A Collision-free Automatic Transplanting Seedling Sequence and Path Determination Method for Column Cultivation

A path determination and collision-free technology, applied in the field of agricultural robots, can solve the problems of high efficiency without collision, short cumulative path of transplanting operations, etc., and achieve the effect of improving the efficiency of transplanting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

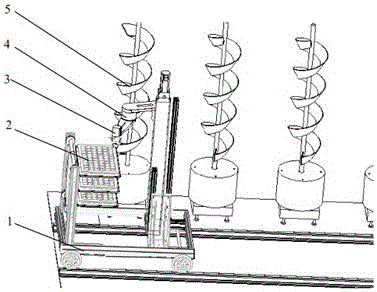

[0020] Such as figure 1 As shown, the column transplanting robot includes a mobile platform 1 , a manipulator 4 and an end effector 3 , the manipulator 4 is installed on the mobile platform 1 , and the end effector 3 is installed on the wrist of the manipulator 4 . Several cultivation columns 5 are evenly arranged on one side of the column transplanting robot. When the seedlings 6 in the tray 2 are automatically transplanted to the cultivation column 5, the mobile platform 1 moves and is positioned at the position of the column to be planted, and the movement of the manipulator 4 completes the planting position of the end effector 3 to the hole of the tray 2 and the cultivation column 5 Positioning, the end effector 3 and the seedling 6 transfer between the hole and the planting position, and the end effector 3 completes the tasks of taking seedlings and planting.

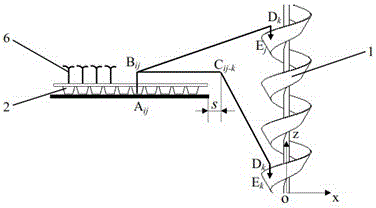

[0021] Such as figure 2 As shown, the numbers of the seedling bottom point and the seedling apex are respecti...

Embodiment 2

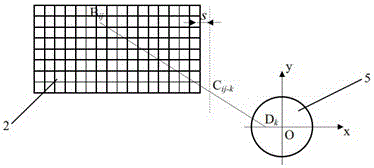

[0029] The size of the tray 2 is 8 rows x 16 columns, the distance between adjacent holes is 33.5mm, and the minimum lifting path of the seedling position is a 0 is 30mm, the lifting path b of the seedling planting position is 30mm, the safe lifting height h determined according to the height of the seedling 6 is 180mm, and the safe distance s is taken as 88mm. The height of the spiral cultivation column 5 is 1m, the screw pitch is 300mm, and the top of the seedling is D k The distance 100mm from the central axis, the seedling distance 150mm planted along the helix, and the number of seedlings 6 that can be planted by every cultivation column 5 is 16. The path lengths of the transplanting trip and the return trip of each transplanting cycle are calculated separately, and then accumulated to obtain the cumulative path length under different seedling-planting sequences.

[0030] (1) The lower right end of the hole plate 2 starts to take the seedlings row by row in the same dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com