Patents

Literature

41results about How to "Accurate delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

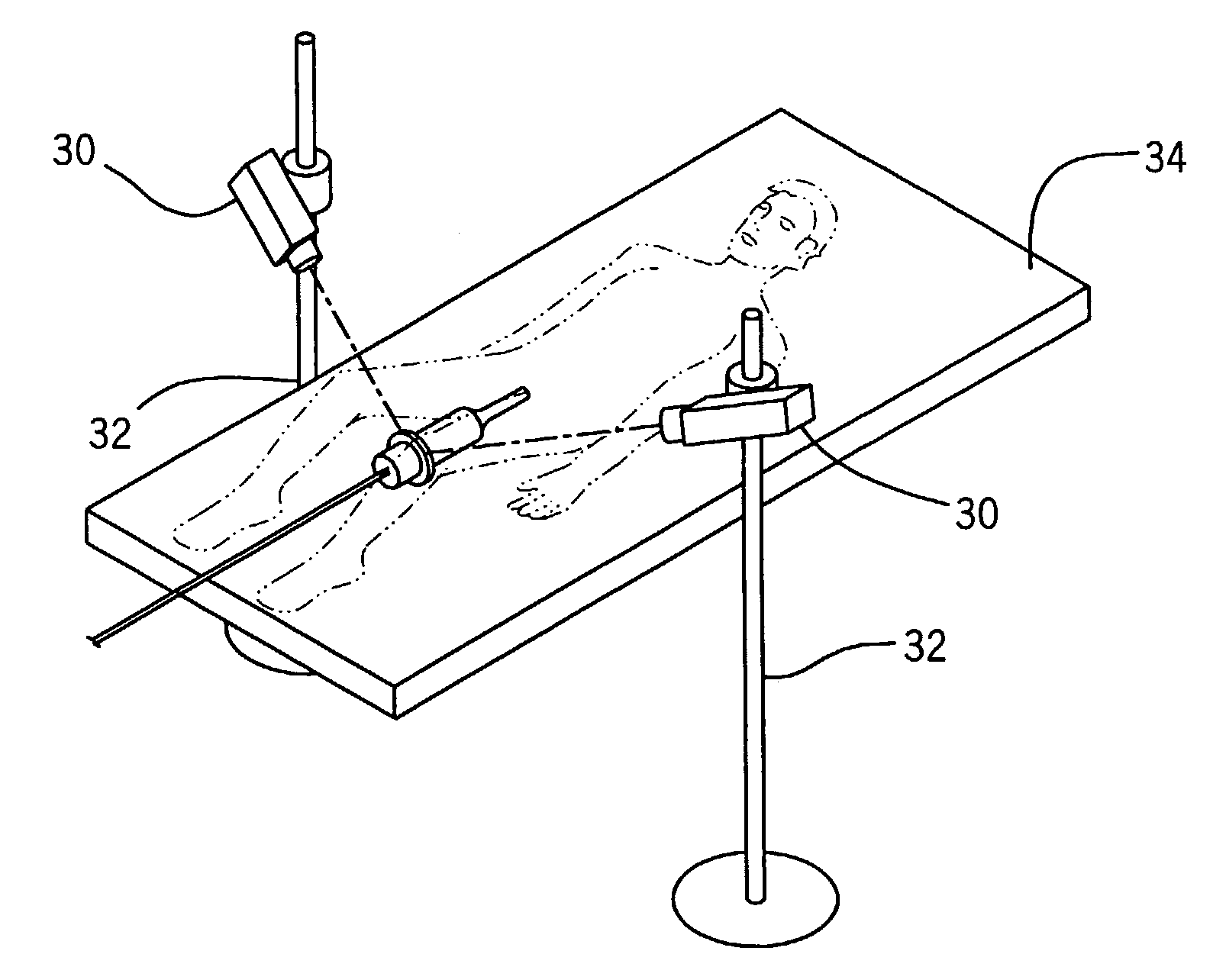

Apparatus and method for registration, guidance and targeting of external beam radiation therapy

ActiveUS7438685B2Accurate deliverySurgical needlesSurgical instrument detailsSoft Tissue TreatmentUltrasound image

An improved system and method for optimizing the planning, registration, targeting, and delivery of conformal, external beam radiation therapy of prostate cancer and other soft-tissue diseases. Real-time ultrasound imaging during planning and treatment is used forlocalization of soft tissue treatment targets and fused with radiographic or CT data for conformal treatment optimization. The fusion technique provides accurate localization of the prostate volume in real time. For treatment of prostate cancer, visualization of the prostate gland is achieved using transrectal ultrasonography and the fusion of that image in the precise location of the prostate within the pelvic region, accurately determining the location of the prostate target by transformation of the ultrasound image data on both the ultrasound and X-ray / CT images. The radiation field may be optimized to significantly reduce the volume of irradiated normal tissue, minimizing the exposure of the surrounding healthy tissues and increasing dosage delivered to the prostate treatment target.

Owner:IMPAC MEDICAL SYST

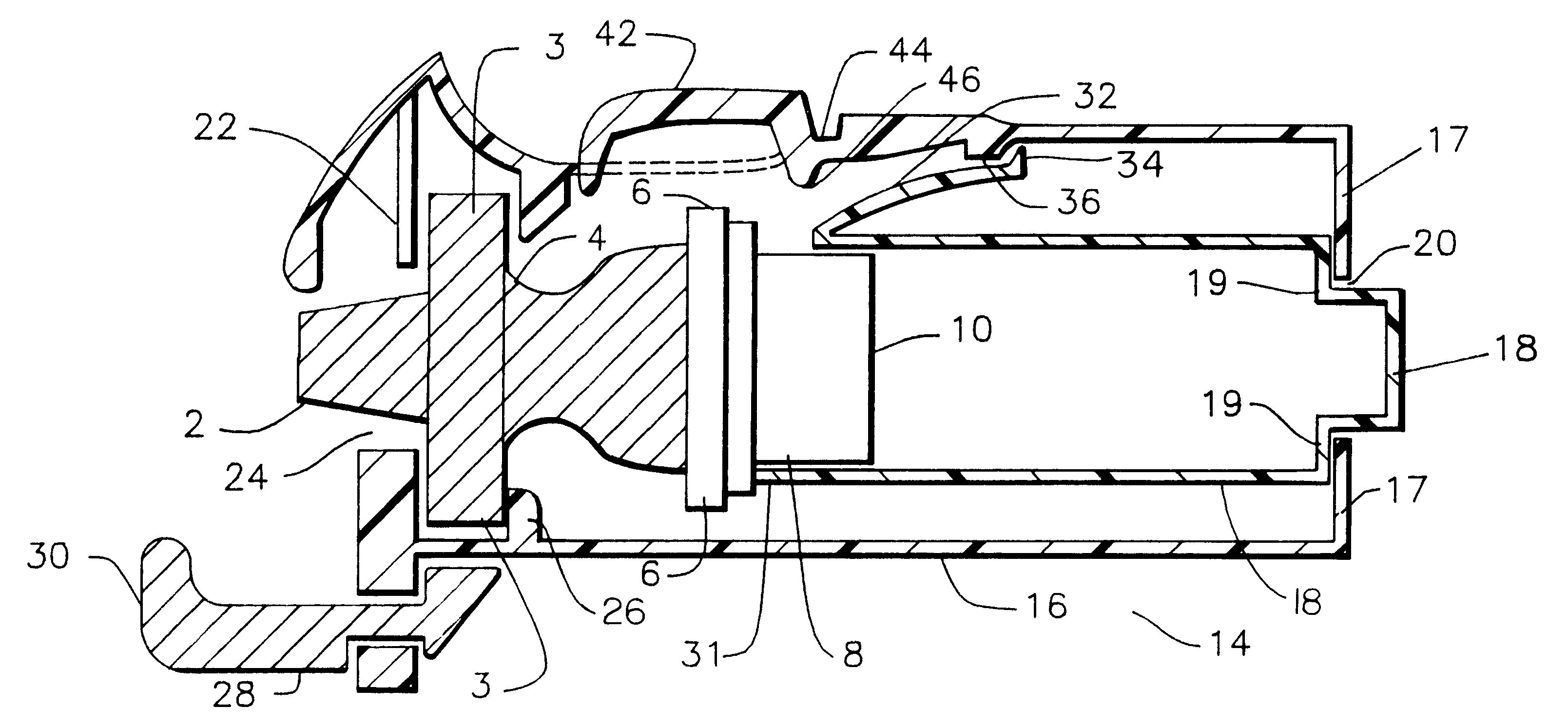

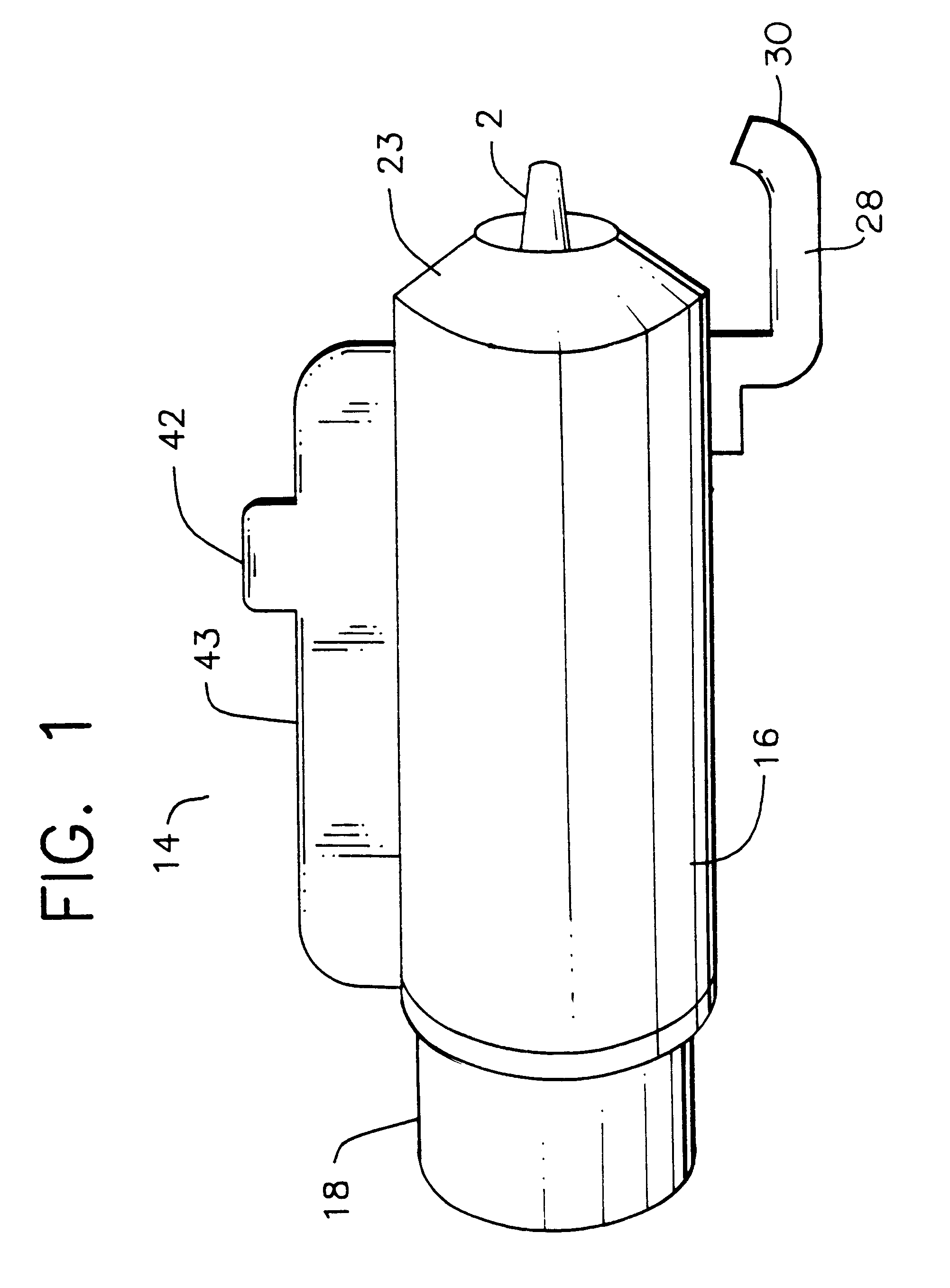

Cartridge for applying medicament to an eye from a dispenser

InactiveUSRE37047E1Accurate deliveryPrecise deliveryPharmaceutical containersLarge containersEyelidVial

A cartridge for actuating a piston-like or accordion-like dispenser-vial for applying medicament to an eye. The cartridge includes a housing for holding the dispenser-vial and a telescoping cylinder for compressing the dispenser-vial in the longitudinal direction to actuate the vial. The cartridge includes a locking mechanism for locking the telescoping cylinder to restrict its movement and a trigger mechanism for releasing the cylinder from the locked position so that a drop is released from the dispenser. The housing includes a finger for engaging the lower eyelid and exposing the conjunctival cul de sac.

Owner:MEDINSTILL DEV

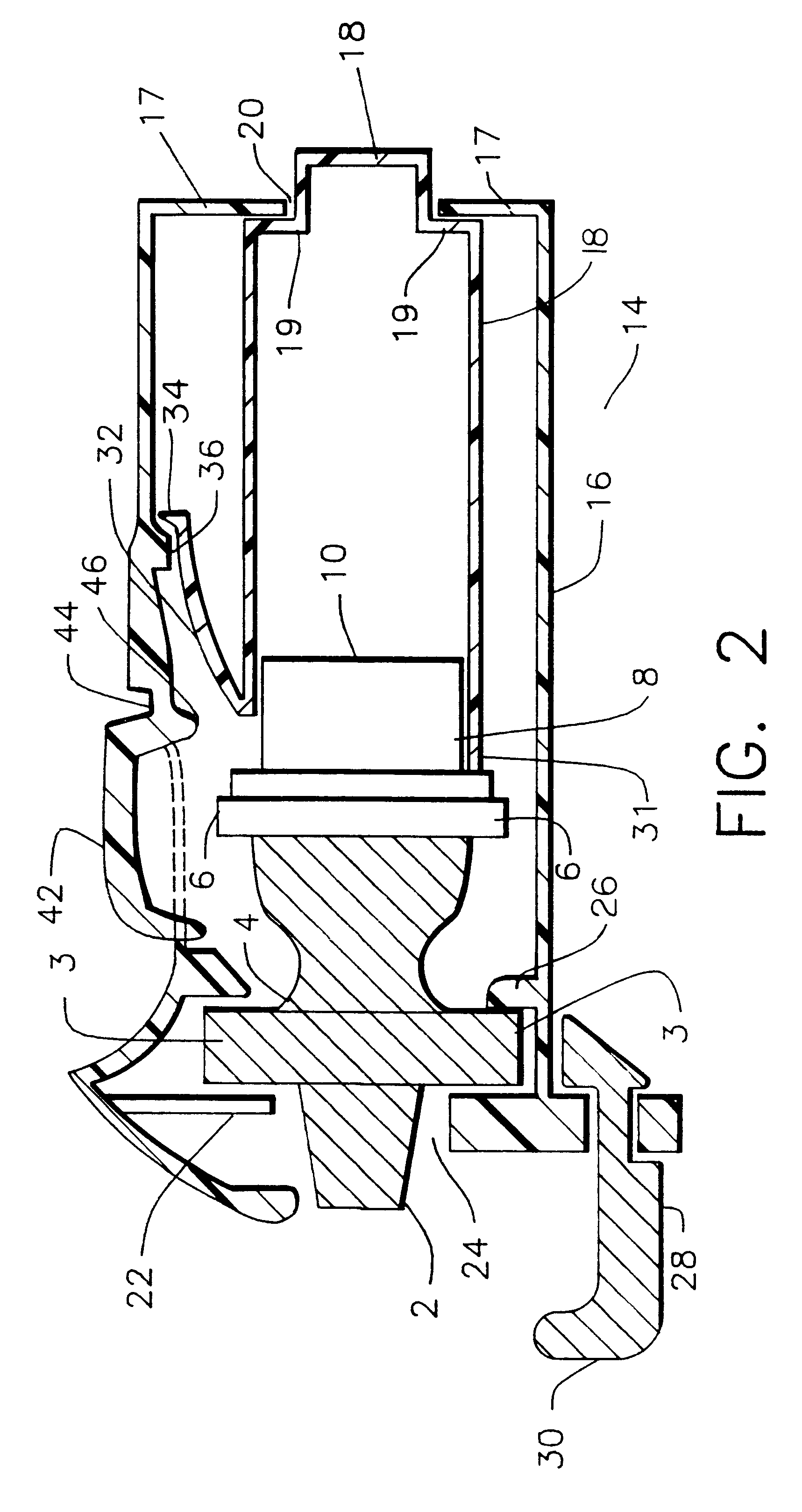

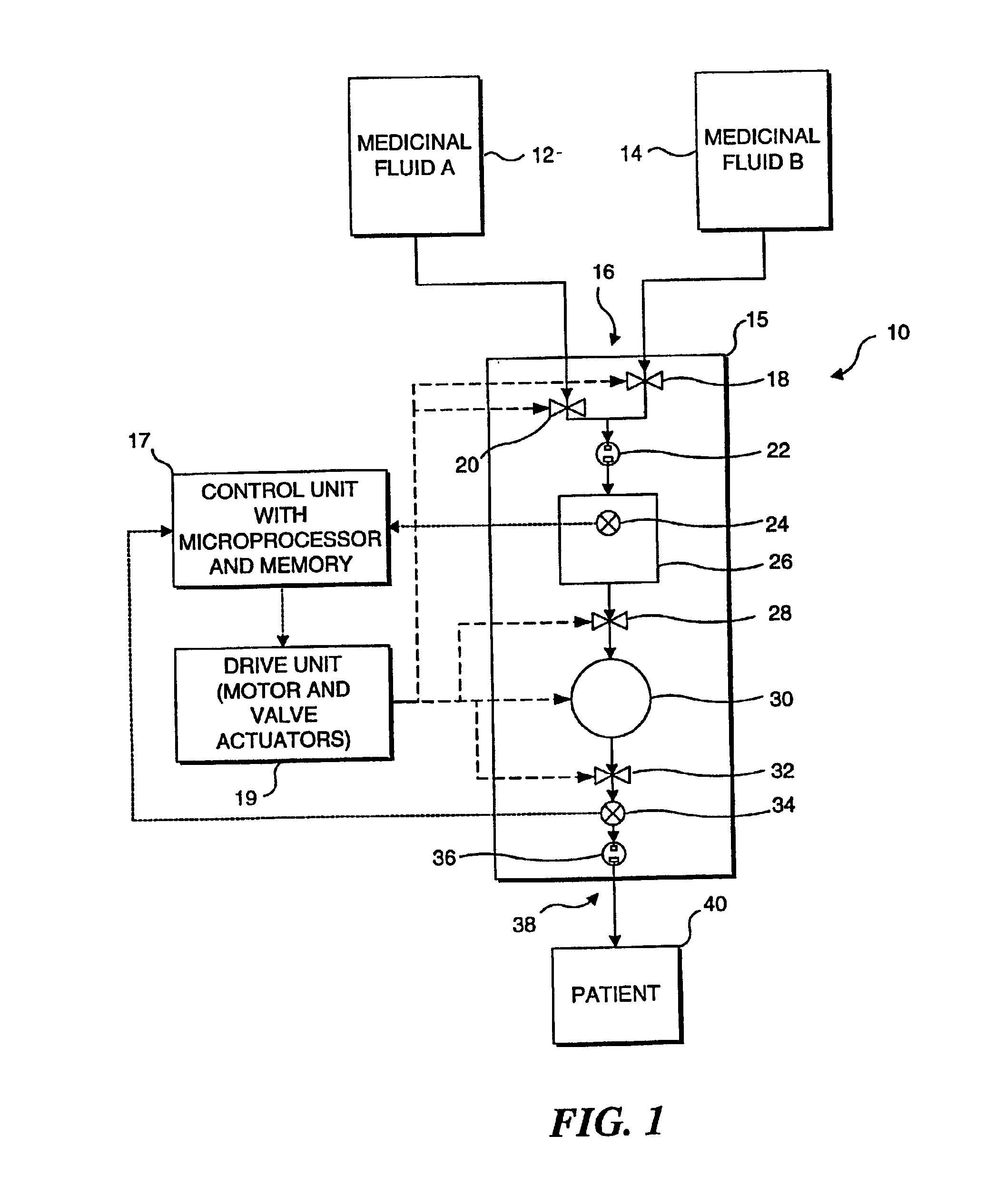

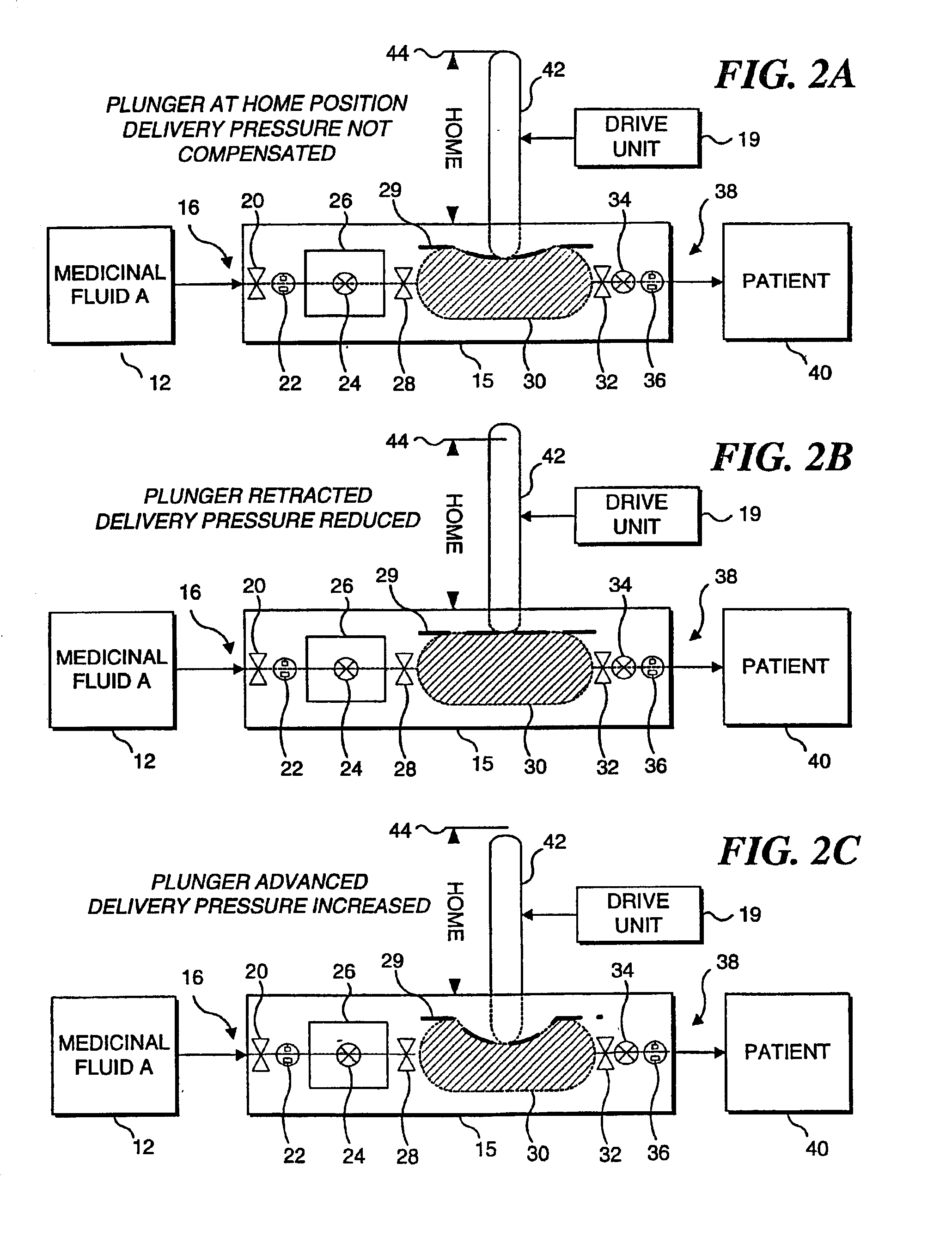

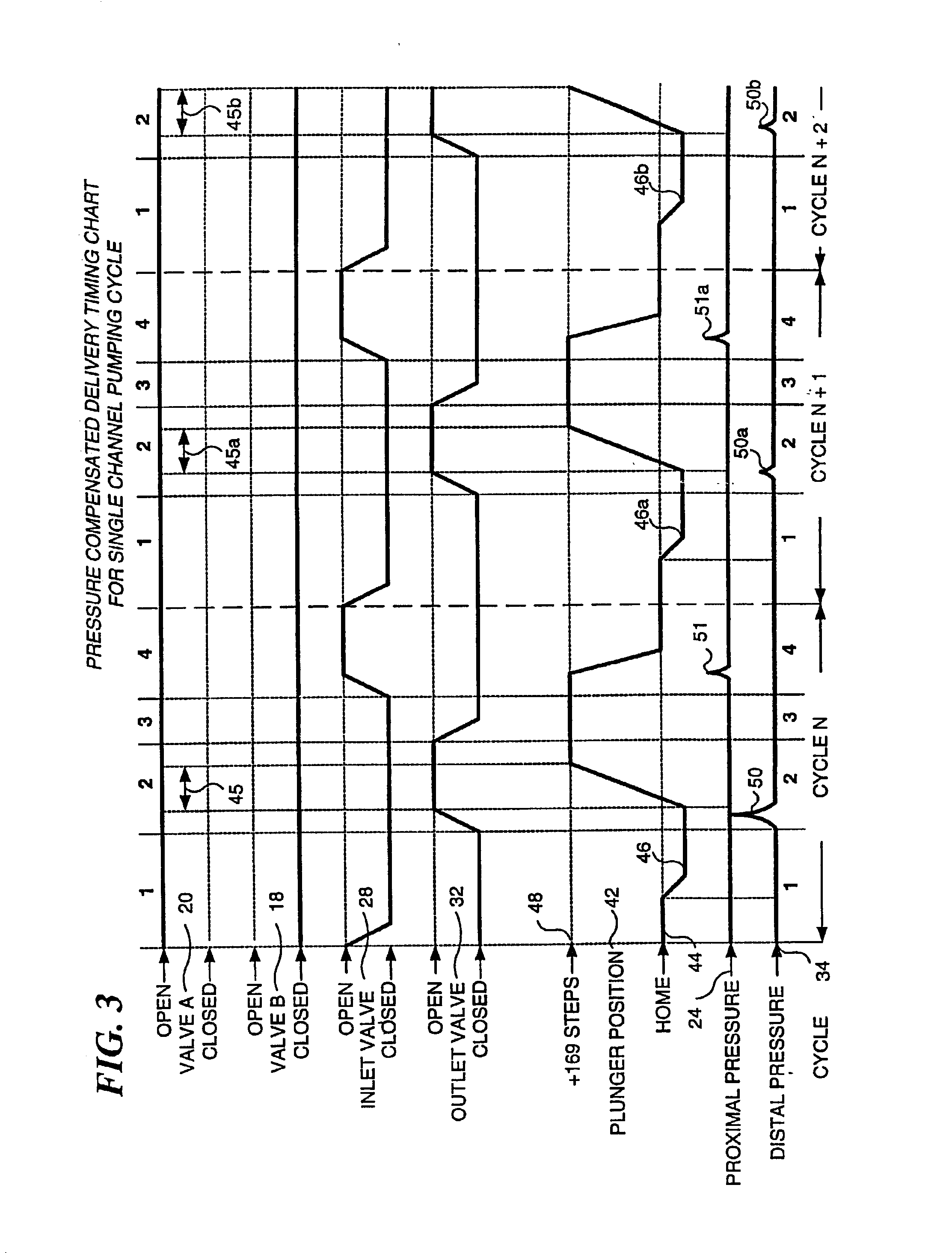

Method for compensating for pressure differences across valves in cassette type IV pump

InactiveUS6942636B2Accurate deliveryAccurate delivery of fluidElectrotherapyMedical devicesHome positionElastance

A pump used to infuse a fluid into a patient is controlled in accordance with an algorithm that enables a microprocessor to monitor and adjust each pump cycle to compensate for a differential pressure between the pump's inlet and outlet. The algorithm defines a fluid delivery protocol that is applied in controlling the operation of the pump to achieve a desired rate, volume, and timing of the fluid infusion. Fluid is delivered by the pump when a plunger compresses an elastomeric membrane overlying a fluid chamber. Due to the small volume of the chamber, an incremental change in the plunger position before the delivery stroke produces a significant change in the delivery pressure. At the beginning of a pump cycle, the microprocessor determines the differential pressure between the inlet and outlet of the pump, and adjusts the plunger position before the delivery stroke to compensate for the differential pressure. A retraction of the plunger from the home position decreases the delivery pressure of the fluid, and an advancement of the plunger increases it. After the position of the plunger is adjusted to compensate for the differential pressure, the pump cycle proceeds. Following the plunger stroke, the outlet pressure is used to determine the actual volume of fluid delivered. The duration of the plunger stroke in the next pump cycle is adjusted to compensate for any volume delivery error produced by the differential pressure compensation.

