Calcium silicon wall ground decoration module and manufacturing method thereof

A wall and floor, silicon-calcium technology, applied in the direction of chemical instruments and methods, laminating devices, hydraulic material layered products, etc., can solve the problems of artificial environmental impact, shedding, and large area of material stacking, etc., which is not easy to achieve Moisture deformation, improved shear performance, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

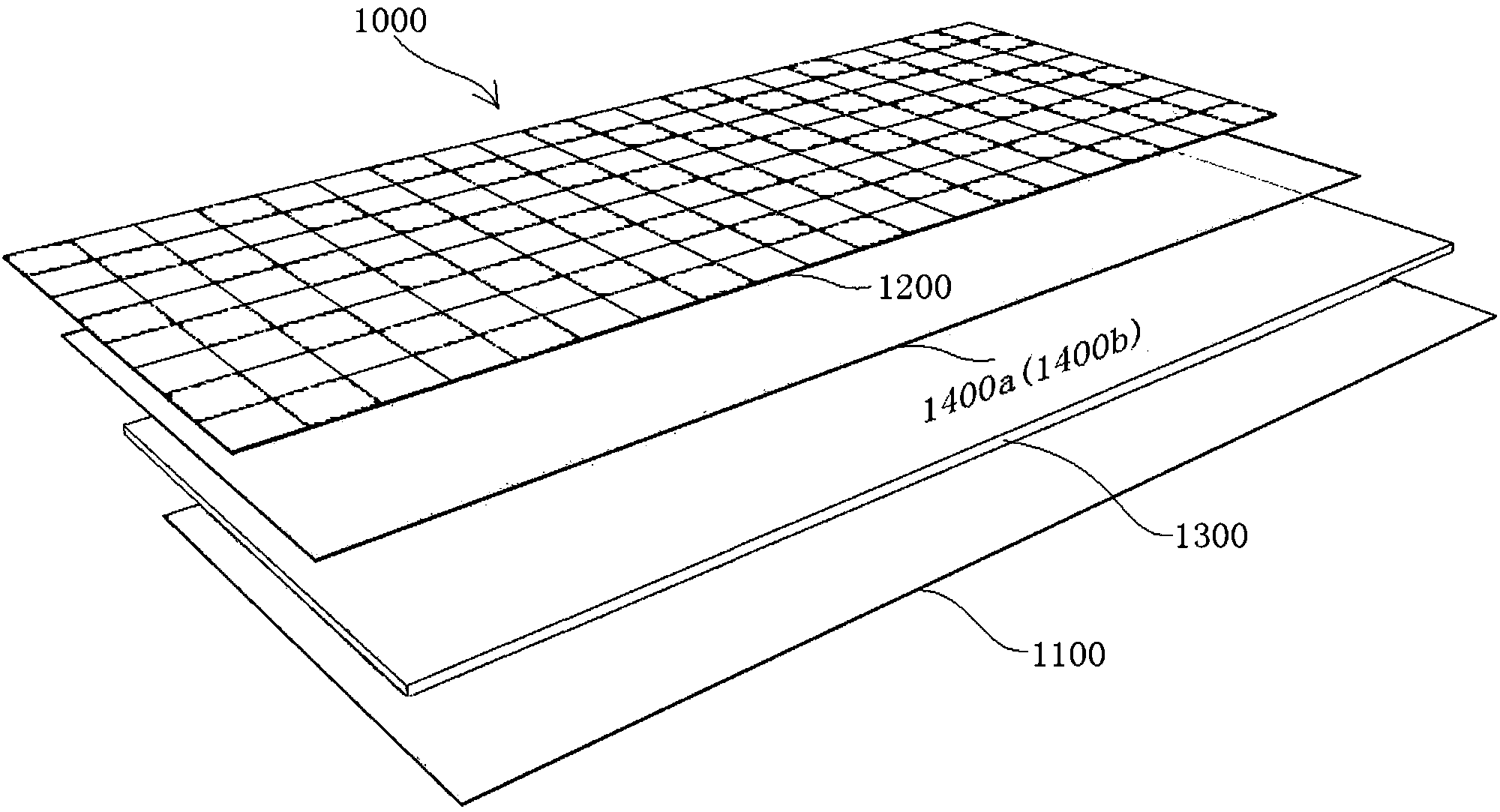

[0035] see figure 1 , the calcium-silicon wall and floor decoration module 1000 shown in the figure, from the inner layer to the outer layer, includes a metal base plate 1100 , a calcium-silicon board 1300 and a decorative surface layer 1200 in sequence. Under the condition of ensuring sufficient strength of the decoration module, its weight should be reduced as much as possible. The thickness of the calcium-silicon board 300 is usually set at 13 mm to 17 mm. Preferably, the thickness of the calcium-silicon board 1300 in this embodiment is set at 15 mm. The decorative surface layer 1200 can use various types of wall and floor tiles, ceramic thin plates, natural stone, artificial stone, fireproof board, mosaic, art glass and so on.

[0036] The preparation method of calcium-silicon wall and floor decoration module 1000, the method is carried out according to the following steps:

[0037] a. Moisture-proof treatment step of the calcium-silicon board, immersing the calcium-silic...

Embodiment 2

[0054] This embodiment is roughly the same as Embodiment 1, the difference lies in step d and step g, see Figure 5 , in step d of this embodiment, the composite resin glue is applied on the back of the decorative surface layer 1200 of the stone to be composited to form a layer of composite resin glue layer 1400b. see Figure 8 , in step g of this embodiment, the wall and floor decoration template 1000 that has not been cured is sent to the curing device 400 for curing. The curing device can be one of a hot-press curing device, a cold-press curing device or a light curing device One or several kinds, the decorative surface layer 1200, the silicon-calcium board 1300 and the metal bottom board 1100 made of stone materials to be compounded are bonded and fixed.

[0055] In summary, the calcium-silicon wall and floor decoration module provided by the present invention can be pre-prepared in the factory, and then transported to the decoration site, and the prefabricated calcium-si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com