Bricklaying mortar joint width control method

A technology of width control and brick laying, applied in chemical instruments and methods, clay preparation devices, building components, etc. Problems such as bonding strength with mortar, to achieve the effect of process standardization, improvement of installation quality, and reduction of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

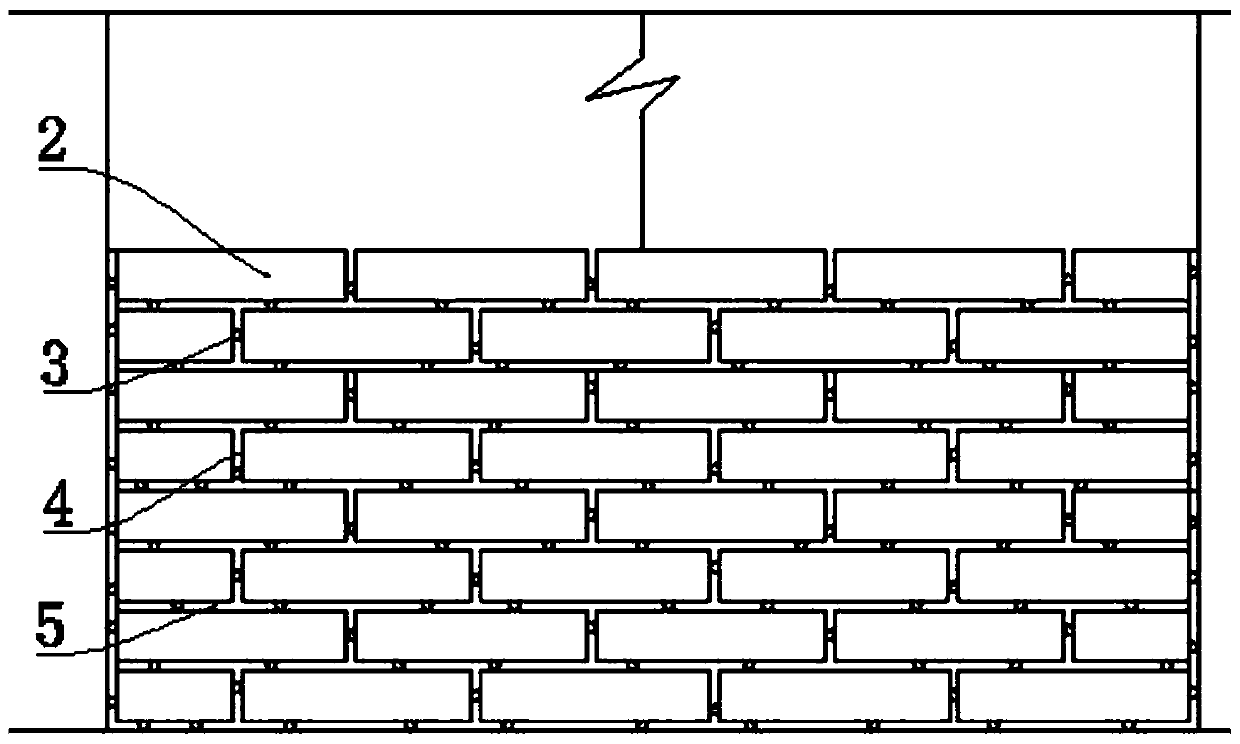

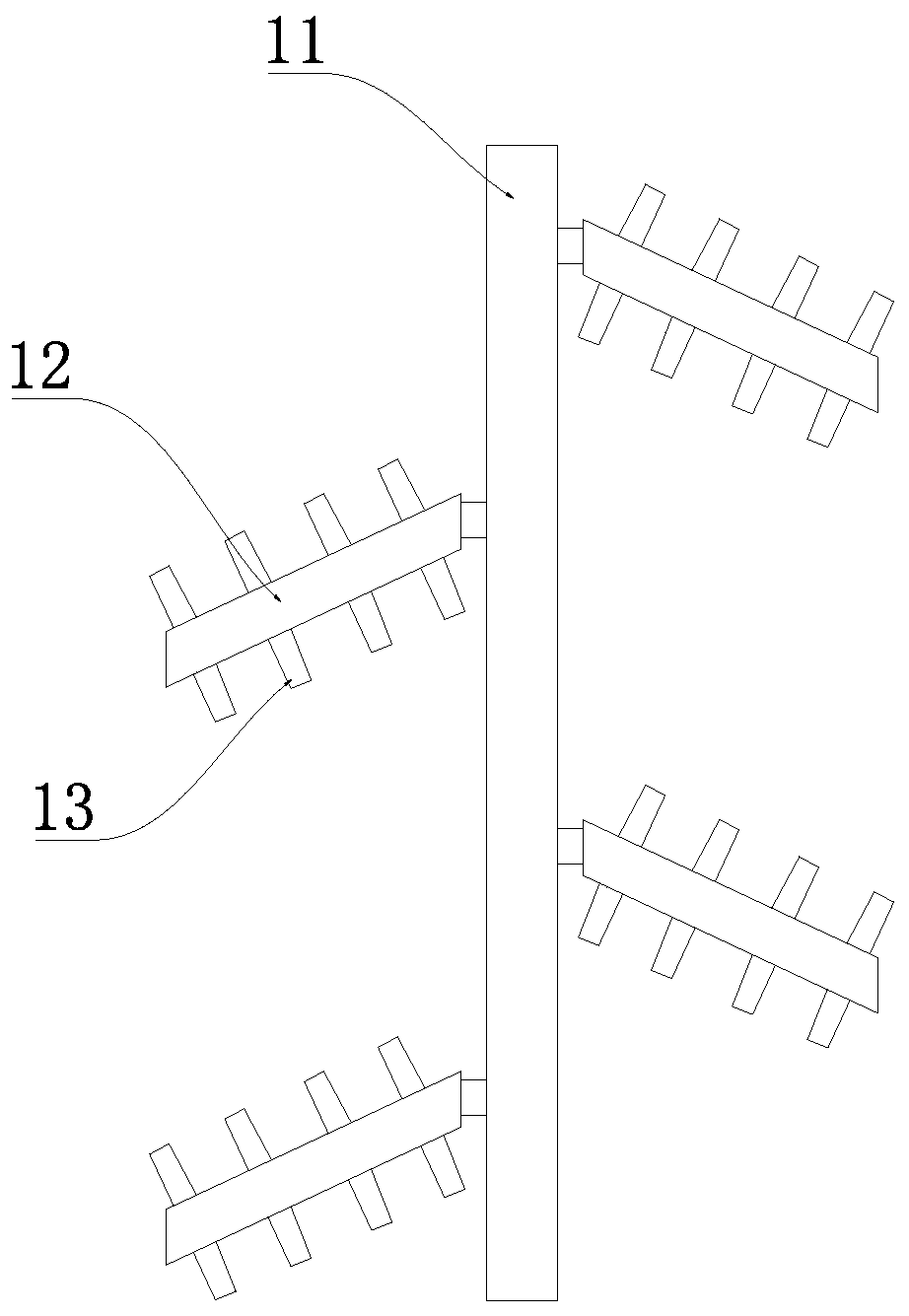

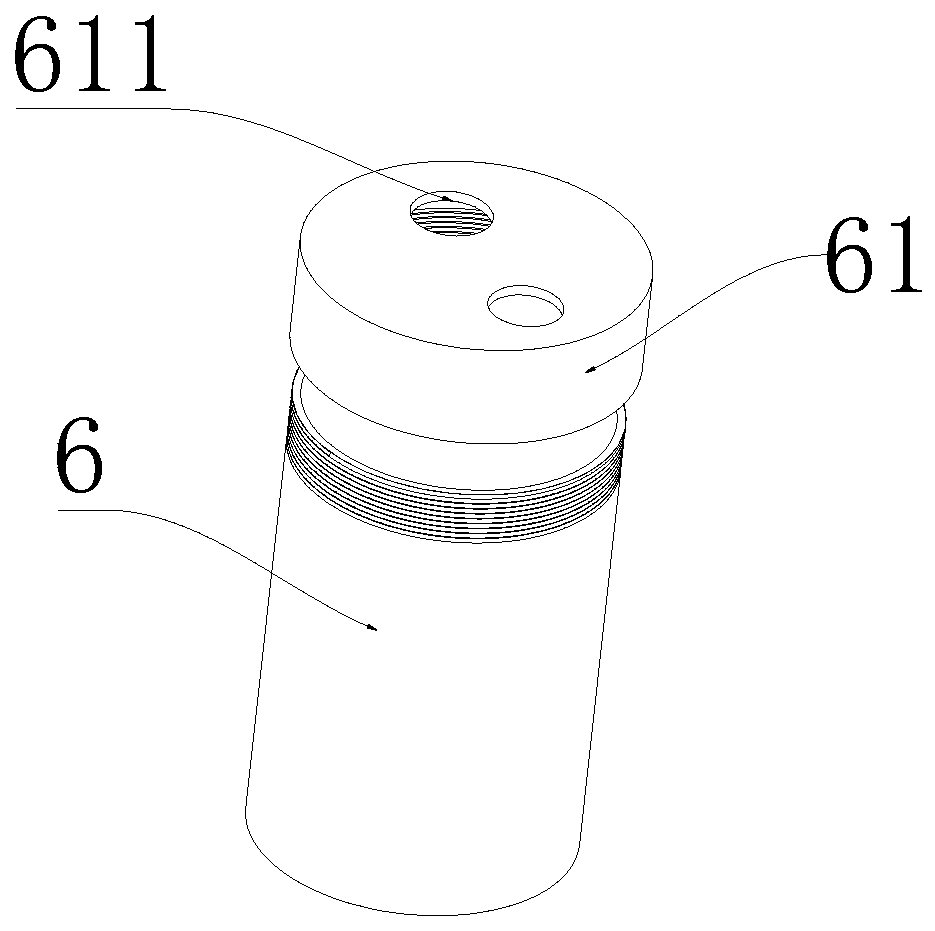

[0022] Such as figure 1 As shown, a method for controlling the width of mortar joints in bricklaying, comprising the following steps: mixing fine bone material, cementitious material and water, and stirring to prepare coarse mortar 4%-10% of the prefabricated block 3, and stir at a stirring speed lower than that of the coarse material mortar, and prepare the prefabricated mortar evenly; the prefabricated block 3 is spherical, and the diameter is less than or equal to the width of the mortar joint; when laying bricks , let the prefabricated mortar be at the position of the vertical mortar joint 4 at the end of the brick 2 and the position of the horizontal mortar joint 5 on the upper surface of the lower brick 2, and ensure that the prefabricated mortar of the vertical mortar joint 4 includes 1-2 prefabricated The block 3 and the prefabricated mortar of the horizontal mortar joint 5 include 2-3 prefabricated blocks 3; if the prefabricated blocks 3 are insufficient, add the pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com