Hinge joint reinforcement bar structure for concrete hollow slab bridge

A technology of hollow slab bridges and hollow slabs, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems such as insufficient anchorage length, achieve insufficient anchorage length and strength, improve service life, and improve shear and bending resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

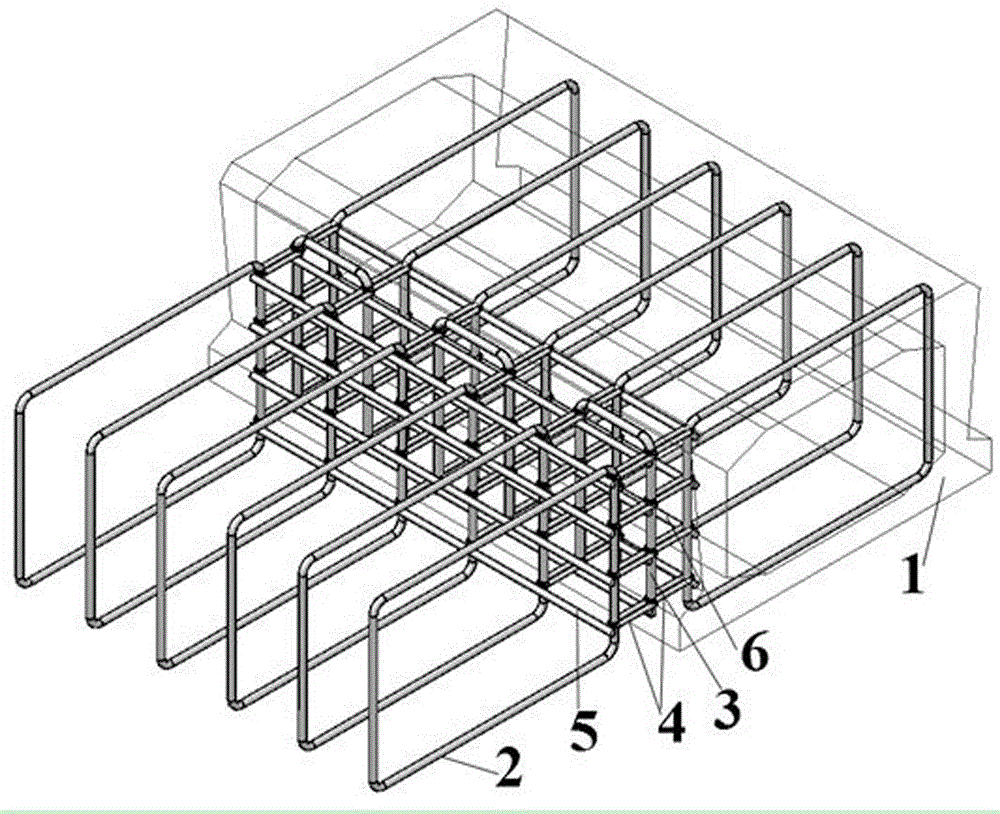

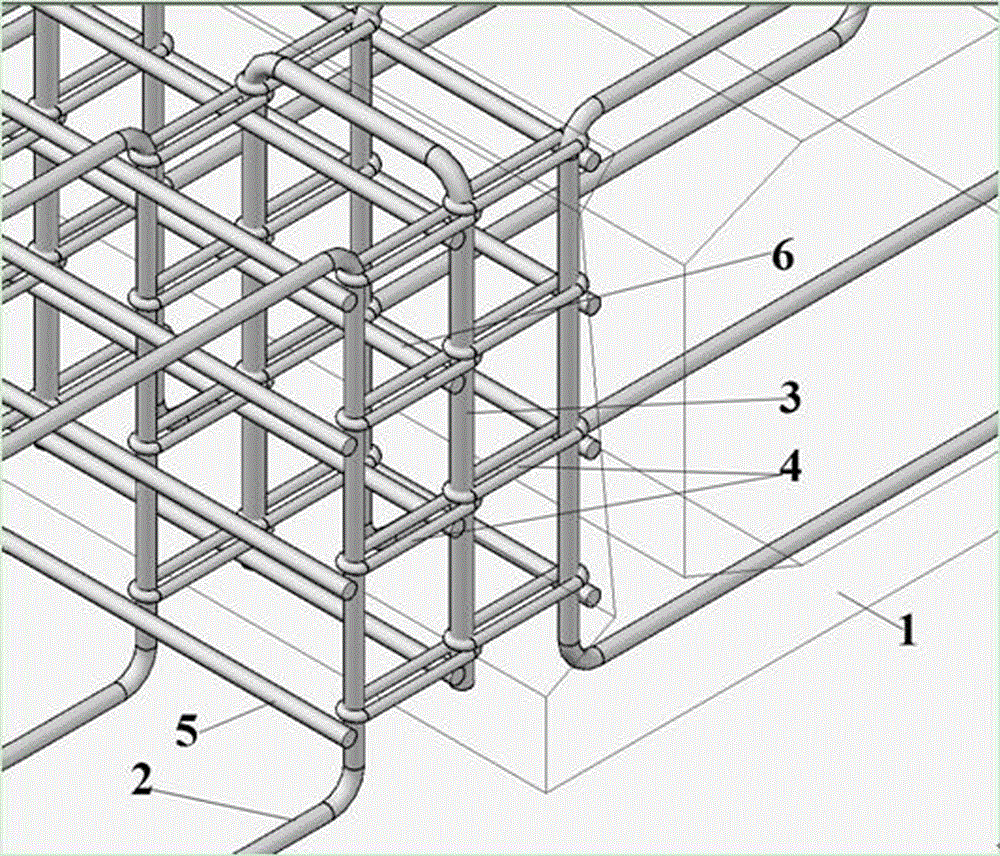

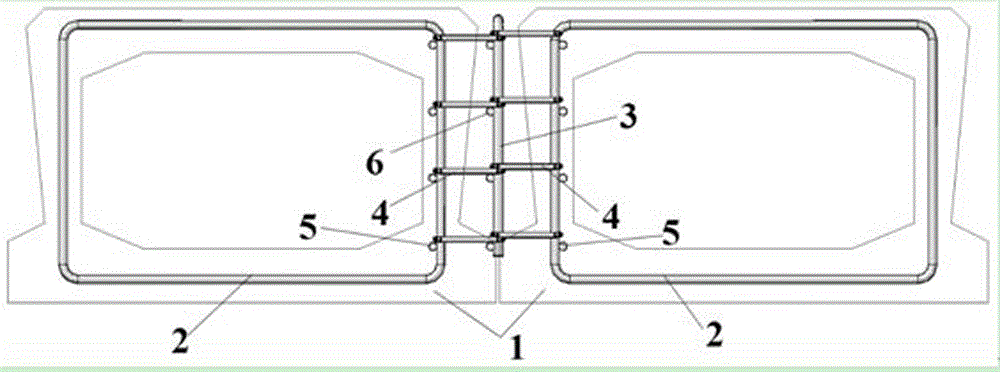

[0029] Embodiment one: if Figure 1-5 As shown, a concrete hollow slab bridge hinge joint reinforcement structure is provided, including a hollow slab body 1 and a hollow slab stirrup 2 arranged inside, and a plurality of U-shaped hinges are arranged between adjacent hollow slab bodies 1 Seam pinned steel bars 3, a plurality of closed ring-shaped hinged tensile steel bars 4 are arranged between the hinged pinned steel bars 3 and the hollow plate stirrups 2 on both sides, and the hinged joints are pinned inside the hollow plate stirrups. Hollow slab longitudinal reinforcement 5 and hinge joint longitudinal reinforcement 6 are arranged respectively between the reinforcement bars.

[0030] The hinged tensile reinforcement 4, the hinged longitudinal reinforcement 6 and the hinged pinned reinforcement 3 are all fixed by spot welding.

[0031] The hinged tensile steel bar 4 is formed by bending a threaded steel bar or a round steel bar with a diameter not less than 10mm.

[0032] ...

Embodiment 2

[0044] Embodiment 2, Hollow slab reinforcement According to the standard diagram of the first-level simply supported 20m hollow slab girder bridge of the new specification of the 2008 general set of drawings of the Ministry of Communications, after the diameter of the web stirrup and the corresponding hollow slab longitudinal reinforcement is increased, it can be It is not necessary to add hollow slab stirrups and longitudinal reinforcements, Figure 6 The web stirrups 7 and longitudinal reinforcements 3 in the hollow slab shown are designed. The diameters of the two are 10 and 12mm in the standard diagram, and here they are uniformly set to 14mm, forming Figure 7 The hinged reinforcement scheme shown.

[0045] The shear force performance of the hinge joint is effectively improved by setting the transverse hinge joint tensile reinforcement at the pin joint of the prefabricated hollow slab bridge, and the longitudinal hinge joint tensile reinforcement arranged in the height dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com