Owner:ICU MEDICAL INC

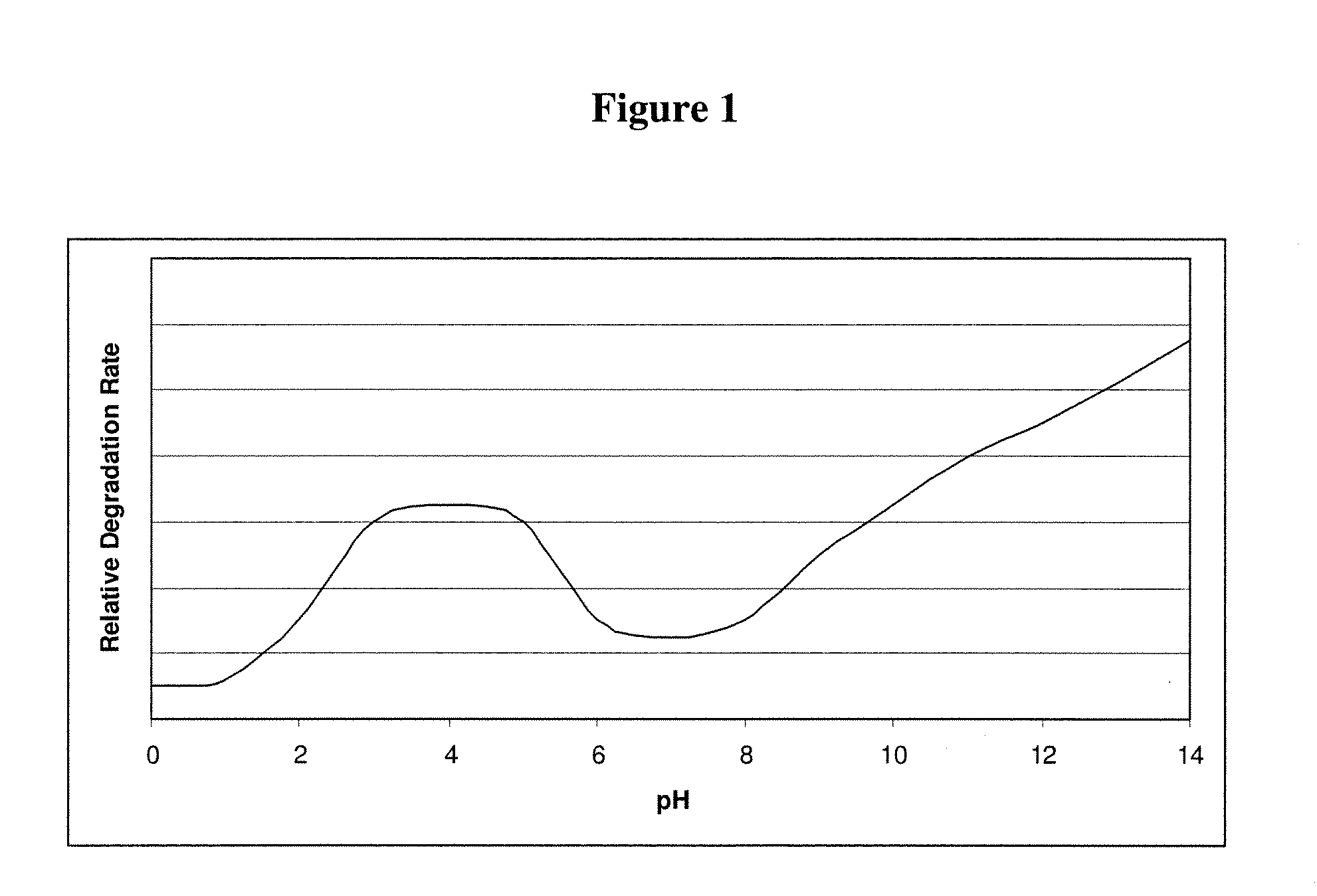

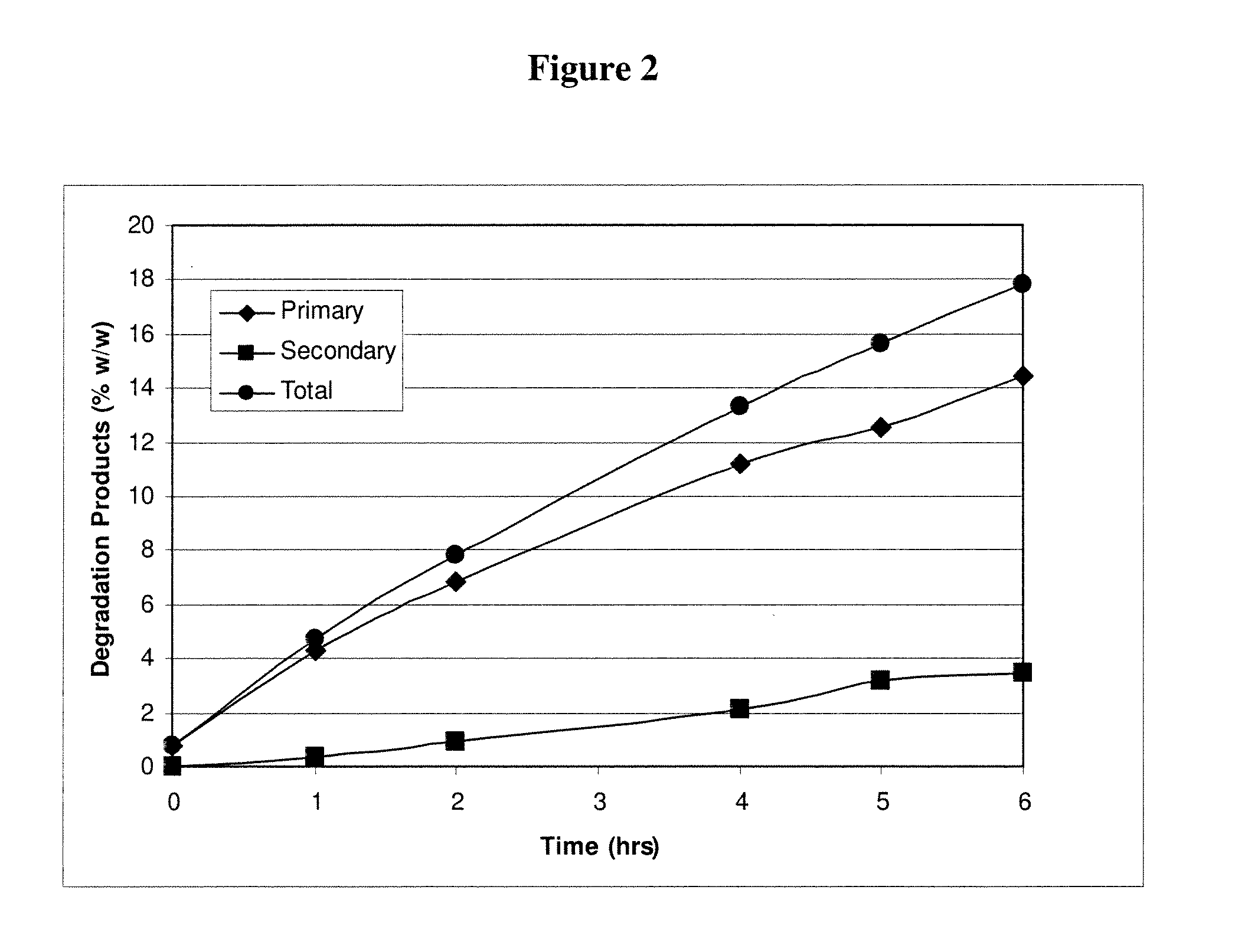

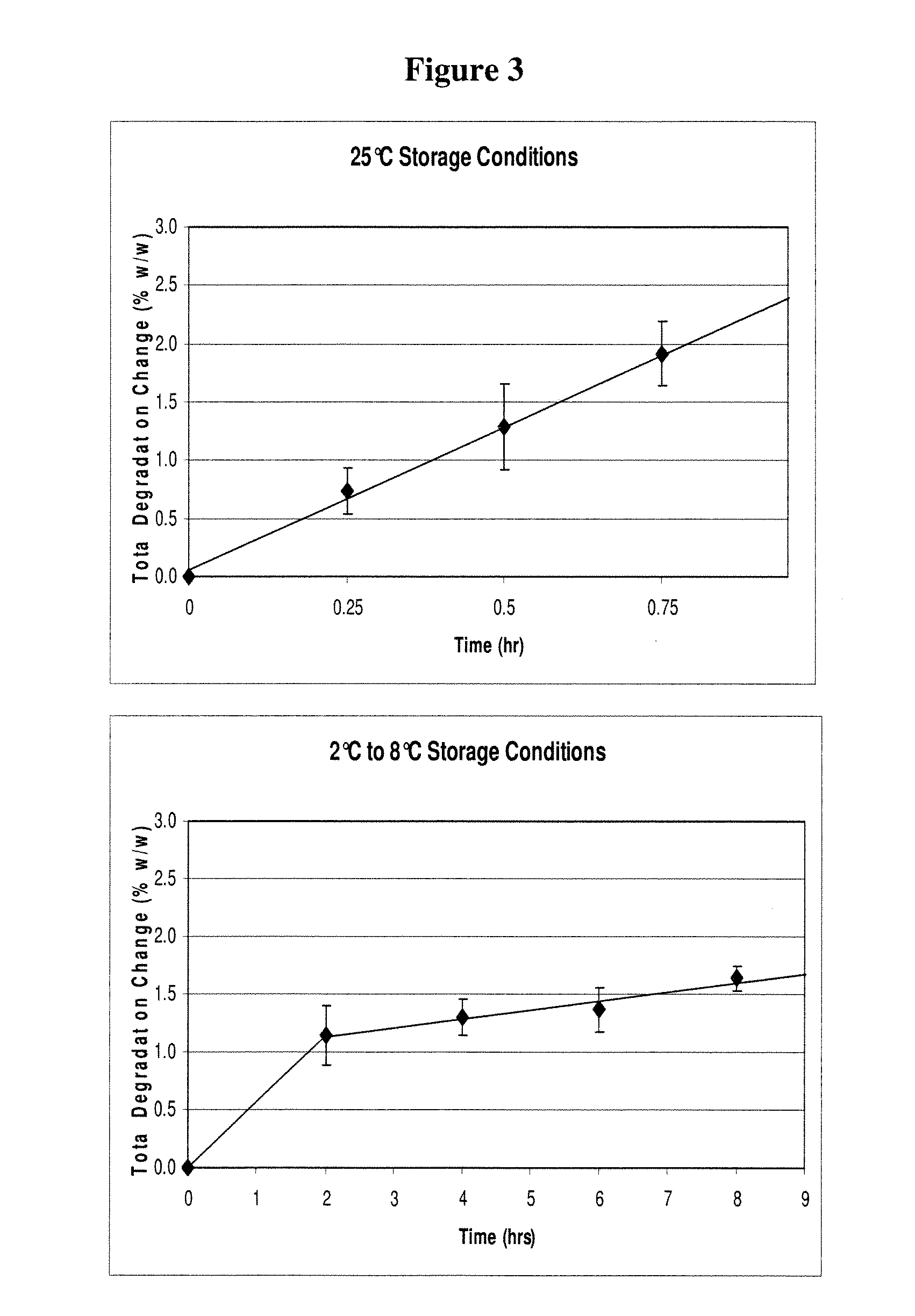

Pharmaceutical compositions of cytidine analogs and methods of use thereof

InactiveUS20120196823A1Accurate deliveryFacilitates accurate deliveryBiocidePharmaceutical delivery mechanismDiseaseCytidine

The present disclosure provides pharmaceutical compositions comprising cytidine analogs for parenteral administration. Also provided are methods of preparing the compositions and methods of treating diseases and disorders using the compositions provided herein.

