Bar-shaped inductive component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

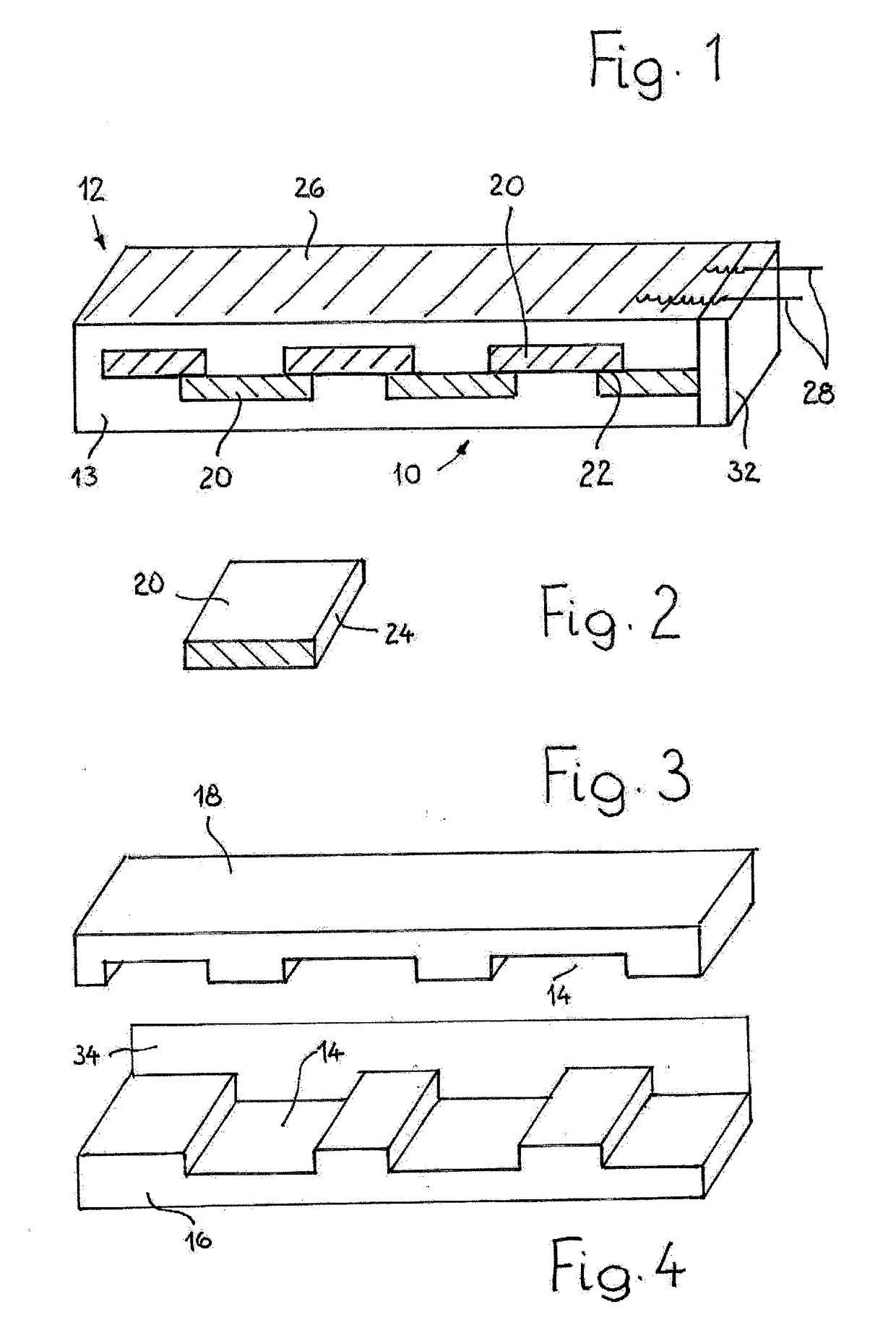

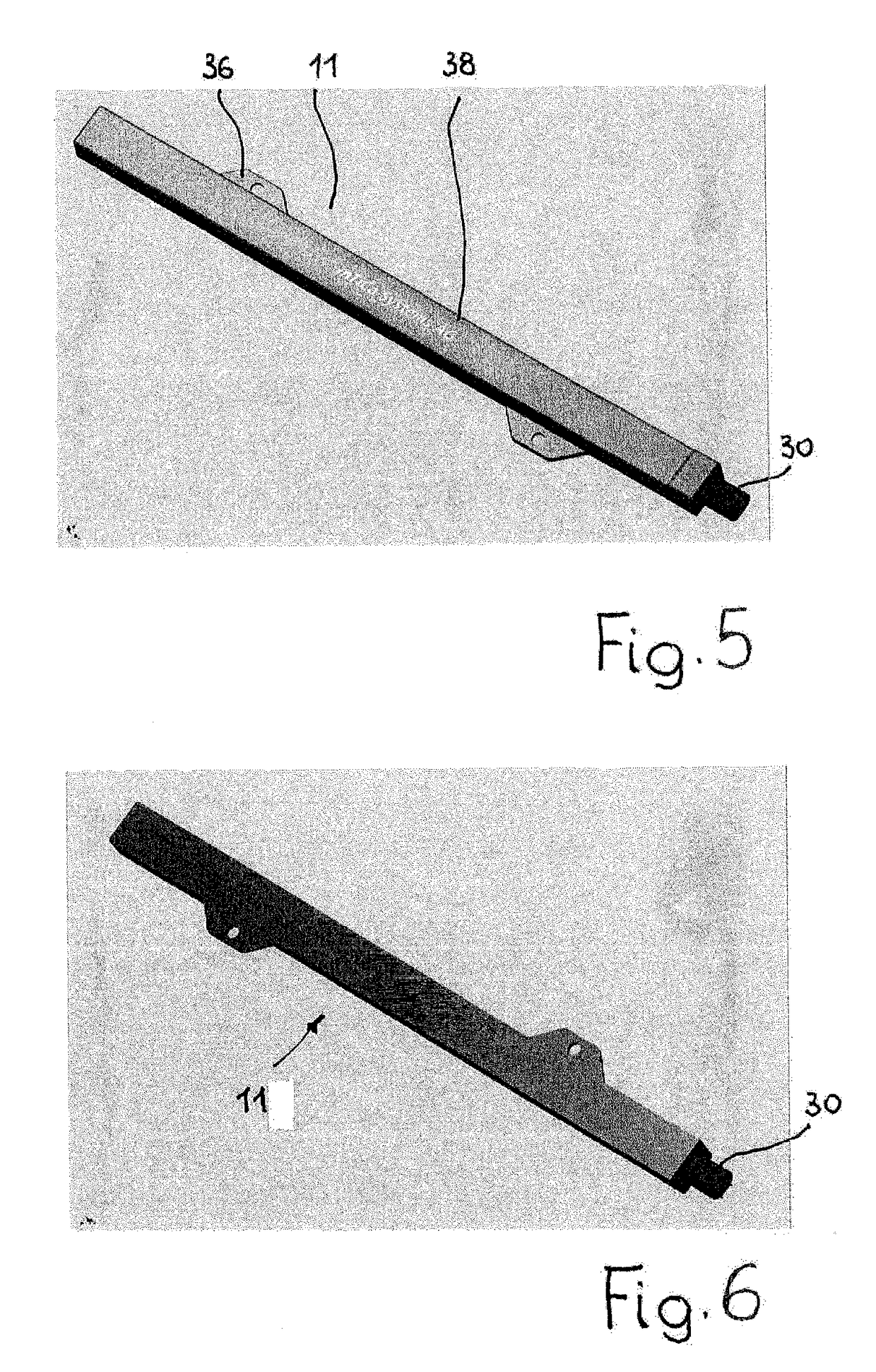

[0018]In FIGS. 1 and 2, as well as in FIGS. 3 and 4, schematic views of two alternatives for the possible construction of a bar-shaped inductive component 10 according to the invention are illustrated which, as shown in FIGS. 5 and 6, can be used as LF [low frequency] ferrite antennas 11 for frequency ranges from approx. 120 to 130 kHz or 14 to 25 kHz.

[0019]The inductive component 10 comprises a core made of magnetic material, in general ferrite, and a mounting element 12 for the core, which is formed as a coil body 13 and can be manufactured as a one-piece injection-moulded component, e.g. from polyamide (PA).

[0020]In the mounting element 12, cuboid recesses 14 are incorporated, which are closed on the not-shown rear side and extend over the width of the coil body 13, the length of which can be 100 mm or more. In the example shown in FIGS. 3 and 4, the coil body 13 is divided in a central plane and thus forms a bottom part 16 and a top part 18, both of which are firmly interconnect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com