Reaction chamber temperature zone control system

A technology of control system and temperature partition, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as thermal process effectiveness of annealing process, different degrees of heating of silicon wafers, warping and deformation of silicon wafers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

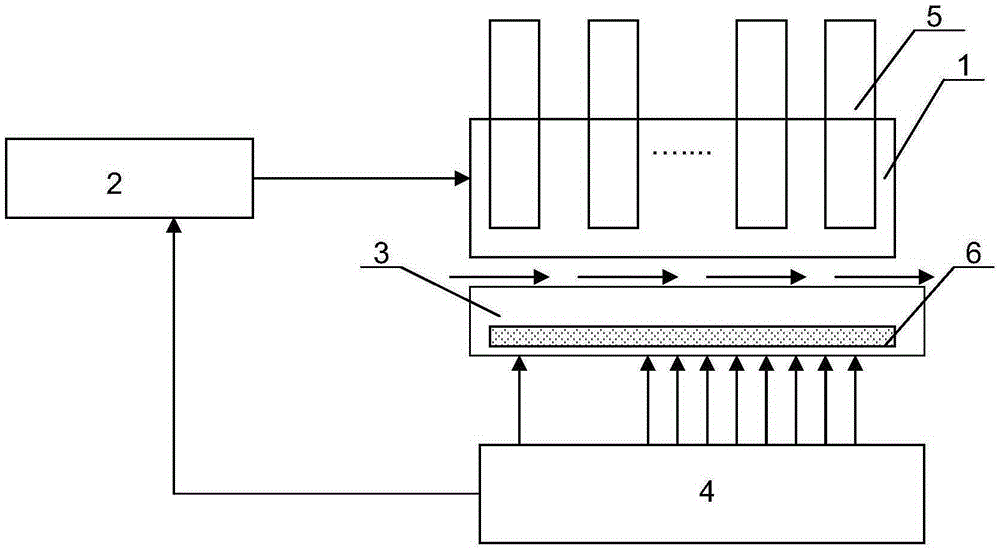

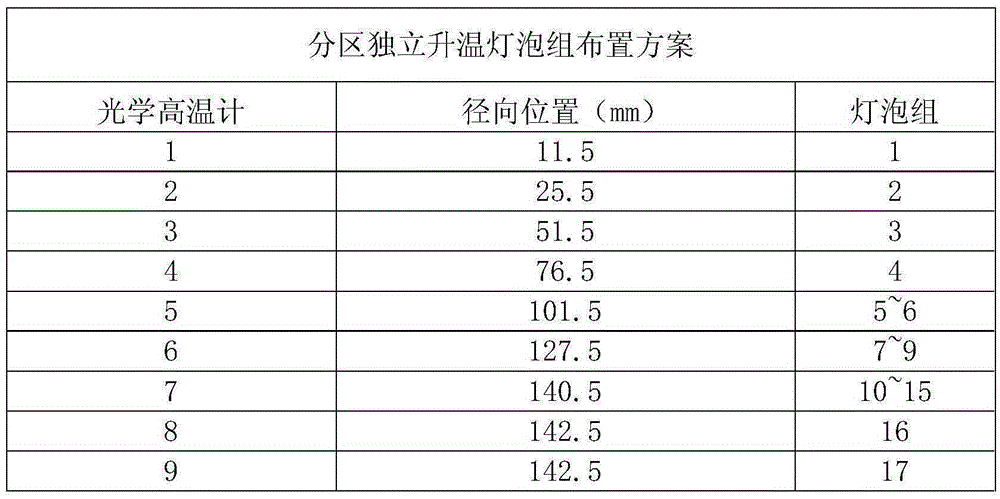

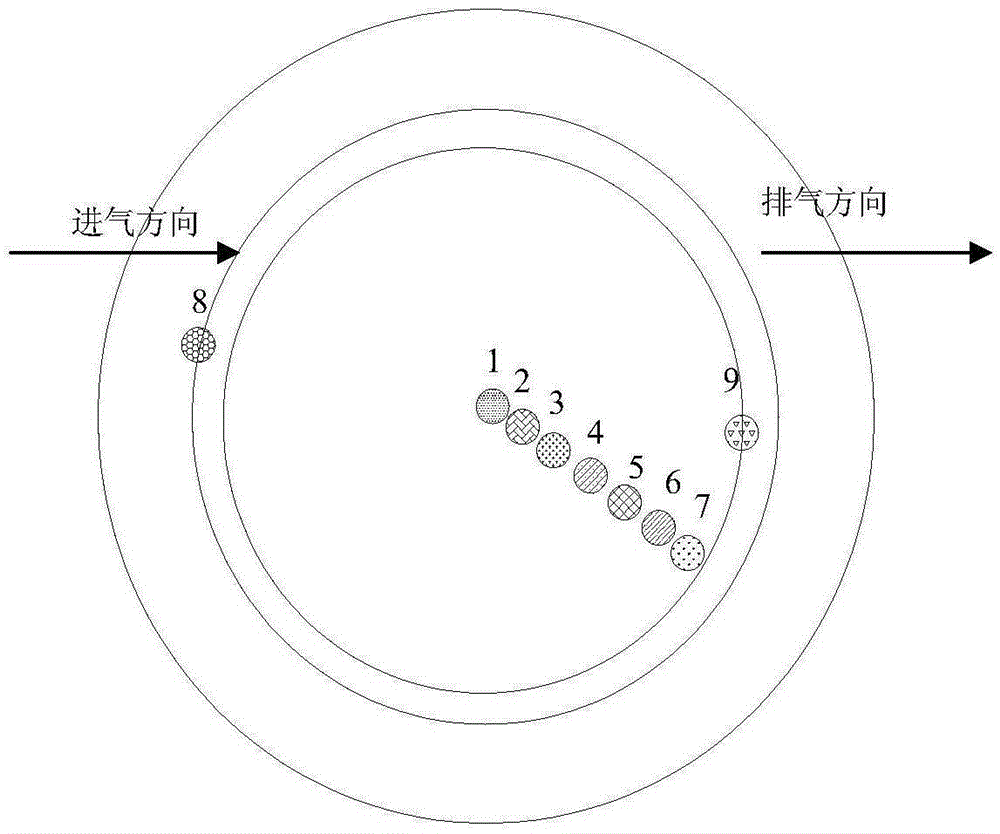

[0025] In order to facilitate the implementation of the present invention by those having ordinary knowledge in the field to which the present invention pertains, examples of the present invention will be described in detail with reference to the accompanying drawings shown below. However, the present invention can be implemented in various forms and is not limited to the examples described here. In order to more clearly describe the present invention, parts irrelevant to the description in the drawings are omitted; and, throughout the specification, similar drawing symbols are assigned to similar parts.

[0026] Throughout the description of the present invention, the "connection" of one part to another part includes not only "direct connection" but also "electrical connection" through other components.

[0027] Throughout the description of the present invention, a certain part is located "above" another part, including not only a state where a certain part is in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com