Shear force connection structure for lightning receptors

A connection structure and shear force resistance technology, applied in circuits, corona discharge devices, electrical components, etc., can solve the problems of easy breakage of air-termination rods, broken air-termination rods, and reduced lightning protection performance of buildings, etc., and achieve low improvement costs. , High safety, excellent shear resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

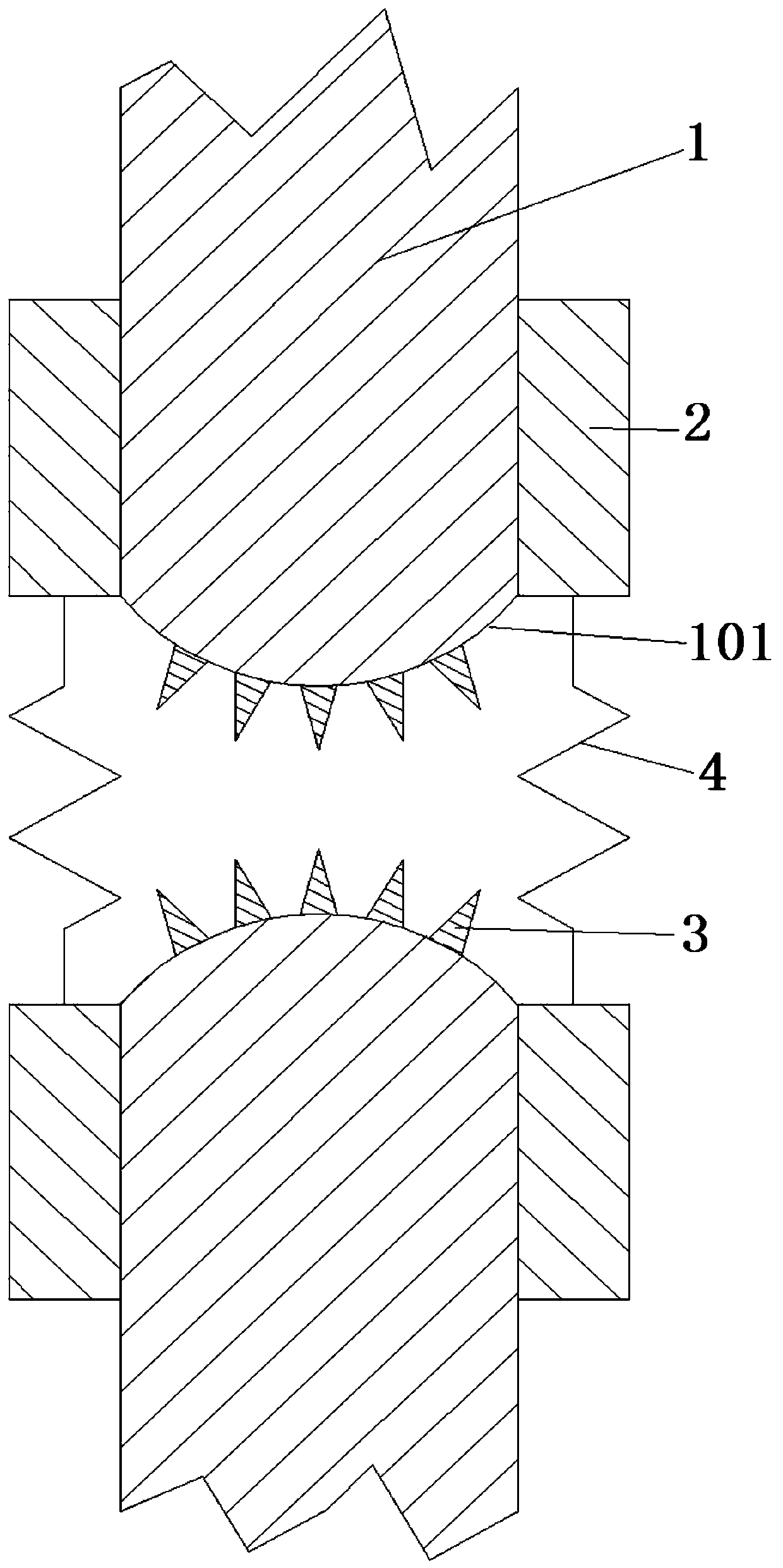

[0019] Such as figure 1 As shown, the lightning-terminating device of the present invention uses a shear force connection structure, including two air-terminating rods (1) with a diameter of 8cm facing each other, and the two lightning-terminating rods (1) are 10cm apart, and the two opposing lightning-terminating rods (1) are 10cm apart. The opposite side (101) of the lightning rod (1) is inferior arc, and the outer surface of the side at the end directly opposite of the lightning rod (1) is also provided with a connecting block (2) with a length of 5 cm matching the shape of the outer surface. ), the connection block (2) protrudes from the outer surface by 2cm, and the two lightning rods (1) are connected by a spring (4) between the connection blocks (2). The number of connecting blocks (2) on the two lightning rods (1) is the same, and the positions are facing one by one, and the spring (4) is connected between the two connecting blocks (2) facing each other. Each lightnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com