Graphene cold-resistant rubber polymer composition and preparation method thereof

A cold-resistant rubber and graphene technology, which is applied in the field of rubber products, can solve the problems of poor mechanical properties such as tensile strength and elongation at break, poor comprehensive performance of shear performance, and failure to meet the requirements of use, etc., to achieve shear performance Excellent, low-temperature shear performance, saving manpower and equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A graphene cold-resistant rubber macromolecular composition is made from the raw materials comprising the following parts by weight:

[0047] 60-68 parts of natural rubber, 8-12 parts of butadiene rubber, 23-29 parts of low-pressure polyethylene, 13-17 parts of polyphenylene ether, 4-6 parts of oxidized polyethylene, 3-4.5 parts of flow aid, 2.6 parts of graphene ~3.4 parts, 5~8 parts of silica modified by silane coupling agent, 3~5 parts of fumed silica, 2~3 parts of foaming agent, 1.4~1.8 parts of activated zinc oxide, 1.6~1.9 parts of bridging agent 1.5-2.2 parts of crosslinking agent, 3-5 parts of antioxidant, 3-5 parts of heat stabilizer; the flow aids are glycerol monostearate and 1,2-capric-3-stearic acid A mixture of glycerides; the graphene is a graphene nanosheet; the crosslinking agent is a mixture of sulfur and trimethylolpropane trimethacrylate.

[0048] Preferably, the graphene cold-resistant rubber polymer composition is made of raw materials comprising ...

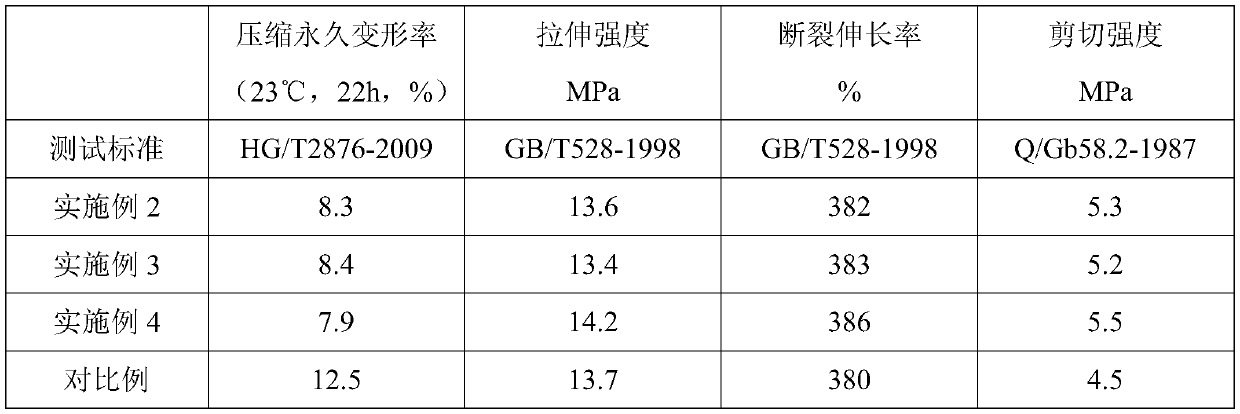

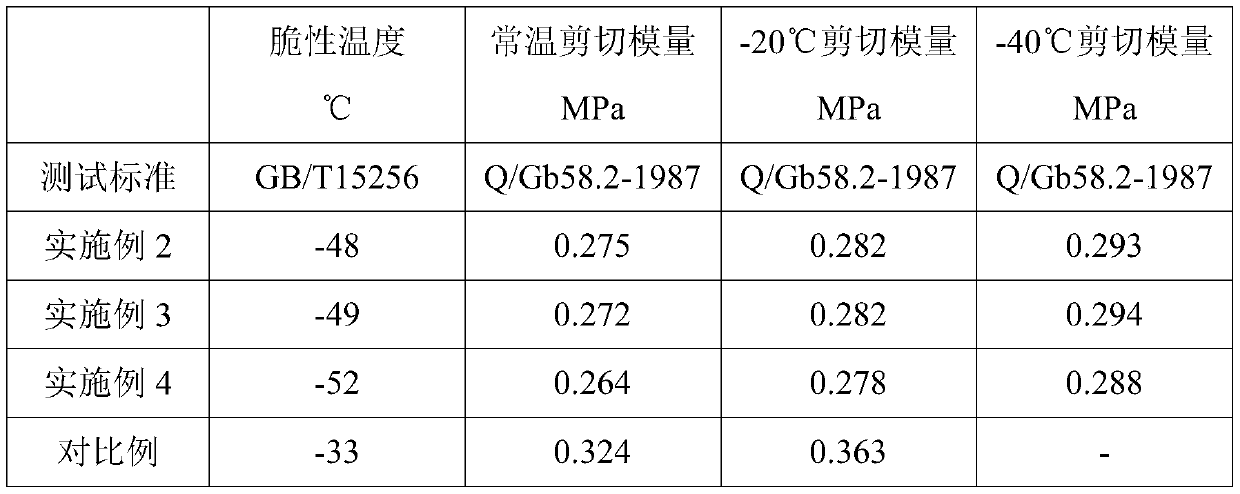

Embodiment 2

[0064] A graphene cold-resistant rubber macromolecular composition is made from the raw materials comprising the following parts by weight:

[0065] 60 parts of natural rubber, 8 parts of butadiene rubber, 23 parts of low-pressure polyethylene, 13 parts of polyphenylene ether, 4 parts of oxidized polyethylene, 3 parts of flow aid, 2.6 parts of graphene, 5 parts of silica modified by silane coupling agent Parts, 3 parts of fumed silica, 2 parts of foaming agent, 1.4 parts of activated zinc oxide, 1.6 parts of bridging agent, 1.5 parts of crosslinking agent, 3 parts of antioxidant, 3 parts of heat stabilizer; the flow aid It is a mixture of glyceryl monostearate and 1,2-capric acid-3-glyceryl stearate; the graphene is a nano-graphene microplate; the cross-linking agent is sulfur and trimethacrylic acid trihydroxy Mixture of methyl propane esters.

[0066] In this embodiment, the number average molecular weight of the oxidized polyethylene is 80,000.

[0067] In this example, t...

Embodiment 3

[0081] A graphene cold-resistant rubber macromolecular composition is made from the raw materials comprising the following parts by weight:

[0082] 68 parts of natural rubber, 12 parts of butadiene rubber, 29 parts of low-pressure polyethylene, 17 parts of polyphenylene ether, 6 parts of oxidized polyethylene, 4.5 parts of flow aid, 3.4 parts of graphene, 8 parts of silica modified by silane coupling agent Parts, 5 parts of fumed silica, 3 parts of foaming agent, 1.8 parts of activated zinc oxide, 1.9 parts of bridging agent, 2.2 parts of crosslinking agent, 5 parts of antioxidant, 5 parts of thermal stabilizer; the flow aid It is a mixture of glyceryl monostearate and 1,2-capric acid-3-glyceryl stearate; the graphene is a nano-graphene microplate; the cross-linking agent is sulfur and trimethacrylic acid trihydroxy Mixture of methyl propane esters.

[0083] In this embodiment, the number average molecular weight of the oxidized polyethylene is 130,000.

[0084] In this exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com