Construction method of concealed distribution box in pre-buried concrete prefabricated frame in brickwork structure

A technology of masonry structure and construction method, which is applied in the direction of building structure, building material processing, construction, etc., can solve the problems of speeding up the construction progress of masonry structures and the size deviation of reserved openings, so as to improve the quality of decoration closing and ensure Accuracy and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

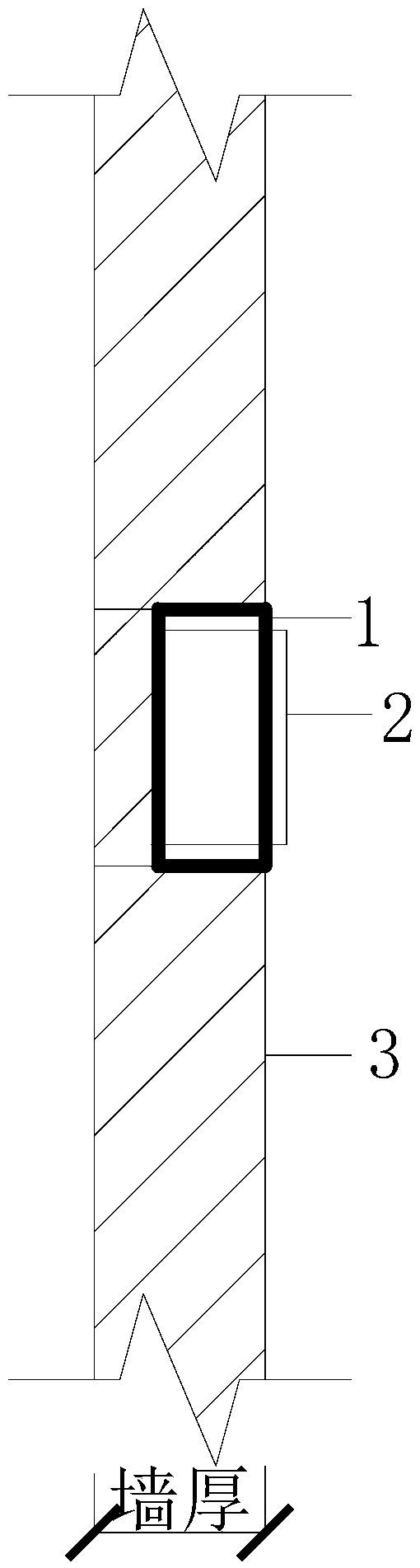

[0017] A construction method for pre-embedding and assembling a concrete prefabricated frame of an electric box in a masonry structure, the specific steps and parameters are as follows:

[0018] 1. Fabrication of concrete prefabricated frame for distribution box: Prefabricated concrete frame in advance according to the size of the concealed electric box. The height of the prefabricated frame is 50mm (the deviation is not greater than ±10mm), and the thickness is the same as the thickness of the distribution box. Each side of the prefabricated frame is around It is 25mm larger than the distribution box (the deviation is not more than ±5mm), and the prefabricated frame is made of C20 concrete;

[0019] 2. Line positioning: put the wall positioning line, and mark the size, position and elevation of the opening of the distribution box;

[0020] 3. Masonry prefabricated frame installation: masonry the wall, and build the prefabricated concrete frame in the wall at the opening of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com