Aluminum alloy electrolytic oxidation film forming device

An electrolytic oxidation and film-forming device technology, which is applied in the field of aluminum alloy film formation, can solve the problems that the film formation temperature cannot be changed, the requirements of aluminum alloy film formation cannot be met, and the temperature cannot be controlled accurately, so as to improve the film formation efficiency, Save cost and avoid the effect of temperature unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

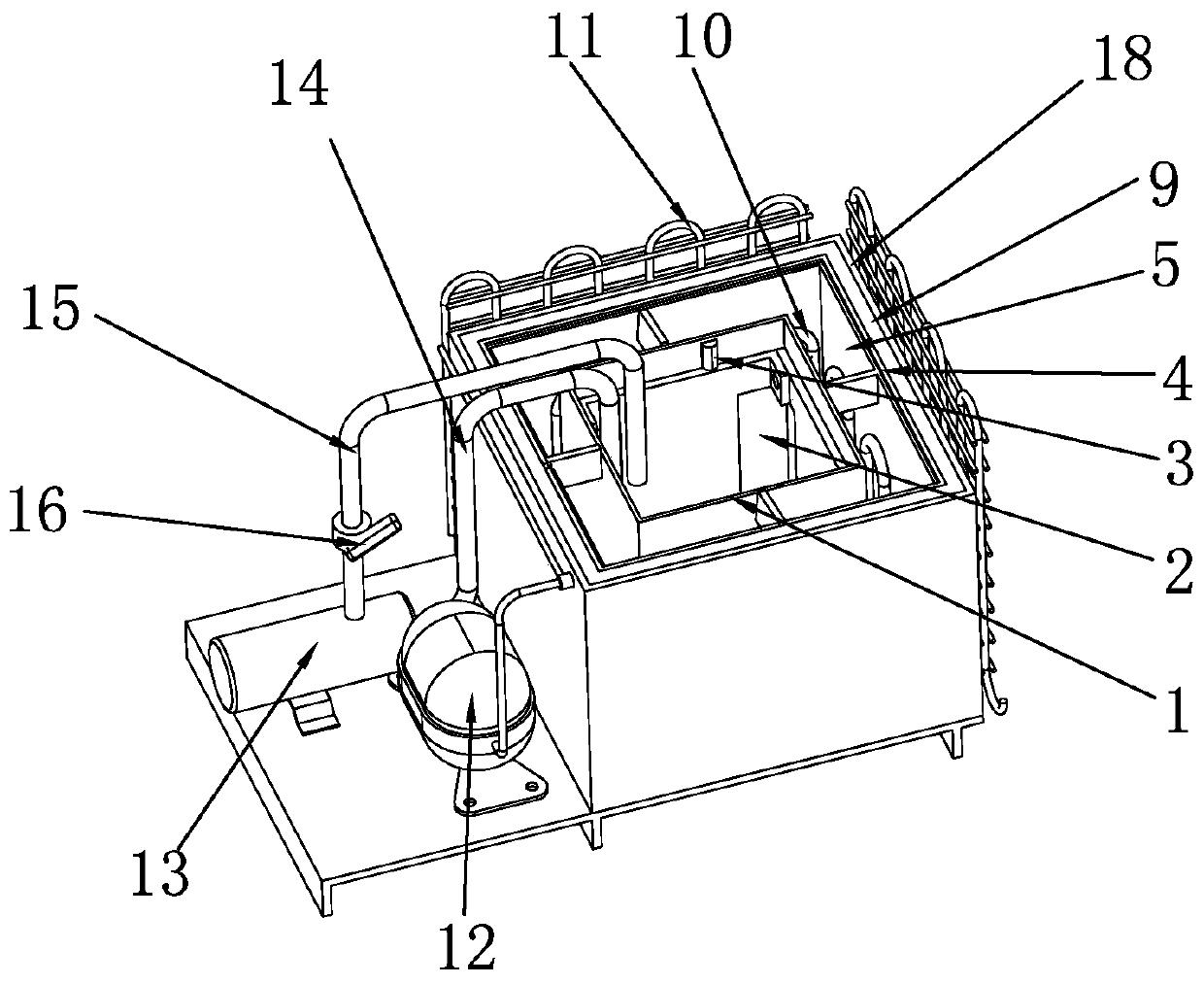

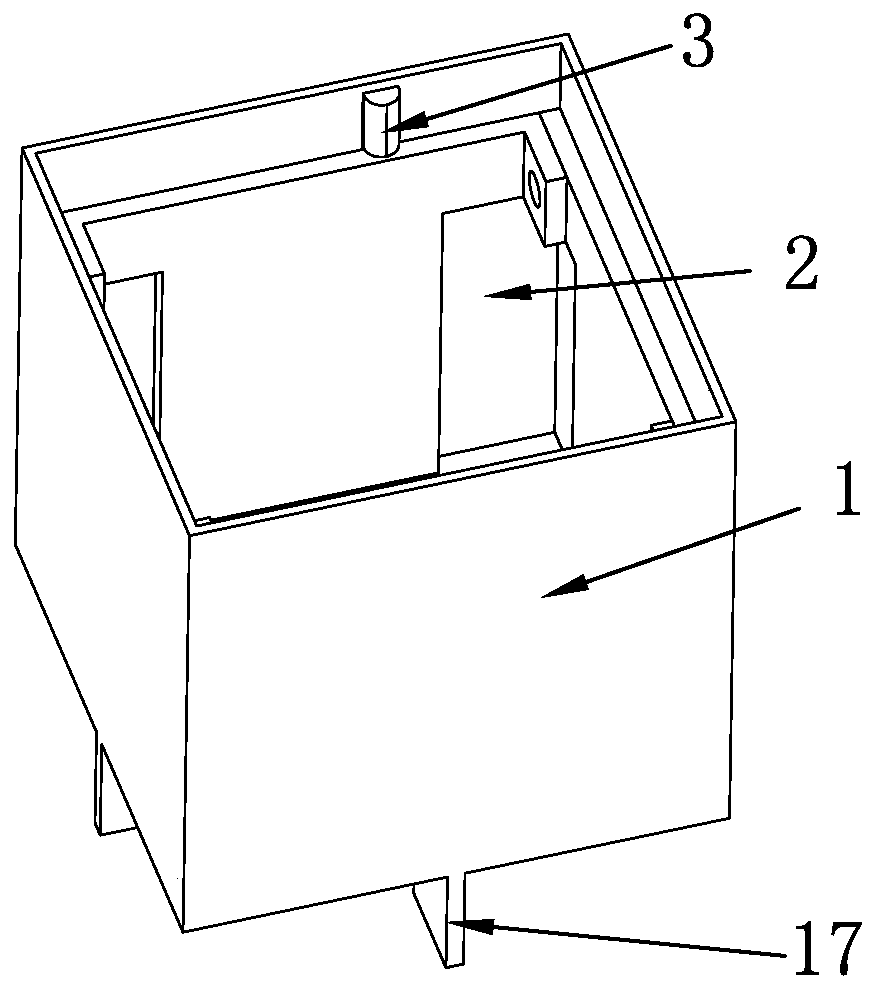

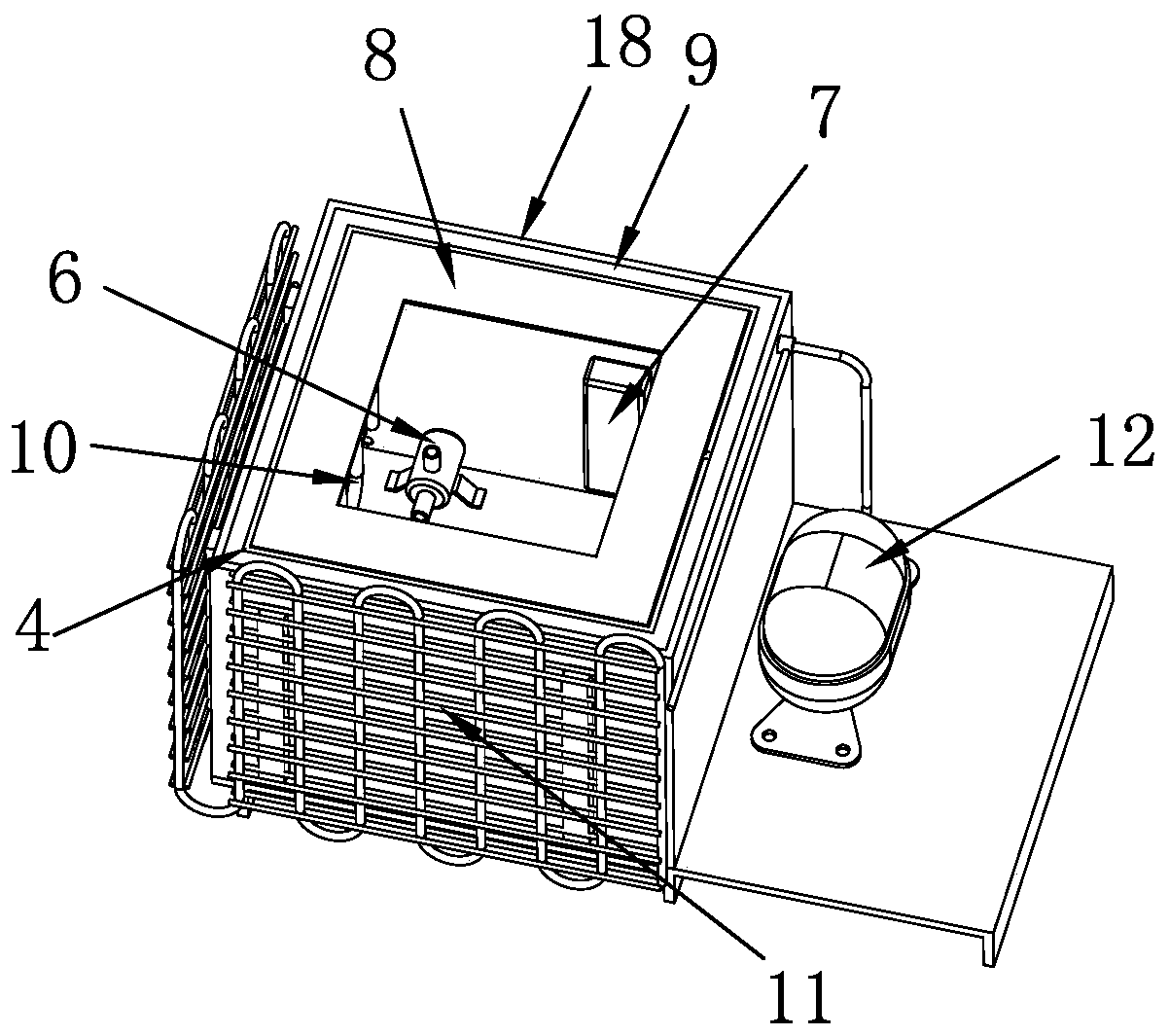

[0033] Such as Figure 1-Figure 4 Commonly shown is an aluminum alloy electrolytic oxidation film forming device, including an oxidation device and a temperature control device; the oxidation device includes an oxidation tank 1 ; an anode electrode