Owner:CELGENE CORP

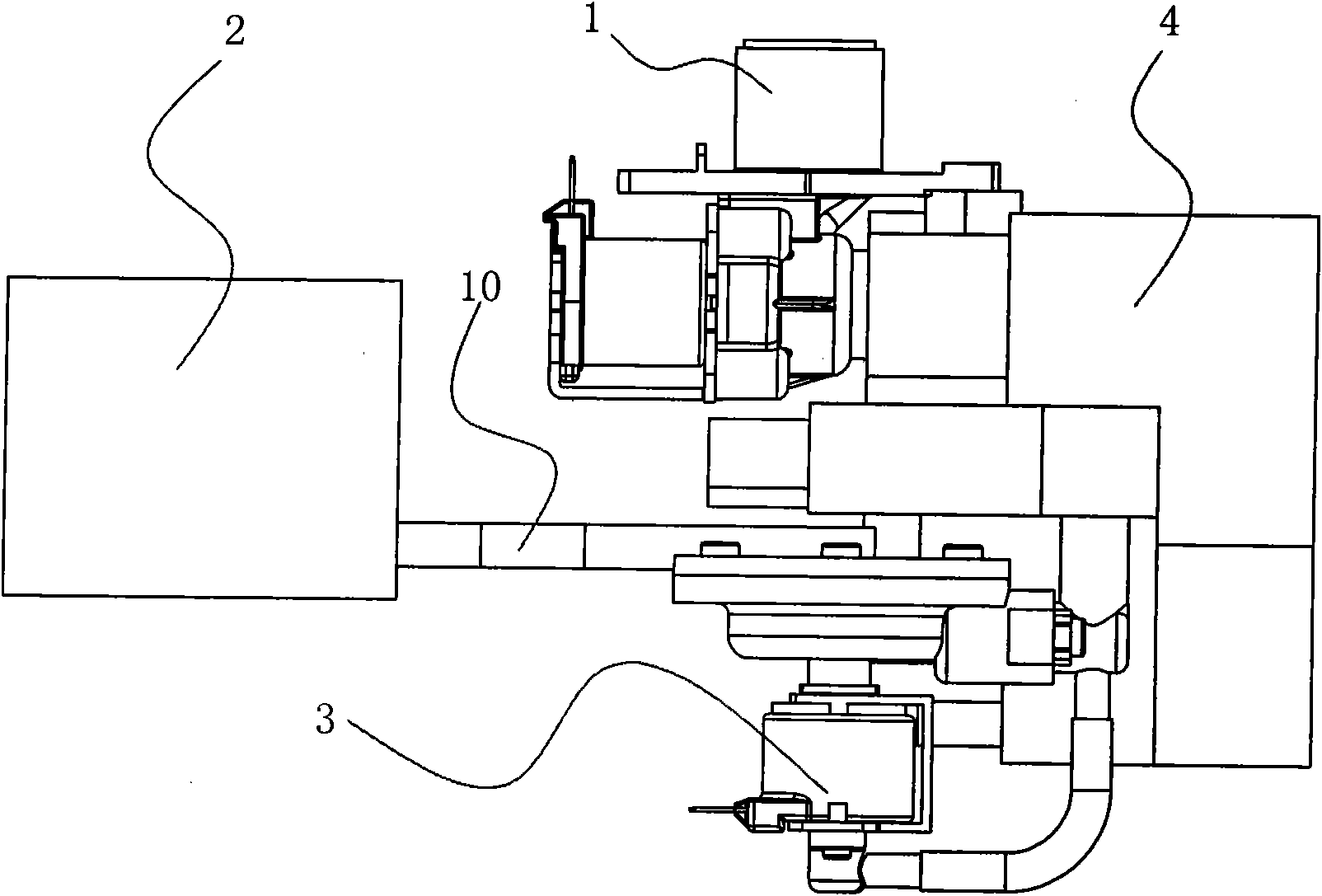

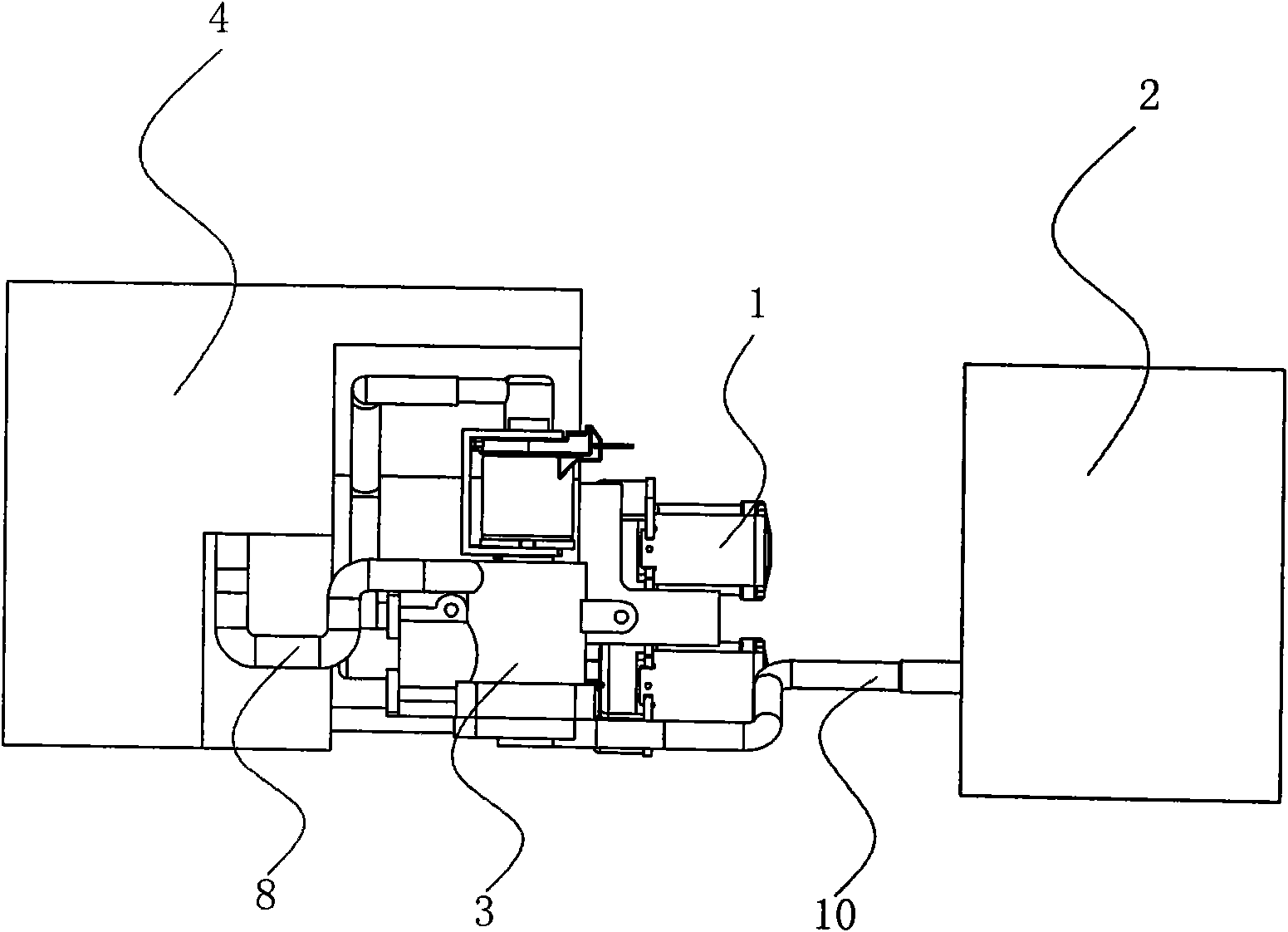

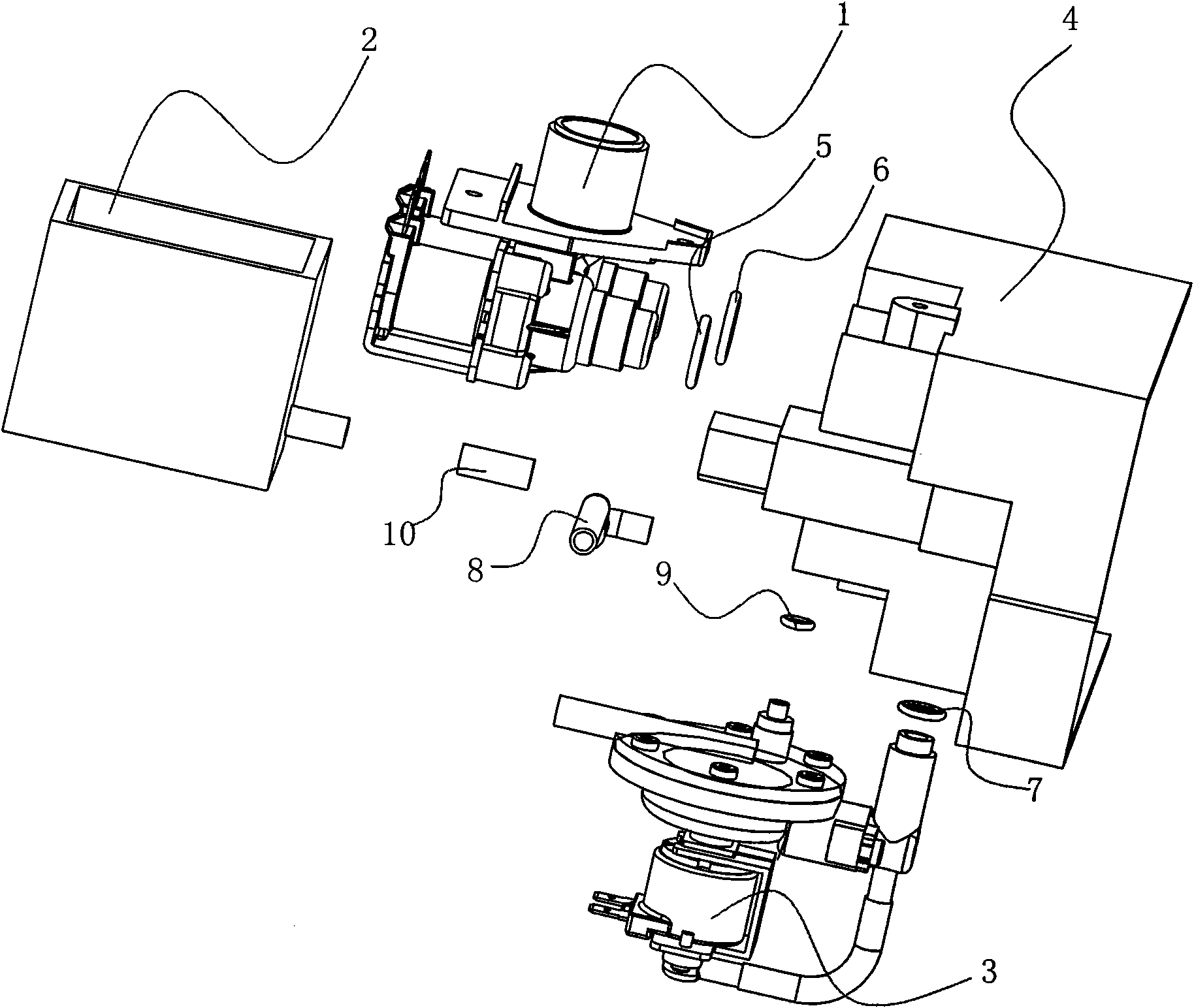

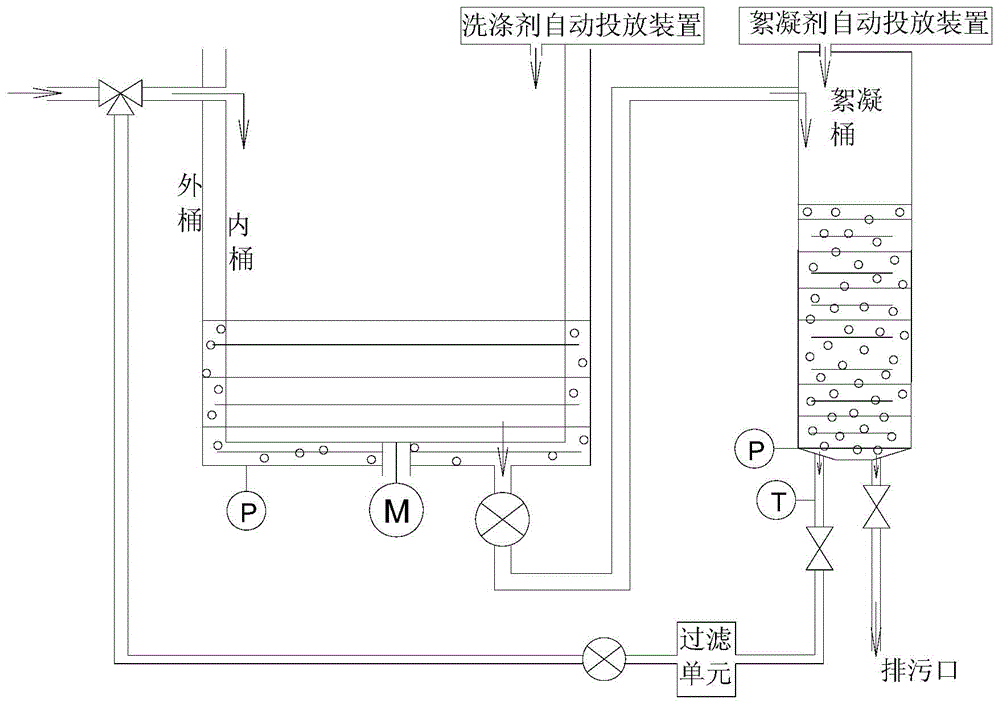

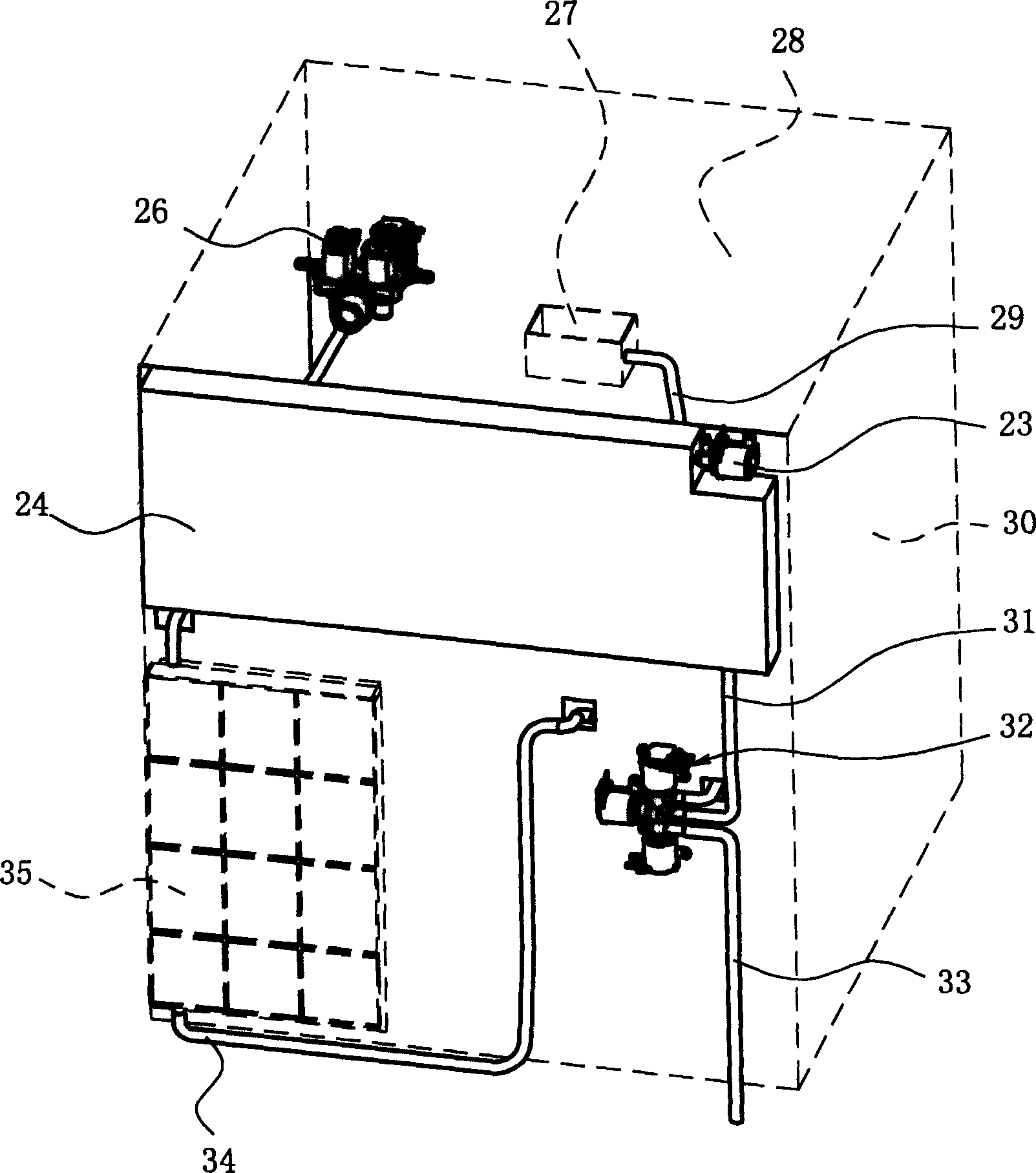

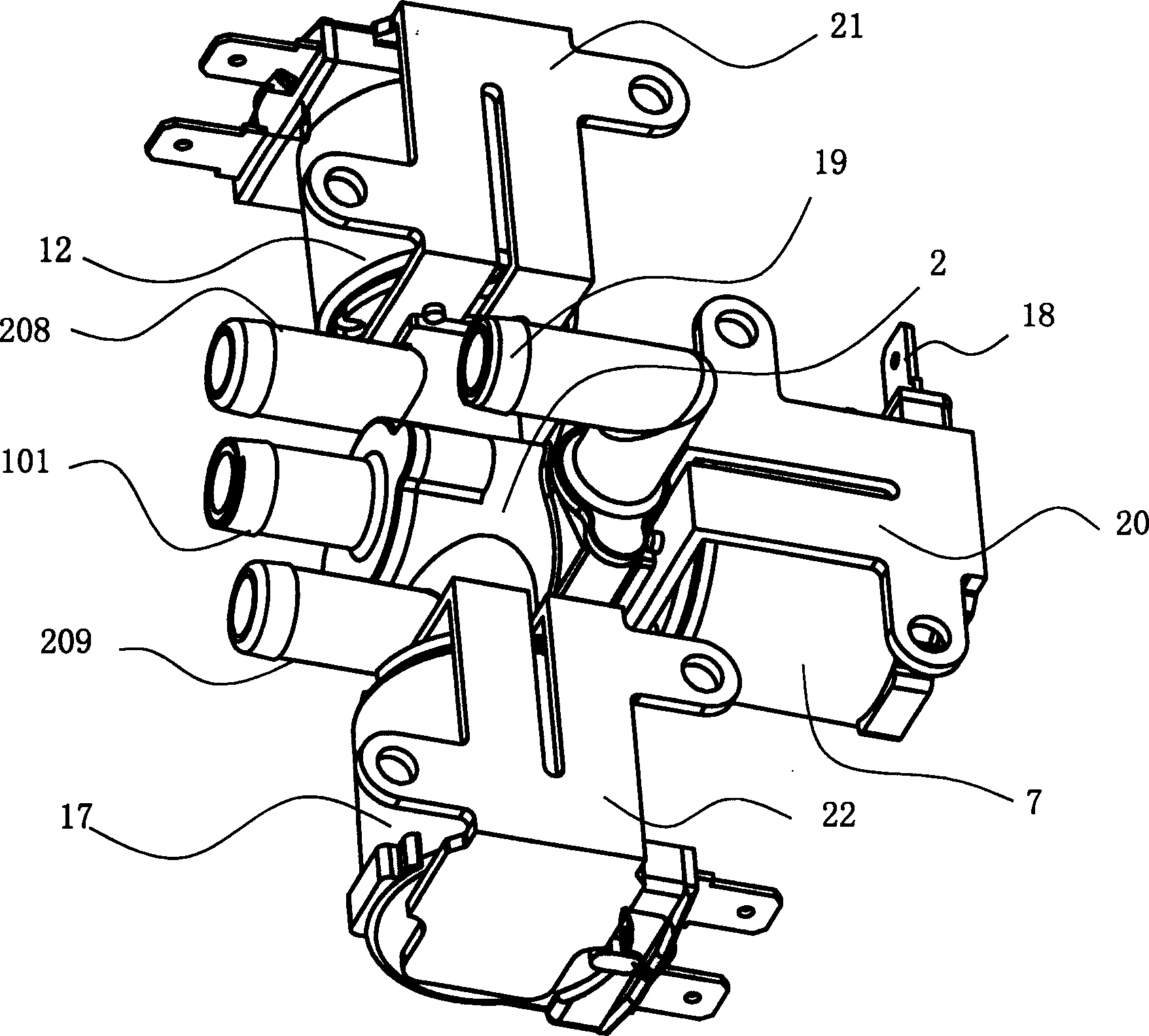

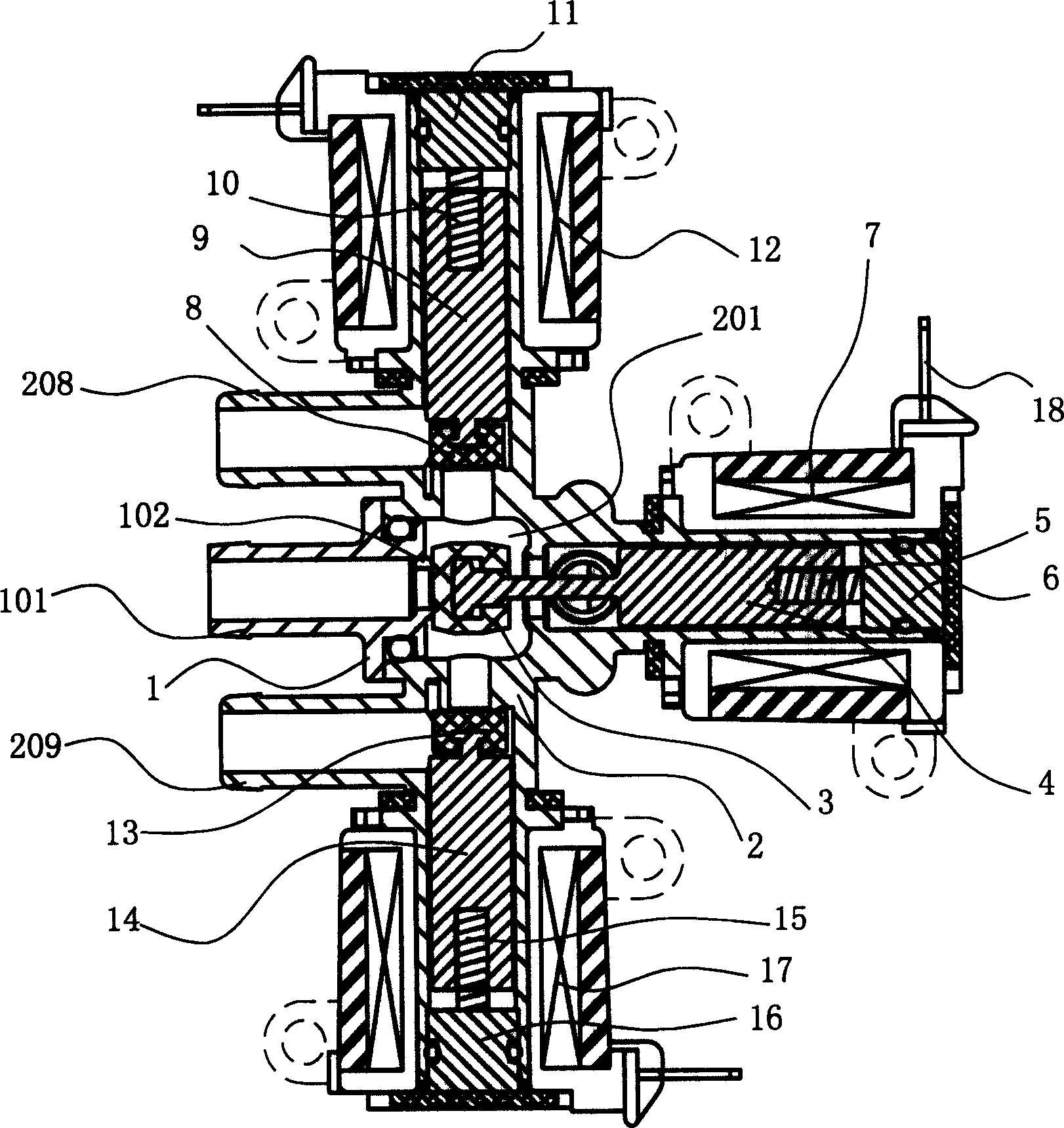

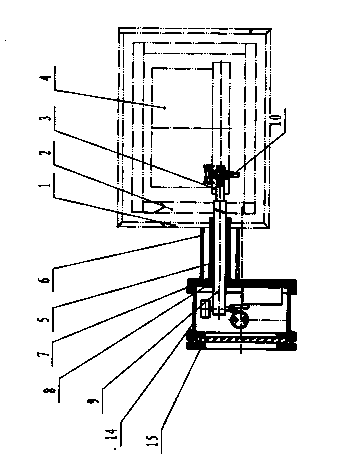

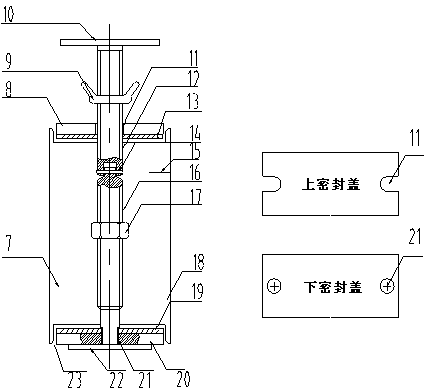

Apparatus for feeding liquid detergent

InactiveCN101671938AAccurate deliveryShorter run timeTableware washing/rinsing machine detailsOther washing machinesEngineeringMechanical engineering

The invention discloses an apparatus for feeding a liquid detergent, which comprises an electromagnetic water feeding valve, a liquid detergent tank, an electromagnetic metering valve, a water box, related pipelines and a sealing component. The electromagnetic water feeding valve is provided with a water inlet, a water outlet A and a water outlet B; the lower part of the liquid detergent tank is provided with a detergent outlet; the valve body of the electromagnetic metering valve is a valve body having a metering chamber and consisting of a valve body A and a valve body B, wherein the valve body is provided with a flow inlet A, a flow inlet B, a flow outlet and a discharge port, the discharge port is communicated with the metering chamber, a one-way valve is arranged in the flow inlet B,a sealing ball is arranged in the metering chamber, a moveable iron core is arranged in a conduit, the front part of the moveable iron core is connected with a piston cap, the rear part of the conduitis provided with a fixed iron core and a spring, and an electromagnetic coil is sleeved outside the conduit; and the water box is provided with a water inlet A, a water inlet B, a water inlet C, a water inlet D, a water inlet chamber and a water outlet chamber. The apparatus for feeding the liquid detergent is suitable for electric washing machines, such as electric washing machines and electricdishwashing driers.

