Automatic plastering plate

A plastering board, automatic technology, applied in the direction of construction, building structure, etc., can solve the problems of labor efficiency and low, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

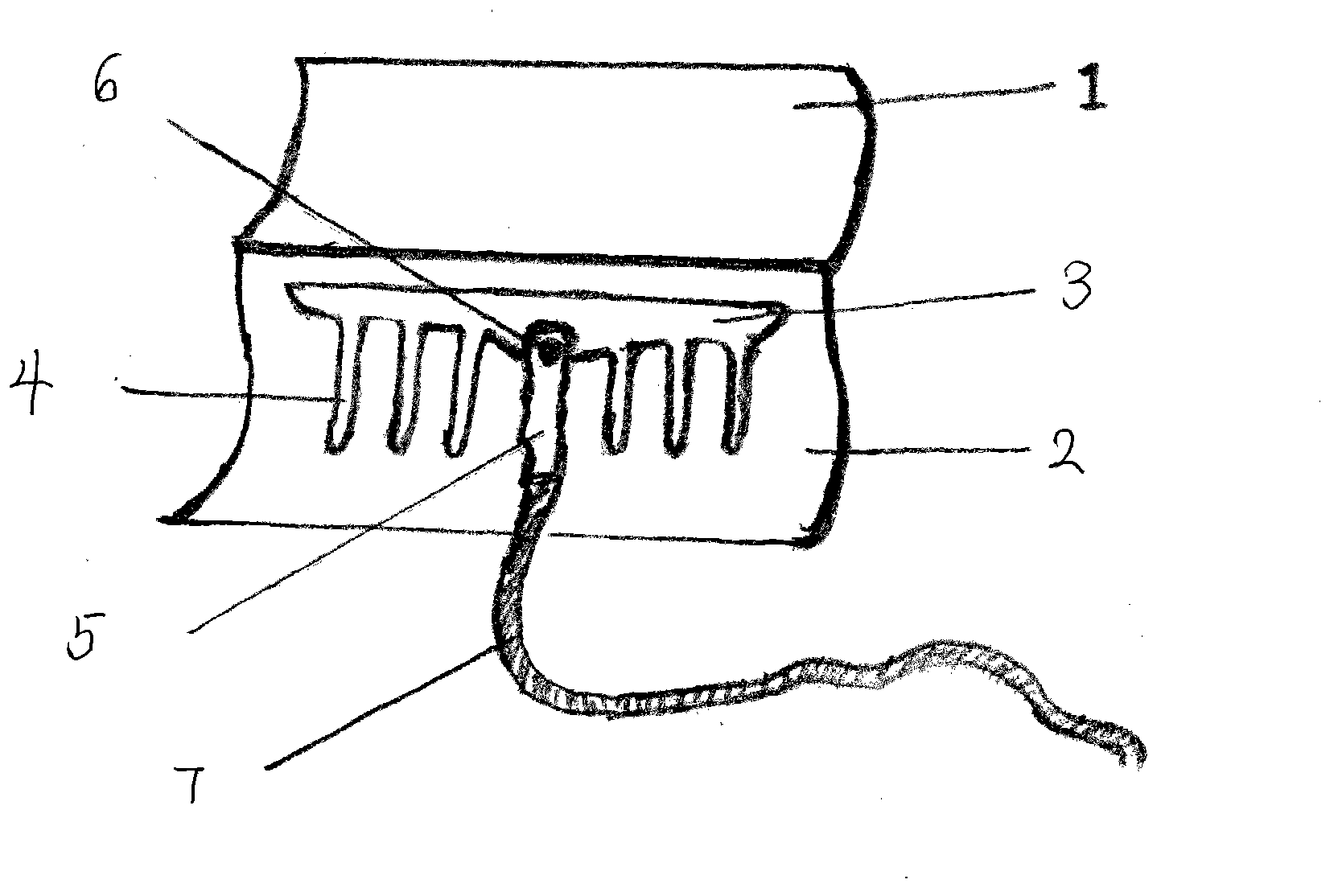

[0009] A square automatic plastering board made of stainless steel with a slightly folded middle and slightly warped upper and lower ends. It is divided into two parts: an upper plastering board and a lower plastering board. Connected, there is a switch on the handle. After it is turned on, the mortar is sent to the handle by the delivery pipe, and then to the convex groove and channel of the lower plastering board. Smoothing work, high efficiency and good effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com