Flexible disc type green Chinese onion automatic transplanter

A transplanting machine and disc type technology, applied in the field of flexible disc type green onion automatic transplanting machines, can solve the problems of high labor intensity, easy lodging of green onion seedlings, large labor consumption of green onions, etc. The effect of low clamping damage rate and high uprightness of green onion seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

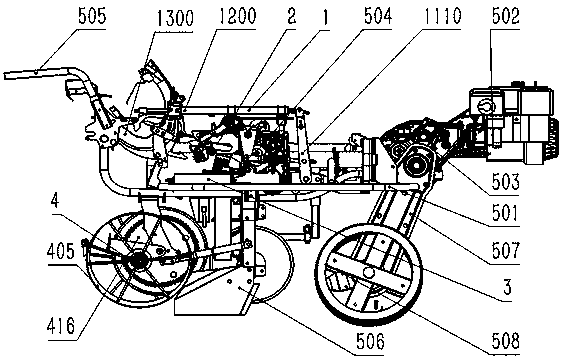

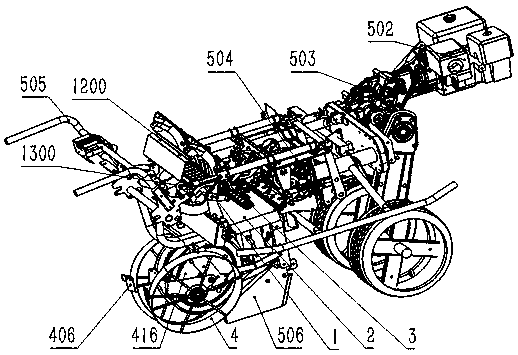

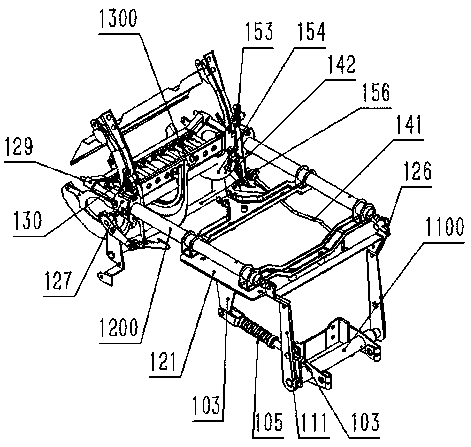

[0070] In order to clearly illustrate the technical characteristics of this program, the following specific implementation methods are combined with the attached Figure 1~44 Describe this plan.

[0071] A kind of flexible disc type green onion automatic transplanting machine, comprises the traction bracket as the complete machine frame, the power device and the depth limiter 6 that are installed on the traction bracket, and the ditch opener 506, Armrest frame 505, and the seedling throwing device driven by the power unit, the seedling receiving and releasing device, the seedling separating device and the seedling planting device.

[0072] The power unit includes an engine 502, and a gearbox I 503 and a gearbox II 504 connected to the power output end of the engine. The gearbox I 503 is connected to the traveling sprocket box 507, and the power is transmitted to the traveling wheel 508 through a chain drive, so as to provide power for the transplanter to move forward.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com