Owner:HANGZHOU KAMBAYASHI ELECTRONICS

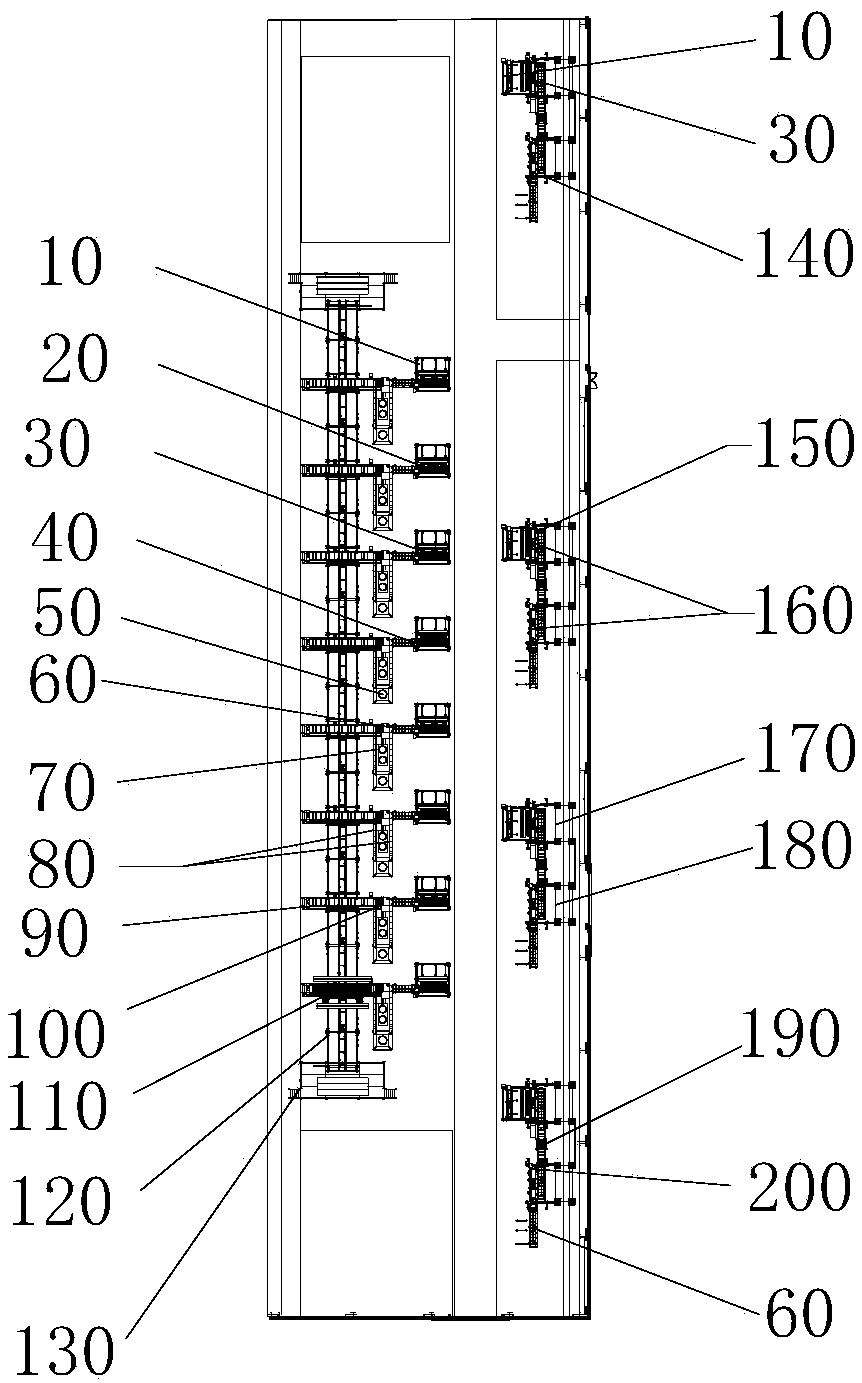

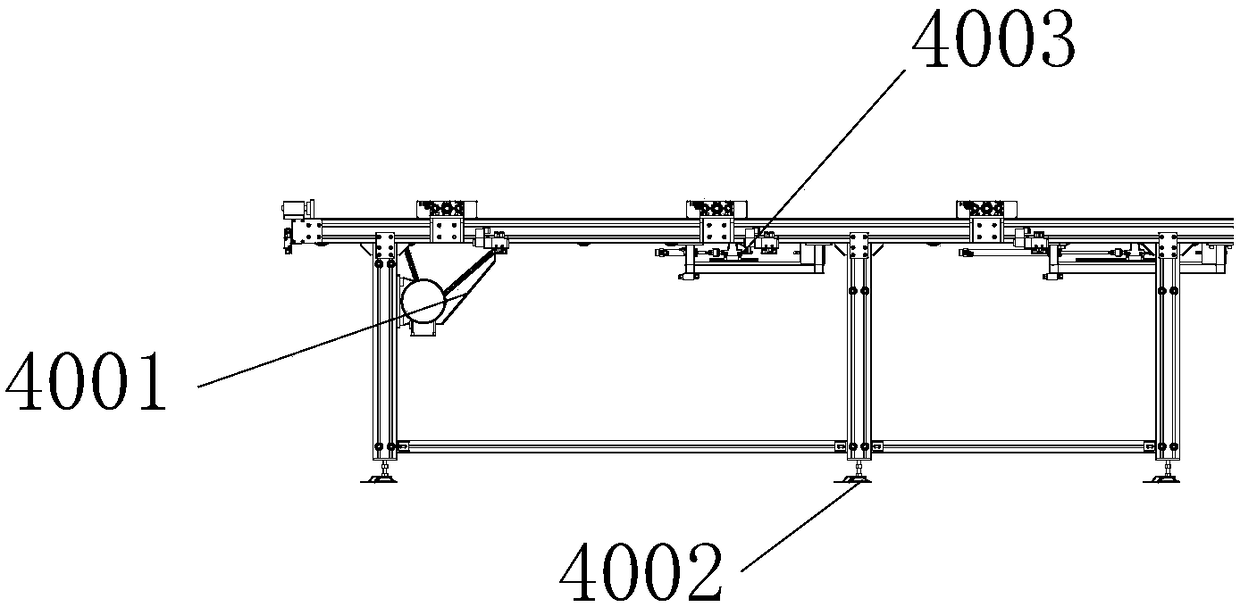

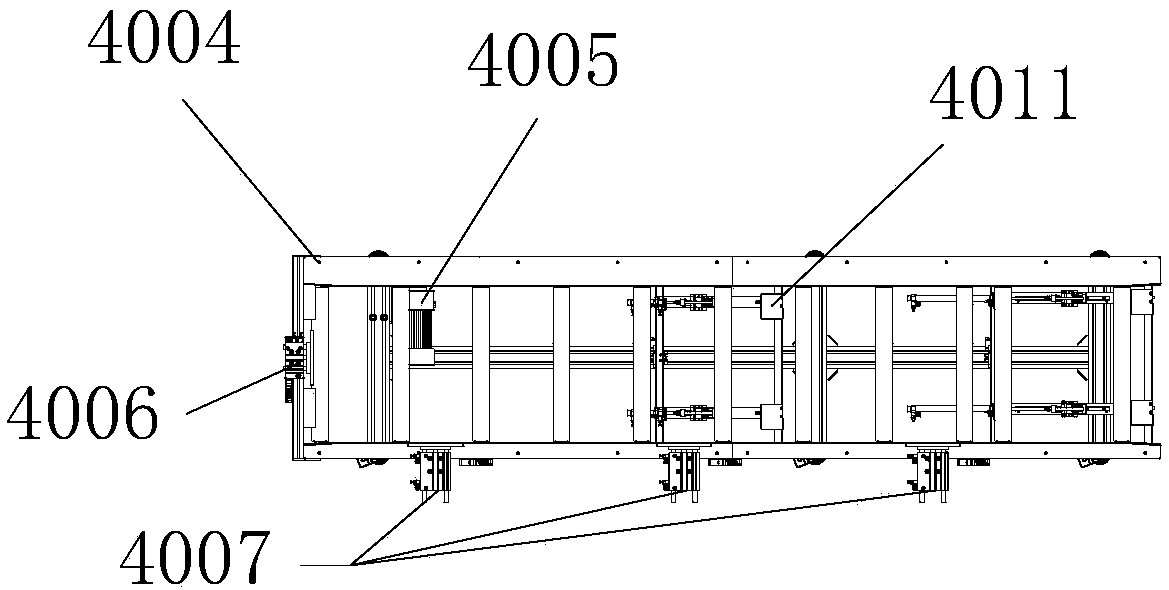

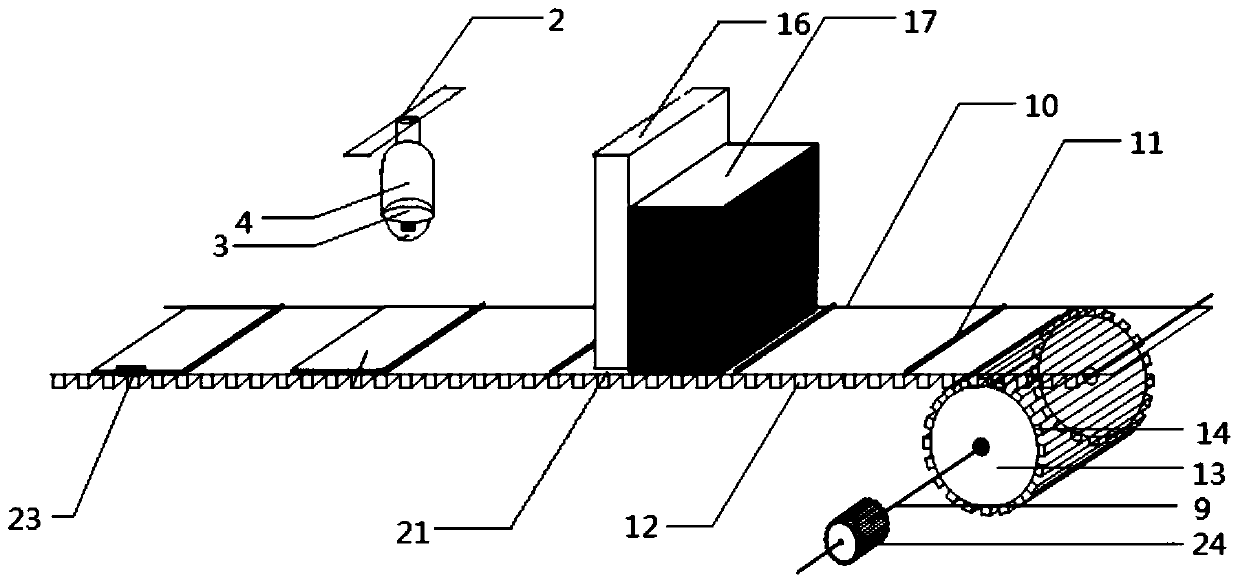

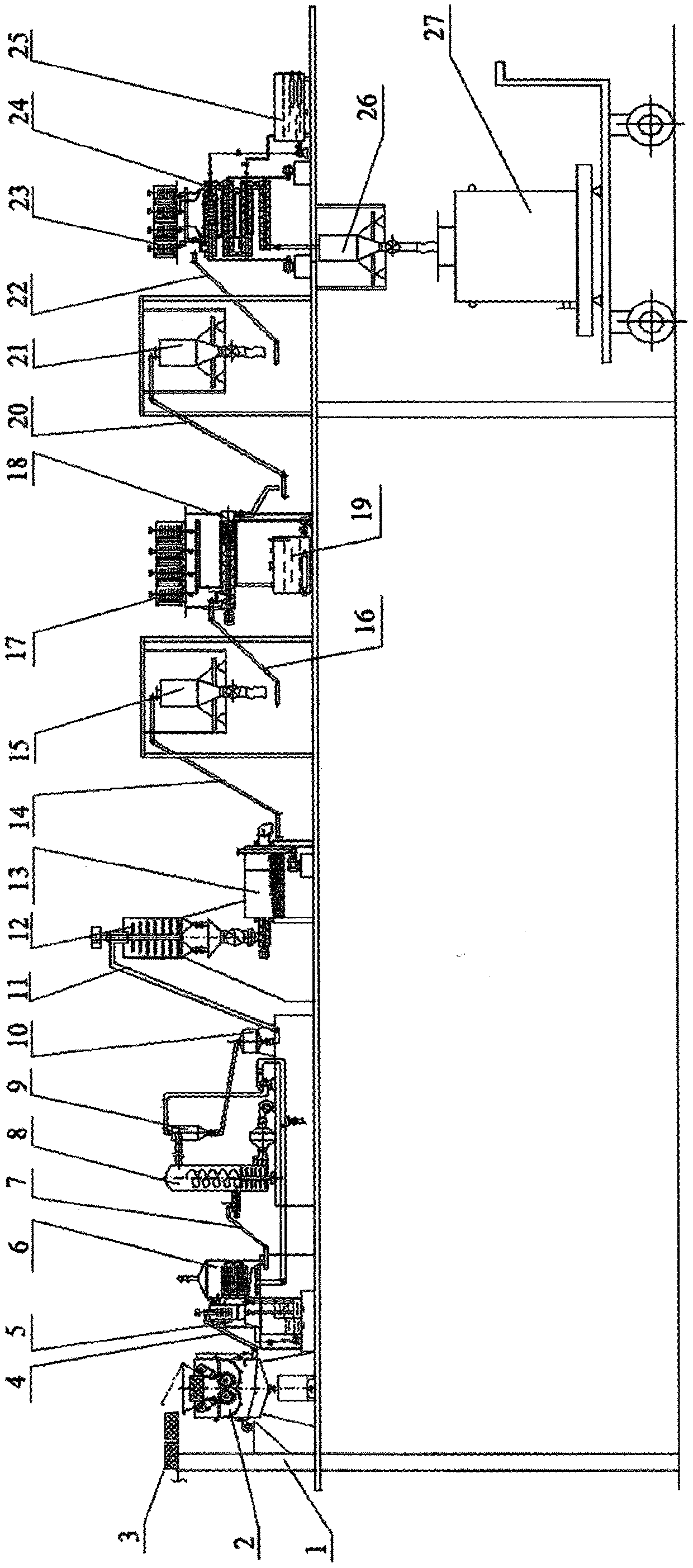

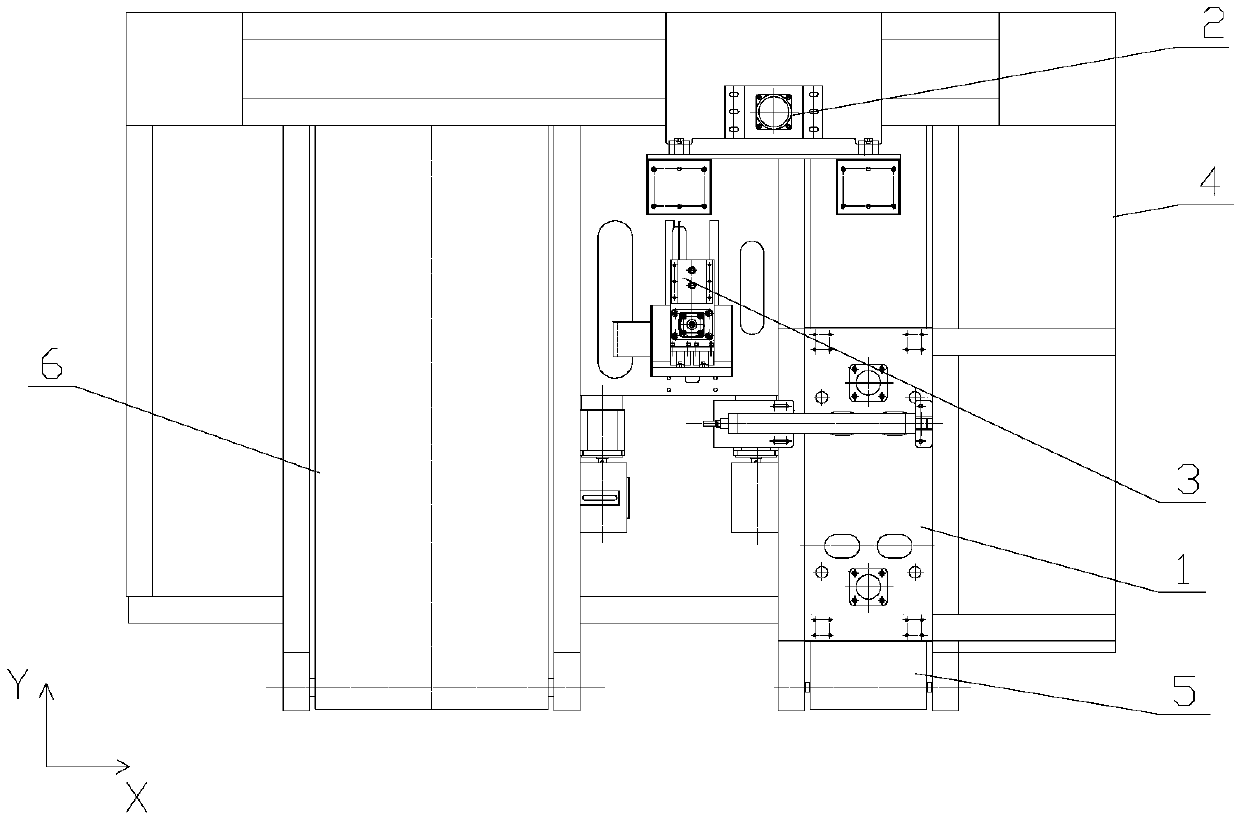

Aluminum plate intelligent feeding, discharging and punching multi-manipulator integrated production line

PendingCN108273900AReal-time deliveryAccurate deliveryMetal-working feeding devicesOther manufacturing equipments/toolsManipulatorAluminium

The invention relates to an aluminum plate intelligent feeding, discharging and punching multi-manipulator integrated production line. The aluminum plate intelligent feeding, discharging and punchingmulti-manipulator integrated production line comprises a stacking gantry, a 180-degree lateral overturning mechanism, an automatic measuring device, a conveying line, an automatic feeding frame, an up-down distribution mechanical arm, an upper air double-line conveying line, a punching four-axis gantry, a secondary fine positioning device, a 360-degree rotating platform and a primary fine positioning platform. The 180-degree lateral overturning mechanism is arranged by the side of the stacking gantry, the automatic measuring device is arranged by the side of a left stacking clamp, and a stub bar recovering line is arranged between the conveying line and a stub bar recovering box. The up-down distribution arm is arranged between the upper air double-line conveying line and the automatic feeding frame, the punching four-axis gantry is arranged on the front side of the right stacking gantry, and the 360-degree rotating platform is arranged between a primary fine positioning mechanism andthe secondary fine positioning device. According to the aluminum plate intelligent feeding, discharging and punching multi-manipulator integrated production line, the manpower efficiency is improved,the error rate is decreased, conveying and delivery of aluminum molds are conducted accurately and stably in real time, the automation and intellectualization degrees are high, and manpower and material resources can be greatly reduced.

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

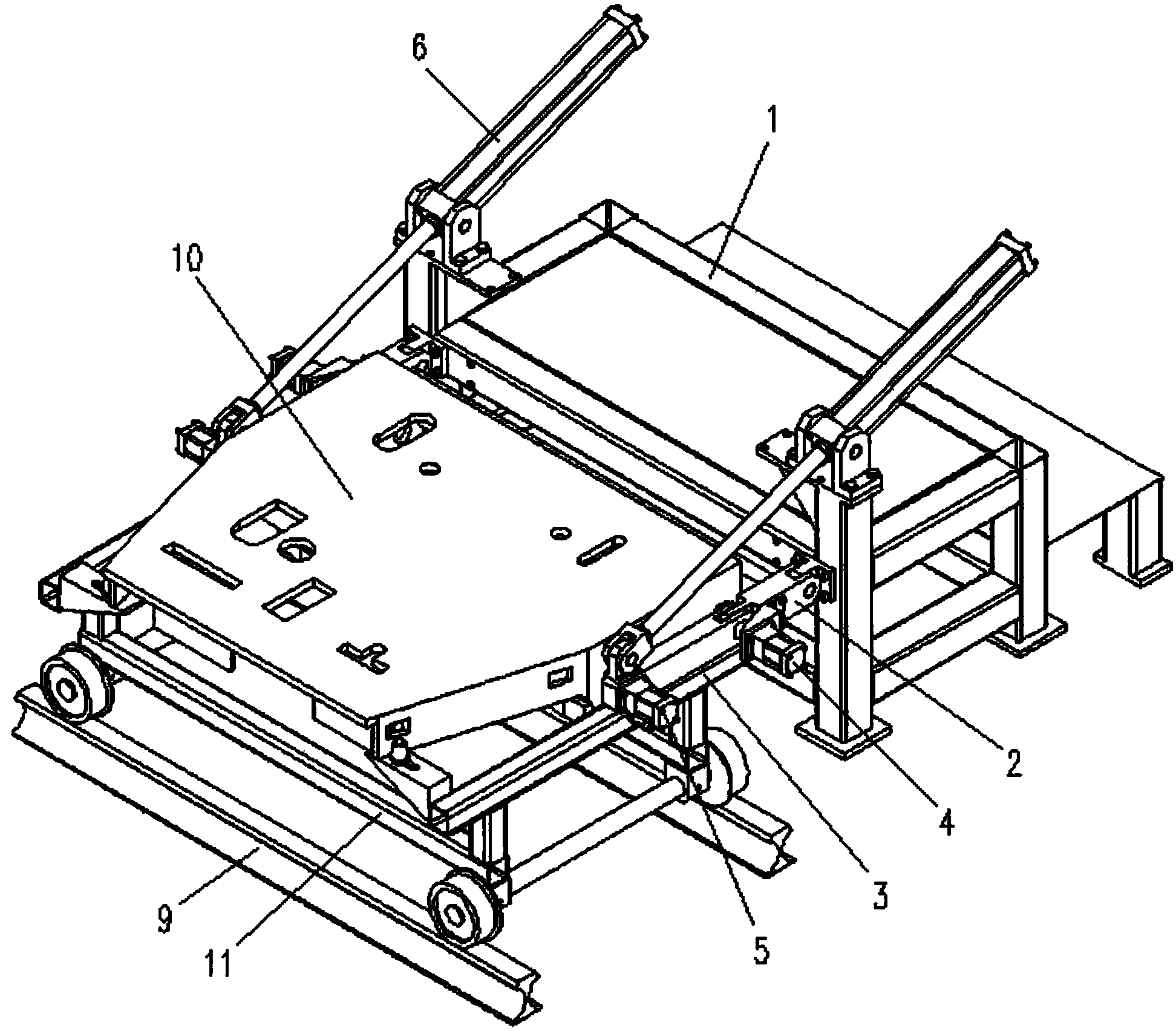

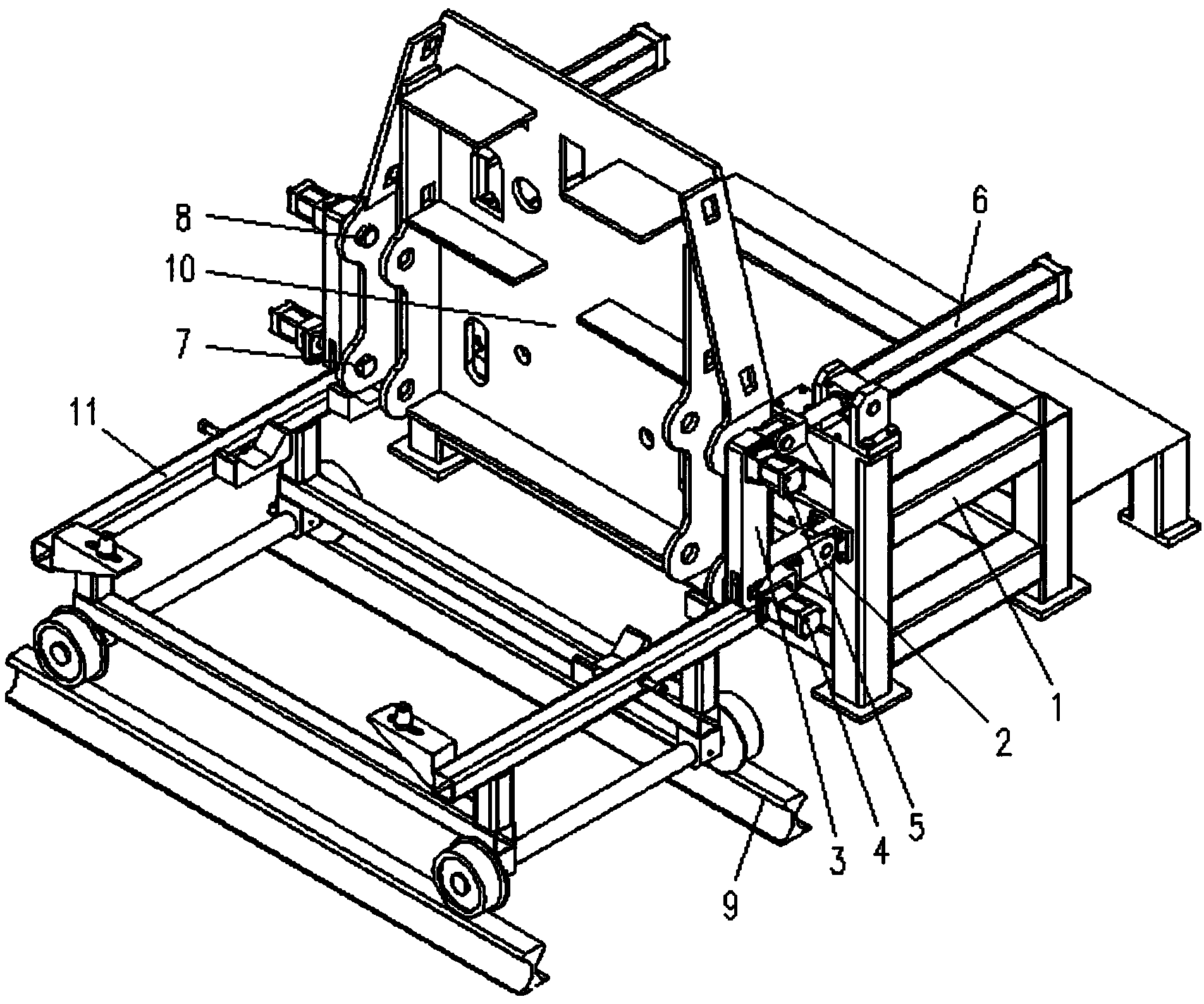

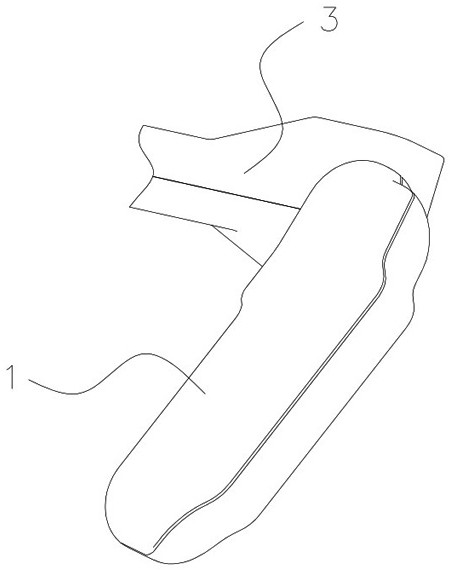

Turnover machine for assembling and base assembling device for engineering machinery

ActiveCN103707034AImprove work efficiencyEasy flipAssembly machinesWork benchesHydraulic cylinderHigh volume manufacturing

The invention discloses a turnover machine for assembling. The turnover machine comprises a machine seat and a pair of turnover manipulators arranged on the machine seat, wherein the turnover manipulators comprise turnover arms, turnover elbows, first insertion pin cylinders, second insertion pin cylinders and turnover hydraulic cylinders. The invention also discloses a base assembling device for engineering machinery. The base assembling device for the engineering machinery comprises vehicle rails and a transporting vehicle which is arranged on the vehicle rails and is used for transporting a base of the engineering machinery. According to the turnover machine for assembling and the base assembling device for the engineering machinery, taking and arrangement of a workpiece to be turned over are realized by controlling insertion pins to be inserted into and released out of the workpiece by the insertion pin cylinders; the turnover elbows and the turnover arms are controlled to integrally rotate around a hinge center, and the turnover arms are controlled to be fixed and the turnover elbows are controlled to rotate independently, so that the turnover machine can catch up and put down the workpiece and enable the workpiece to randomly rotate between 0-90 degrees; a large-size workpiece can be turned over conveniently through the turnover machine; the working efficiency for assembling parts on the upper surface and the lower surface of the large-size workpiece is improved; the assembling work is high in safety; the turnover machine is applicable to large-batch production.

