Reinforced concrete laminated slab

A technology of reinforced concrete and laminated slabs, applied in the direction of floor slabs, structural elements, building components, etc., can solve the problems of high cost, joint surface cannot be equal to cast-in-place, inconvenient prefabricated slab production and construction, etc. The effect of shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

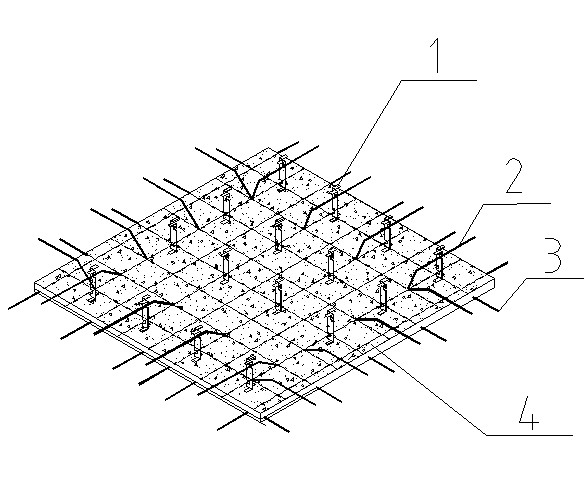

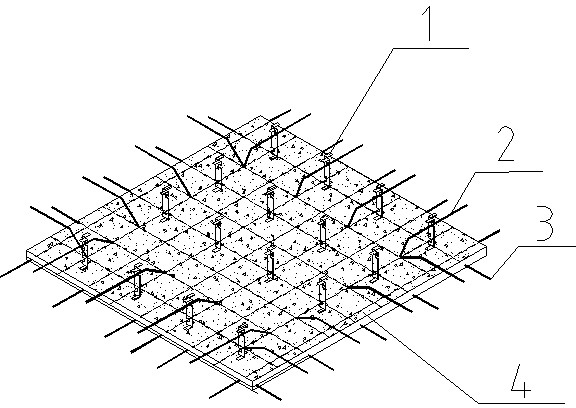

[0008] The reinforced concrete composite slab of the present invention will be further described below in conjunction with the accompanying drawings.

[0009] from figure 1 It can be seen that the reinforced concrete composite slab is composed of the bottom steel bar 3, the bent steel bar 2, the limiter 1 and the prefabricated layer 4. It is composed of a connecting body between the upper limit surface and the lower limit surface. The lower limit surface of the stopper is located in the prefabricated layer 4. The thickness of the laminated plate is controlled by the distance between the upper limit surface and the lower limit surface of the stopper 1. Half of the bent steel bar 2 is set in the prefabricated layer 3 to strengthen the connection between the cast-in-place layer and the prefabricated layer.

[0010] The invention fully considers the stress characteristics of the slab, fully utilizes the function of the material, and ensures that the joint surfaces of the prefabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com