plate 2 and a temperature sensor 3 are arranged in the oxidation tank 1 . The temperature control device includes a temperature control tank 4, the oxidation tank 1 is placed in the temperature control tank 4, and a temperature control chamber 5 is formed between the oxidation tank 1 and the temperature control tank 4; A built-in circulation pump 6 is provided in the chamber 5; a heating device is provided in the temperature control chamber 5, and the heating device includes an electric heating rod 7 arranged in the temperature control chamber 5, and the upper part of the temperature control chamber 5 is provided with There is a ring-shaped heat preservation cover 8; the outer wall of the temperature control tank 4 is provided with ...

Embodiment 2

[0035] The difference from Example 1 is that the oxidation tank liquid circulation device includes an air compressor and a compressed air pipeline connected thereto; the outlet of the compressed air pipeline is arranged at the bottom of the oxidation tank; the outlet of the compressed air pipeline There are multiple aeration holes. The air compressor is electrically connected to the controller.

[0036] As a preferred embodiment, the radiator 11 includes at least two cooling fins, the cooling fins are fixed on the outer wall of the outer box 18; the outer wall of the outer box 18 is provided with a fixing plate, and the cooling fins are fixed on the fixed plate. The external dimensions and internal dimensions of the heat preservation cover 8 are adapted to the external wall dimensions of the temperature control tank 4 and the internal wall dimensions of the oxidation tank 1 respectively. The temperature control tank 4 is a temperature control tank for anti-corrosion material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com