Owner:CMCU ENG

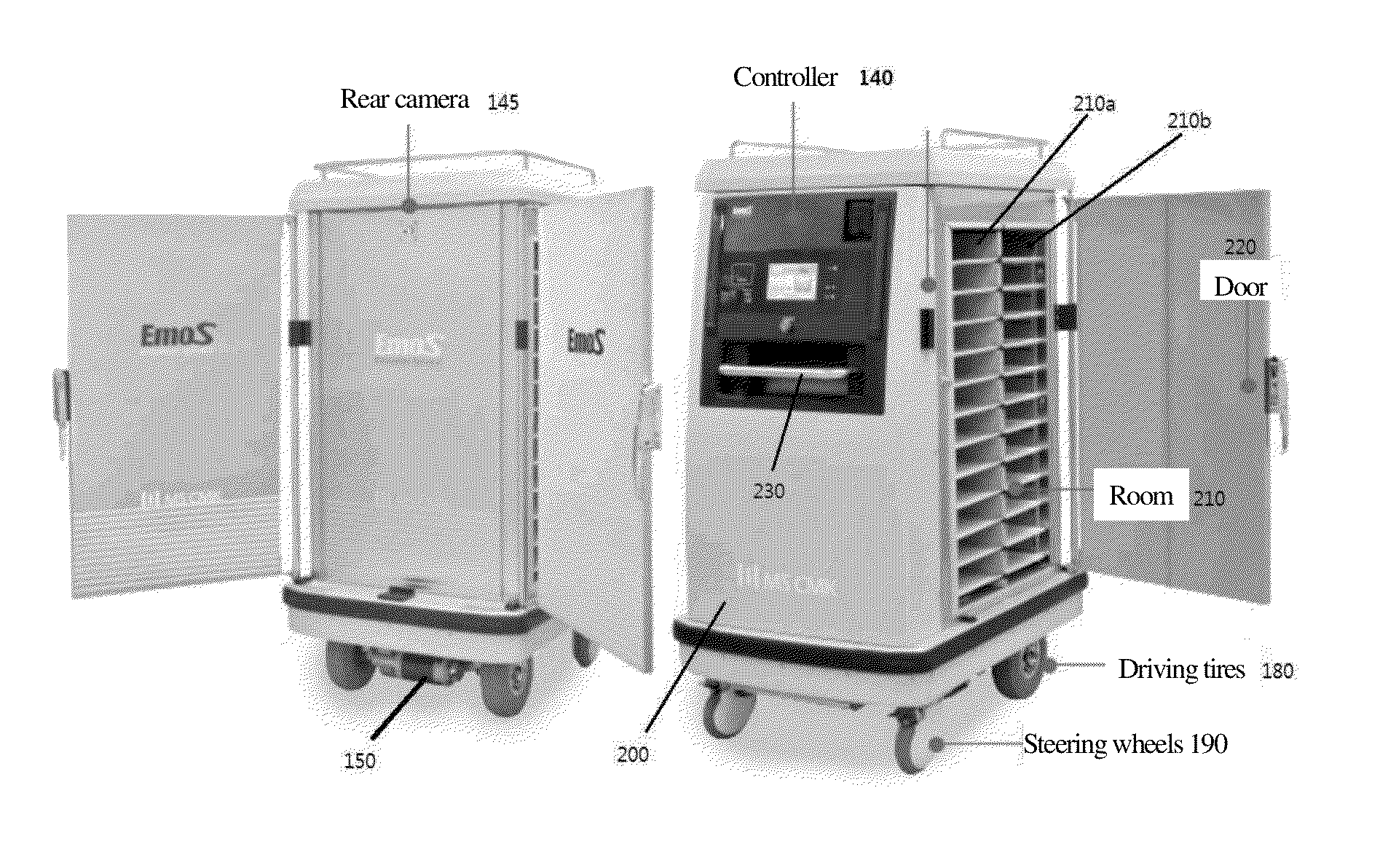

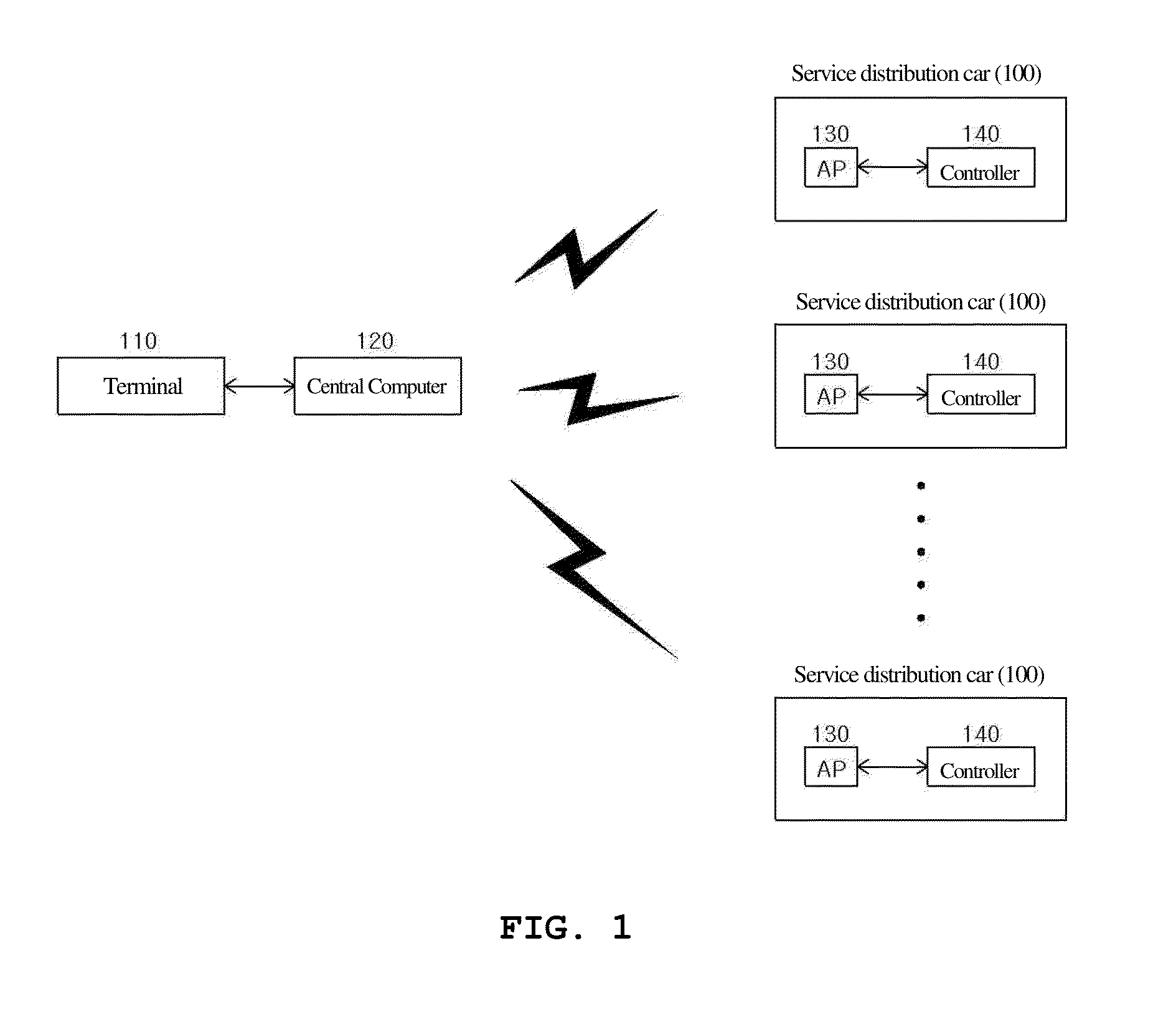

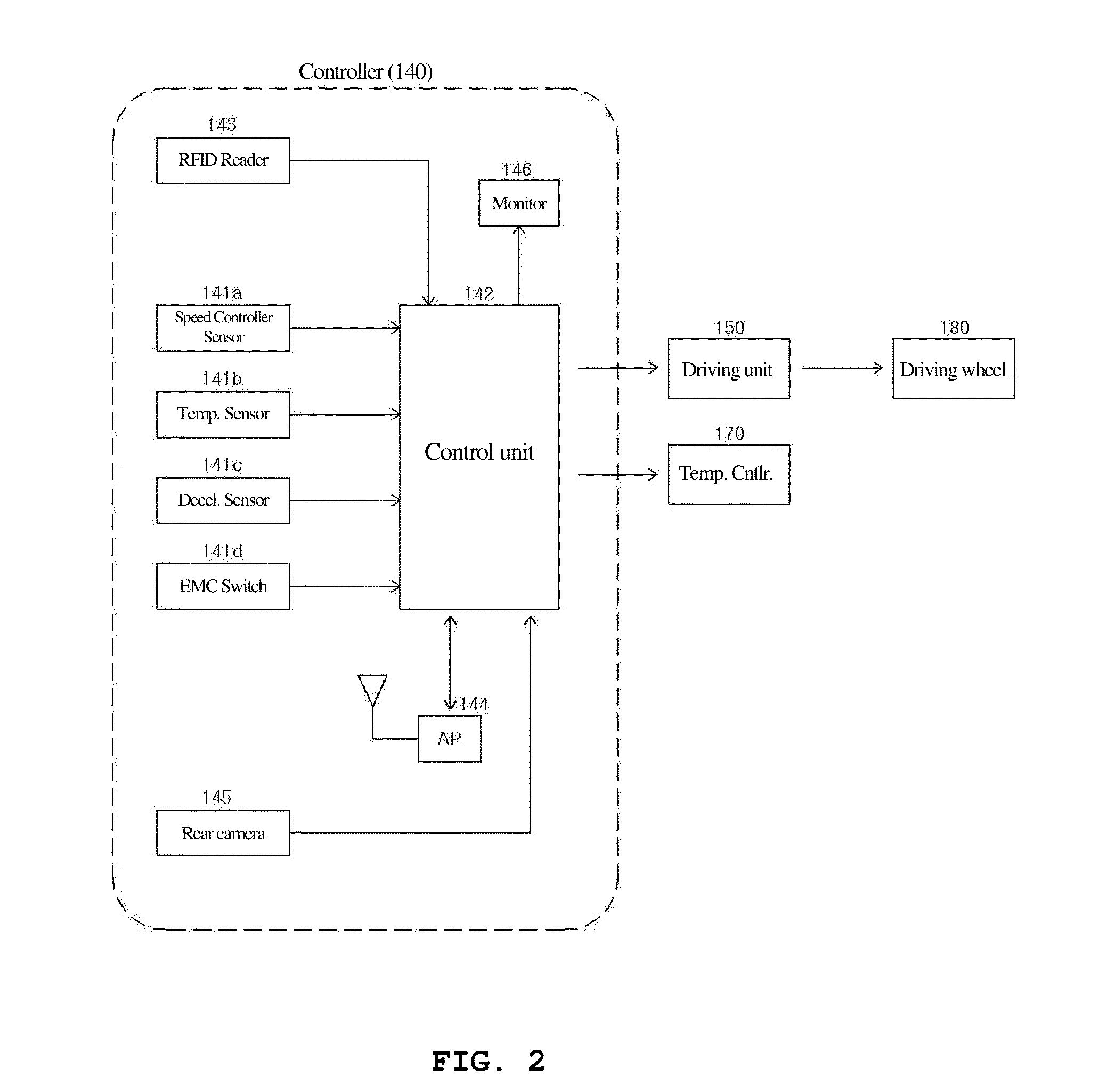

Integrated control system for service distribution car using wireless communications and service distribution car

ActiveUS20140333190A1Efficiently manageAccurate deliveryFurniture partsServing tablesControl systemTemperature control

Owner:MYUNGSAE C M K

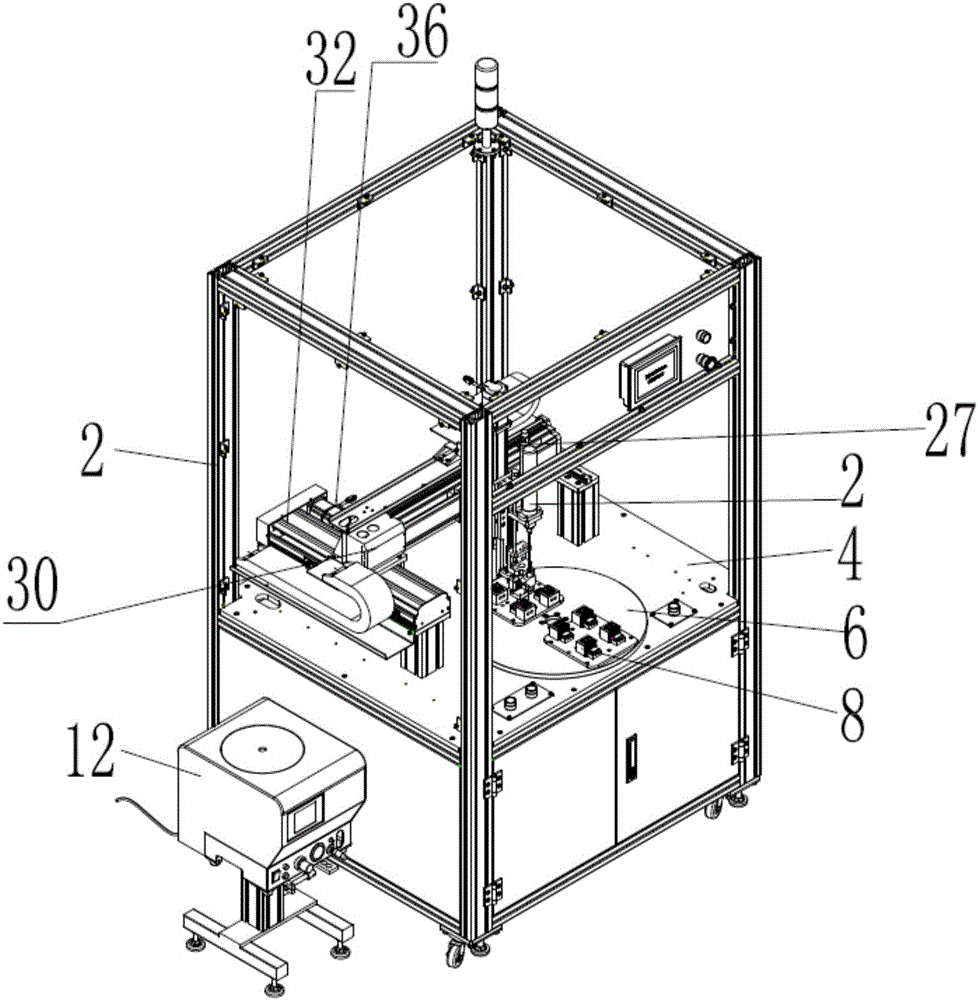

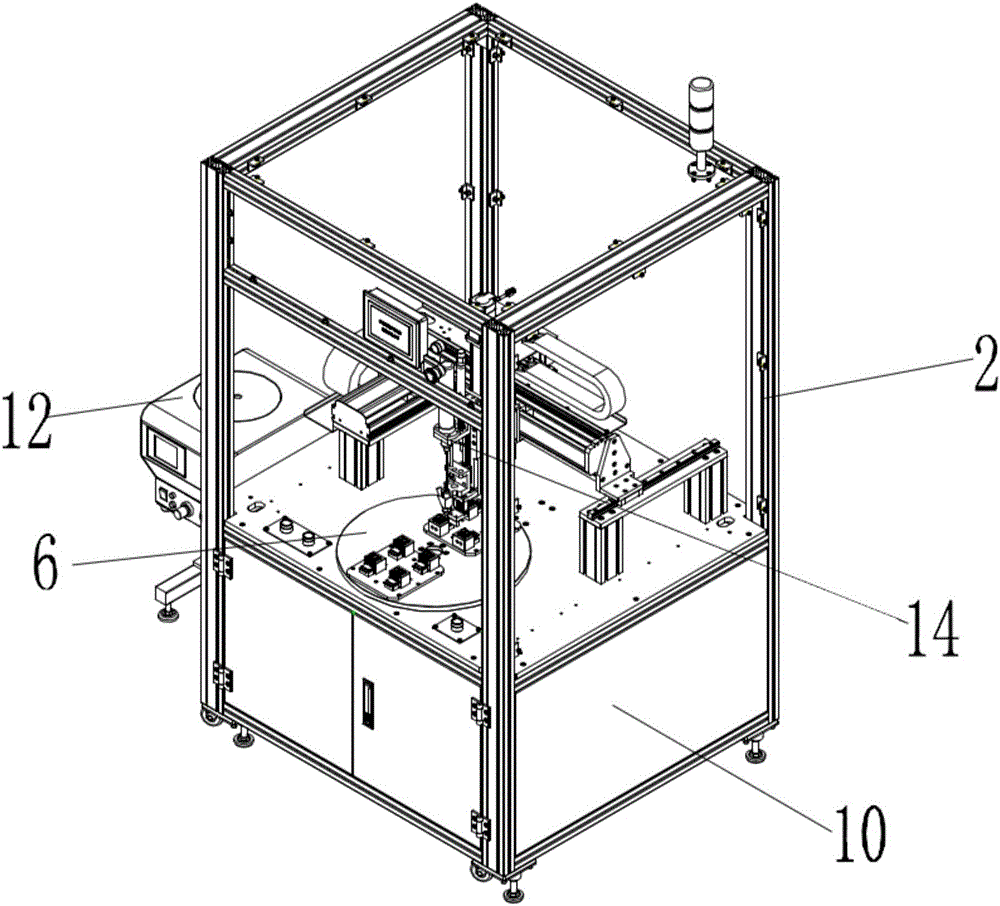

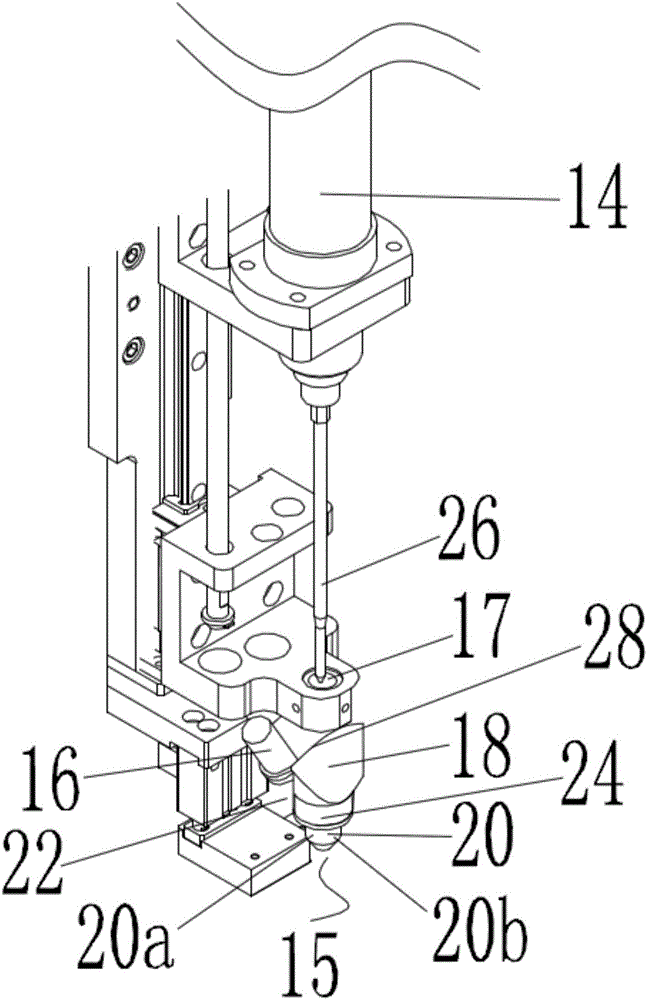

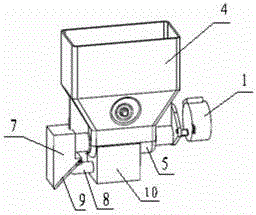

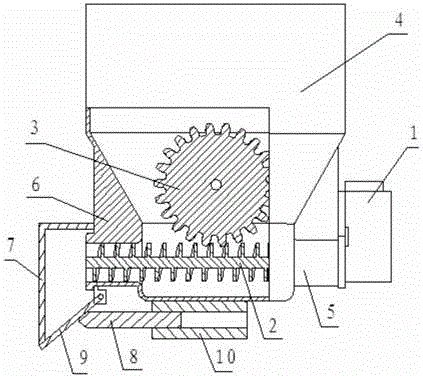

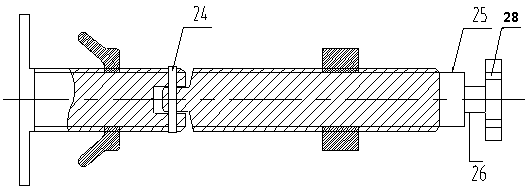

Automatic screwing machine

InactiveCN105855857AOvercome the defect that the action cannot share the deviceNovel structureMetal working apparatusEngineeringAutomation

The invention provides an automatic screwing machine which comprises a clamping installation base, a controller, a screw feeder, a screwdriver and a three-directional adjusting workbench. The screw feeder comprises a storage pipe, a screw guide cup and a feeding nozzle, wherein the feeding nozzle is provided with a first nozzle body and a second nozzle body which are arranged in a split mode and further provided with a nozzle air cylinder for driving the first nozzle body and the second nozzle body to be coupled face to face or separated backwards; and a containing cavity matched with screws in shape is formed inside the first nozzle body and the second nozzle body when the first nozzle body and the second nozzle body are coupled. The spiral feeder of the optimized structure can complete screw feeding and screwing actions under the effect of driving force, two functions are combined into one device really, and the defect that screw feeding and screwing actions cannot share the device of a screwing machine traditionally is overcome; and meanwhile, in cooperation with the three-directional adjusting workbench uniformly controlled by the controller, the feeding and locking positions of the screwdriver can be adjusted freely, screw feeding is accurate, the screw feeding place is accurate, and full automation is achieved.

Owner:SUZHOU MENGCHUAN AUTOMATION TECH

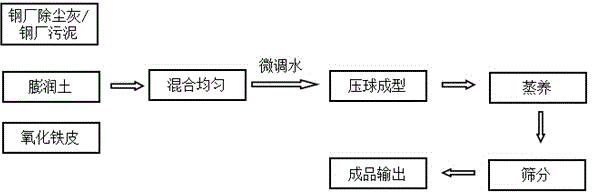

Method and system for manufacturing cooled slag-making pellets from steel plant dedusting ash or steel plant sludge

The invention discloses a method and a system for manufacturing cooled slag-making pellets from steel plant dedusting ash or steel plant sludge. The preparation method comprises the following steps: 1), preparing the steel plant dedusting ash or the steel plant sludge; 2), in accordance with the mass ratio, weighting raw materials of 75-85% of the steel plant dedusting ash and / or the steel plant sludge, 10-20% of iron oxide scales and 2-15% of bentonite, and mixing evenly; 3), fine blending the mixture with water, and carrying out ball pressing and molding into pellets; 4), sending the prepared pellets into a closed still kettle, directly introducing steam, carrying out steam curing heating on the pellets, and allowing to generate a steam curing reaction, wherein a steam curing medium is water steam, the steam curing pressure is 0.05-1.4 MPa, the water steam temperature is 105 DEG-195 DEG C, and the steam curing time is 0.5-2 h; and 5), carrying out dust separation and screening on the product after steam curing, and thus finally obtaining the finished product. The cooled pellets are prepared by the method, so that the energy can be saved, the production equipment investment and the production cost are reduced, the production cycle is shortened, and the product quality is improved.

Owner:江阴市元丰环保工程有限公司

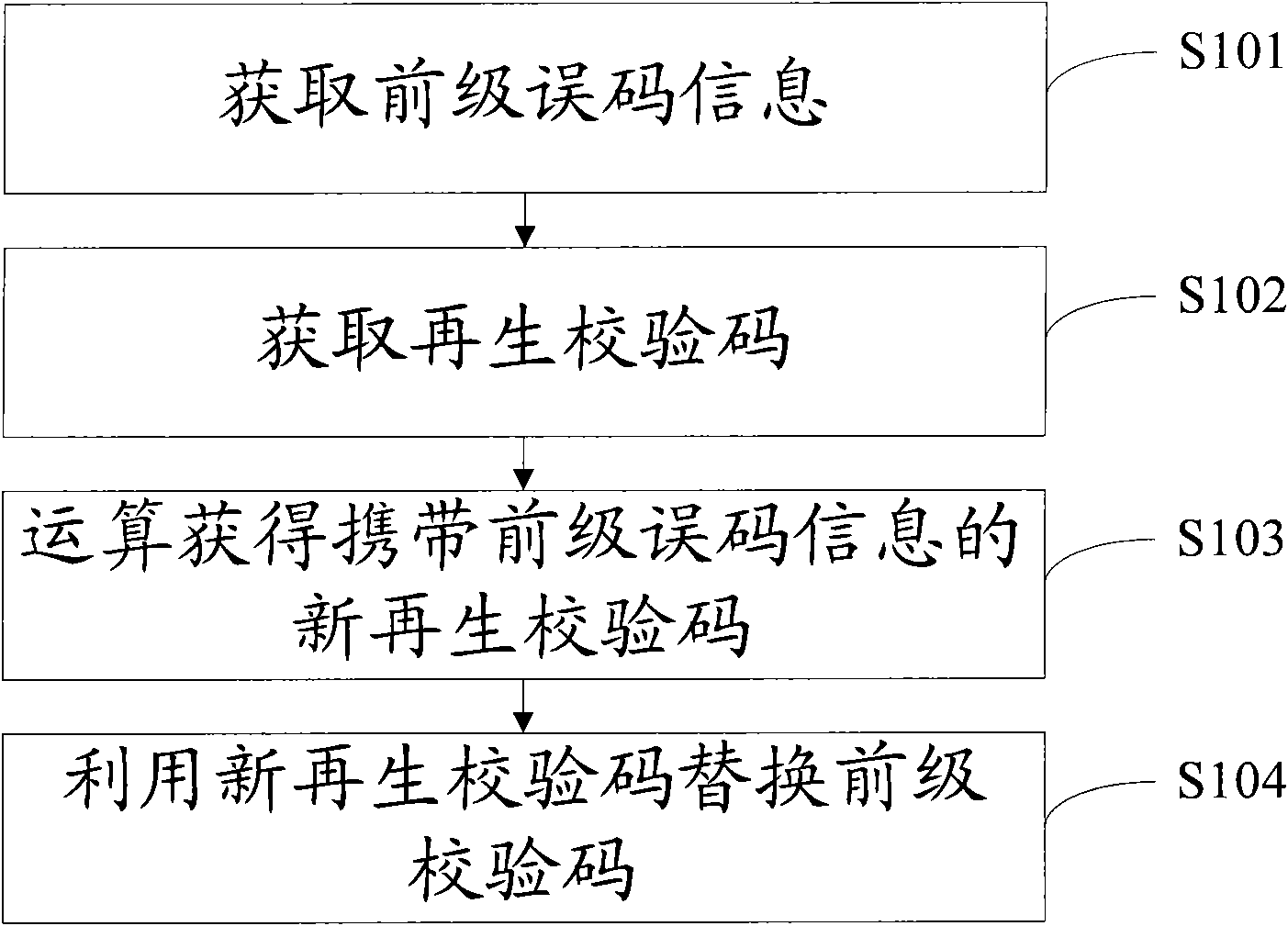

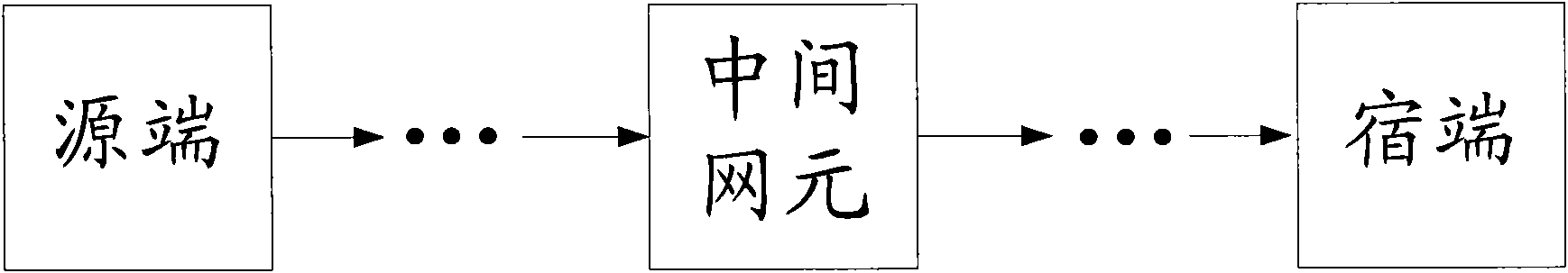

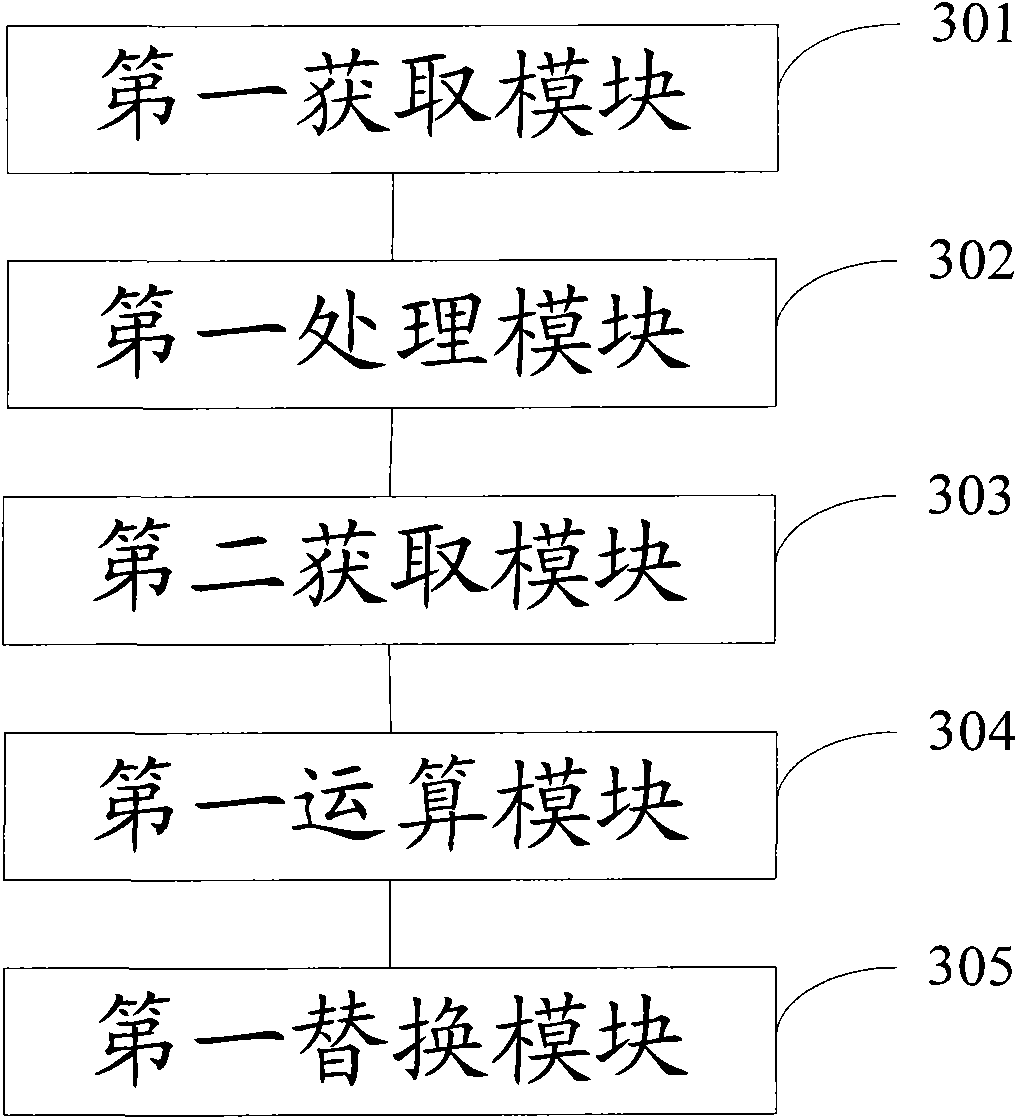

Method and device for correcting data

The invention discloses a method for correcting data, which comprises the following steps of: verifying a preceding stage data unit by utilizing a pre-stage check code of the preceding stage data unit to acquire pre-stage error code information; processing the part, except for the pre-stage check code, of the preceding stage data unit to generate a new data unit; performing verifying operation on the new data unit to acquire a regenerated check code; acquiring a new regenerated check code according to the exclusive OR operation of the pre-stage error code information and the regenerated check code; and substituting the new regenerated check code for the pre-stage check code in the new data unit to generate the corrected data unit. The invention also discloses a device for correcting the data. Due to the technical scheme of the embodiment of the invention, the pre-stage error code information is directly transferred and serial port expenditure or other gateway channel mode does not need to be adopted, the error code information can be transferred correctly and the waste of bandwidth resources is avoided.

