Anti-aging plastic particles and preparation method thereof

A plastic granule and anti-aging technology, which is applied in the field of plastic processing, can solve the problems of affecting the aesthetics and performance of plastic products, poor anti-oxidation performance, and reduced finish, achieving excellent anti-oxidation performance, high tensile strength, and low production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] An anti-aging plastic granule, comprising the following components by weight: 70-90 parts of polyethylene, 30-40 parts of EPDM rubber, 20-30 parts of polycarbonate, 5-15 parts of polyetherimide 5-15 parts of polyimide, 5-10 parts of antioxidant, 5-10 parts of toughening agent, 2-5 parts of coupling agent, 2-5 parts of dispersant, 2-5 parts of stabilizer, plasticizer 1-5 parts of anti-aging agent and 2-5 parts of anti-aging agent.

[0043] The antioxidant is one of antioxidant 1076, antioxidant CA, antioxidant DNP, and antioxidant DLTP, and the dispersant is monoglyceride stearate or microcrystalline paraffin.

[0044] The stabilizer is calcium stearate, epoxy resin or zinc stearate, and the plasticizer is dioctyl phthalate, dibutyl phthalate or diisononyl phthalate.

[0045] The anti-aging agent is nano titanium dioxide, and the particle size of the nano titanium dioxide is 20-60nm.

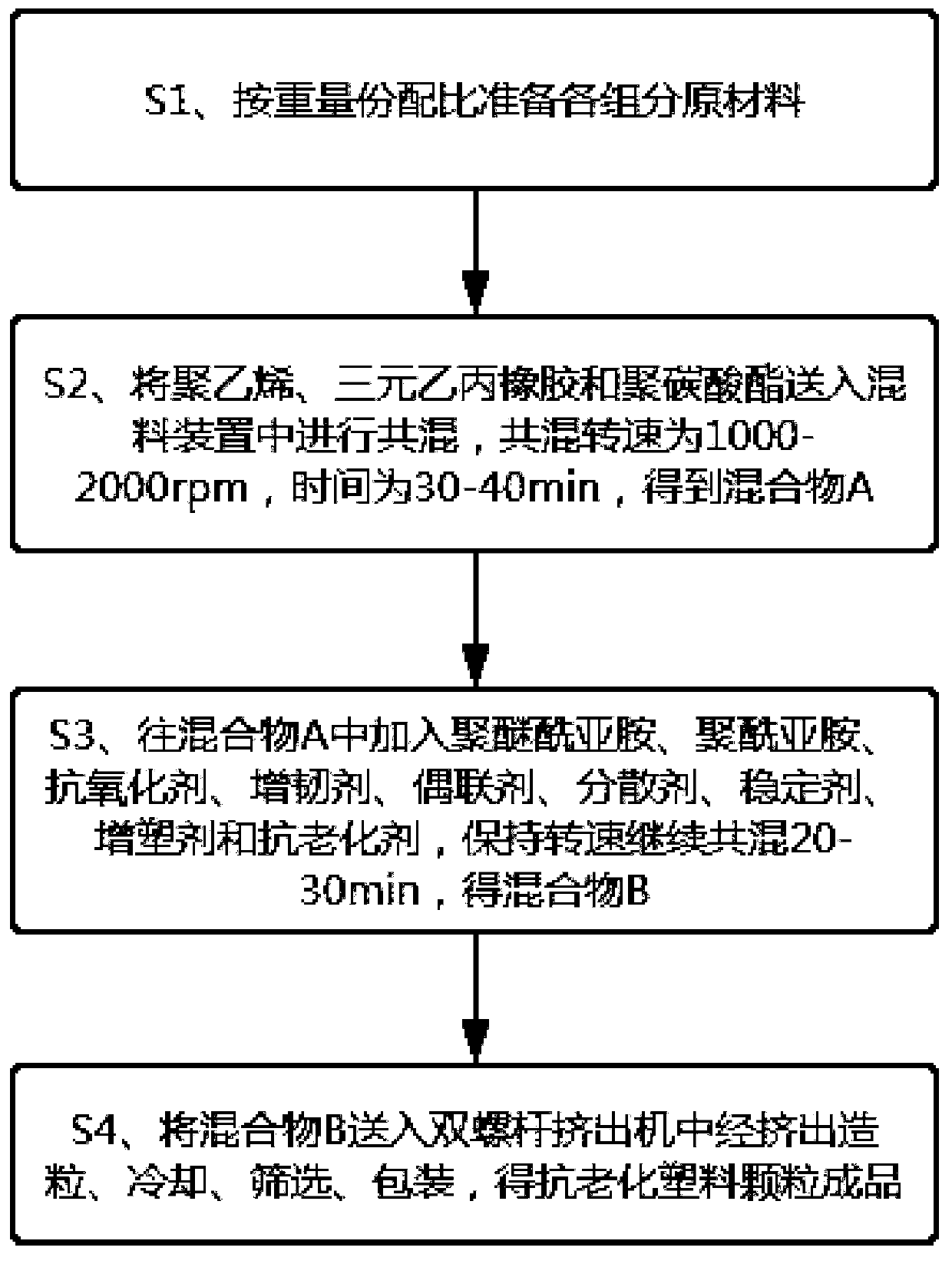

[0046] see figure 1 , a preparation method of anti-aging plastic particles, compris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com