High-performance insulation lubricating grease and preparation method thereof

A lubricating grease and high-performance technology, which is applied in the field of high-performance insulating lubricating grease and its preparation, can solve the problems of poor ink adhesion and stability, easy structuring, short shelf life, etc., and achieve oil separation, enhanced compatibility, The effect of not easy to sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

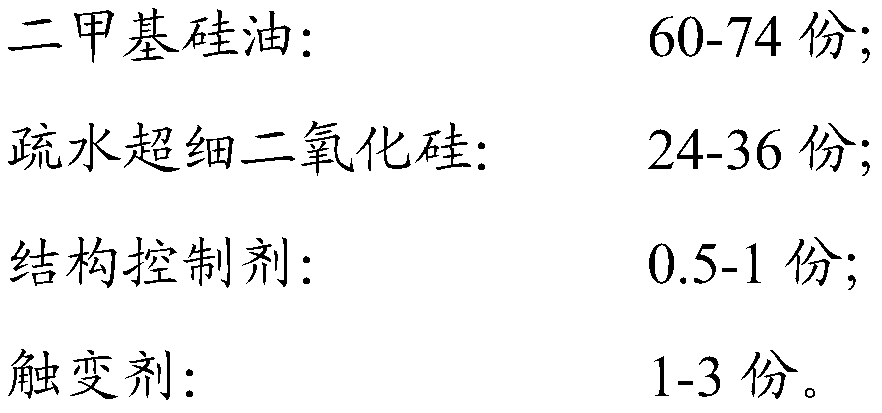

Method used

Image

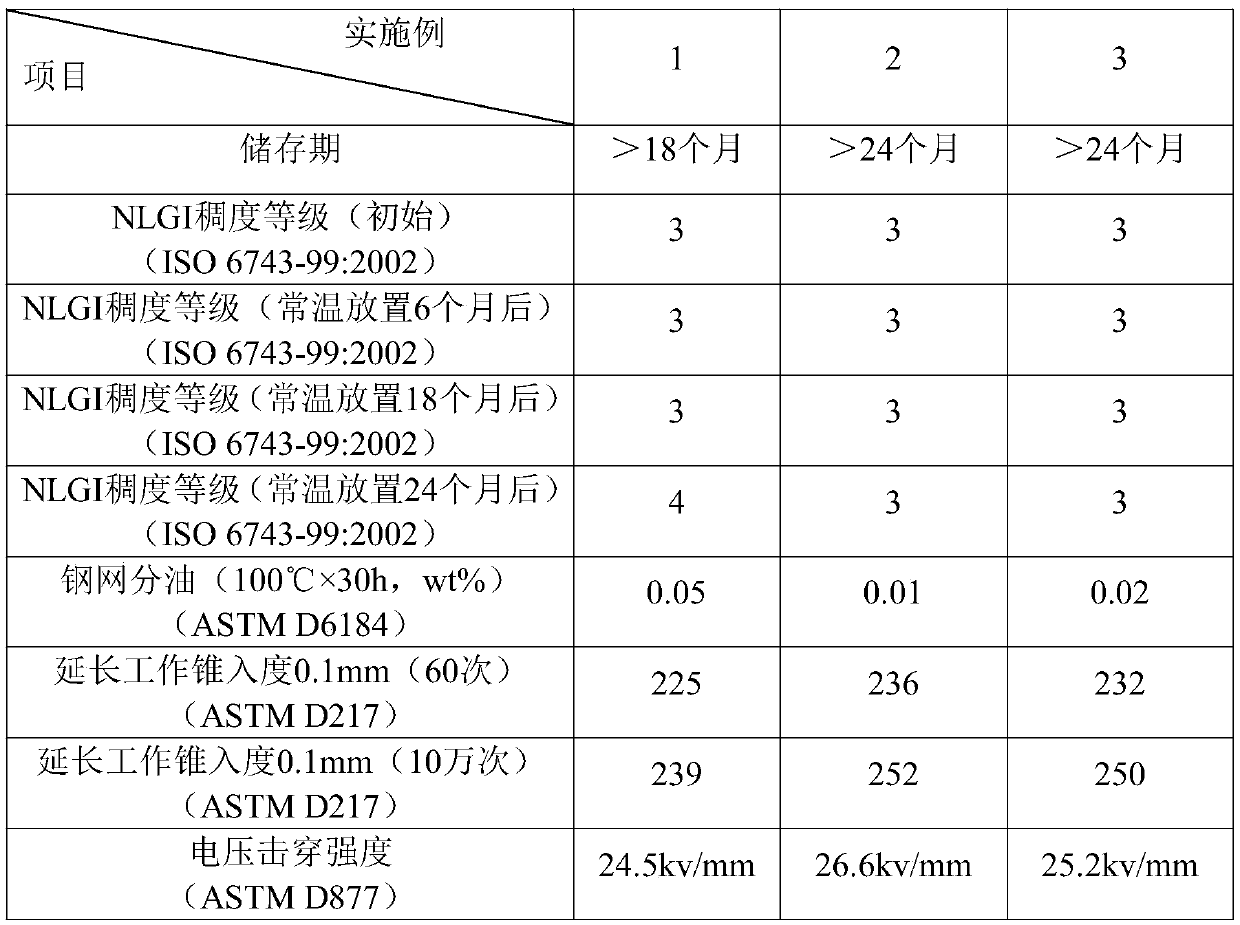

Examples

Embodiment 1

[0042] Hydrophobic ultrafine silica pre-preparation: 100 parts with a specific surface area of 100m 2 / g, precipitated silica with a particle size of 30nm was put into the reactor, started to stir, then added 10 parts of hexamethyldisilazane and 2 parts of purified water by spraying, and discharged after airtight treatment at room temperature for 4 hours. Seal it with a PE bag and store it at room temperature for 30 days.

[0043] Preparation of high-performance insulating grease: put 60 parts of simethicone oil with a viscosity of 500CS into the kneader, and then put in 36 parts of hydrophobic superfine silica in batches, stir to form a mass, and continue to stir at a material temperature of 90°C 2h, stirring speed 50r / min, vacuum stirring at material temperature 190°C for 2h, vacuum degree: 680mmHg stirring speed 35r / min, lowering material temperature to 130°C, adding 4 parts of hydroxyl-terminated silicone oil with a viscosity of 25CS, and continuing to decompress Stir f...

Embodiment 2