Owner:HUAWEI TECH CO LTD

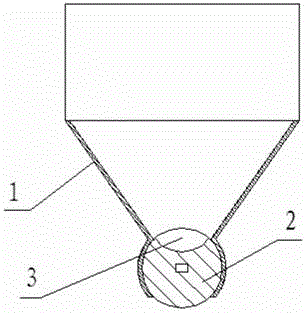

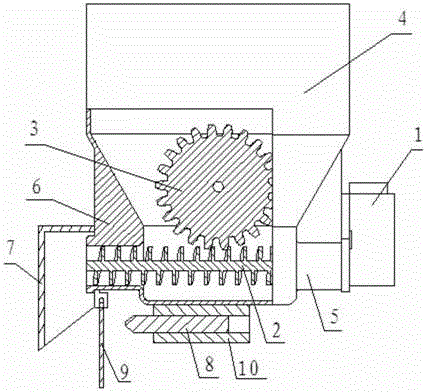

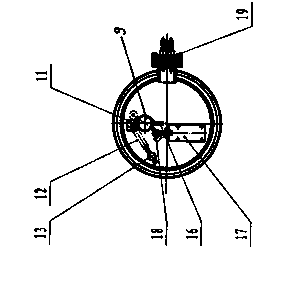

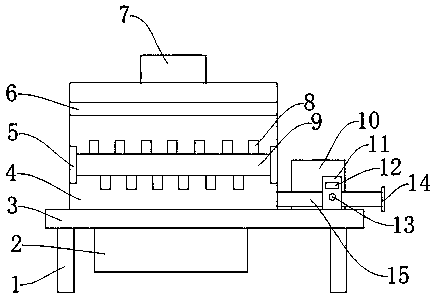

Automatic throwing device for solid powder materials

InactiveCN104631055AEliminate rotational errorsAccurate deliveryOther washing machinesTextiles and paperMechanical engineeringEngineering

The invention provides an automatic throwing device for solid powder materials. The automatic throwing device comprises a material box, a stirring mechanism and a throwing mechanism. A cylinder serves as the throwing part of the material box, a rotating shaft is installed inside the cylinder through a bearing, can rotate inside the cylinder and is connected with a driving device, and the stirring mechanism is installed inside the part, above the cylinder, of the material box and obtains driving force through engagement between a second gear installed on the stirring mechanism and a first gear installed on the rotating shaft. The driving device drives the rotating shaft to rotate several times and then rotates the same times in the reverse direction, and the action is repeated. The stirring mechanism is installed inside the material box to smash caked detergent powder, and it is prevented that due to caking of the detergent powder, the throwing amount is inaccurate. Because the driving device drives the rotating shaft to rotate several times for throwing in one direction and then rotates the same times for throwing in the reverse direction, rotating errors caused by rotating of the driving device can be eliminated, and accuracy of the throwing amount is guaranteed.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

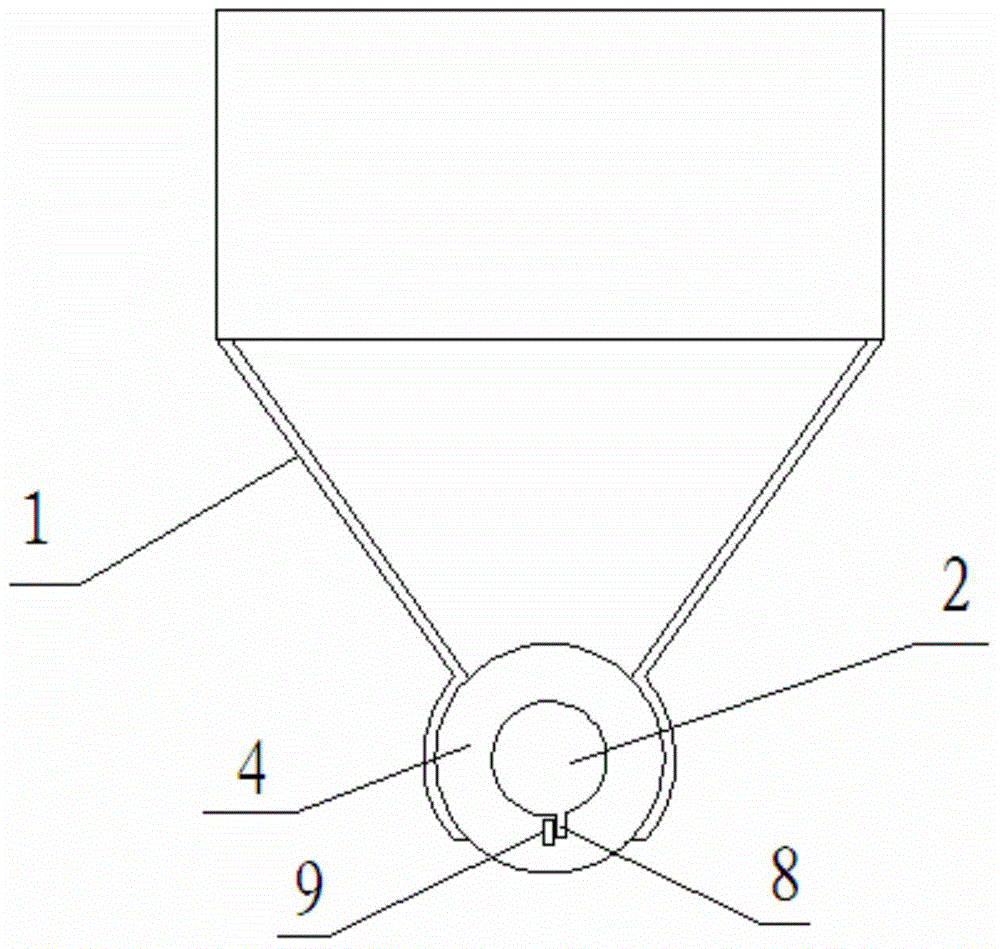

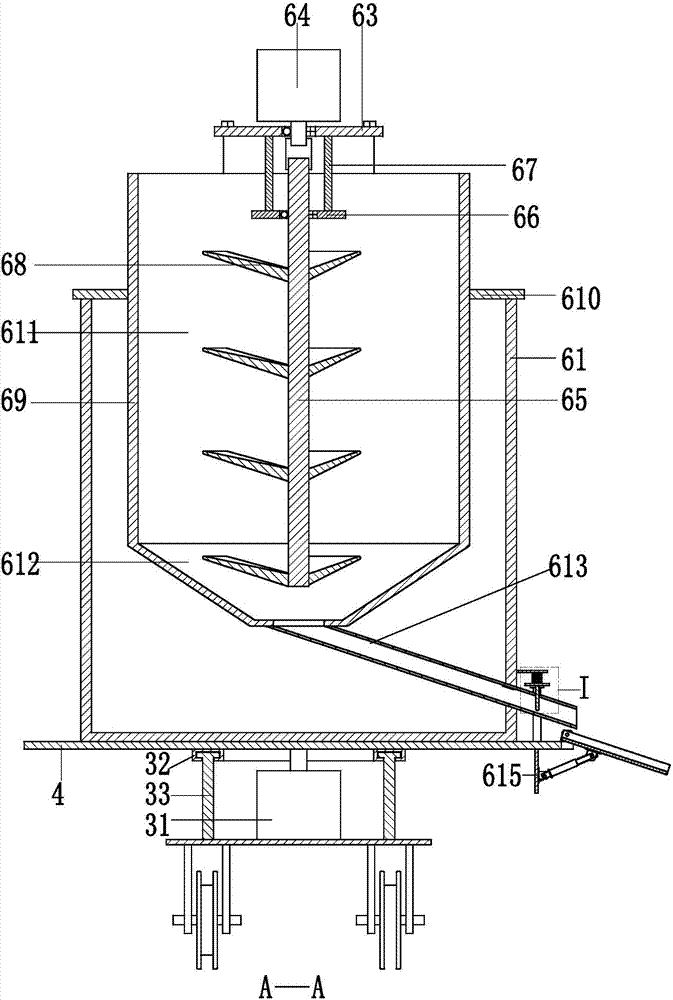

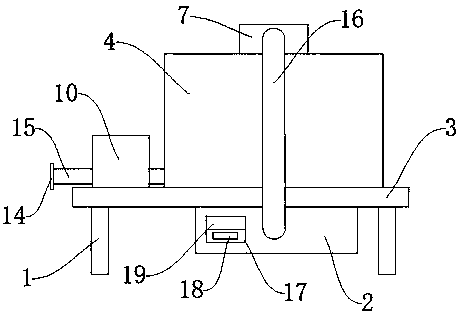

Flocculant dispenser of washing machine

ActiveCN104652097AEasy to moveAvoid cakingOther washing machinesTextiles and paperMotor driveEngineering

The invention provides a flocculant dispenser of a washing machine. The flocculant dispenser of the washing machine comprises a material box, a flocculant conveying device and prestorage box, wherein the flocculant conveying device comprises a screw barrel, a conveying screw, a stirring gear and a motor; the lower end of the material box is communicated with the screw barrel; the conveying screw is arranged inside the screw barrel, one end of the conveying screw is connected with a motor, and the port of screw barrel, which corresponds to the other end of the conveying screw, is communicated with the prestorage box; the lower end of the prestorage box is provided with an openable blanking port; the stirring gear is arranged inside the material box and engaged with the conveying screw. According to the flocculant dispenser of the washing machine, the motor drives the conveying screw to rotate, and the conveying screw drives the stirring gear to rotate and further to stir flocculant; after the flocculant falls into the screw barrel from the material box, the conveying screw conveys the flocculant out and stores the flocculant inside the prestorage box; when the flocculant inside the prestorage box meets dispensing demands, the bottom end of the prestorage box can be opened to complete dispensing in one step. The flocculant dispenser of the washing machine can achieve automatic and quantitative dispensing of the flocculant, shorten the dispensing time and reduce moisture absorption of the flocculant.

Owner:HAIER GROUP TECHN R&D CENT +1

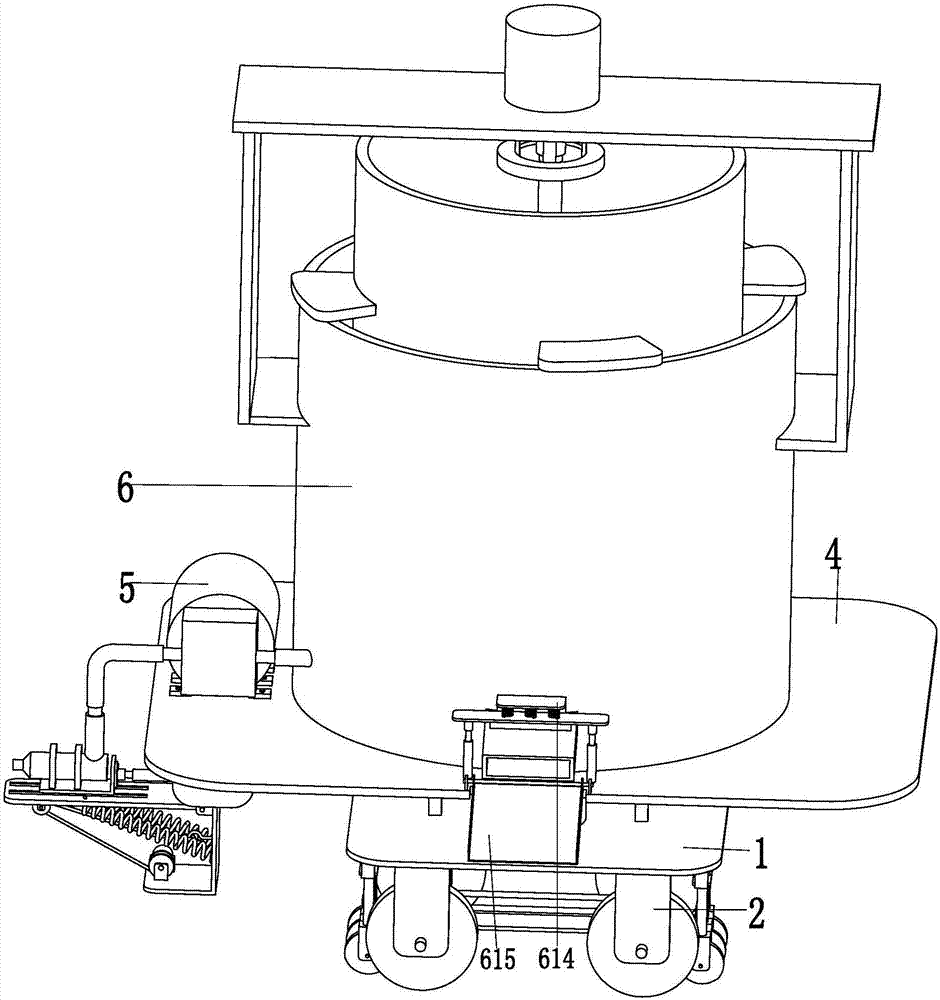

Live pig breeding feeder special flushing feeding machine

InactiveCN107135972APlay a supporting rolePlay an auxiliary roleAnimal feeding devicesHollow article cleaningPig breedingEngineering

The invention relates to a special washing feeder for pig breeding troughs. A bottom plate is provided with a walking wheel at the lower end of the bottom plate, a rotating device is mounted on the upper end of the bottom plate, a supporting plate is mounted on the upper end of the rotating device, and a flushing device is mounted on the front end of the supporting plate. A stirring and feeding device is arranged in the middle of the upper end of the feeder, and the rotating device, the flushing device and the stirring and feeding device cooperate with each other to complete the process of automatic flushing and quantitative feeding of the pig trough. The present invention can solve the need to manually feed the live pigs at regular intervals in the existing live pig breeding process, to manually rinse the live pig trough before feeding the live pigs, to manually re-stir the food materials before feeding the live pigs, and to manually control the use of tools. The food is put into pig troughs of different sizes, and the troughs are manually washed, which has problems such as poor stability, low accuracy, high labor intensity, and low work efficiency. The functions of automatic flushing and quantitative feeding of pig troughs can be realized.

Owner:安庆米锐智能科技有限公司

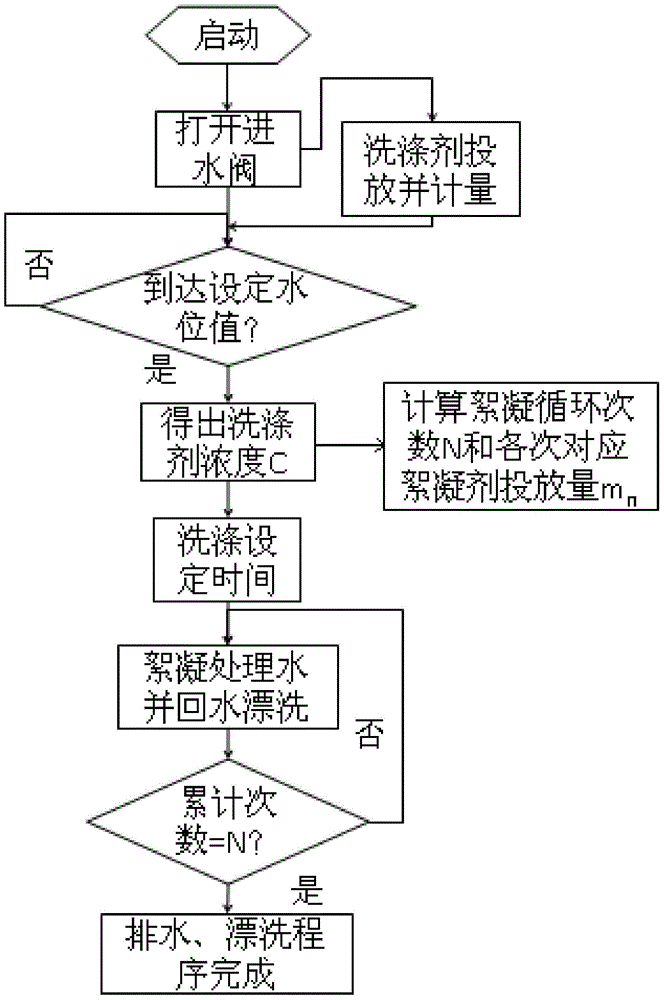

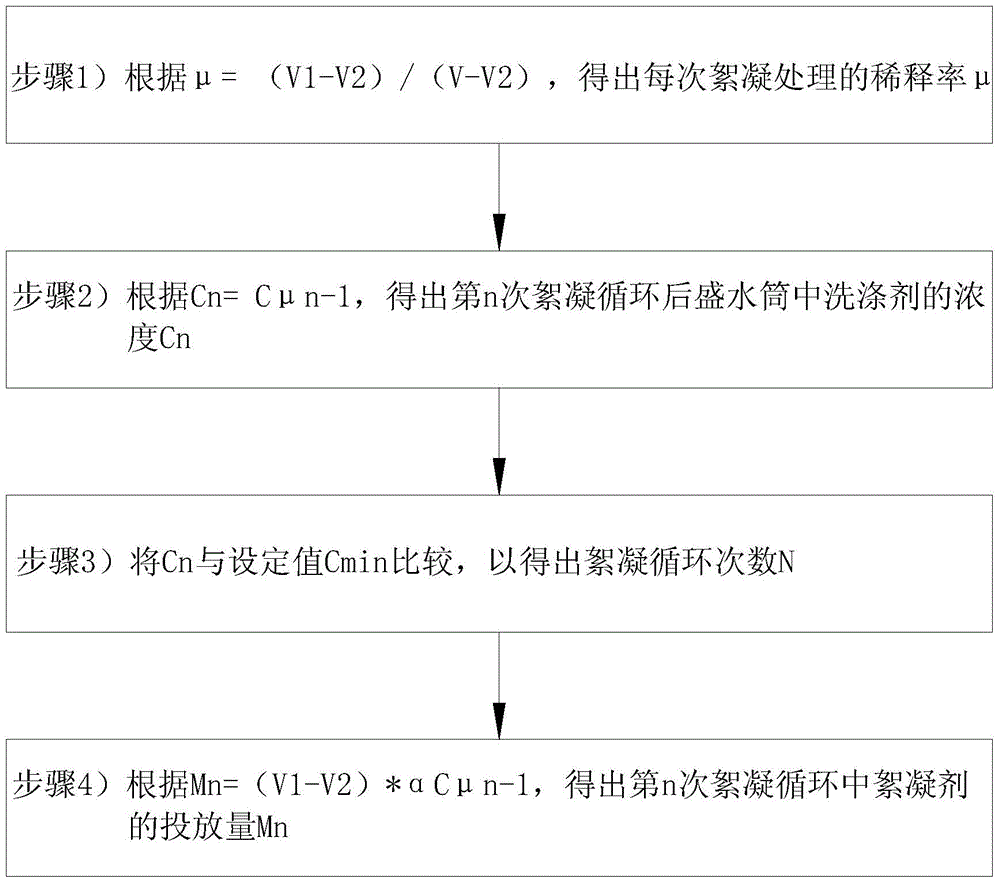

Control method of flocculation washing machine and washing machine

ActiveCN106283488AAchieve removalAccurate deliveryWater treatment parameter controlOther washing machinesEngineeringCycle time

The invention discloses a control method of a flocculation washing machine. The control method includes the steps that the washing water amount V and the washing-agent putting amount m in the washing procedure are obtained and detected respectively to obtain the washing-agent concentration C which is the quotient of m and V; according to the washing-agent concentration C, the number N of flocculation cycle times of washing water and the flocculating-agent putting amount Mn corresponding to all flocculation cycles are determined. In the control method, the number N of the flocculation cycle times and the flocculating-agent putting amount Mn corresponding to all the flocculation cycles can be accurately obtained only through the parameter of the washing-agent concentration in the washing procedure, and accurate controlling for the washing-machine flocculation treating process is achieved; meanwhile, flocculation treatment and the rinsing procedure of the washing machine are synchronously carried out, and when the washing machine is in the ending node, the concentration of a washing agent in an outer barrel is lower than a preset value accordingly to achieve the aim that the residual washing agent on cloth is removed. The invention also discloses the washing machine in which the control method is used.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

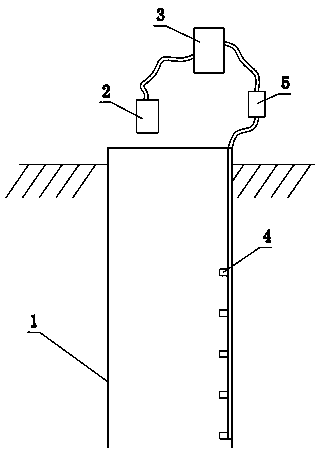

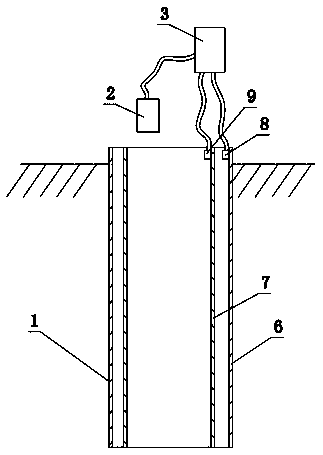

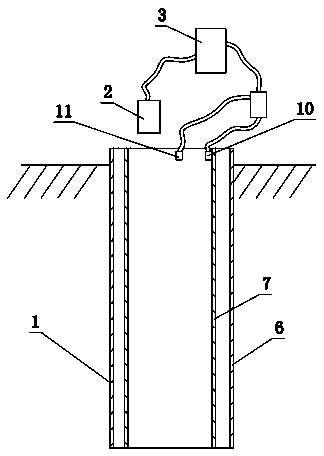

Automatic throwing system for foam scrubbing agent used in foam scrubbing gas production of gas reservoir with water

InactiveCN105604531AAutomatically judge the delivery timeAccurate deliveryFluid removalElectricityProcess engineering

The invention relates to dedicated equipment of foam scrubbing gas production, in particular to an automatic throwing system for a foam scrubbing agent used in foam scrubbing gas production of a gas reservoir with water. The automatic throwing system comprises a foam scrubbing agent throwing device arranged above a well opening of the gas reservoir with the water, wherein the foam scrubbing agent throwing device is electrically connected with a control cabinet with a PLC control strip through a cable, the control cabinet with the PLC control strip is arranged in an operation room, and a motor of the foam scrubbing agent throwing device is controlled by the control cabinet with the PLC control strip to be started up and shut down. A detecting device is fixed to the inner wall of the gas reservoir with the water, and the detecting device is electrically connected with the control cabinet arranged in the operation room and provided with the PLC control strip through a cable. By means of the structure, the automatic throwing system has the advantages of automatically throwing the foam scrubbing agent, accurately throwing the foam scrubbing agent in real time and improving the throwing accuracy.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

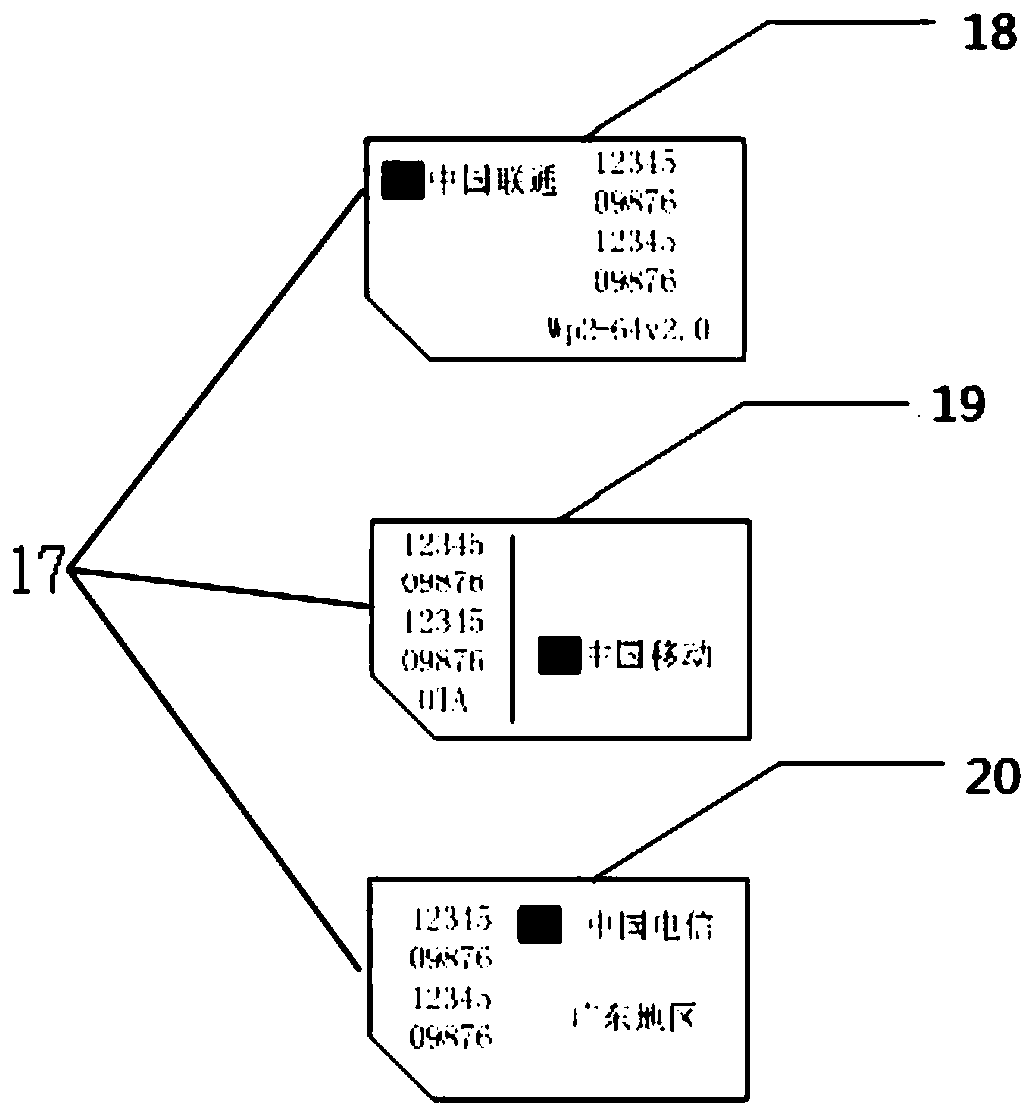

SIM card sorting system

The invention discloses an SIM card sorting system which comprises a shell. A recognition device and a taking and conveying device are arranged in the shell. The recognition device comprises a camerashooting mounting rack arranged at the top of the shell, and the camera shooting mounting rack is provided with a camera through a swivel joint. The taking and conveying device comprises a conveying component, an SIM card box, a non-defective product collecting box and a faulty card collecting box, and the conveying component comprises two conveying rotation shafts and a conveying belt wound between the two conveying rotation shafts. A plurality of card boards and ejectors are arranged on the upper surface of the conveying belt, and the ejectors is one-one corresponding to the card boards andare arranged on the front sides of the card boards. The accurate taking and conveying of SIM cards is realized.

