Cast-in-situ concrete construction method for pseudo-classic architecture slope roof

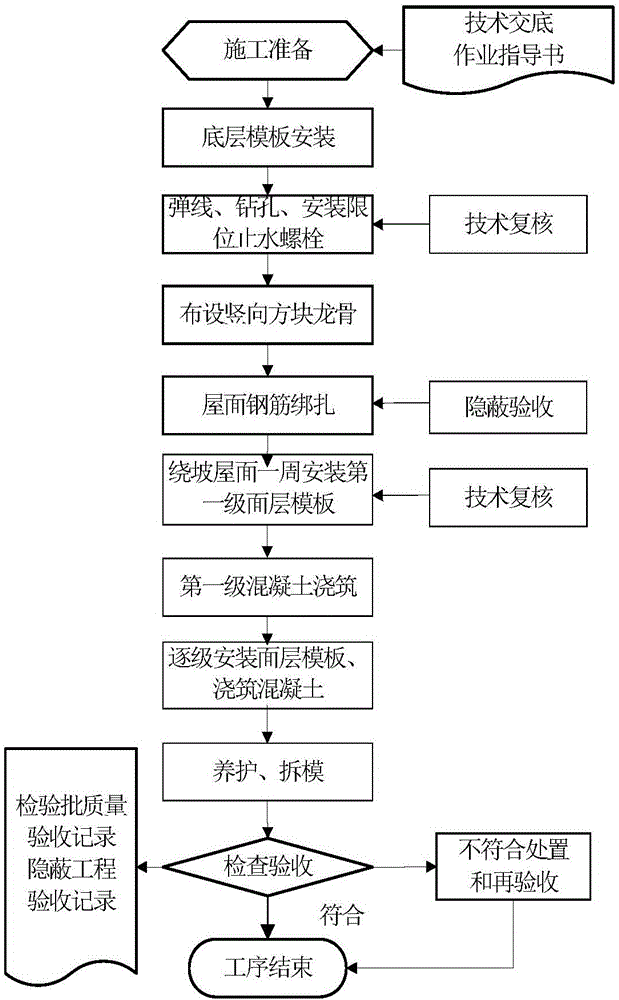

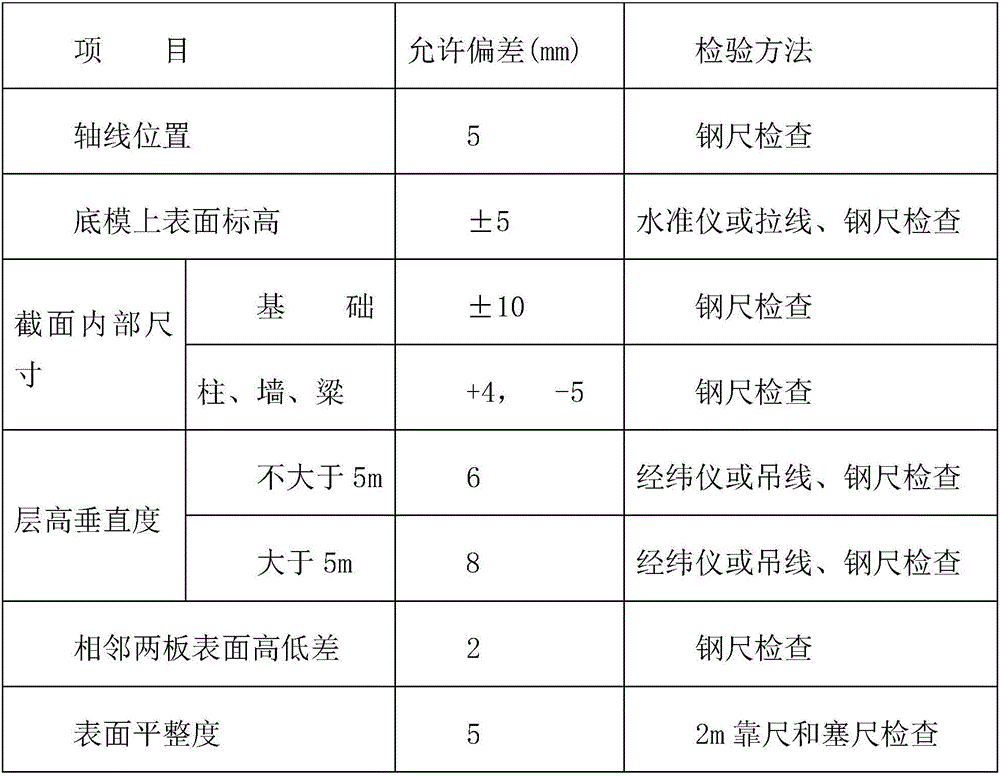

A technology of antique buildings and construction methods, which is applied in the on-site preparation of building components, construction, building components, etc., can solve the problems of poor concrete pouring, leakage, etc., to ensure the quality of concrete structures, speed up the construction progress, and simplify the operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

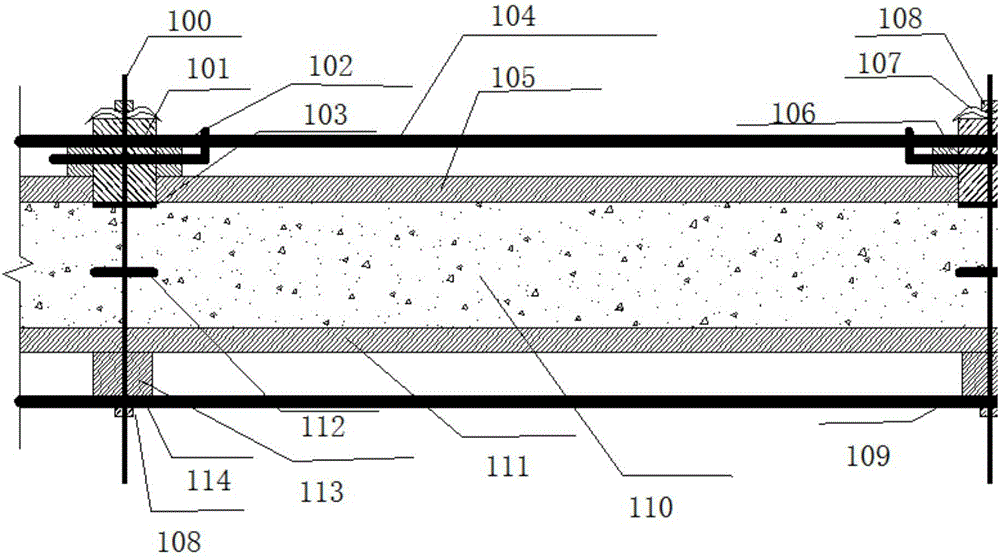

[0036] This technical solution is to arrange the vertical keel 113 of the bottom formwork along the direction from the bottom of the slope to the top of the slope according to the direction of the slope roof after the bottom formwork 111 of the slope roof is installed according to the requirements. Clamp and position the water stop bolts to control the thickness of the structure and the basis for installing the surface formwork 105. The surface formwork 105 is graded and prefabricated in advance according to the results of lofting. When installing, the surface formwork 105 is placed between the vertical keels 101 of the surface formwork, and inserted into the vertical keel 101 of the surface formwork and the surface course through the hook pin 102. The template 105 can be fixed in the pre-drilled circular hole. The carpenter installs the surface formwork 105 step by step around the sloping roof from bottom to top, and concrete can be poured every time one level is installed, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com