CPC-AC composite pavement fiber asphalt mixture and preparation method thereof

An asphalt mixture and CPC-AC technology are applied in the field of CPC-AC composite pavement fiber asphalt mixture and its preparation, and the field of fiber asphalt mixture of composite pavement surface layer, which can solve the problems of insufficient shear resistance of the asphalt surface layer, and achieve The effect of suitable promotion, improving shear resistance and improving shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

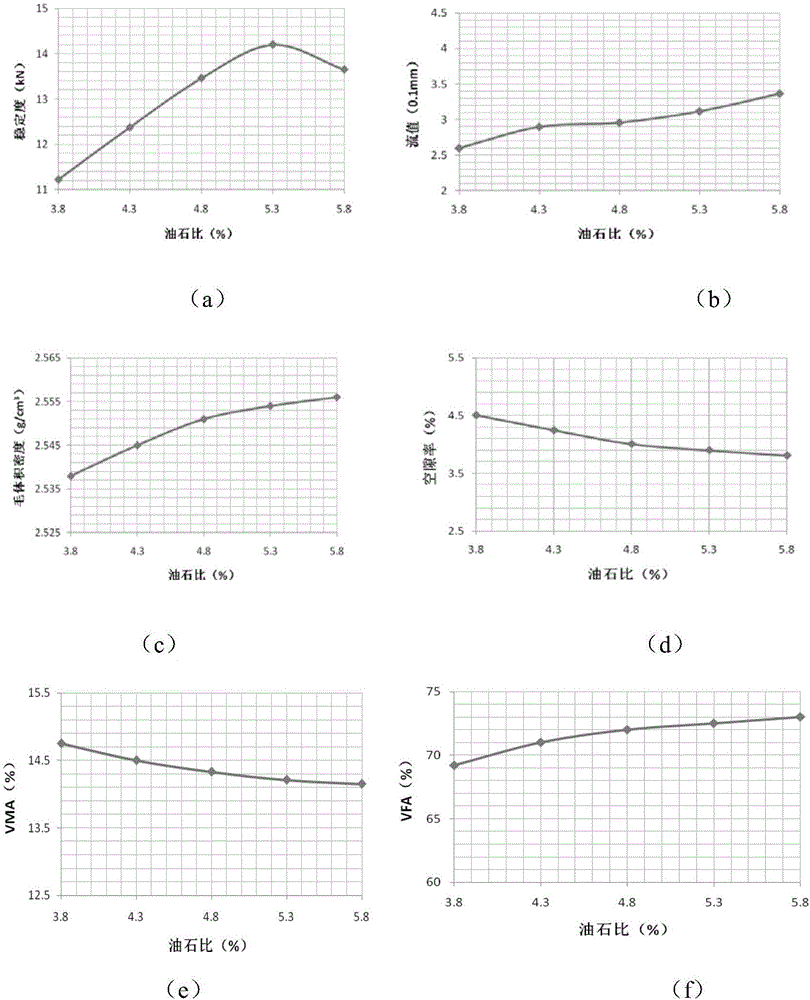

Embodiment 1

[0034] The CPC-AC composite pavement fiber asphalt mixture of this embodiment is composed of the following raw materials in parts by weight: 100 parts of ore material, 4.95 parts of asphalt, and 0.2 part of glass fiber. The asphalt is SBS modified by Shell matrix asphalt processing modification Asphalt, the gradation type of the mineral material is vibration compact AC-13 type (see Table 1 for the specific gradation composition).

[0035] Table 1 Vibration dense AC-13 type gradation composition

[0036]