Owner:GUANGDONG POWER GRID CO LTD +1

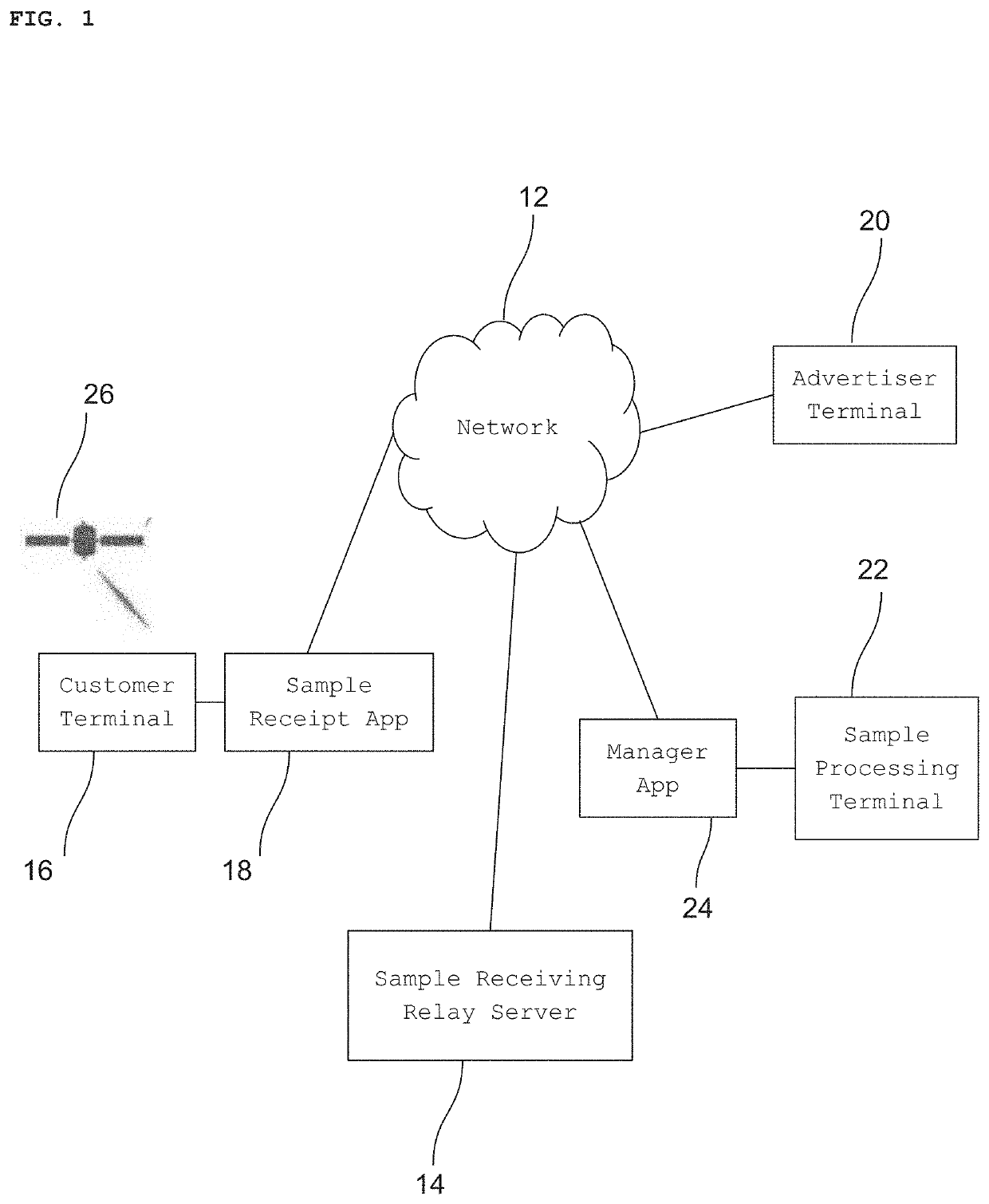

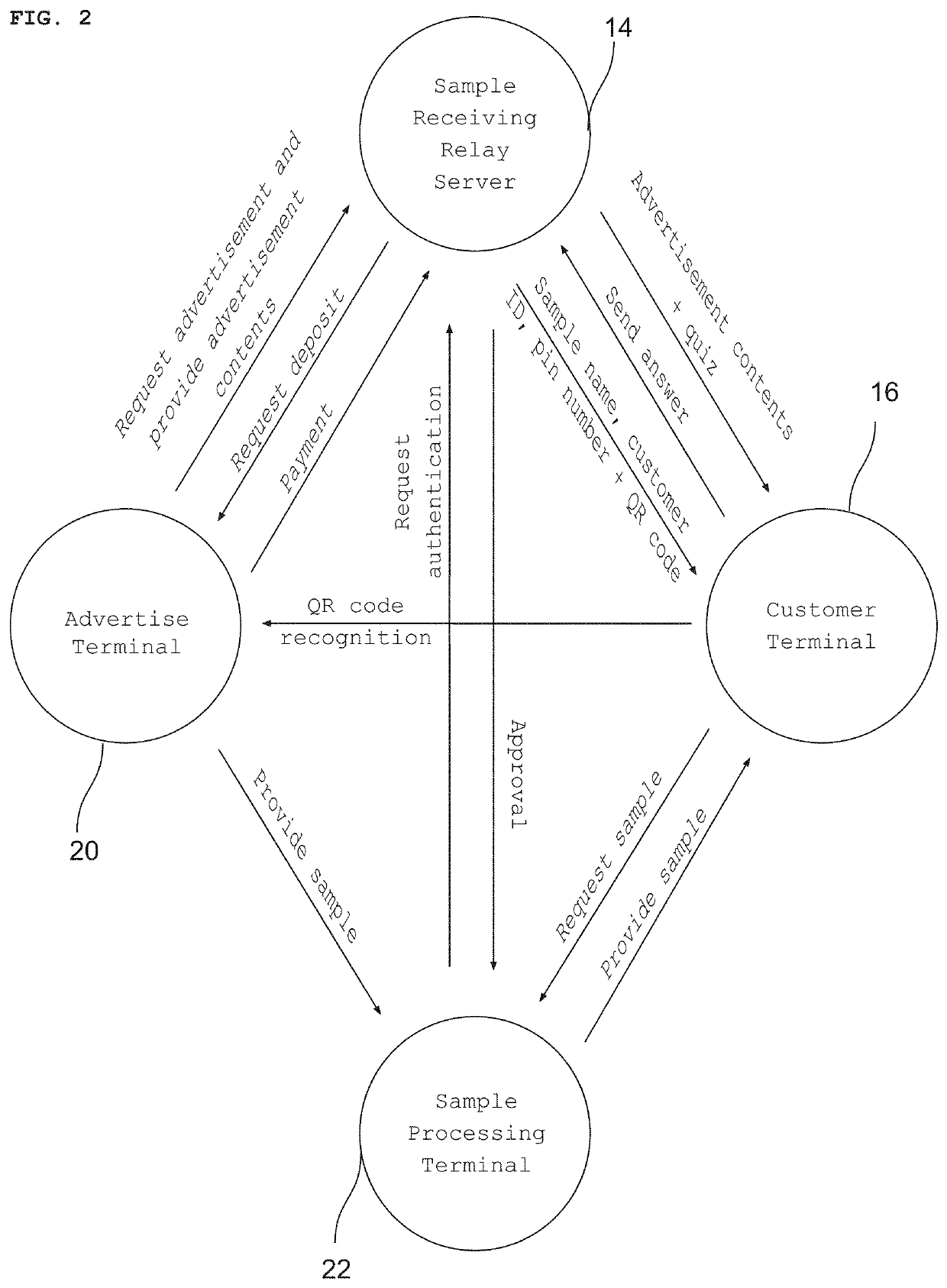

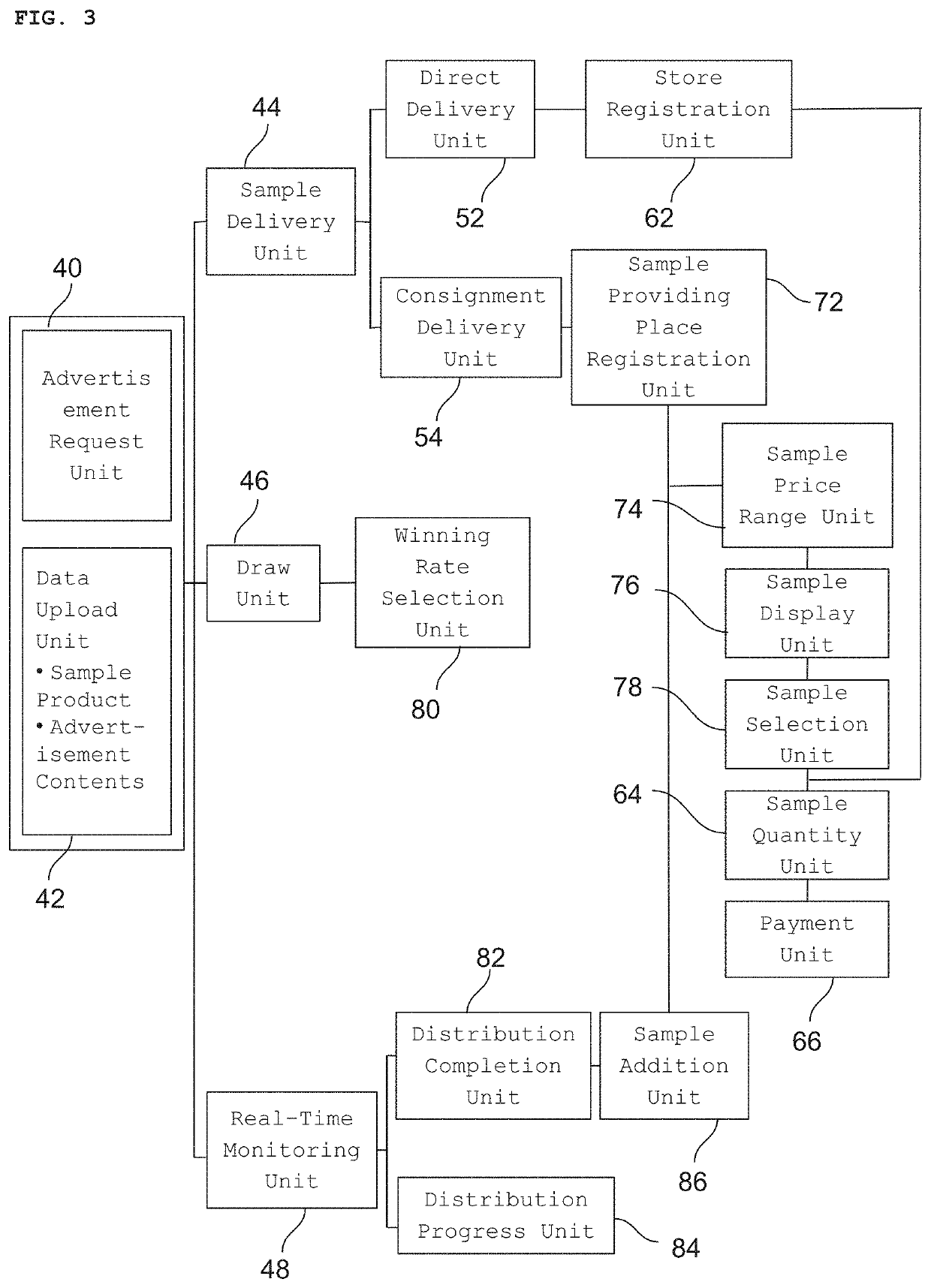

System and method for receiving promotional sample product

ActiveUS20200320581A1Accurate deliveryReduce expense and timeAdvertisementsRecord carriers used with machinesTrunkingSample handling

A system and method for receiving a promotional sample product, which can enable an advertiser to check whether a sample product, provided by the advertiser, is accurately delivered to a customer, thereby securing the reliability of means for seeking exposure advertisement by providing samples, and maximizing the promotion effects. A system for receiving a promotional sample product includes: a sample receiving relay server; an advertiser terminal; a customer terminal; and a sample processing terminal. The sample receipt app generates only one authentication key per customer ID in order to prevent duplicated samples from being provided for one customer ID.

Owner:LEE SANGHYUB

Apparatus for feeding liquid detergent

InactiveCN1607289AAccurate deliveryShorter run timeOther washing machinesTextiles and paperEngineeringGuide tube

A quick and precision liquid detergent put device consists of electromagnetic water feeding valve, liquid detergent trough with air taking valve on upper part and detergent outlet , electromagnetic four-way switching valve with measuring chamber, relative pipe line, valve unit with conduit A, B, and C, valve seat A, B, and C, liquid inlet open, valve cover, bi-directional switching valve A, unidirectional open / close valve B, C. said invention is adapted for electric washing machine and dishwasher etc using liquid detergent and water.

Owner:HANGZHOU KAMBAYASHI ELECTRONICS

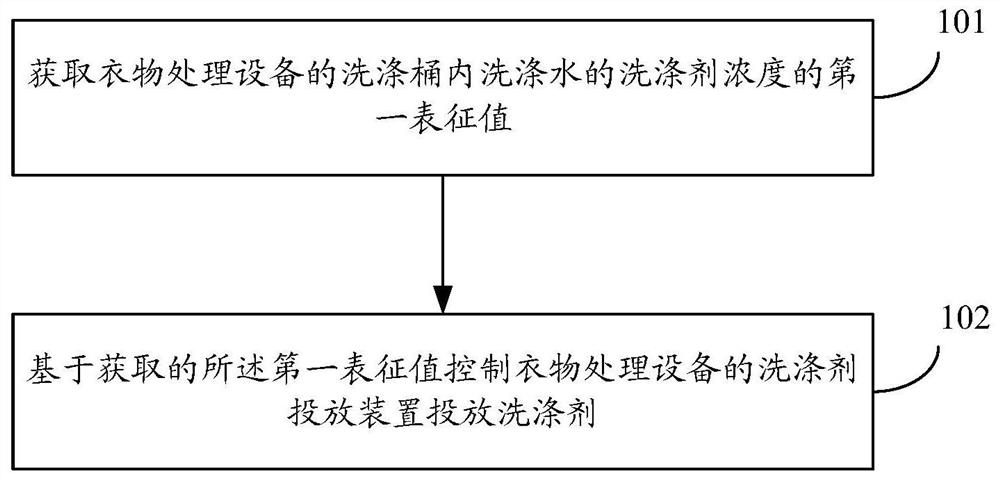

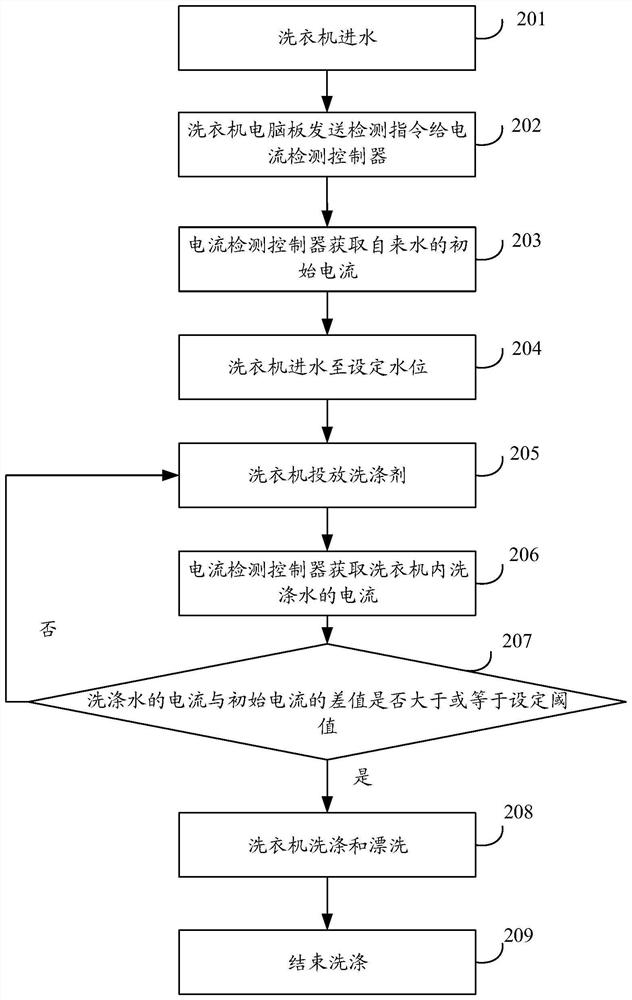

Clothes treatment equipment, control method and device thereof and storage medium

PendingCN114075744ASimple control strategyAccurate deliveryControl devices for washing apparatusTextiles and paperProcess engineeringManufacturing engineering

The invention discloses clothes treatment equipment, a control method and device thereof and a storage medium. The control method comprises the steps: obtaining a first characterization value of the detergent concentration of washing water in a washing barrel of the clothes processing equipment; and controlling a detergent putting device of the clothes processing equipment to put a detergent based on the acquired first characterization value. According to the embodiment of the invention, the first characterization value of the detergent concentration in the washing water can be directly obtained, which is different from the existing control thought of identifying the detergent concentration of different types of detergents, and the putting amount of the detergent does not need to be pre-determined based on auxiliary factors such as the clothes weight and the washing water level; whether the detergent putting device continues to put the detergent or not is controlled based on the first characterization value of the detergent concentration of the washing water in the detergent putting process, the control strategy is simple, the putting amount of the detergent is more accurate, and the washing effect is improved.

Owner:HEFEI MIDEA WASHING MACHINE

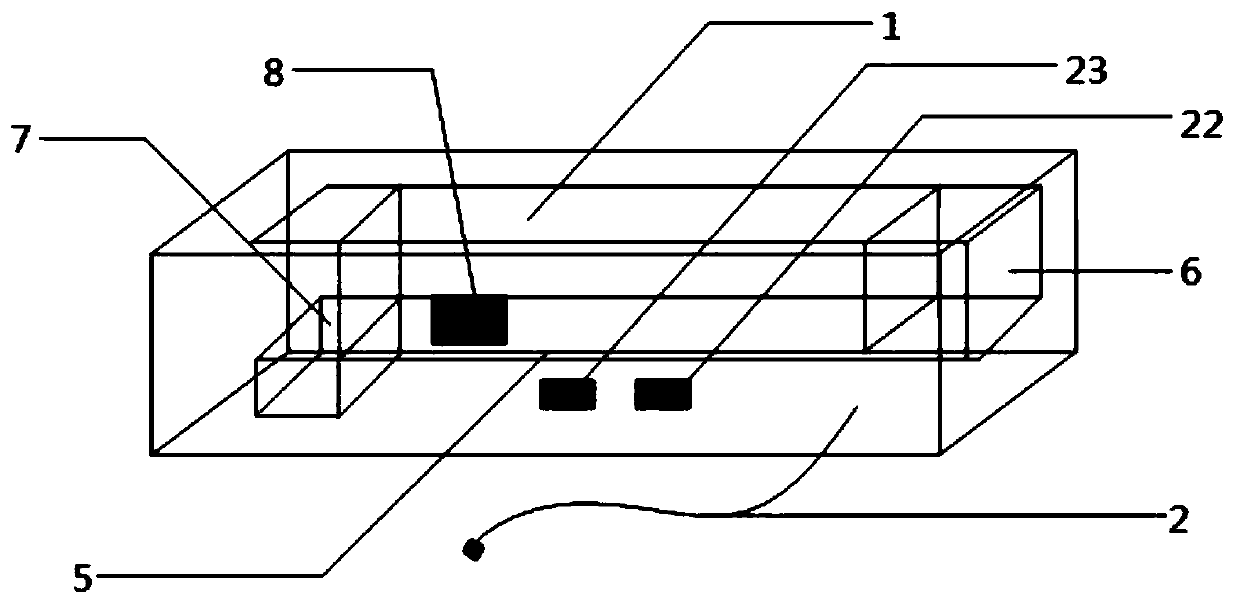

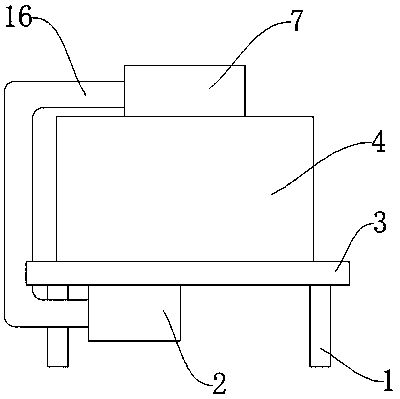

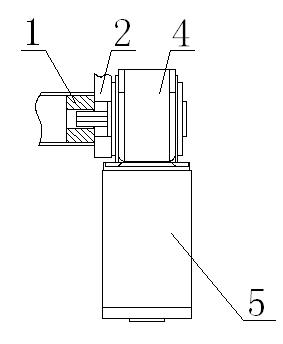

Charging basket on-line detecting mechanism of multi-chamber vacuum furnace

InactiveCN103644746AAccurate deliveryImprove work efficiencyCharge supportsVacuum furnaceEngineering

The invention discloses a charging basket on-line detecting mechanism of a multi-chamber vacuum furnace. The technical problem of accurate charging basket position detecting in a heating chamber of an automatic continuous vacuum furnace is solved. The charging basket on-line detecting mechanism comprises a vacuum heating chamber (1), a vacuum heating chamber roller transmission mechanism (3) and a charging basket (4) are arranged inside the vacuum heating chamber (1), a sealed detecting rotating shaft bearing base (5) and a brass shaft sleeve (7) are arranged on the side wall of the vacuum heating furnace, a charging basket position detecting rotating shaft (9) is movably arranged inside the brass shaft sleeve (7), the inner side end of the charging basket position detecting rotating shaft penetrates through the side wall of the vacuum heating chamber (1) and a vacuum heating chamber furnace container (2) in sequence and then is connected with a T-shaped detecting rod (10), the T-shaped detecting rod is arranged above the vacuum heating chamber roller transmission mechanism (3) , the outer side end of the detecting rotating shaft bearing base (5) is connected with a sealed detecting barrel body (14), and a position switch (17) is arranged inside the sealed detecting barrel body. The working efficiency of heating pipe vacuum annealing is improved, and the vacuum annealing quality of a heating pipe is guaranteed.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 2 RES INST

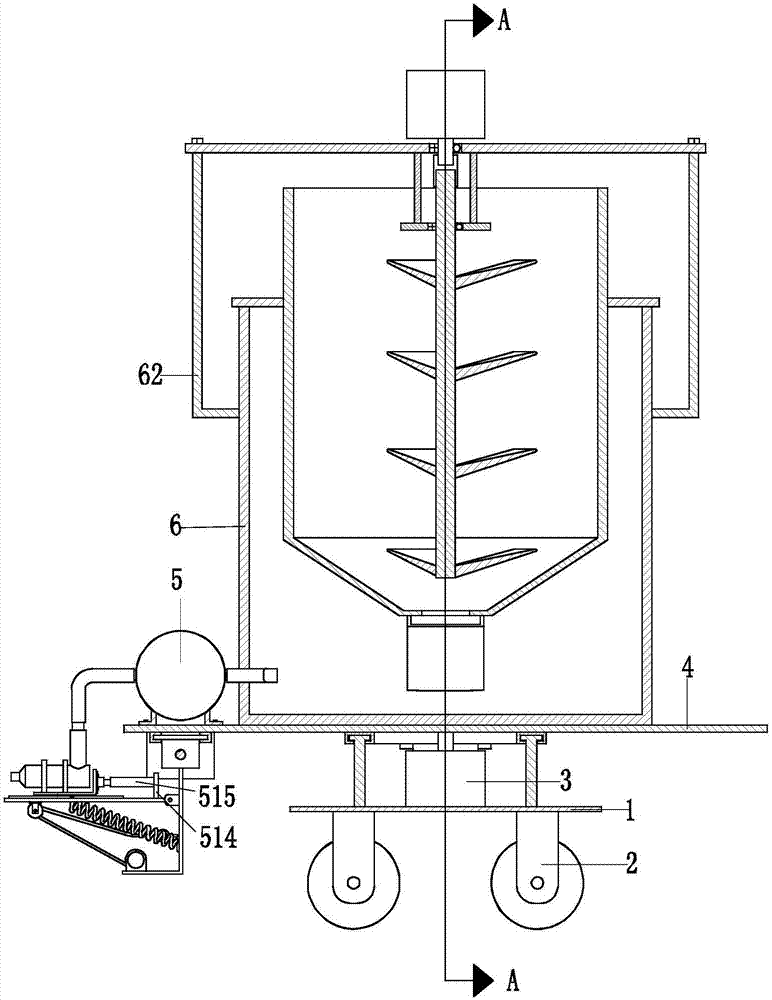

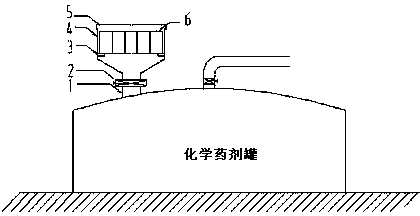

Quantitative drug adding device used in sewage treatment

InactiveCN108211870AAccurate deliveryEasy to handleTransportation and packagingRotary stirring mixersControlled drugsMedicine

The invention discloses a quantitative drug adding device used in sewage treatment. The quantitative drug adding device used in sewage treatment comprises a supporting seat, a sieve, a transfer pump,and a material blending button; the lower part of the supporting seat is provided with supports; the lower surface of the supporting seat is provided with a drug box; the upper surface of the supporting seat is provided with a stirring box; bearings are arranged on the internal wall of the stirring box; a stirring rod is arranged on the bearings; stirring blades are arranged on the stirring rod; the sieve is arranged above the stirring rod; the upper surface of the stirring box is provided with a feed inlet box; one side of the stirring box is provided with a discharging pipe; and the transferpump is arranged on the discharging pipe. The beneficial effects are that: the quantitative drug adding device is capable of realizing regulation of drugs using the material blending button, stirringdrugs fully using the stirring rod and the stirring blades, controlling drug flow amount using a counter, setting the working time of the transfer pump using a timer, and increasing drug adding accuracy. The quantitative drug adding device is simple in structure, accurate in drug adding amount, and higher in sewage treatment effect.

