Summer cotton precision no-tillage planter capable of realizing seedling strip cleaning

A seeder and cleaning technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of high cost of seedlings, lack of molding machinery, etc., to achieve good results, ensure the consistency of sowing depth, and the structure of the whole machine is reasonable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

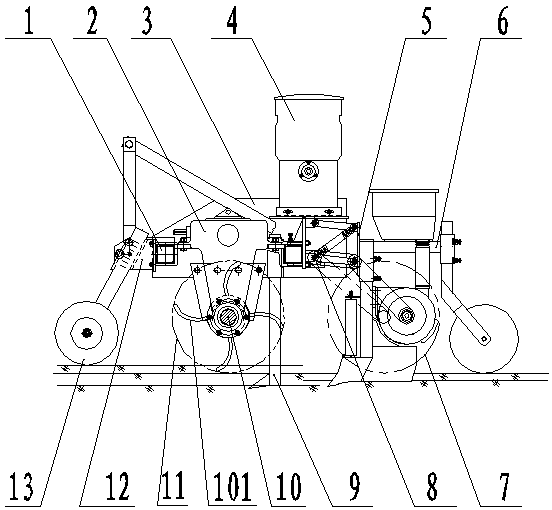

[0020] Accompanying drawing is a kind of specific embodiment of the present invention.

[0021] The present invention will be further described below in conjunction with the embodiment that accompanying drawing provides.

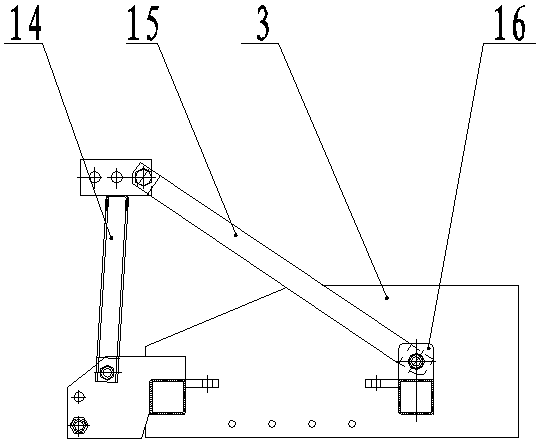

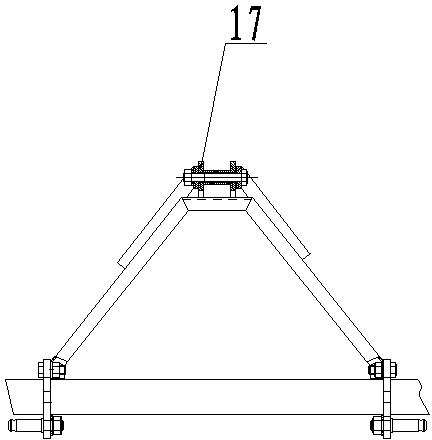

[0022] As shown in the accompanying drawings, a kind of summer cotton precision no-tillage planter of the present invention that can realize the cleaning of seedling belts has a frame 1, and the depth-limiting wheel fixing sleeve 12 is fixed on the transverse middle part of the front side of the frame to limit the The deep wheel 13 is installed on the fixed cover of the depth-limiting wheel, the gearbox 2 is fixed at the front of the frame, the fertilizer box 4 is fixed at the rear of the frame, side plates 3 are respectively arranged on both sides of the frame, and a The grass clearing and stubble removal rotary tillage mechanism 11, the grass clearing and stubble removal rotary tillage mechanism has a rotary tiller shaft 10 installed between the two side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com