Bricklayer auxiliary device for building materials

An auxiliary device, bricklayer's technology, applied to clay preparation devices, construction, building construction, etc., to achieve the effect of easy operation and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

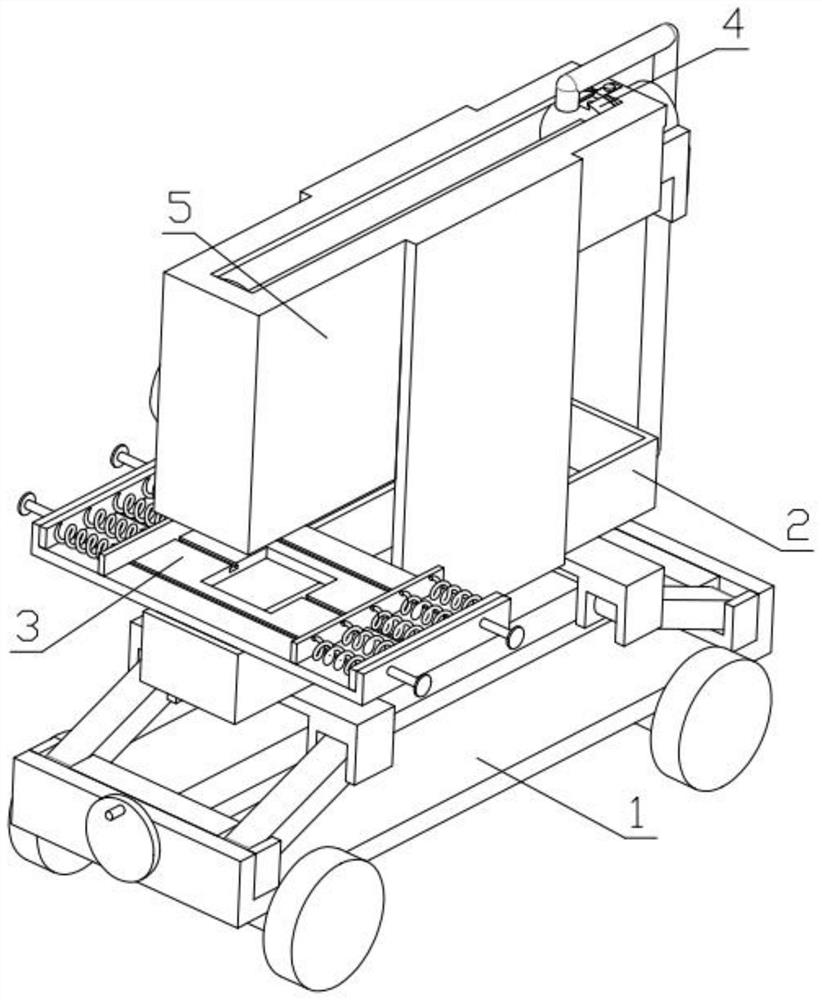

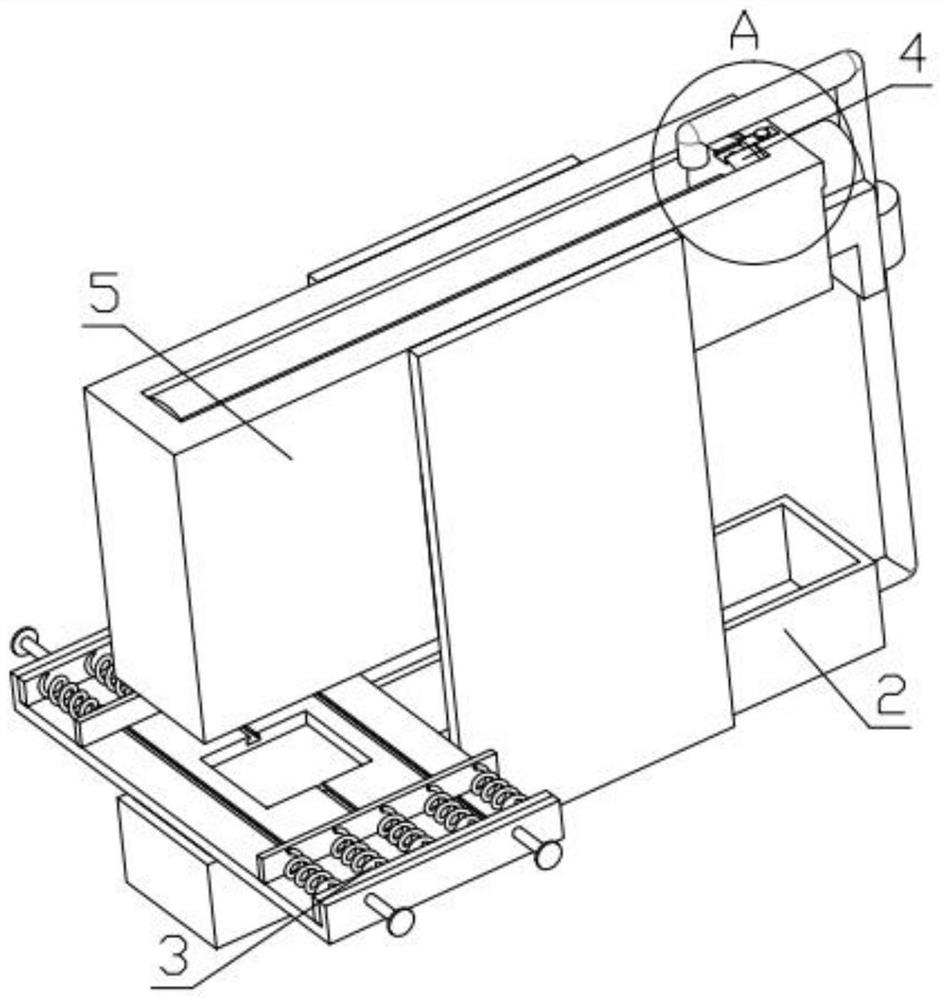

[0039] Combine below Figure 1-17Describe this embodiment, a bricklayer auxiliary device for building materials, including a lifting and moving mechanism 1, a waste water collection mechanism 2, a tile placement mechanism 3, a stirring and pushing mechanism 4, a top box body 5, and a feeding mechanism 6. The waste water collection mechanism 2 is fixedly installed on the mobile mechanism 1, the top box body 5 is fixedly installed on the waste water collection mechanism 2, the feeding mechanism 6 is fixedly installed on the top box body 5, and the tile placement mechanism 3 is fixedly installed on the waste water collection mechanism 2 Above, the stirring and pushing mechanism 4 is fixedly installed on the top box body 5 .

specific Embodiment approach 2

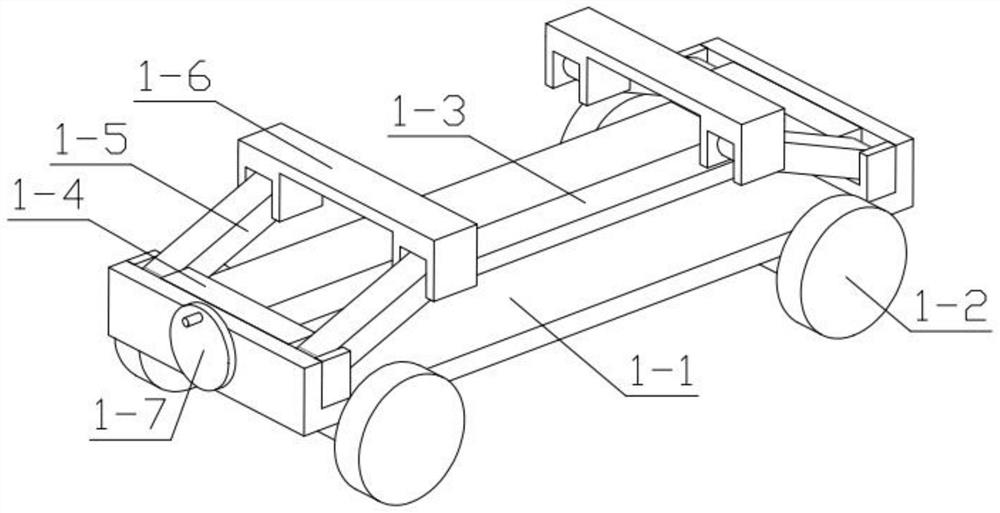

[0041] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the first embodiment, the described lifting and moving mechanism 1 includes a vehicle chassis 1-1, a moving wheel 1-2, a two-way threaded rod 1-3, a push horizontal plate 1-4, Supporting