Prefabricated composite wall panel

A composite wallboard and layer technology, applied in the direction of floor, covering/lining, construction, etc., can solve the problems of high level requirements of construction personnel, low tile flatness, complex process, etc. High surface flatness and good construction site environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific examples.

[0030] The up, down, left, and right described in the present invention refer to the observer facing the decorative panel layer 1 of the composite wallboard; meanwhile, the described inside refers to the side close to the wall 9, and the outside is the side close to the observer.

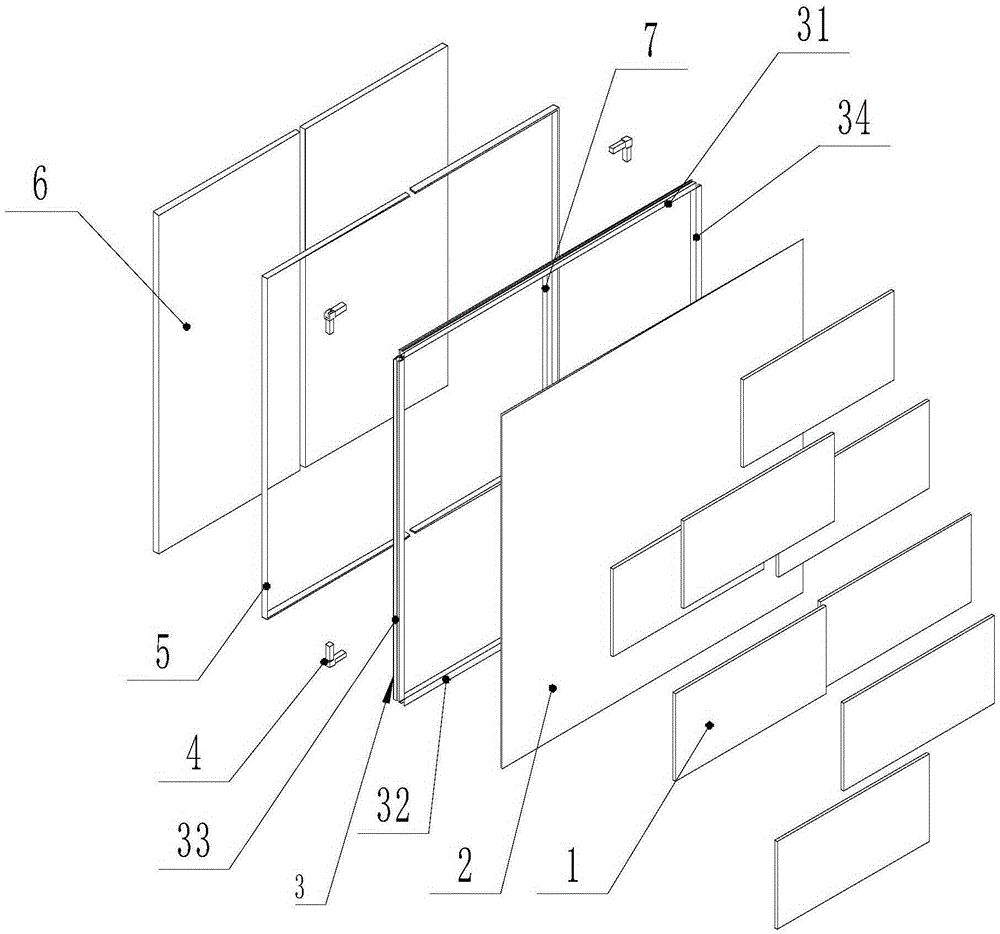

