Transplanting and ridging equipment

A technology of equipment and installation department, which is applied in the direction of transplanting machinery, shovel, planting method, etc., can solve the problems that the amount of seedlings and plant spacing cannot be standardized, increase the labor intensity of staff, and take a long time to plant, so as to meet the requirements of agronomy, The effect of saving labor costs and increasing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

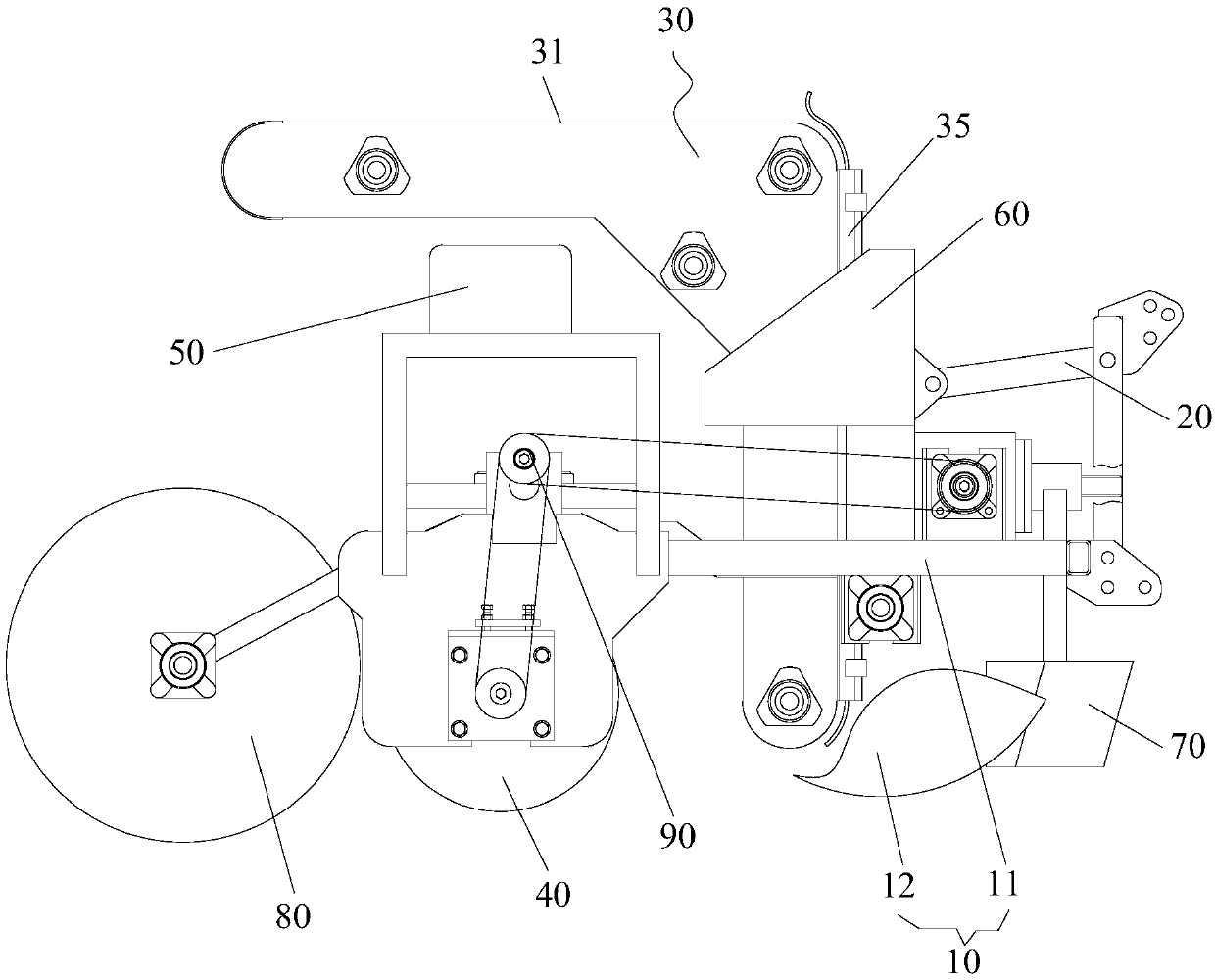

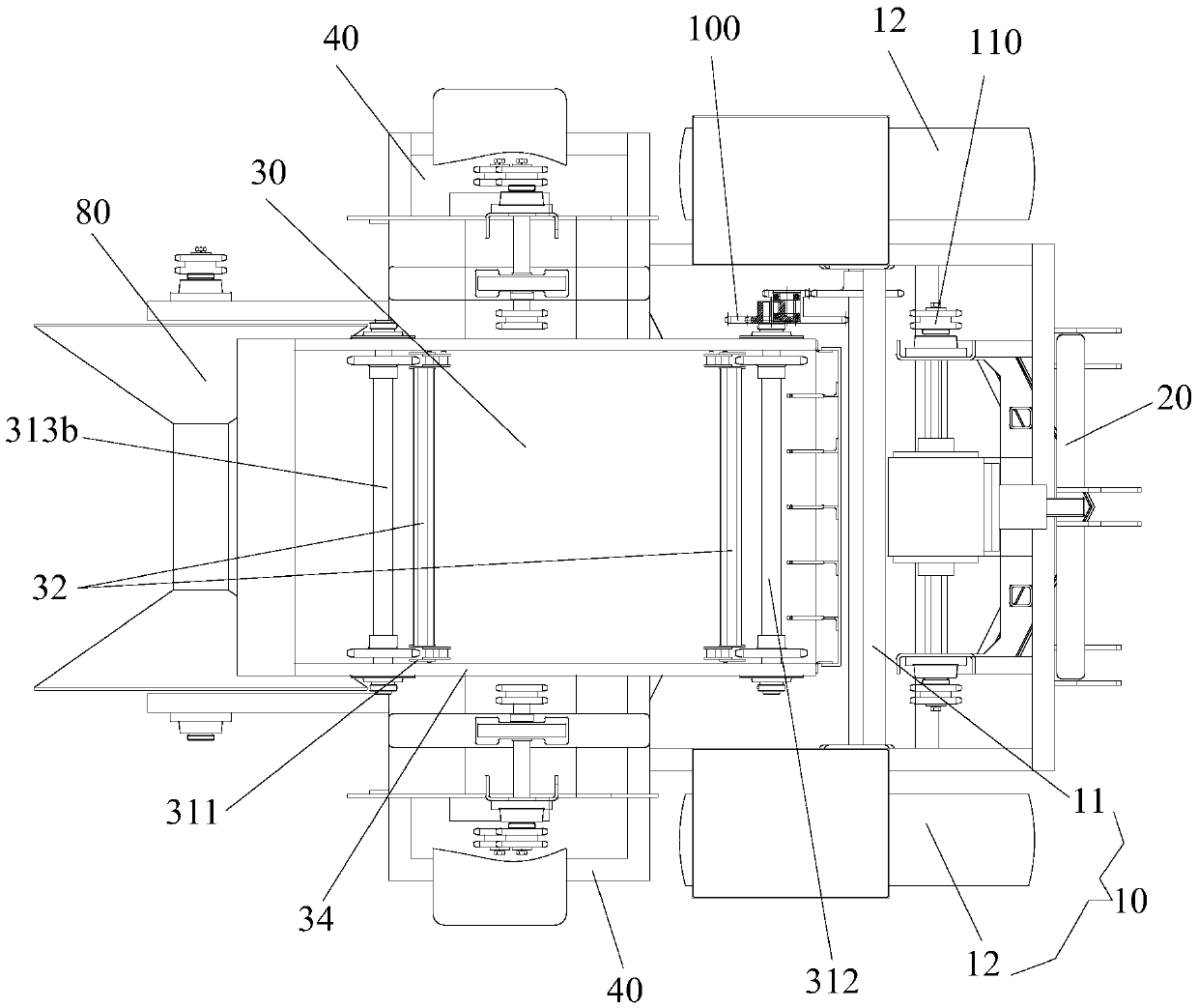

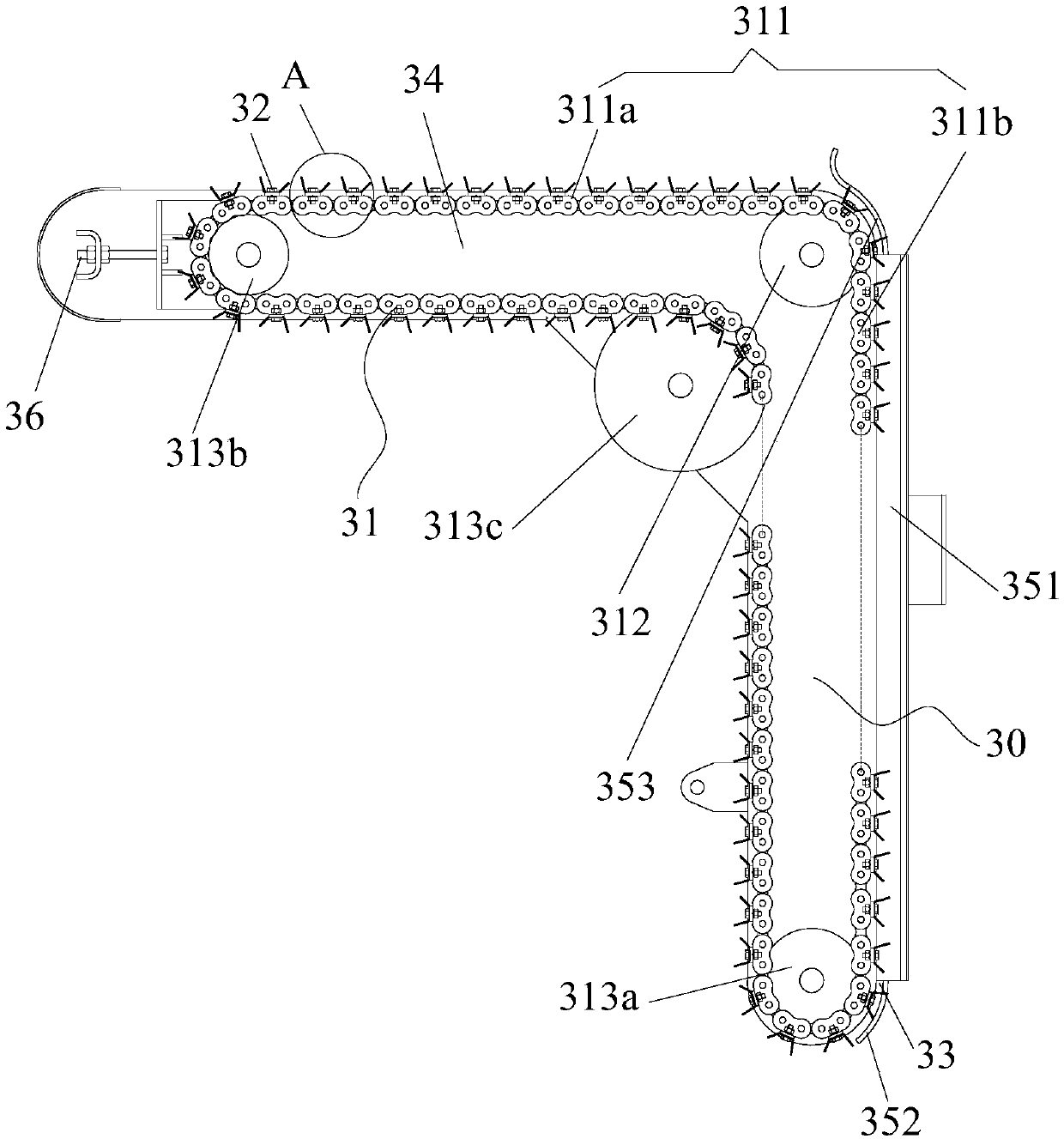

[0031] Such as figure 1 and figure 2 As shown, the transplanting and ridging equipment includes a frame assembly 10 , a transplanting device 30 and a ridging structure 40 . Wherein, the frame assembly 10 includes a frame body 11 and ground wheels 12 arranged on the frame