Method for improving interface performance of resin matrix and carbon fibers

A resin matrix, carbon fiber technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

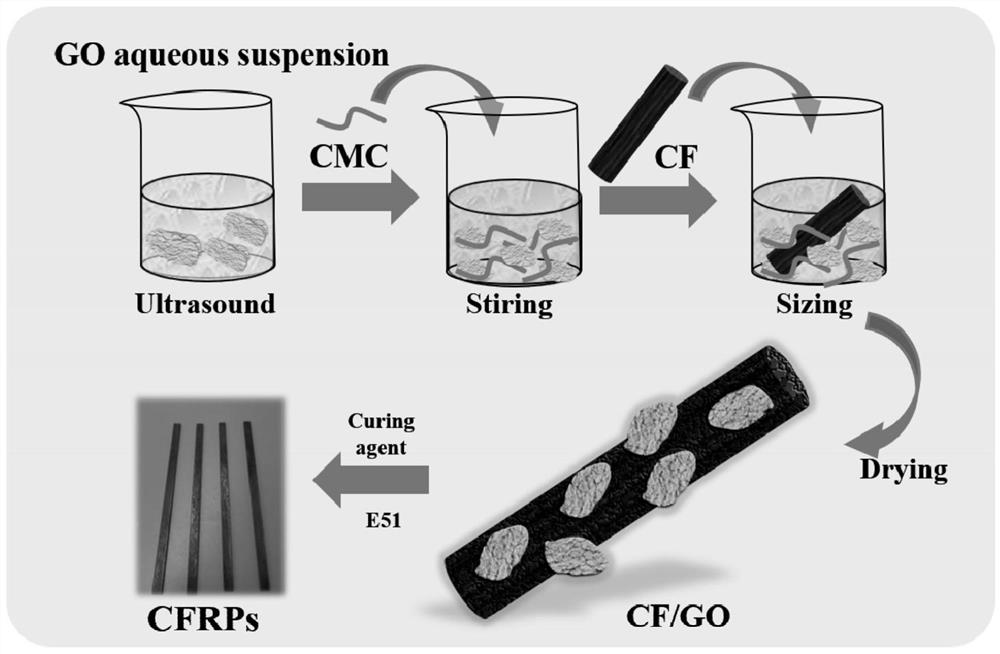

[0050] Embodiment 1, prepare the GO / CF reinforced epoxy composite material of the present invention

[0051] Step 1: Preparation of graphene oxide modified carbon fiber

[0052] The CFs were refluxed in acetone at 80 °C for 48 h, then washed with acetone, and dried in a vacuum oven at 80 °C for 12 h to remove residual acetone and contaminants.

[0053] In a 200 mL beaker filled with 100 mL of deionized water, 6 mL of GO aqueous suspension with a lateral dimension of 200 nm (where the GO concentration was 5 mg / mL) was added, and sonicated (ultrasonic power: 600 W) for 30 minutes to separate GO sheets. Then 0.075 g of CMC was added to the above solution and mixed uniformly to obtain a sizing agent. The CFs were immersed in the sizing agent for sizing for 15 minutes, and dried in an oven at 80 °C for 24 hours to obtain a carbon fiber sample after introducing GO, which was named as M40 J / GO-200nm.

[0054] Step 2: Prepare composite material

[0055] Composite materials were pr...

Embodiment 2

[0056] Embodiment 2, prepare the GO / CF reinforced epoxy composite material of the present invention

[0057] Step 1: Preparation of graphene oxide modified carbon fiber

[0058] Referring to the method of step 1 of Example 1, the only difference is that 6 mL of GO aqueous suspension (wherein the GO concentration is 5 mg / mL) with a lateral dimension of 200 nm is replaced by 10 mL of GO aqueous suspension with a lateral size of 1 μm (wherein the GO concentration is 5 mg / mL). / mL), and a carbon fiber sample introduced with GO was prepared, which was named M40 J / GO-1μm.

[0059] Step 2: Prepare composite material

[0060] Referring to the method of step 2 of Example 1, the only difference is that the M40 J / GO-200nm carbon fiber is replaced by the M40 J / GO-1 μm carbon fiber to obtain the composite material of the present invention: M40 J / GO-1 μm-epoxy composite material.