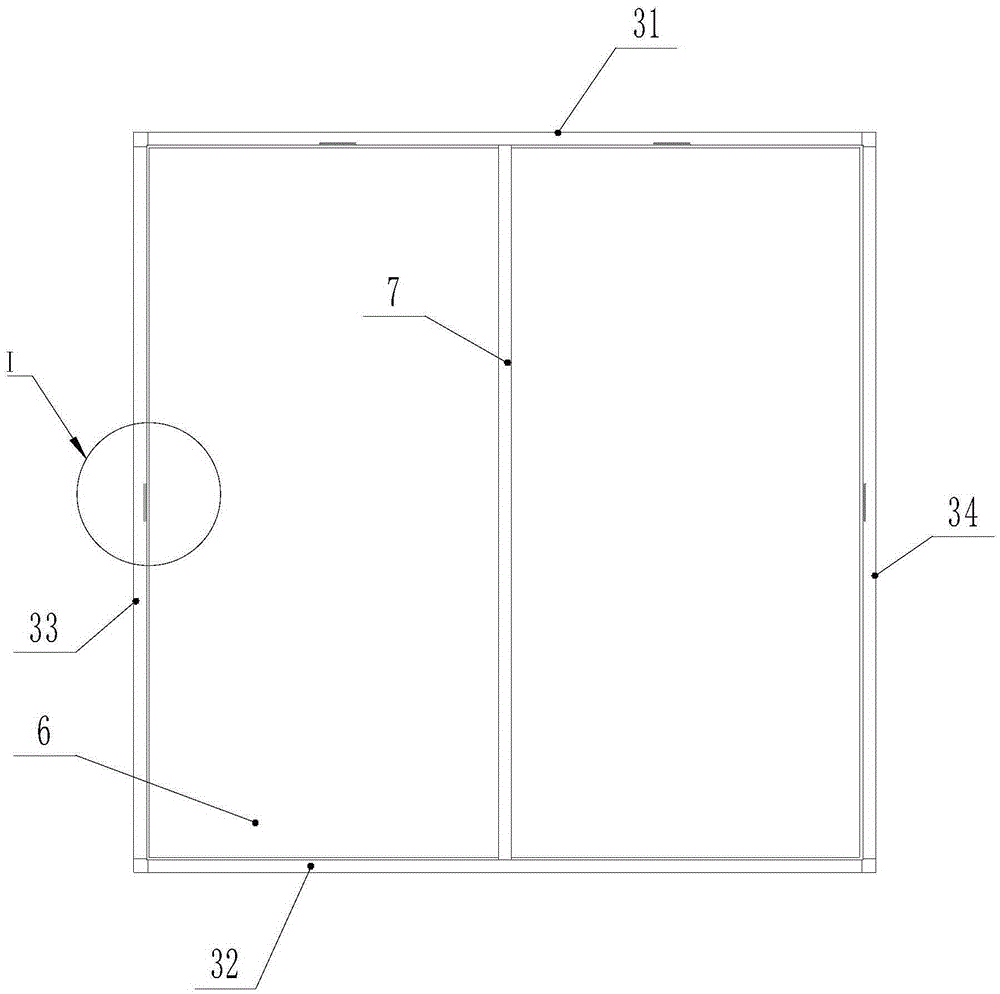

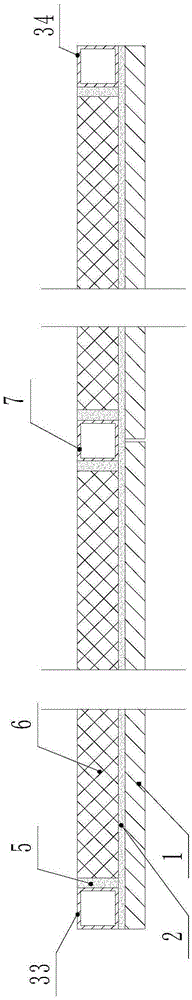

[0031] like Figure 1 to Figure 10 As shown, a prefabricated composite wall panel includes a decorative panel layer 1, a peripheral frame 3 and a functional panel layer 6, and the peripheral frame 3 includes an upper frame 31, a lower frame 32, a left frame 33 and a right frame all made of metal 34. The upper frame 31, the lower frame 32, the left frame 33 and the right frame 34 are fixed to each other to form a rectangular frame, such as figure 1 As shown, the upper frame 31, the lower frame 32, the left frame 33 and the right frame 34 are connected by four connecting corner pieces 4, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com