Room-temperature cured high-temperature-resistant epoxy resin plugging material and preparation method thereof

An epoxy resin, room temperature curing technology, applied in the direction of epoxy resin glue, adhesive type, adhesive, etc., can solve the problems of high brittleness and poor temperature resistance of epoxy resin plugging materials, and achieve strong operability, Effect of short curing time and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

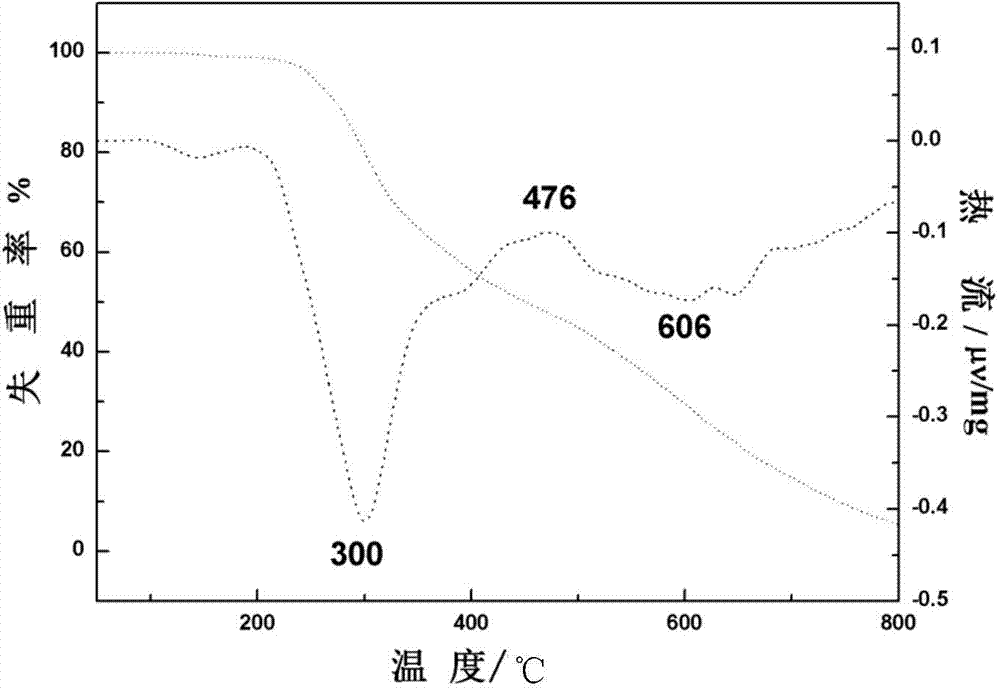

Image

Examples

Embodiment 1

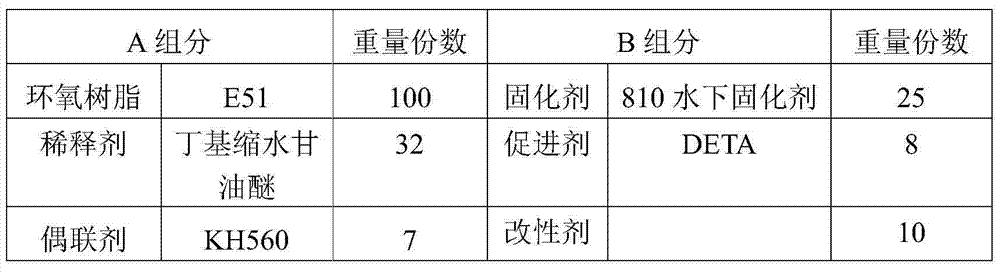

[0027] The composition and content of room temperature curing and high temperature resistant epoxy resin plugging materials are shown in Table 1.

[0028] Table 1

[0029]

[0030] The method of preparation and use is as follows:

[0031] 1) Preparation of component A: Add the components of component A into the reaction kettle according to the weight ratio shown in the above table, and stir evenly to obtain component A.

[0032] 2) Preparation of modifier: Dehydrate polyether polyol (PPG-2000) under vacuum for 3 hours, then add MDI, the molar ratio of polyether polyol to MDI is 1.4:1, and under the protection of nitrogen at 70°C Stir for 4h. The system was left at room temperature to cool down to obtain a modifier.

[0033] 3) Preparation of component B: Add 810 curing agent and accelerator in another reaction kettle according to the weight ratio shown in Table 1, and finally add the modifier prepared in step 2) in this embodiment, and stir evenly, that is Get the B com...

Embodiment 2

[0037] The composition and content of room temperature curing and high temperature resistant epoxy resin plugging materials are shown in Table 2.

[0038] Table 2

[0039]

[0040] The method of preparation and use is as follows:

[0041] 1) Preparation of component A: Add the components of component A into the reaction kettle according to the weight ratio shown in the above table, and stir evenly to obtain component A.

[0042] 2) Preparation of modifier: Dehydrate polyether polyol (PPG-2000) under vacuum for 3 hours, then add IPDI, the molar ratio of polyether polyol to IPDI is 1.6:1, and store at 80°C under nitrogen protection Stir for 4h. The system was left at room temperature to cool down to obtain a modifier.

[0043] 3) Preparation of component B: Add 810 curing agent and accelerator in another reaction kettle according to the weight ratio shown in Table 2, and finally add the modifying agent prepared in step 2) in this embodiment, after stirring evenly, that is ...

Embodiment 3

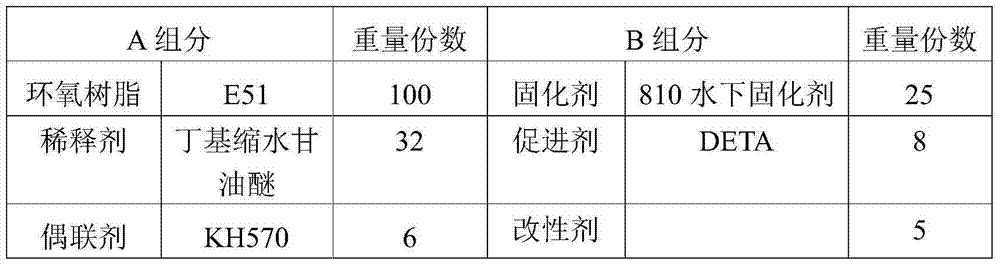

[0046] The composition and content of room temperature curing and high temperature resistant epoxy resin plugging materials are shown in Table 3.

[0047] table 3

[0048]

[0049] The method of preparation and use is as follows:

[0050] 1) Preparation of component A: Add the components of component A into the reaction kettle according to the weight ratio shown in the above table, and stir evenly to obtain component A.

[0051]2) Preparation of modifier: Dehydrate polyether polyol (PPG-2000) under vacuum for 3 hours, then add TDI, the molar ratio of polyether polyol to TDI is 1.3:1, and under the protection of nitrogen at 100°C Stir for 4h. The system was left at room temperature to cool down to obtain a modifier.

[0052] 3) Preparation of component B: Add 810 curing agent and accelerator in another reaction kettle according to the weight ratio shown in Table 3, and finally add the modifier prepared in step 2) in this embodiment, and stir evenly, that is Get the B com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com