experiment example 1

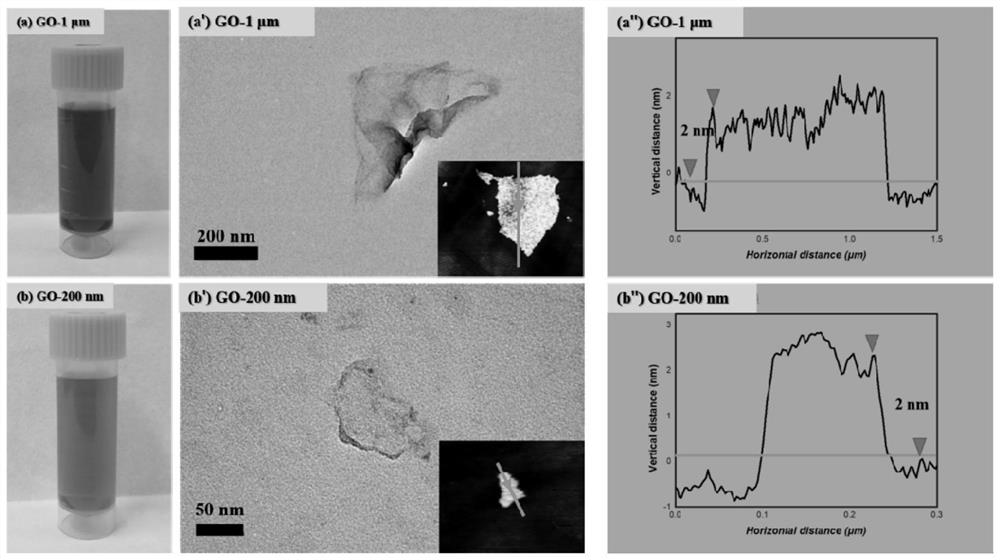

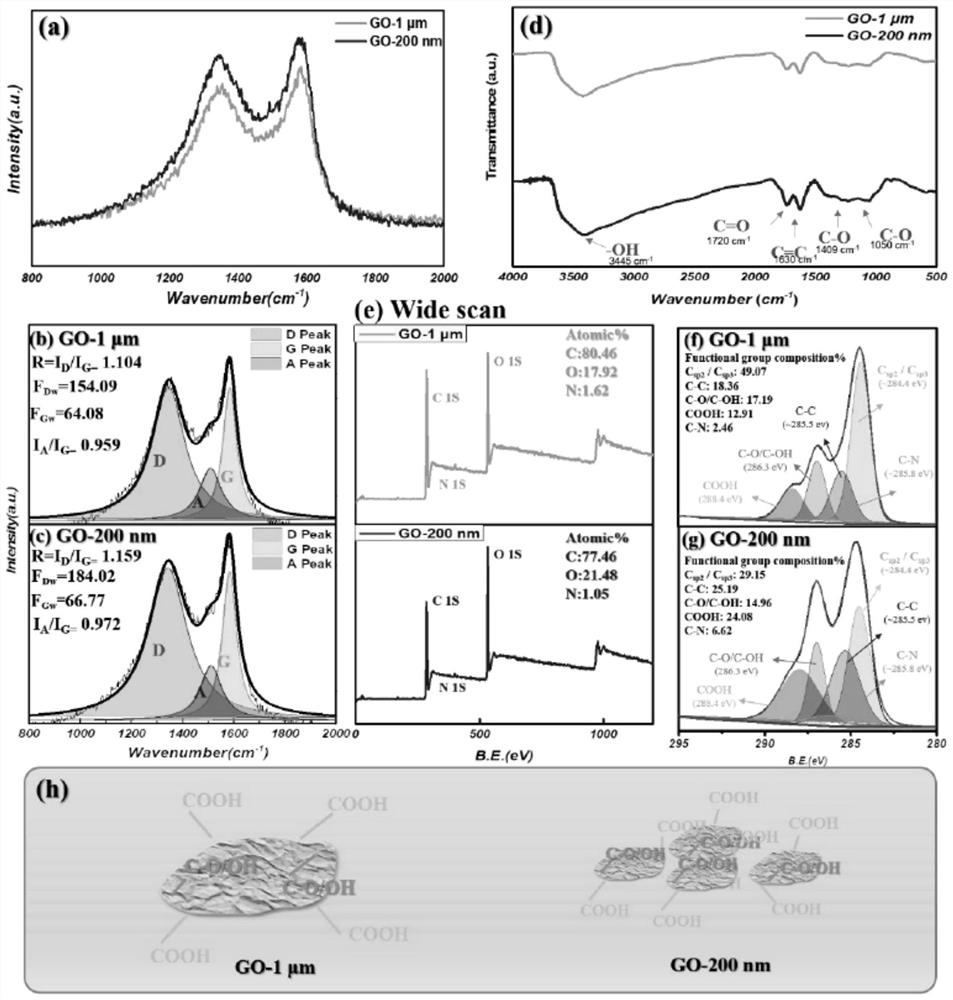

[0067] Experimental Example 1. Structure and Morphological Characterization of Graphene Oxide Sheets with Different Lateral Sizes

[0068] 1. Experimental method

[0069] Test samples: 5 mg / mL GO aqueous suspension with a lateral dimension of 200 nm was sonicated for 30 minutes, and 5 mg / mL GO aqueous suspension with a lateral dimension of 1 μm was sonicated for 30 minutes.

[0070] Detection method: transmission electron microscope (TEM), atomic force microscope (AFM).

[0071] 2. Experimental results

[0072] The result is as figure 2 shown. From figure 2 (a) and figure 2 (b) It can be seen that the GO aqueous suspension with a lateral dimension of 5 mg / mL of 200 nm and the aqueous suspension of GO with a lateral dimension of 1 μm in 5 mg / mL are ultrasonically treated, and the system is transparent, uniform and stable, and the color of the liquid is yellow (color mainly determined by the concentration of GO in the solution).

[0073] From figure 2 (a') and figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com