Tower crane standard joint high in shear resistance

A standard section and anti-shear technology, applied to cranes and other directions, can solve problems affecting the firmness of the connection of the main chord, endangering the safety of the tower crane, and loosening of the connection parts, so as to improve the ability of anti-shear force, Easy disassembly and assembly, enhanced firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

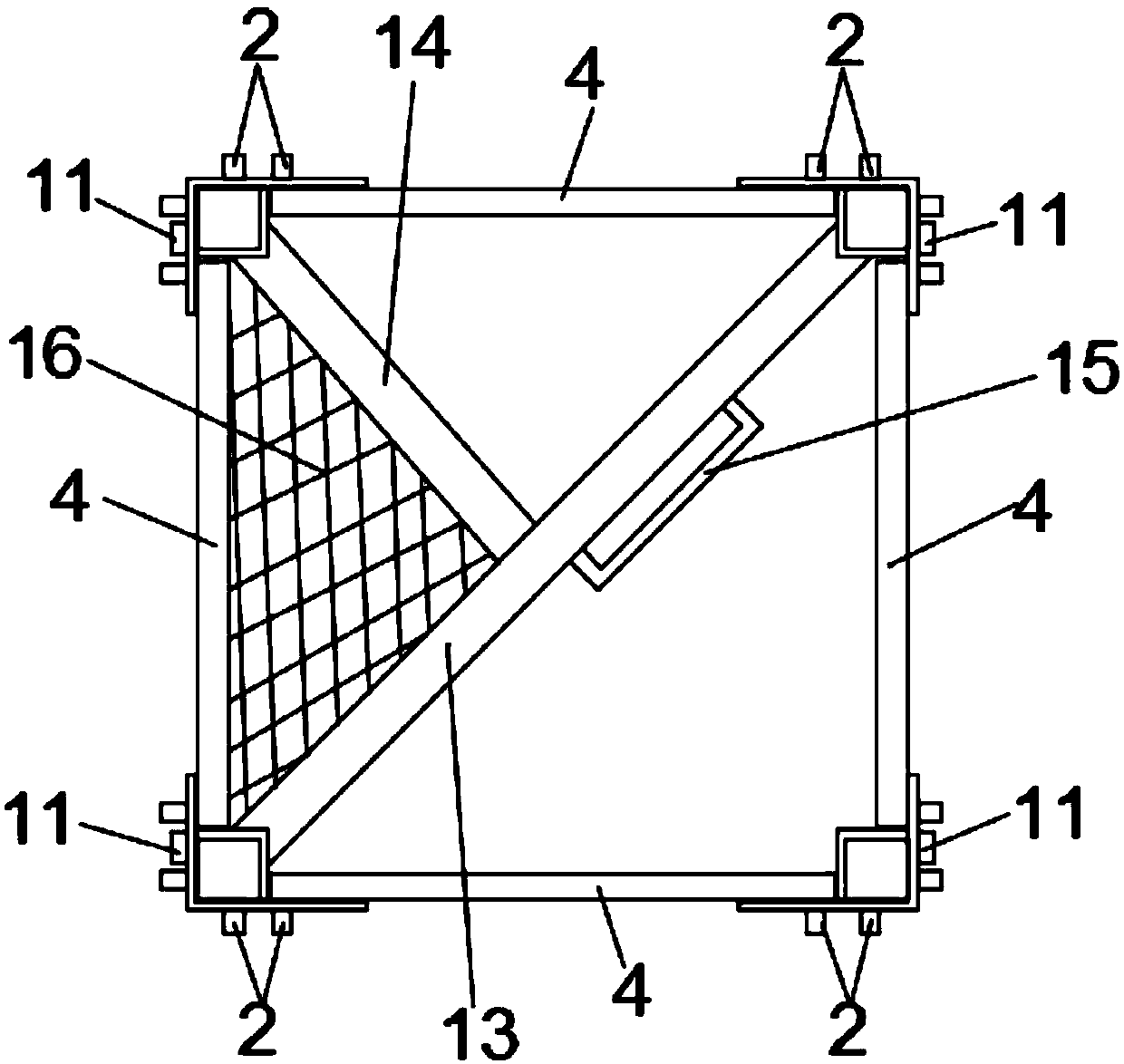

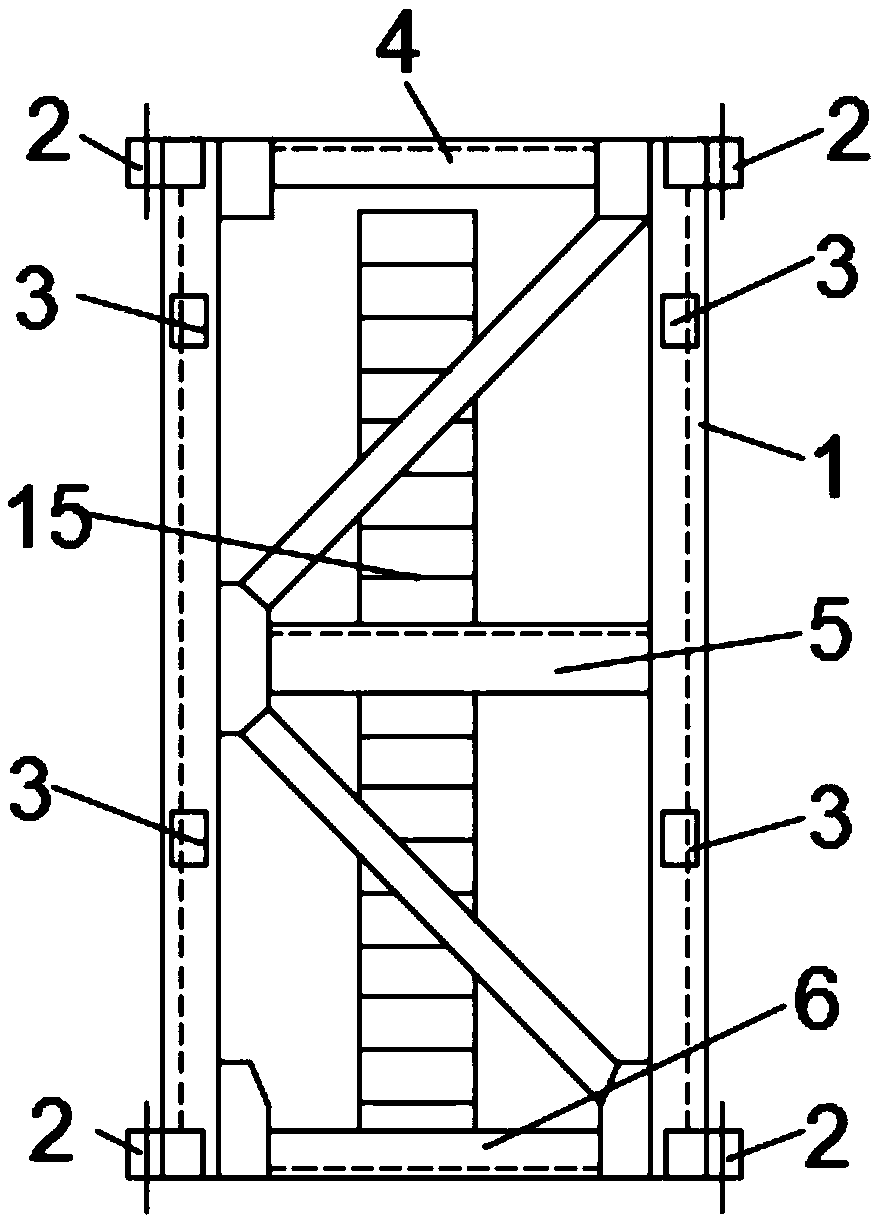

