Manufacturing method for environment-friendly fiber reinforced plastic (FRP) iron wire compound type anchor rod

A manufacturing method and composite technology, applied in the direction of sheet pile walls, coatings, buildings, etc., can solve the problems of insufficient tension force of FRP anchors, easy corrosion of steel anchors, etc., to achieve the benefits of automatic control and continuous production, The effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

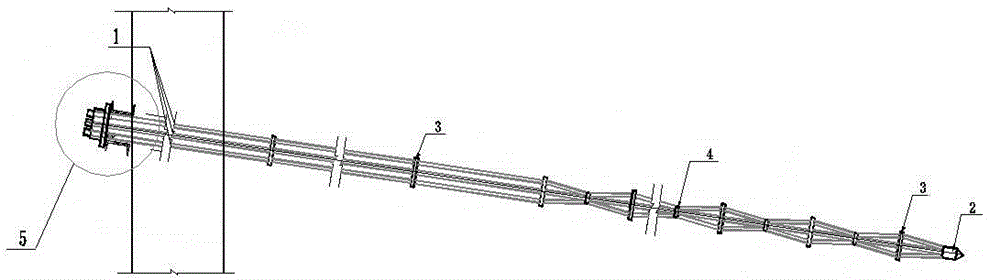

Image

Examples

Embodiment 1

[0055] Production of FRP iron wire composite anchor rods with a size of Φ22mm×1500mm:

[0056]Mix the components of unsaturated polyester resin, polyurethane, glass fiber, and mold release agent in the resin glue tank according to the mass percentage of 70%: 3%: 15%: 1%, and stir for 15 minutes until it is uniform High-performance FRP material. According to the size of the resin glue tank of the production line, in order to ensure that the glass fiber is fully impregnated, at least 5kg of high-performance FRP material should be configured. Put the well-stirred high-performance FRP material into a vacuum drying oven to vacuumize the degassing pressure to below -0.1Mpa, and continue vacuuming for 60 minutes to eliminate the air bubbles in the high-performance FRP material; put 20% of the model into EDR480- 76 strands of T910 alkali-free glass fibers are pulled out from the wire rack, twisted with 6 Φ0.4 iron wires, and then twisted through the twisting bracket to make each bund...

Embodiment 2

[0058] Production of FRP iron wire composite anchor rods with a size of Φ20mm×1500mm:

[0059] Mix the components of unsaturated polyester resin, polyurethane, glass fiber, and mold release agent in the resin glue tank according to the mass percentage of 75.2%: 5%: 18%: 1.8%, and stir for 15 minutes until it is uniform High-performance FRP material. According to the size of the resin glue tank of the production line, in order to ensure that the glass fiber is fully impregnated, at least 5kg of high-performance FRP material should be configured. Put the well-stirred high-performance FRP material into a vacuum drying oven to vacuumize the degassing pressure to below -0.1Mpa, and continue vacuuming for 30 minutes to eliminate the air bubbles in the high-performance FRP material; the 18% model is EDR480- The 76 bundles of T910 alkali-free glass fibers are pulled out from the wire frame, twisted with 5 Φ0.5 iron wires, and then twisted through the twisting bracket, so that each bu...

Embodiment 3

[0061] Production of FRP iron wire composite anchor rods with a size of Φ18mm×1500mm:

[0062] Mix the components of unsaturated polyester resin, polyurethane, glass fiber, and mold release agent in the resin glue tank according to the mass percentage of 85%: 6%: 20%: 3%, and stir for 15 minutes until it is uniform High-performance FRP material. According to the size of the resin glue tank of the production line, in order to ensure that the glass fiber is fully impregnated, at least 5kg of high-performance FRP material should be configured. Put the well-stirred high-performance FRP material into a vacuum drying oven to vacuumize the degassing pressure to below -0.1Mpa, and continue vacuuming for 30 minutes to eliminate the air bubbles in the high-performance FRP material; put 15% of the model into EDR480- 76 bundles of T910 alkali-free glass fibers are pulled out from the wire frame, twisted with 3 Φ0.6 iron wires, and then twisted through the twisting bracket to make each bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com