Design method for forming transplanting track by using five-rod driving mechanism with two degrees of freedom

A technology of driving mechanism and design method, which is applied in planting methods, transplanting machinery, applications, etc., can solve the problems that it is difficult to ensure the full automation of flower transplanting machines, and cannot realize the double-ring buckle track, so as to achieve high flexibility and realize full Automatic, flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the drawings and embodiments.

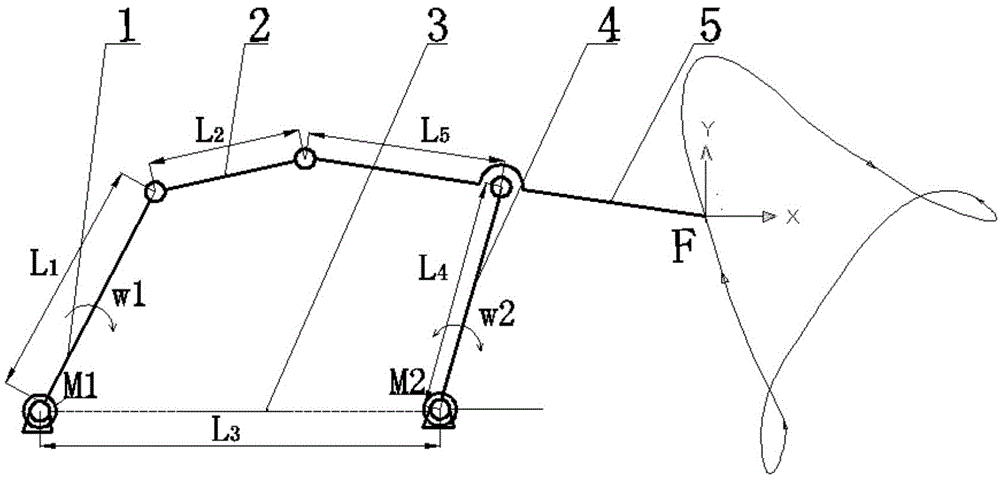

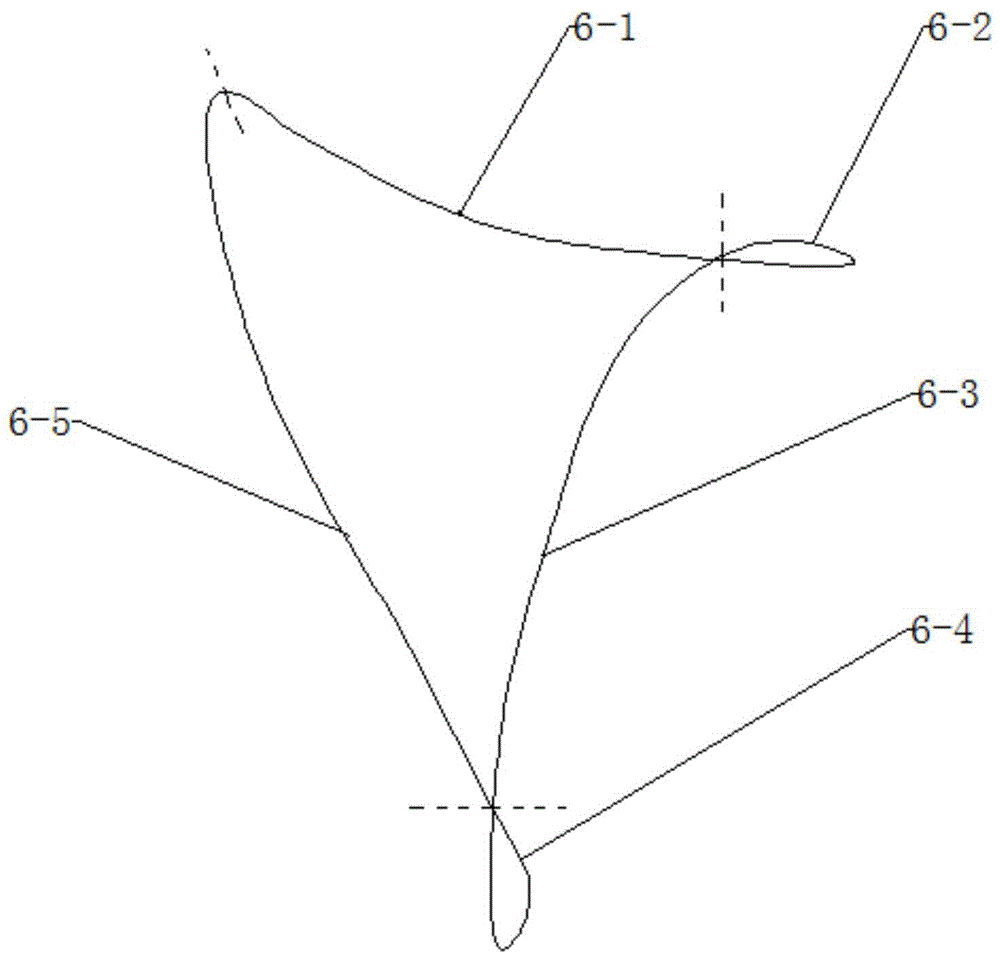

[0022] Such as figure 1 with 2 As shown, the design method of transplanting trajectory formed by a two-degree-of-freedom five-bar drive mechanism is as follows:

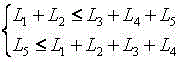

[0023] Step 1. Construct a two-degree-of-freedom five-bar drive mechanism. The two-degree-of-freedom five-bar drive mechanism includes a first crank 1, a first connecting rod 2, a second crank 4, a second connecting rod 5, a constant speed motor M1 and an adjustable speed motor M2; one end of the first crank 1 is fixed at the constant On the output shaft of the speed motor, the other end is hinged with one end of the first connecting rod 2; one end of the second crank 4 is fixed on the output shaft of the adjustable speed motor M2, and the other end is hinged with the middle of the second connecting rod 5; One end of the two connecting rod 5 is hinged with the other end of the first connecting rod 2, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com