Front precision planter for notoginseng

A seeder and sophisticated technology, applied in the field of agricultural machinery, can solve problems such as low production efficiency and operation quality, inability to realize standardized operations, and unfavorable high-quality production of Panax notoginseng, so as to achieve good operation quality, improve planting level, and improve market competitiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

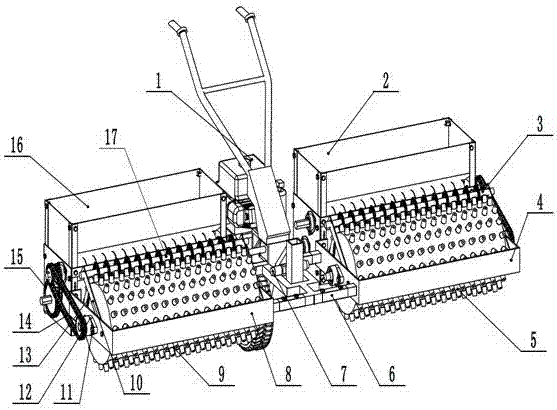

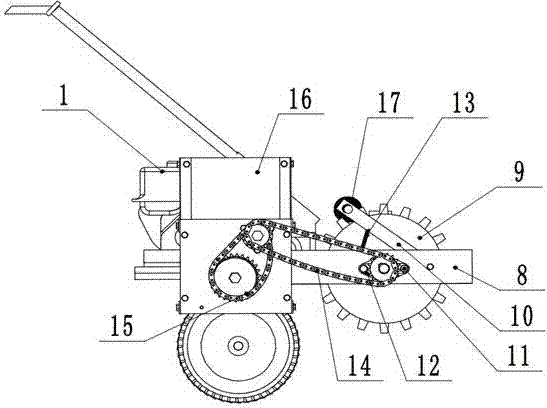

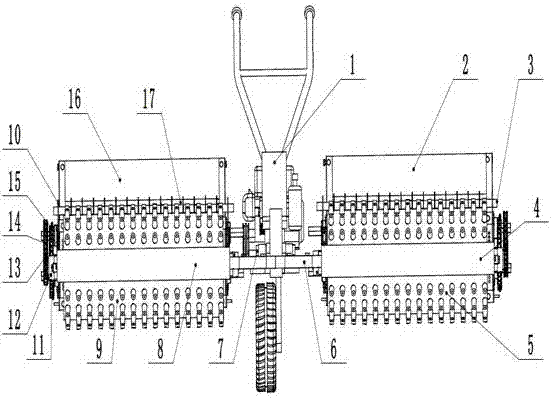

[0034] Embodiment 1: as Figure 1-4 As shown, a front-mounted Panax notoginseng precision seeder includes a walking tractor 1, a seed metering mechanism I2, a soil brushing device I3, a right frame 4, a hole pressing mechanism I5, a main frame 6, a pin shaft 7, and a left Frame 8, hole pressing mechanism Ⅱ 9, soil brushing device bracket 10, bearing with seat 12, primary transmission mechanism 14, secondary transmission mechanism 15, seed metering mechanism Ⅱ 16, soil cleaning device Ⅱ 17; walking tractor 1 and main frame 6 Connected by the pin shaft 7; the left frame 8 and the right frame 4 are respectively fixed on the left and right sides of the main frame 6; The hole mechanism II9 is fixed on the left frame 8; the seed meter mechanism I2 is fixed on the rear end of the right frame 4, and the seed meter mechanism II16 is fixed on the rear end of the left frame 8; the hole pressing mechanism I5 passes through a The first-stage transmission mechanism 14 is connected with the...

Embodiment 2

[0035] Embodiment 2: the remainder of this embodiment is the same as the previous embodiment, wherein as Figure 5 As shown, the cavitation mechanism I5 and the cavitation mechanism II9 have the same structure, including a roller 18, a cavitation rubber column 19, an end cover 20, and a short shaft 21. There are short shafts 21, and a number of cavitation rubber columns 19 are fixed on the outer surface of the drum 18; the short shafts 21 at both ends of the cavitation mechanism I5 are respectively fixed in the bearings 12 on the left and right sides of the right frame 4; the cavitation mechanism II9 The short shafts 21 at both ends are respectively fixed in the belt seat bearings 12 on the left and right sides of the left frame 8 .

Embodiment 3

[0036] Embodiment 3: the remainder of this embodiment is the same as the previous embodiment, wherein as Figure 6 As shown: the soil brush I3 and the soil brush II17 have the same structure, including a soil brush shaft 22 and a wire brush 23, and a number of wire brushes 23 are fixed at equal intervals on the soil brush shaft 22; the left and right ends of the soil brush I3 pass through the soil brush bracket 10 Fixed on the right side frame 4; the left and right ends of the soil brusher II 17 are fixed on the left side frame 8 through the soil brusher bracket 10; the middle part of the soil brusher bracket 10 is fixed on the right side frame 4 and the left side machine On the frame 8; All are bolted connections between the end points of the soil brushing device support 10 and the right side frame 4 and the left side frame 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com