body 11, and the frame assembly 10 is provided with a suspension structure 20 for connecting with a dragging device. Transplanting device 30 is arranged on the frame body 11, and transplanting device 30 comprises transmission assembly 31 and is arranged on a plurality of installation parts 32 on transmission assembly 31, and installation part 32 is used for placing transplanted seedling, ground wheel 12 and transmission assembly 31 to drive the transmission assembly 31 to move in a predetermined direction, and the transmission assembly 31 drives a plurality of installation parts 32 and the transplanted seedlings to move to the seedling exit 33 of the transplanting device 30, so as to fall on the seedbed thro...

Embodiment 2

[0063] The difference between the transplanting and ridging equipment in the second embodiment and the first embodiment lies in that the structure of the transmission components is different.

[0064] In this embodiment, the transplanting device further includes a mounting bracket, on which the transmission assembly is arranged, and the transmission assembly includes a conveyor belt and a conveyor pulley. Wherein, a plurality of installation parts are arranged on the conveyor belt, and the plurality of installation parts are arranged at intervals along the conveying direction of the conveyor belt. The conveyor belt wheel is movably arranged on the mounting bracket. The conveyor belt wheel includes a driving wheel and a driven wheel. The ground wheel is connected with the driving wheel to drive the driving wheel to rotate. The driving wheel drives the driven wheel to rotate through the conveyor belt to place the The transport of the transplanted seedlings to the emergence port....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com