[0023] See attached Figure 1 to Figure 5 As shown, a standard section of a tower crane with strong shear resistance in this embodiment includes four main chords 1 vertically placed and arranged in a rectangular shape, and a plurality of steps 3 are evenly fixed on the main chord 1 , the upper ends of the four main chords 1 are detachably fixedly connected through four upper beams 4, the middle parts of the four main chords 1 are detachably fixedly connected through four middle beams 5, and the four main chords The lower ends of 1 are detachably fixedly connected by four lower beams 6; the upper and lower ends of the main chord 1 are respectively fixedly provided with upper and lower corresponding connecting sleeves 2. In this embodiment, the upper and lower ends of each main chord 1 are evenly provided with two connecting sleeves 2 on its circumference, which are used to improve the firmness when the upper and lower standard joints are connected.

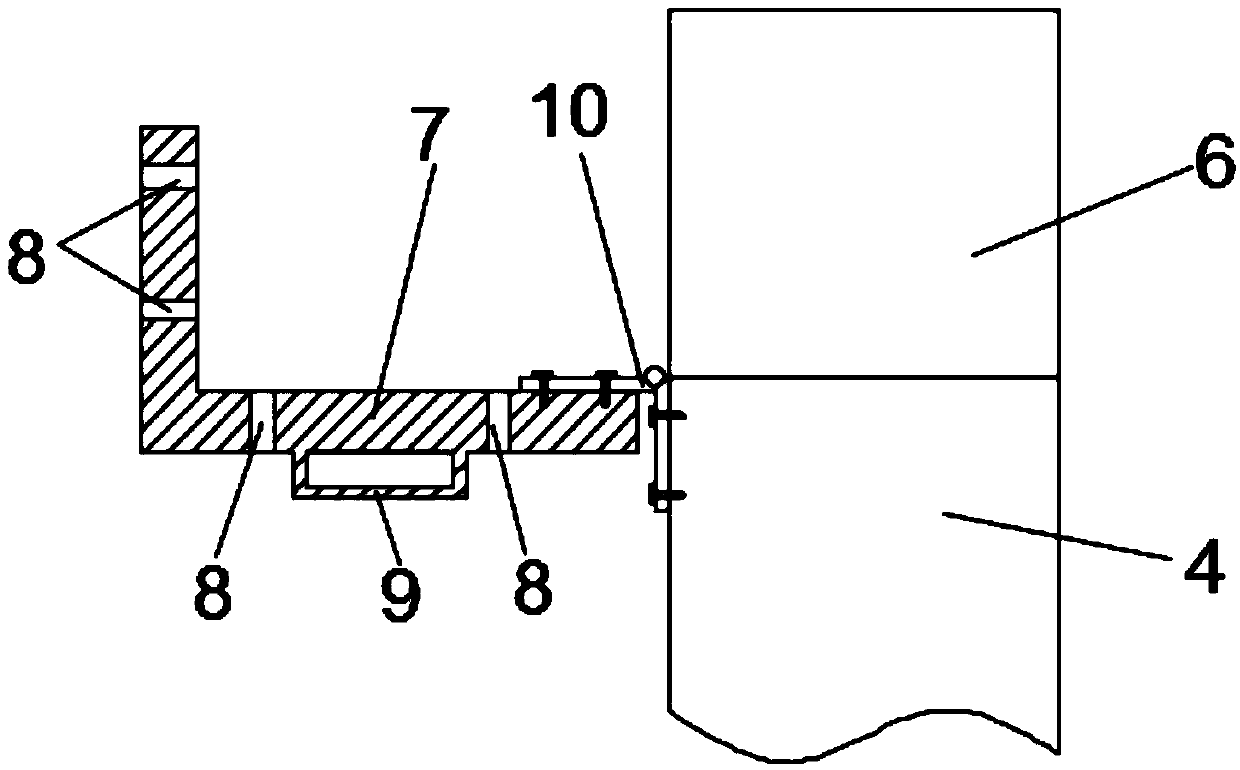

[0024] Such as image 3 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com