hinge 1-5, U-shaped connecting plate 1-6, rotating disc 1-7, moving wheel 1-2 is installed in the groove provided on the vehicle chassis 1-1 in rotation, pushes the horizontal plate 1-4 to slide and install In the groove provided on the undercarriage 1-1, the two ends of the push cross plate 1-4 are respectively hinged with supporting hinges 1-5, and the other end of the supporting hinges 1-5 is hinged on the U-shaped connecting plate 1- 6, the two-way threaded rod 1-3 is rotatably installed in the groove provided on the undercarriage 1-1, and the rotating disk 1-7 is fixedly installed on one end of the two-way threaded rod 1-3, and the two-way threaded rod 1-3 is connected with the push Horizonta...

specific Embodiment approach 3

[0043] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain Embodiment 2. The waste water collection mechanism 2 includes a water tank 2-1, an upper water pipe 2-2, a water pump 2-3, a drain pipe 2-4, and a water tank 2-1 Fixedly installed on the U-shaped connecting plate 1-6, one end of the upper water pipe 2-2 is fixedly installed at the through hole provided on the water tank 2-1, and the other end of the upper water pipe 2-2 is fixedly installed on the water pump 2-3, The water pump 2-3 is fixedly installed with a drainage pipe 2-4, and the water pump 2-3 is fixedly installed on the top casing 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com