[0045] Hydrophobic ultrafine silica pre-preparation: 100 parts with a specific surface area of 400m 2 / g, fumed silica with a particle size of 3nm was put into the reaction kettle, started stirring, then added 45 parts of hexamethyldisilazane and 15 parts of purified water by spraying, stirred at 95°C for 4h, and depressurized at 180°C Stir for 4 hours, then lower the temperature of the material to below 120°C, discharge the material after the vacuum is eliminated with nitrogen, and obtain a hydrophobic ultrafine silica with a methanol value of 48.

[0046] Preparation of high-performance insulating grease: put 74 parts of simethicone oil with a viscosity of 15000CS into the kneader, and then put in 24 parts of hydrophobic superfine silica in batches, stir to form a mass, and continue to stir at a material temperature of 80°C 4h, stirring speed 35r / min, vacuum stirring at material temperature 180°C for 4h, vacuum degree: 570mmHg, stirring speed 50r / min, lowering material tem...

Embodiment 3

[0048] Hydrophobic ultrafine silica pre-preparation: 100 parts with a specific surface area of 300m 2 / g, fumed silica with a particle size of 10nm was put into the reactor, started to stir, then added 25 parts of hexamethyldisilazane and 7 parts of purified water by spraying, stirred at 70°C for 2h, and depressurized at 170°C Stir for 2 hours, then lower the temperature of the material to below 120° C., discharge the material after the vacuum is eliminated with nitrogen, and obtain hydrophobic ultrafine silica with a methanol value of 45.

[0049] Preparation of high-performance insulating grease: Put 68 parts of simethicone oil with a viscosity of 2000CS into the kneader, and then put in 30 parts of hydrophobic superfine silica in batches, stir to form a mass, and continue to stir at a material temperature of 60°C 3h, stirring speed 20r / min, vacuum stirring at material temperature 160°C for 3h, vacuum degree: 720mmHg, stirring speed 20r / min, lowering material temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com