Assembled block wall and hoisting system thereof

A block wall and assembly technology, which is applied to walls, building components, buildings, etc., can solve the problems of low processing efficiency and complex structure, and achieve the effects of short delivery cycle, simple masonry structure and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

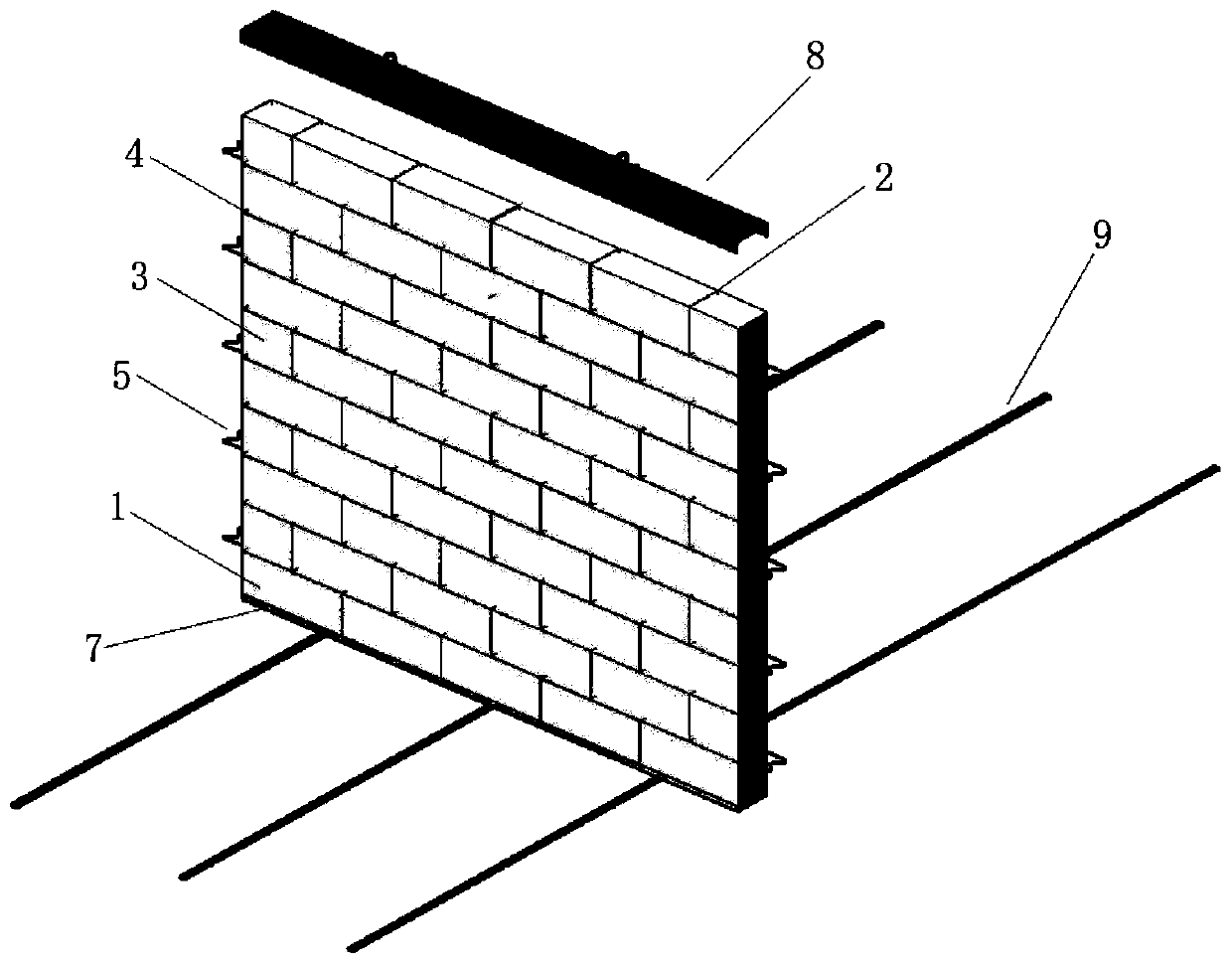

[0034] Such as Figure 1-2 As shown, the prefabricated block wall of this embodiment includes a multi-layer block layer (the example in the figure is ten layers of block layers) stacked by blocks 1 .

[0035] Wherein, the blocks of this embodiment are autoclaved sand aerated concrete blocks, which are self-insulating materials, and the size is 600mm long*250mm high*180mm thick, light weight blocks, and small bulk density (density 525-1000kg / m 3 ), which is convenient for transportation and installation, reduces the self-weight of the building, and reduces the structural cost. In addition, after the blocks are polished by special equipment, the accuracy (that is, the height error) is less than or equal to 0.5mm. At present, the error of the highest-precision blocks is 1-3mm, so special equipment is required for grinding. Because the thickness of the mortar joint of the automatic masonry wall is a fixed value (ie 1-3mm), it is impossible to adjust the error of the block through...

Embodiment 2

[0074] The hoisting system of the prefabricated block wall of this embodiment differs from that of Embodiment 1 in that:

[0075] Replace the steel belt in Example 1 with the steel wire rope of this example. Due to the structure and size of the steel wire rope, if it is placed directly under the angle steel, it will easily cause the bottom of the wall masonry to be unstable. Therefore, in this embodiment, a support is provided between the masonry platform and the angle steel, and the support and the steel wire rope are misplaced to avoid the influence of the movement of the steel wire rope on the angle steel. In addition, the steel strips and steel wire ropes can also be replaced with existing commonly used binding ropes, strips, etc., as long as they have sufficient binding strength.

[0076] The structure of the prefabricated block wall in this embodiment can refer to the first embodiment.

[0077] For other structures of the hoisting system of the prefabricated block wall ...

Embodiment 3

[0079] The difference between the prefabricated block wall of this embodiment and embodiment one is:

[0080] The blocks are sintered thermal insulation blocks, so that the prefabricated block wall also has self-insulation performance, and realizes the diversity of material selection. In addition, the blocks can also be other existing blocks with thermal insulation performance or blocks with other functions.

[0081] For other structures of the prefabricated block wall of this embodiment, reference may be made to Embodiment 1.

[0082] For the hoisting system of the prefabricated block wall in this embodiment, reference may be made to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com