Embodiment 2

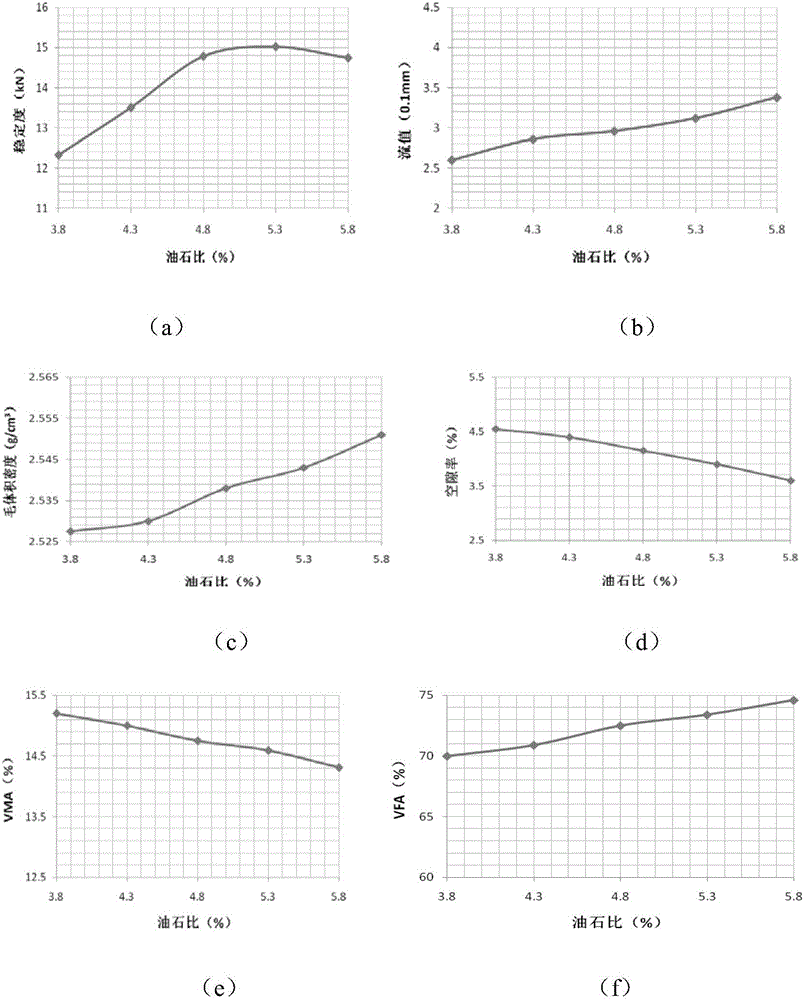

[0038] The CPC-AC composite pavement fiber asphalt mixture of this embodiment is composed of the following raw materials in parts by weight: 100 parts of ore material, 4.9 parts of asphalt, and 0.2 part of glass fiber. The asphalt is SBS modified by Shell base asphalt processing modification Asphalt, the mineral material gradation type is multi-stage interlocking shear AC-16 type (see Table 2 for specific gradation composition).

[0039] Table 2 Multi-stage interlocking shear AC-16 type gradation composition

[0040]

Embodiment 3

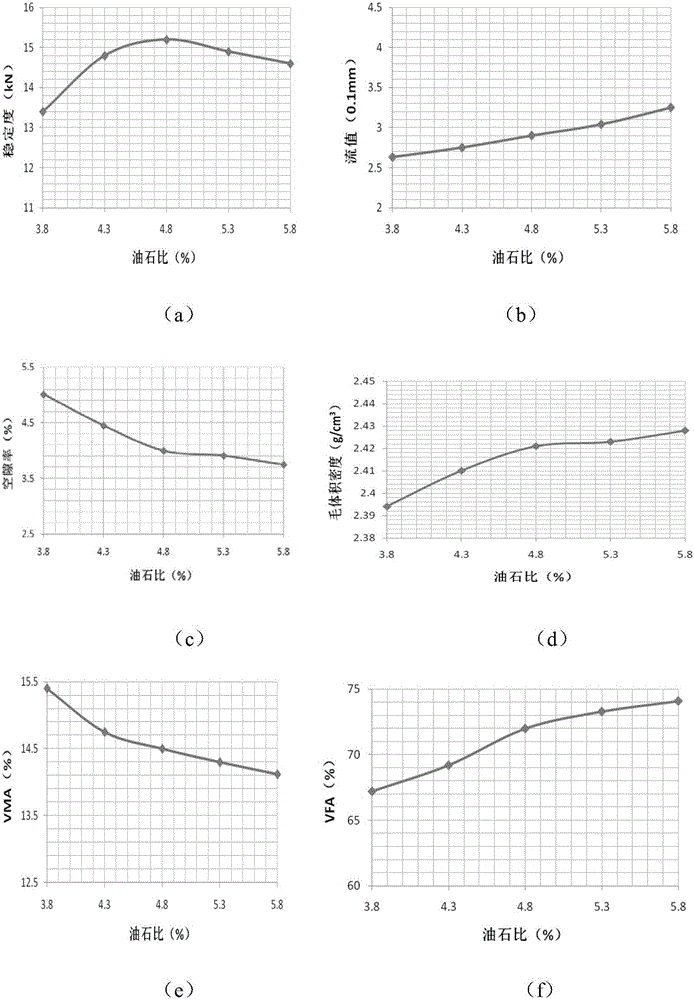

[0042]The CPC-AC composite pavement fiber asphalt mixture in this embodiment is composed of the following raw materials in parts by weight: 100 parts of ore material, 4.8 parts of asphalt, and 0 parts of glass fiber. The asphalt is SBS modified by Shell matrix asphalt processing modification Asphalt, the gradation type of the mineral material is vibration compact AC-13 type (see Table 3 for the specific gradation composition).

[0043] Table 3 Vibration dense AC-13 type gradation composition

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com