A drilling fluid for protecting coalbed methane reservoirs

A drilling fluid and coalbed methane technology, applied in the direction of drilling compositions, instruments, analysis materials, etc., can solve the problems of failure to effectively protect coalbed methane reservoir coal seam wall stability, coalbed methane reservoir damage, and reduce storage capacity. problems such as layer permeability, to achieve the effect of strengthening promotion and application value, preventing hydration, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

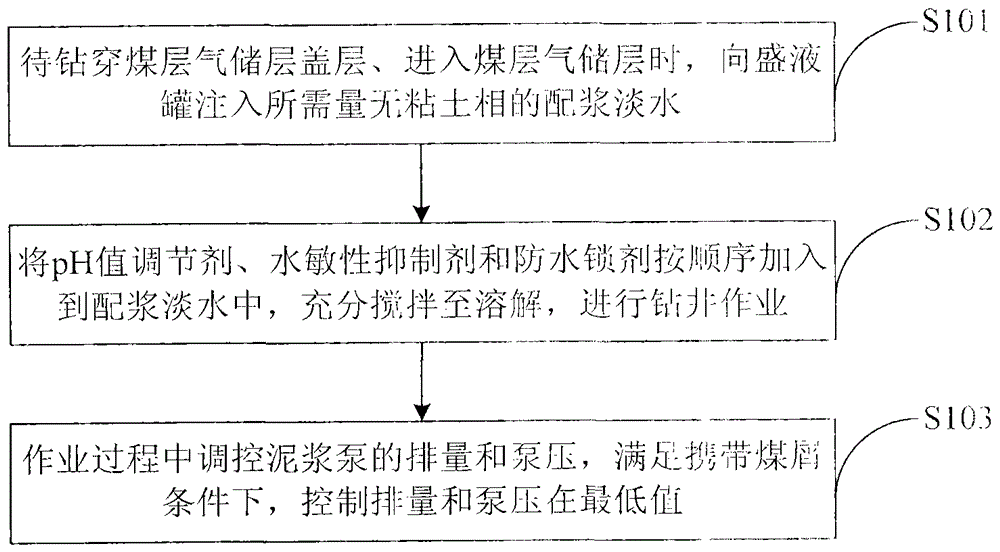

Method used

Image

Examples

specific Embodiment approach

[0060] Specific embodiments: The experimental methods adopted in the following specific examples are conventional methods unless otherwise specified.

[0061] The materials and reagents used in the following specific examples can be obtained from commercial sources unless otherwise specified.

[0062] Sodium hydroxide and potassium hydroxide in the pH regulator in the following specific examples of the present invention were purchased from Jinan Century Lianxing Economic and Trade Co., Ltd., and sodium carbonate and sodium bicarbonate were purchased from Jinan CITIC Chemical Co., Ltd.

[0063] Sodium chloride, potassium chloride, calcium chloride, and magnesium chloride in the water-sensitivity inhibitors in the following specific examples of the present invention were all purchased from Jinan Xintongchuang Chemical Co., Ltd.

[0064] The polyoxyethylene alkylphenol ether in the waterproof locking agent in the following specific examples of the present invention was purchased ...

example 1

[0066] Example 1: Preparation of Drilling Fluid for Protecting Coalbed Methane Reservoirs

[0067] Formula 1: 400mL fresh water, 0.60g sodium carbonate, 0.40g sodium hydroxide, 12.00 water sensitivity inhibitor (sodium chloride), 1.20g waterproof lock agent (polyoxyethylene alkylphenol ether, polyoxyethylene octylphenol ether The mass ratio of polyether diamine and polyether diamine in the preparation is 3:5:2).

[0068] According to the composition of formula 1, under low-speed (600rpm) stirring conditions, add sodium carbonate, sodium hydroxide, water-sensitivity inhibitor, and waterproof lock agent to fresh water in sequence to obtain the drilling fluid for protecting the coalbed methane reservoir, which is recorded as 1 #drilling fluid.

example 2

[0069] Example 2: Preparation of Drilling Fluid for Protecting Coalbed Methane Reservoirs

[0070] Formula 2: 400mL of fresh water, 0.60g of sodium carbonate, 0.40g of sodium hydroxide, 14.00g of water-sensitive inhibitor (the mass ratio of sodium chloride to calcium chloride is 6:1), 1.20g of waterproof locking agent (polyoxyethylene alkanes The mass ratio of base phenol ether, polyoxyethylene octyl phenol ether and polyether diamine during preparation is 2:5:3).

[0071] According to the composition of formula 2, under low-speed (600rpm) stirring conditions, add sodium carbonate, sodium hydroxide, water-sensitivity inhibitor, waterproof locking agent to the fresh water in turn, and obtain the drilling fluid for protecting the coalbed methane reservoir, denoted as 2 #drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com