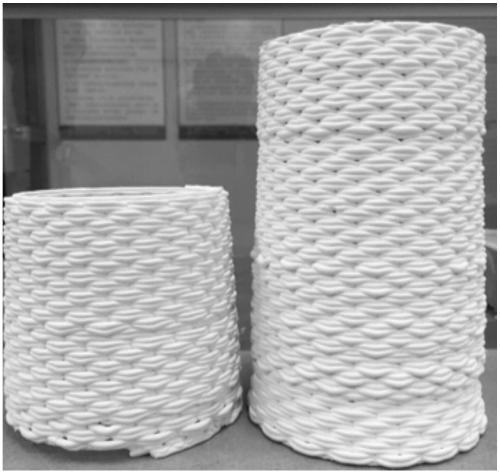

Slurry used for extrusion type 3D white marble powder printing and preparation method thereof

A white marble extrusion technology, applied in the field of 3D printing, can solve the problems of late start and weakness of 3D printing technology, and achieve the effects of good industrial applicability, high printing accuracy and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

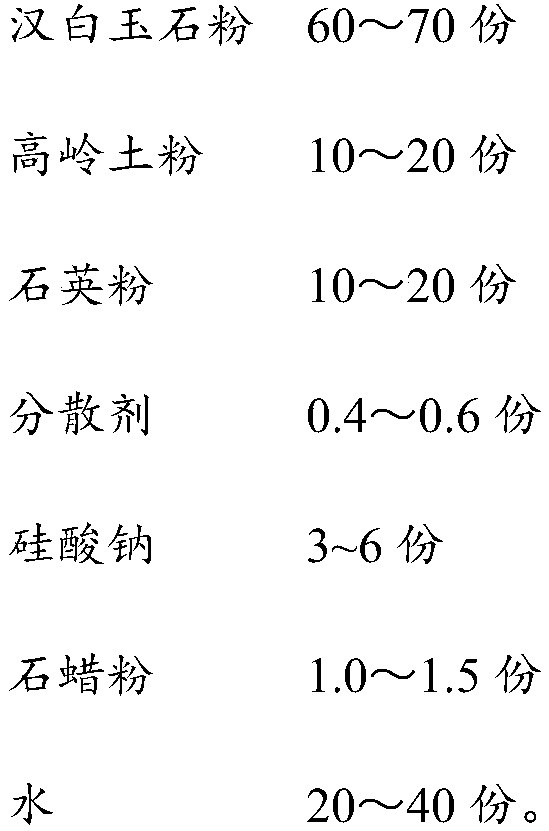

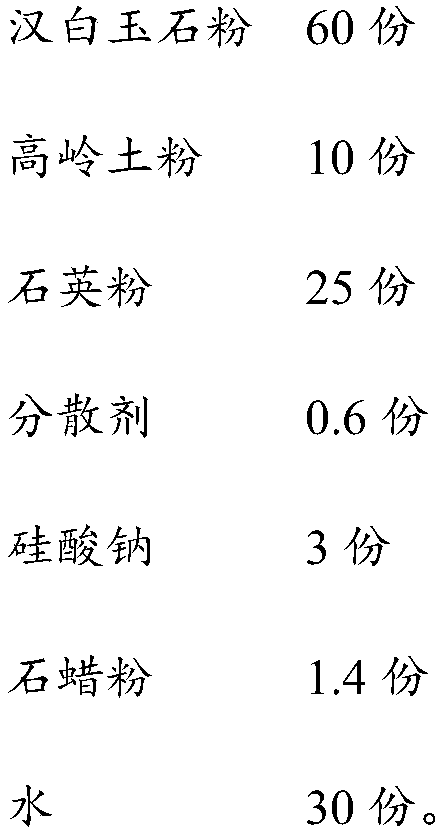

[0026] An extruded 3D white marble powder printing slurry in this embodiment has a solid content of 90% and consists of the following components:

[0027]

[0028] Wherein, the kaolin powder is calcined and ground at a high temperature of 850-1000 degrees Celsius, and its particle size is 1250-1500 mesh, the particle size of white marble powder is 300 mesh, and the particle size of quartz powder is 1500-2000 mesh. The sodium tripolyphosphate is purchased from the market, and its viscosity ranges from 2000 to 2500 mPa·s.

[0029] The preparation method of present embodiment slurry is as follows:

[0030] (0) The white marble powder was wet-milled for 2 hours with a ball mill and a dispersion medium until the particle size was 300 mesh;

[0031] (1) Get 60g white marble powder, 10g kaolin powder and 25g quartz powder and mix them with a mixer for 4 hours until uniformly mixed to obtain mixed powder A;

[0032] (2) Add 0.6g sodium tripolyphosphate, 3g sodium silicate and 1.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com