving rods opposite to each other, connection parts are connected by the spring, the spring can be bent when a shearing force such as cross wind is applied, the lightning receiving rods are enabled not to be broken, and the lightning receiving rods are recovered under the effect of the spring during no wind and are enabled to be vertical and upward; and meanwhile, the opposite surfaces are arc surfaces and are beneficial for point discharge, namely, the two lightning receiving rods are not physically connected. The shearing force resistant connection structure has the advantages of excellent shearing force resistant performance, high safety and low improvement cost, the lightning receiving rods are enabled not to be broken by a shearing force, and an existing lightning receiving rod can be directly changed.

Owner:SICHUAN NUOTE TECH

Assembled swimming pool and installation method

PendingCN111395819AOptimize the installation methodReduce labor costsPipe supportsGymnasiumWater treatment systemStructural engineering

The invention discloses an assembled swimming pool and an installation method, belonging to the technical field of swimming pool building, and solving the problems of long construction time of swimming pool building and consumption of a lot of manpower and material resources for swimming pool building in the prior art. The assembled swimming pool comprises a modular swimming pool body and a watertreatment system, and is formed by assembling prefabricated parts, wherein the modular swimming pool body comprises a swimming pool frame structure, swinging pool modular components and a swinging pool baseplate; and the swinging pool modular components are connected to the swimming pool frame structure to form the side walls of the modular swimming pool body. The assembled swimming pool and the installation method have large site adaptability; the installation method is relatively simple and convenient; and meanwhile the labor cost is saved.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com