Lining building structure of horizontal converter mouth

A converter mouth and masonry structure technology, applied in the direction of drum furnaces, furnaces, furnace types, etc., can solve the problems of difficult masonry lining of the furnace mouth of the horizontal converter, low service life, and rapid erosion, etc., to achieve The effect of improving the operation rate of the converter, increasing the service life, and simple masonry method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

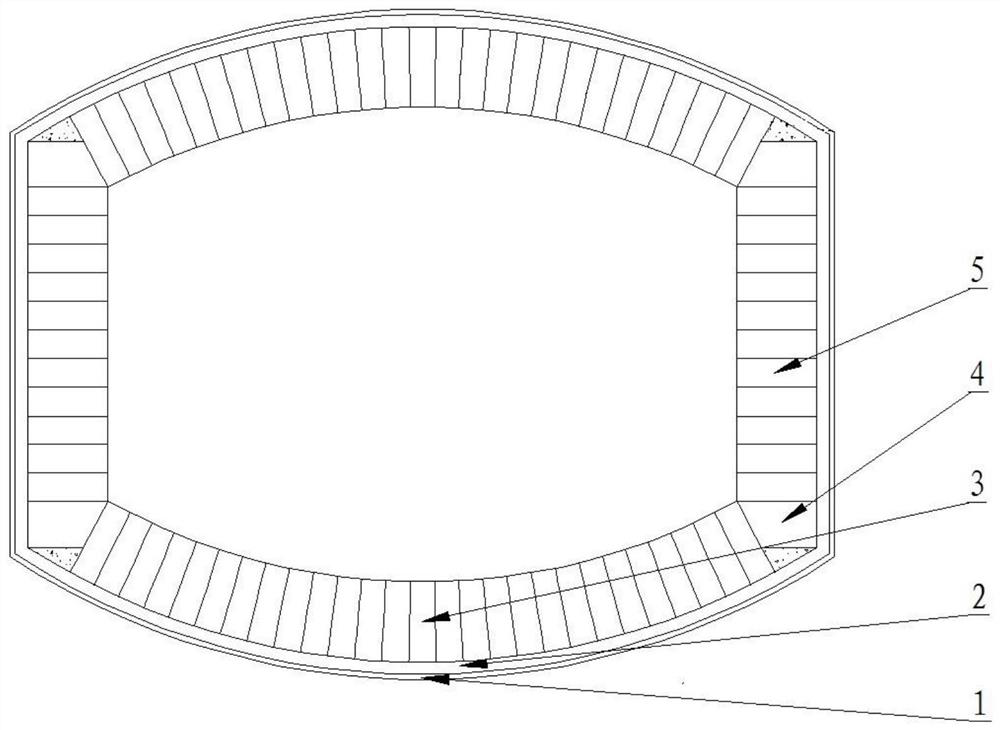

[0012] see figure 1 , a horizontal converter mouth lining masonry structure according to the present invention, comprising a plurality of transition bricks 1, a plurality of arch bricks 2, a plurality of locking bricks 3, a plurality of tongue bricks 4, and a plurality of side wall bricks 5, The main function of the lining of the furnace mouth is to provide channels for the outflow of high-temperature melt and the escape of high-temperature flue gas; in terms of structure, the main function is to protect the furnace shell of the alloy furnace mouth. The furnace mouth of the horizontal converter is an alloy furnace mouth. The furnace mouth of the horizontal converter includes four inner sides. The other two inner sides opposite to the furnace mouth are built into a side wall brick layer by a plurality of side wall bricks 5, the bottom of the locking brick layer is flush with the bottom of the side wall brick layer, and the bottom of the locking brick layer is aligned with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com