Method for preparing duplex metal composite material through solid-liquid compounding and drawing combination of solid steel

A technology of solid-liquid compounding and composite materials, which is applied in the direction of metal extrusion control equipment, metal extrusion, metal processing equipment, etc., can solve the problem of low performance of interactive bimetallic composite materials, and achieve improved mechanical and physical properties , Shear performance improvement, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

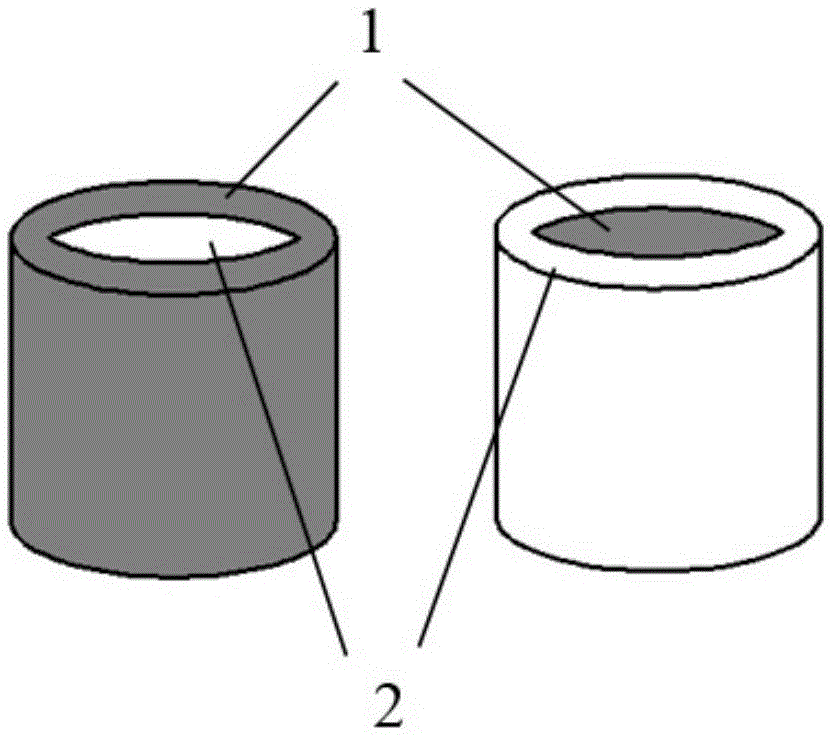

[0031] This embodiment relates to a method for preparing a bimetallic composite material by solid-liquid compounding and drawing combination of solid steel, including the following steps:

[0032] Step 1. Perform thermal spraying zinc surface treatment on the pre-installed material of the solid Q235A structural steel to be connected, and the thickness of the zinc layer is 0.1 μm;

[0033] Step 2, presetting the surface-treated solid Q235A structural steel at the required position in the mold cavity;

[0034] Step 3: Melt 6101 extruded aluminum alloy in the cavity of the resistance furnace, use the processing technology of metal mold casting, and the pouring temperature is 750°C, so that the metallurgical bond between steel and aluminum is formed;

[0035] Step 4. Perform annealing treatment on the obtained Q235-6101 steel-aluminum bimetal drawing blank before drawing. The annealing temperature is 100° C., and the annealing time is 300 minutes. Then, the drawing process is cont...

Embodiment 2

[0039] This embodiment relates to a method for preparing a bimetallic composite material by solid-liquid compounding and drawing combination of solid steel, including the following steps:

[0040] Step 1. Perform thermal spraying zinc surface treatment on the solid 316L stainless steel preset material to be connected, and the thickness of the zinc layer is 15 μm;

[0041] Step 2, presetting the surface-treated solid 316L stainless steel at the required position in the mold cavity;

[0042] Step 3: Melt the A356 cast aluminum alloy in the resistance furnace and pour it into the mold cavity. Using the processing technology of squeeze casting, the pouring temperature is 700°C, and the squeeze casting pressure is 70MPa to form a metallurgical bond between steel and aluminum;

[0043] Step 4. Perform annealing treatment on the obtained 316L-A356 steel-aluminum bimetallic drawing blank before drawing. The annealing temperature is 300°C, and the annealing time is 50 minutes. The tem...

Embodiment 3

[0047] This embodiment relates to a method for preparing a bimetallic composite material by solid-liquid compounding and drawing combination of solid steel, including the following steps:

[0048] Step 1. Perform thermal spraying zinc surface treatment on the solid 316L stainless steel preset material to be connected, and the thickness of the zinc layer is 50 μm;

[0049] Step 2, presetting the surface-treated solid 316L stainless steel at the required position in the mold cavity;

[0050] Step 3: Melt the AZ91 magnesium alloy in the resistance furnace and pour it into the mold cavity. Using the processing technology of squeeze casting, the pouring temperature is 680 ° C, and the squeeze casting pressure is 50 MPa, so that the metallurgical bond between steel and magnesium is formed;

[0051] Step 4, drawing the obtained 316L-AZ91 steel-magnesium bimetal, the process is direct drawing, the drawing temperature is 250°C, the diameter reduction ratio is 50 / 100, and the drawing sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com