Multilayer architectural structure adopting prefabricated panel and construction method thereof

A multi-layer building and board technology, applied in the direction of building structure, construction, etc., can solve the problems of slow construction progress and high construction cost, and achieve the effect of low construction cost, low production cost and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

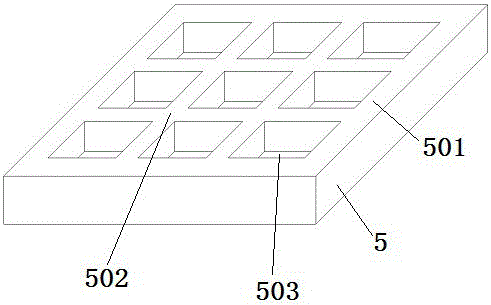

[0041] Such as figure 2 Shown, the present invention a kind of prefabricated plate material that multi-storey building structure uses, and this prefabricated plate material 5 is the rectangular plate material of 3m*2.4m*0.24m, is shaped by the rectangular outer frame 501 of steel bar binding, and the member of 2.4m width is convenient to install Car transportation, two reinforcing ribs 502 parallel to the long sides of the rectangle and two reinforcing ribs 502 parallel to the short sides of the rectangle are arranged in the outer frame, the reinforcing ribs 502 are bundled with steel bars, and the four reinforcing ribs 502 The rectangular space in the outer frame 501 is equally divided into 9 small rectangles, and these small rectangles are filled with hollow bricks or sound-proof materials, and finally the whole board is grouted and poured to form a whole with a thickness of 3m*2.4m*0.24m and a thickness of 240mm.

Embodiment 2

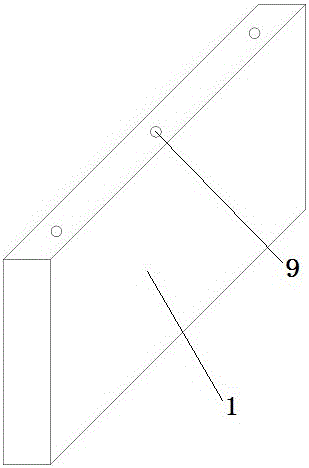

[0043] Such as image 3 , Figure 5 As shown, the present invention is a multi-layer building wall panel using prefabricated panels. The wall panel 1 is made of prefabricated panels 5 as described in Embodiment 1. The difference is that the prefabricated panels 5 used in the wall panel 1 are 5m*2.4 m*0.24m rectangular plate, and the number of reinforcing ribs 502 parallel to the short side of the rectangle is 4, forming a total of 15 small rectangles; at the same time, the surface of 5m*0.24m is used as the top surface and the bottom surface, and the surface of 5m*2.4m The faces are used as the front and the back, wherein, facing the interior of the building is the front, and a row of jacks 9 for interspersing short ribs 8 are opened between the top and bottom, and the jacks 9 are arranged along the direction of the wall, and each A jack 9 is set at an interval of 1m, and the depth of the jack 9 is 30cm.

Embodiment 3

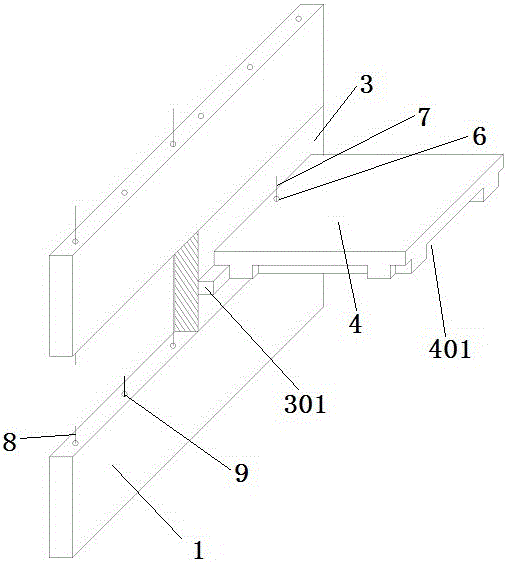

[0045] Such as image 3 , Figure 4 As shown, the present invention is a multi-layer building wall panel using prefabricated boards. The difference between this embodiment and Embodiment 2 is that the wall panel 1 described in this embodiment is a connecting wall panel 3 for connecting the wall surface and the floor slab. The difference between the connecting wall panel 3 and the wall panel 1 is that a row of corbels 301 are arranged on the front of the wall panel 1, and the corbels 301 are rectangular concrete columns of 90cm*40cm*40cm poured, along the horizontal centerline of the front of the wall panel 1 Arrangement, the 90cm long ribs are all parallel to the bottom surface of the wall panel 1, and one of the 90cm*40cm faces overlaps with the front of the wall panel 1, the gap between two adjacent corbels 301 is 30cm, and the corbel 301 is also open There are through holes 6 for passing through steel bars 7 in the vertical direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com