Hot press device and hot press method using the same

A heat and control unit technology, which is applied in the direction of electric heating devices, auxiliary devices, printed circuits assembled with electric components, etc., can solve problems such as uneven temperature on the pressing surface, and achieve the effect of avoiding uneven temperature and improving the quality of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

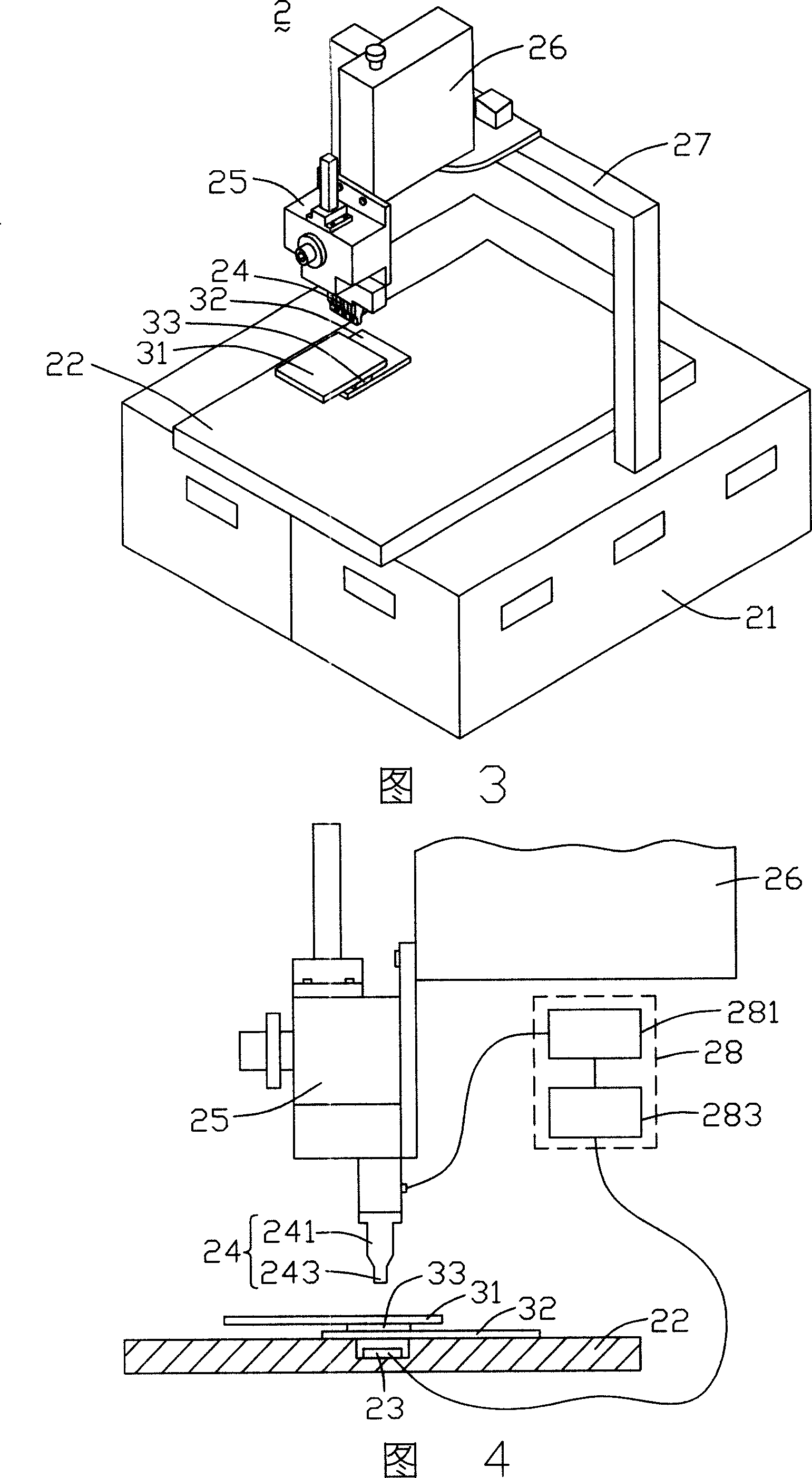

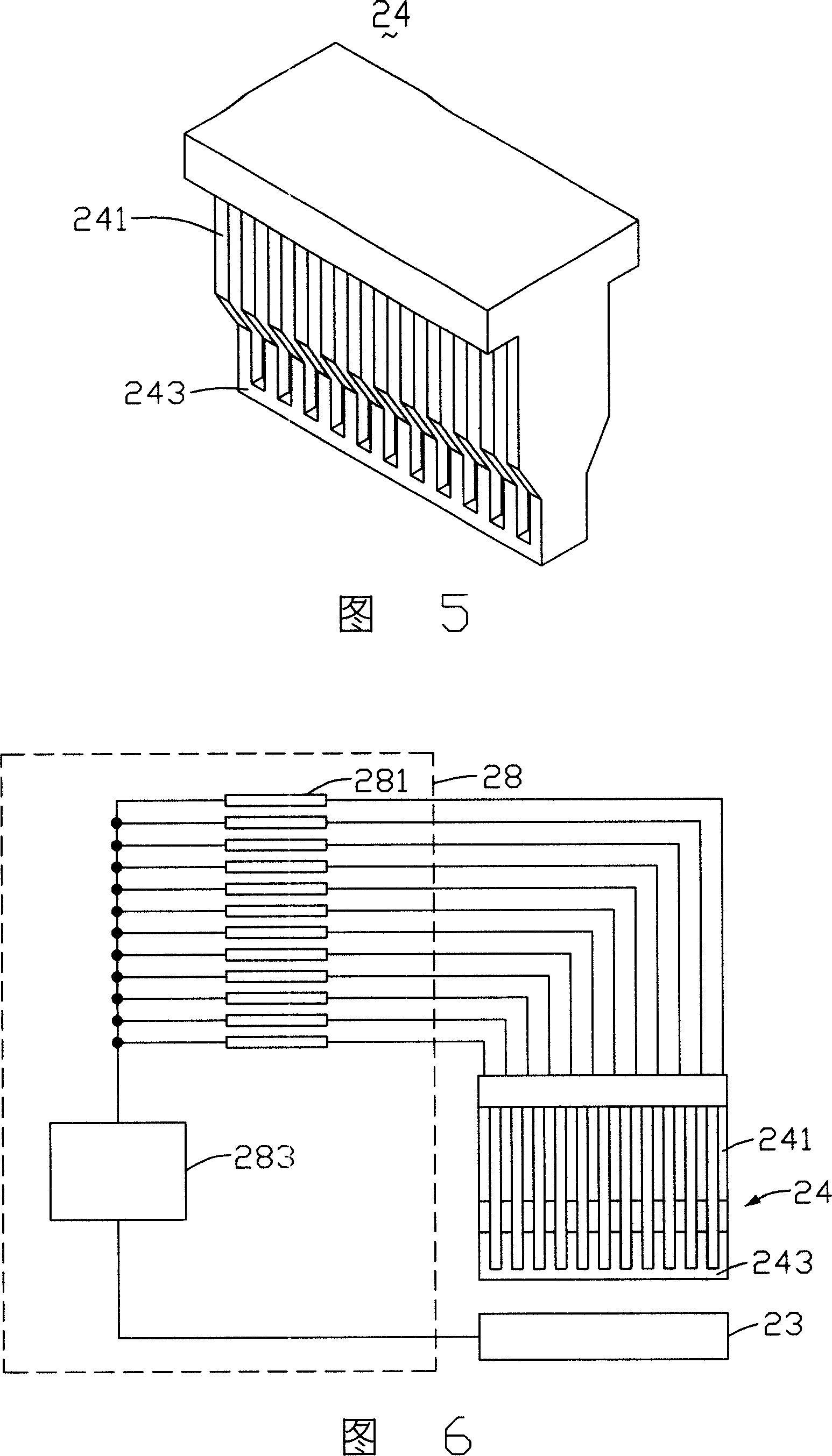

[0020] Please refer to FIG. 3 and FIG. 4 together. FIG. 3 is a schematic perspective view of a thermocompression bonding device disclosed in a preferred embodiment of the present invention, and FIG. 4 is a plan view of a working state of the thermocompression bonding device from another angle of the present invention. The thermocompression bonding device 2 is used to bond two electronic components 31, 32 to be bonded by solder 33, and includes a base 21, an X-Y machine 22, an infrared temperature sensor 23, and a thermocompression contact 24. A lifting mechanism 25, a movable table 26, a horizontal frame 27 and a control unit 28.

[0021] The X-Y machine table 22 is set on the base 21 to play a supporting role, and it can move along the X direction and the Y direction perpendicular to each other in the horizontal plane.

[0022] The infrared temperature sensor 23 is used to sense temperature and convert the sensed temperature signal into an electrical signal. It is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com