Owner:长兴长龙环保科技有限公司

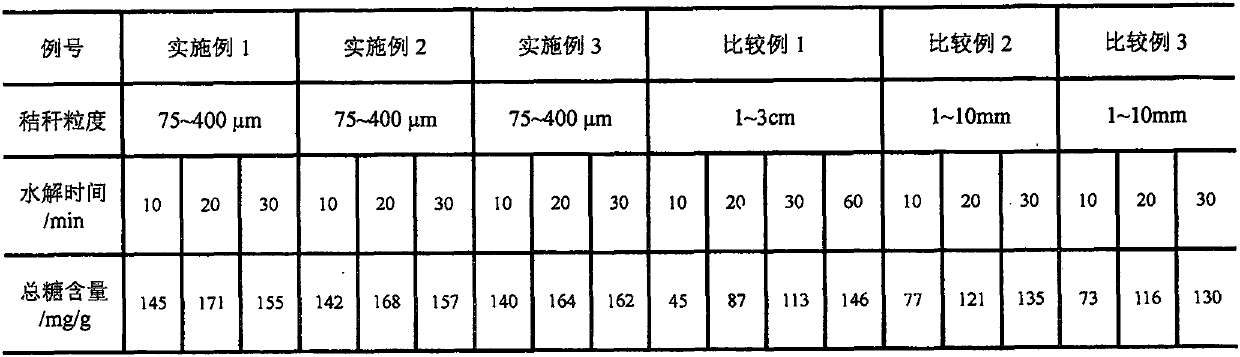

Preparation method and device of sulfonation-hydroxymethylation modified straw-based water reducing agent

ActiveCN111592662ATake advantage ofImprove drying efficiencyPulp and paper industryHydrolytic Process

The invention relates to a preparation method and device of a sulfonation-hydroxymethylation modified straw-based water reducing agent, relates to the method and the equipment for preparing the straw-based biomass water reducing agent through modification, and aims at preparing the biomass water reducing agent through pretreatment and sulfonation-hydroxymethylation modification of a straw raw material. The preparation method comprises two parts of straw raw material pretreatment and sulfonation-hydroxymethylation modification, wherein the straw pretreatment comprises the processes of primary crushing, cleaning, drying, secondary crushing, micro-crushing and hydrolysis; the sulfonation-hydroxymethylation modification is composed of material oxidation chain scission, sulfonation modification, alkalization and hydroxymethylation modification. The used equipment comprises a primary crushing device, a cleaning device, a drying device, a cyclone separator, a secondary crushing device, a micro-crushing device, an aggregate bin weighing device, a screw extrusion hydrolyzer, a batching storage tank, a screw extrusion modification reaction unit and a storage tank. The method is used for preparing the straw-based biomass water reducing agent.

Owner:TIANSHUI NORMAL UNIV

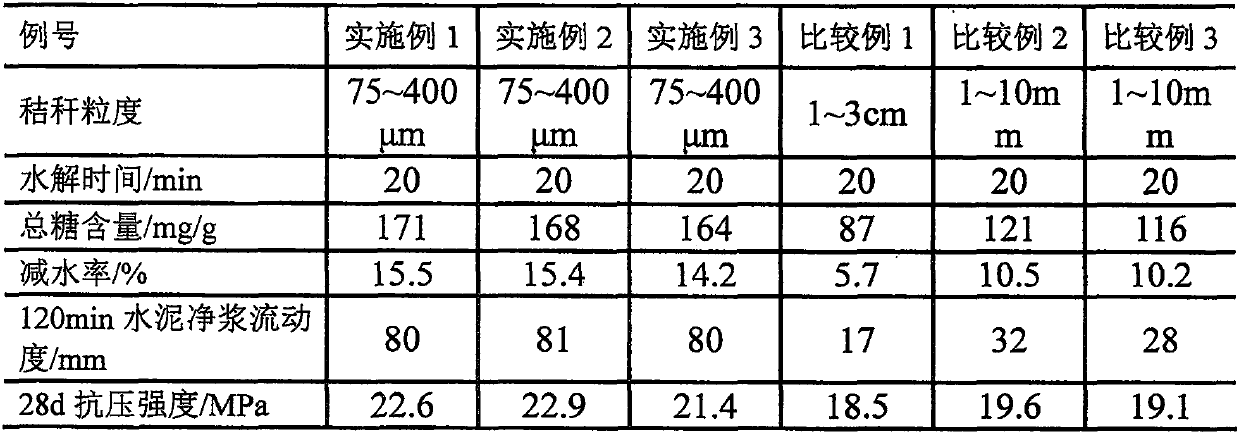

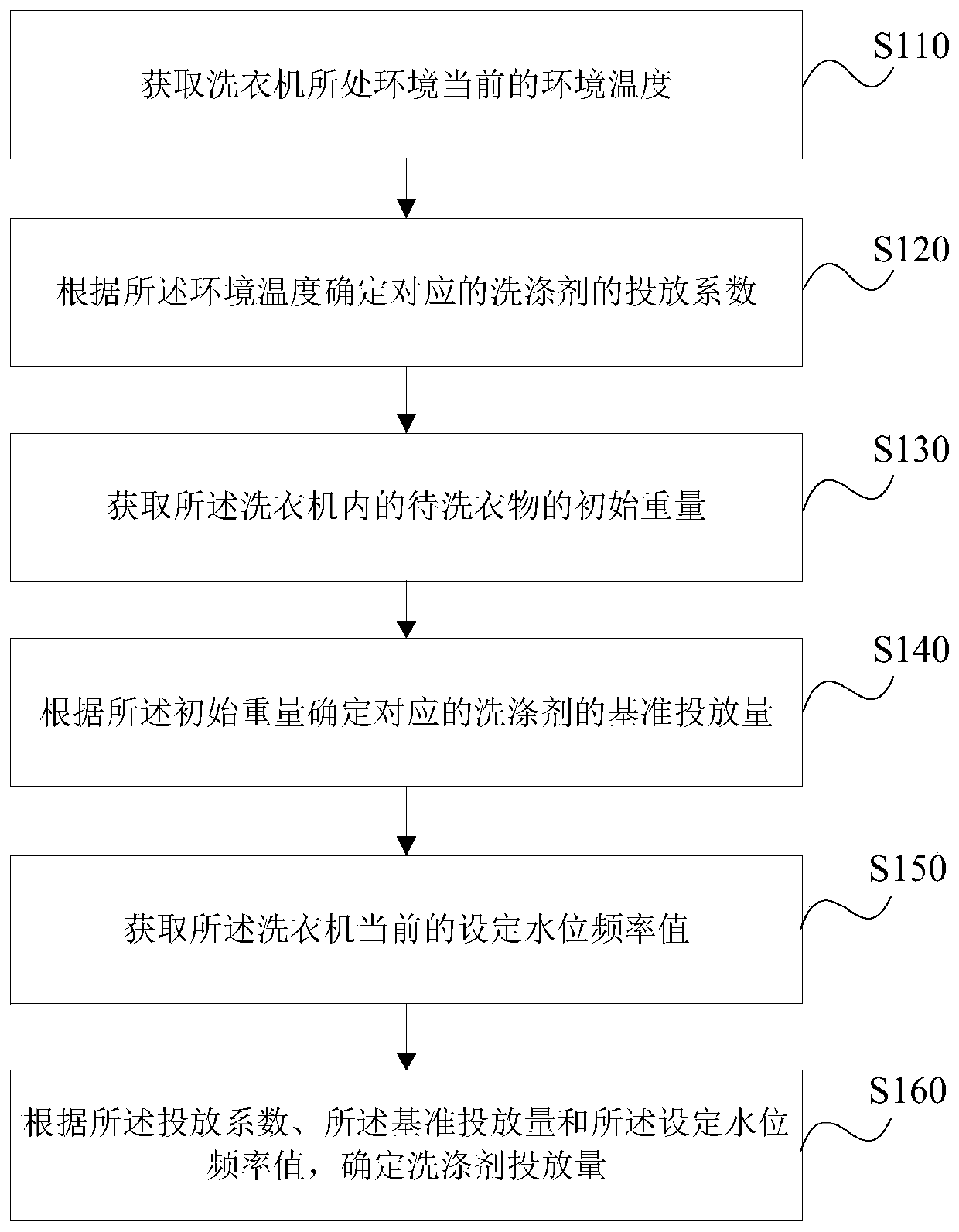

Determination method and device of detergent feeding amount, storage medium and washing machine

ActiveCN110067110AAccurate deliveryPrecise deliveryControl devices for washing apparatusTextiles and paperEngineeringWater level

The invention provides a determination method and a device of a detergent feeding amount, a storage medium and a washing machine. The method comprises the steps of obtaining a current ambient temperature of an environment in which the washing machine is located, determining a feeding coefficient of a detergent according to the ambient temperature, obtaining initial weight of clothing to be washedin the washing machine, determining a corresponding reference feeding amount of the detergent according to the initial weight, obtaining a current set water level frequency of the washing machine, anddetermining the detergent feeding amount according to the feeding coefficient, the reference feeding amount and the set water level frequency. Inaccuracy of the initial detergent feeding amount due to inaccurate weighing can be reduced, and the detergent feeding amount is preciser.

Owner:GREE ELECTRIC APPLIANCES INC

Multi-lattice agent storage hopper and quantitative throwing-in method

The invention discloses a multi-lattice agent storage hopper and a quantitative throwing-in method. A multi-lattice quantitative agent storage box is manufactured and arranged in a sealed barrel-shaped funnel; the upper portion of the barrel-shaped funnel is used for storing the multi-lattice quantitative agent storage box, and the lower funnel-shaped portion of the barrel-shaped funnel is used as a special pipeline for throwing in agents; a sealed space is formed between an upper sealing cover of the barrel-shaped funnel and a ball valve on the lower side of a funnel-shaped channel and used for secondary sealing protection of stored agents. A multi-lattice agent storage box body is then manufactured, and quantitative agents are stored in the multi-lattice agent storage box body; in site operation, the quantitative agents can be thrown into a chemical agent tank on site only by opening a lower sealing cover of a single-lattice storage box; the quantitative agents which need to be thrown in next time can be stored after the lower sealing cover is locked and the upper sealing cover is opened; the sealed state of the agents in the storage box can be ensured after the upper sealing cover is locked and sealed. According to the multi-lattice agent storage hopper and the quantitative throwing-in method, the agent storage effect is good, the agent throwing-in quantity is accurate, the agent throwing-in process is safe, the work efficiency is improved, and energy conservation and environment protection are guaranteed.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

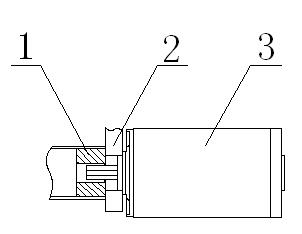

Collection motor for drawing machine

InactiveCN102001541ALow powerWith reverse self-locking functionMechanical energy handlingWebs handlingElectric machineSelf locking

The invention relates to the technical field of a motor for a drawing machine, in particular to a collection motor for a drawing machine. The collection motor comprises a collection rod and an installing plate, wherein the collection rod is connected with a worm gear speed reducer through the installing plate, and the worm gear speed reducer is connected with a servo motor. By adopting the servo motor with speed reduction, the invention lowers the power of the collection motor and the noise; according to the servo control, the invention enables the collection to be more accurate and the transmission to be more stable; and the worm gear has a reverse self-locking function, so that the drawn pattern is more accurate and can be controlled more easily.

Owner:CHANGZHOU SINAJET SCI & TECH

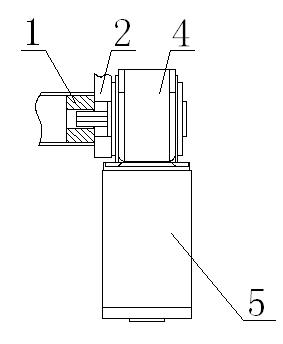

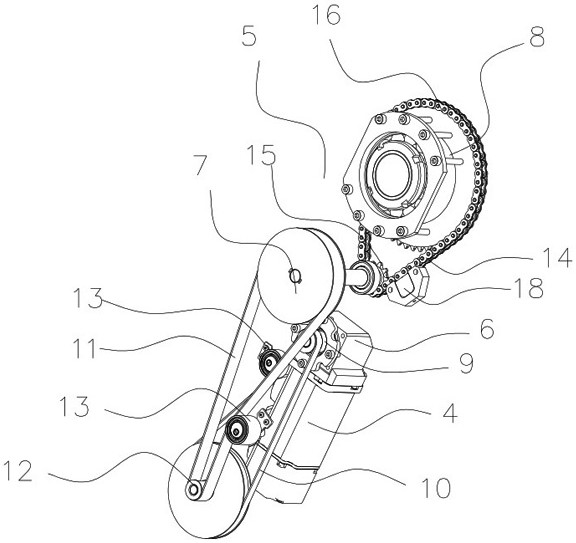

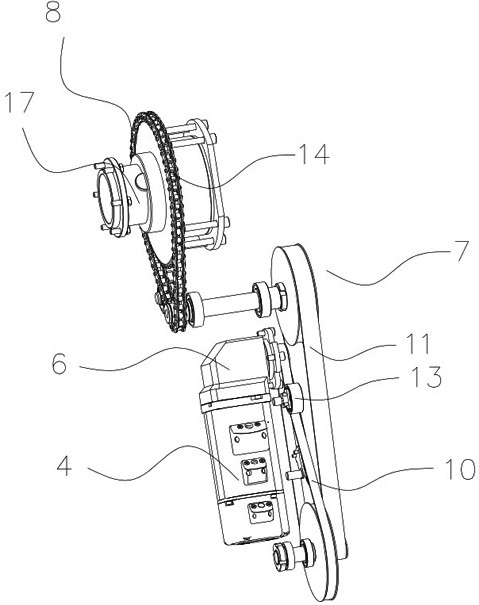

An elbow joint of a mechanical arm and its action method

ActiveCN108340401BEasy to operateAccurate deliveryProgramme-controlled manipulatorJointsElbow jointsEngineering

The invention discloses an elbow joint of a mechanical arm. The elbow joint comprises a big arm, a small arm, a driving assembly and a transmission assembly. The big arm is a support arm used for achieving movement of the elbow joint. An installing seat is arranged in the big arm. The small arm is an executive component connected with the big arm to achieve the movement of the elbow joint. The driving assembly is a driving component which is arranged in the installing seat and is used for achieving movement of the elbow joint. The transmission assembly is a transmission component which is arranged in the installing seat and transmits driving force of the driving assembly to the small arm. The transmission assembly comprises a right angle type planetary reducer, a belt transmission part anda chain transmission part which are in transmission connection sequentially. The chain transmission part is connected with the small arm and drives the small arm to move to achieve driving of the elbow joint. According to the elbow joint of the mechanical arm, through combined type transmission of the belt transmission part and the chain transmission part, the structure is more compact, the layout is more reasonable, free swinging of the elbow joint is achieved, manufacturing is convenient, and cost is low. A movement method is convenient to operate, transmission is precise, control is simpler and more convenient, the whole elbow joint is more compact, and swinging is more flexible.

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

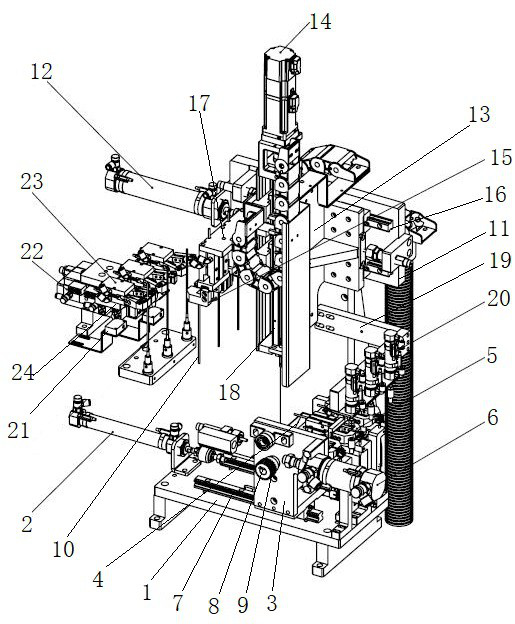

Single-hand clamp feeding mechanism

The invention discloses a single-hand clamp feeding mechanism. The mechanism comprises a single-hand clamp material distributing mechanism, a feeding mechanism and a righting mechanism, wherein the single-hand clamp material distributing mechanism comprises a material distributing base, a single-hand clamp material distributing translation air cylinder, a single-hand clamp material distributing translation frame, a rotating plate, a single-hand clamp material distributing and taking clamping jaw and a single-hand clamp material distributing rotating air cylinder, wherein the single-hand clampmaterial distributing translation air cylinder, the single-hand clamp material distributing translation frame, the rotating plate, the single-hand clamp material distributing and taking clamping jaw and the single-hand clamp material distributing rotating air cylinder are arranged on the material distributing base; the feeding mechanism comprises a feeding frame, a feeding translation air cylinder, a feeding translation base, a feeding servo lead screw motor and a feeding taking clamping jaw, and the righting mechanism comprises a righting support, a righting translation air cylinder and a righting clamping jaw air cylinder. The single-hand clamp feeding mechanism is simple in structure; PLC control is used, so that the accurate conveying of an extension pipe by all parts can be achieved;the feeding accuracy of the extension pipe is guaranteed, machining is rapid, feeding is stable, manpower resources are effectively saved, and the productivity is improved.

Owner:苏州凌稳智能装备有限公司

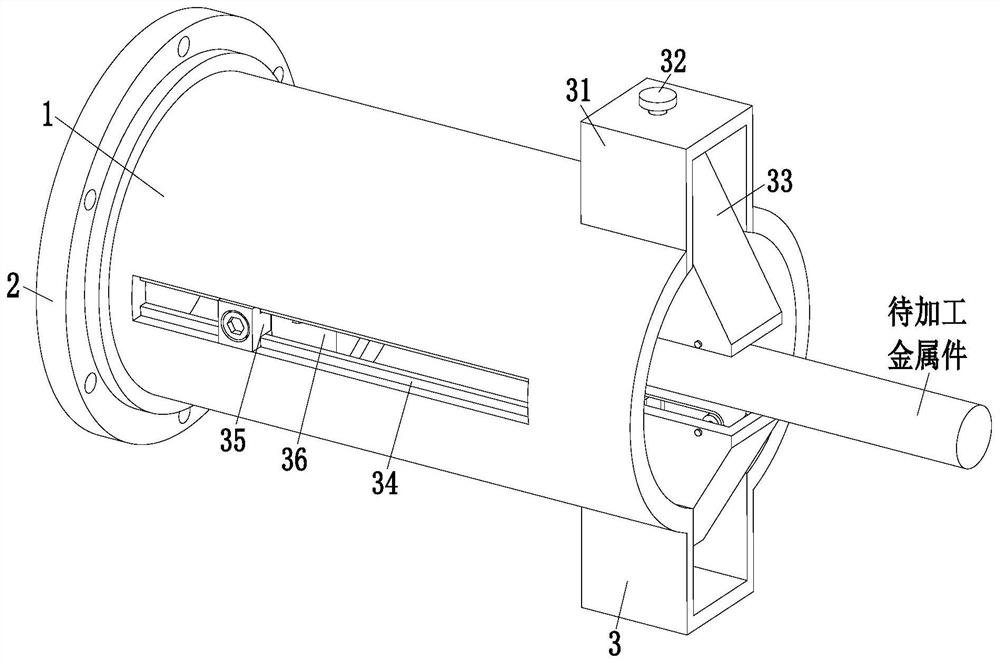

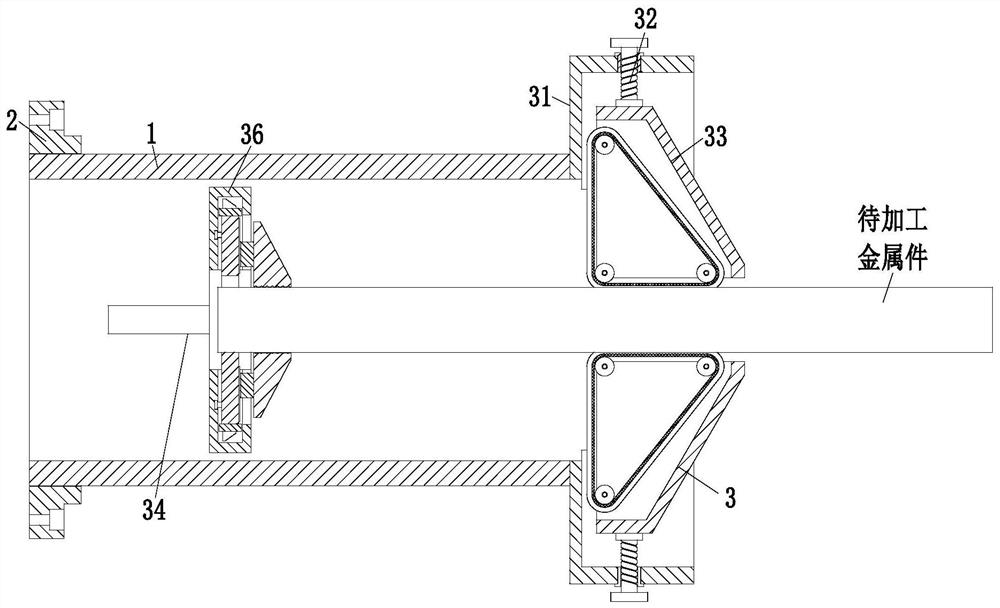

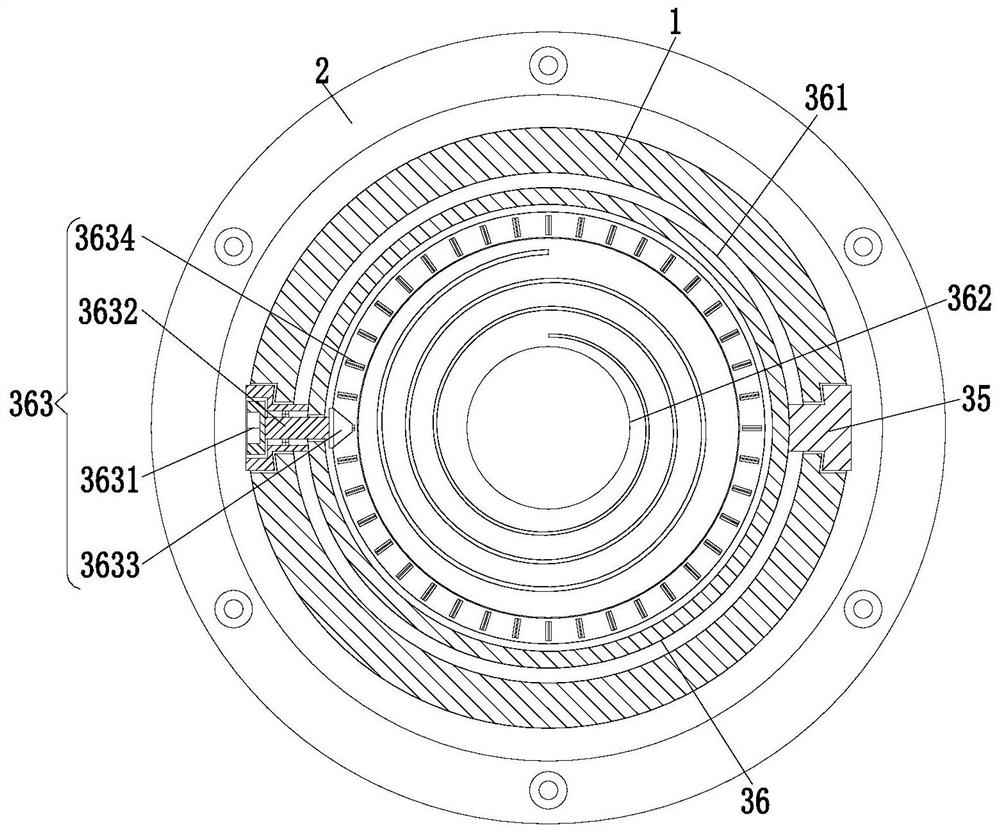

Clamp device of numerical control equipment

ActiveCN112935903AGood clamping effectAccurate deliveryMetal working apparatusProcessing accuracyStructural engineering

The invention relates to a clamp device of numerical control equipment. The device comprises a fixing sleeve, a connecting flange and a clamp device body, wherein the fixing sleeve is of a cylindrical hollow structure, the connecting flange is installed on the outer side of the left end of the fixing sleeve, installation holes are evenly formed in the connecting flange, and the clamp device body is installed on the right side of the fixing sleeve. The device can solve the problems that when existing numerical control equipment clamps a metal part, the clamping effect and positioning are not accurate, the metal part is prone to shaking, consequently, the machining precision of the metal part is low, and the follow-up use effect of the part is affected, and meanwhile when the existing numerical control equipment clamps the metal part, the metal parts cannot be accurately conveyed and usually need to be manually adjusted after numerical control equipment is stopped, so that the machining effect of the metal parts is poor, the efficiency is low, the production cost of enterprises is increased and the like are solved.

Owner:深圳市荣士海精密工业有限公司

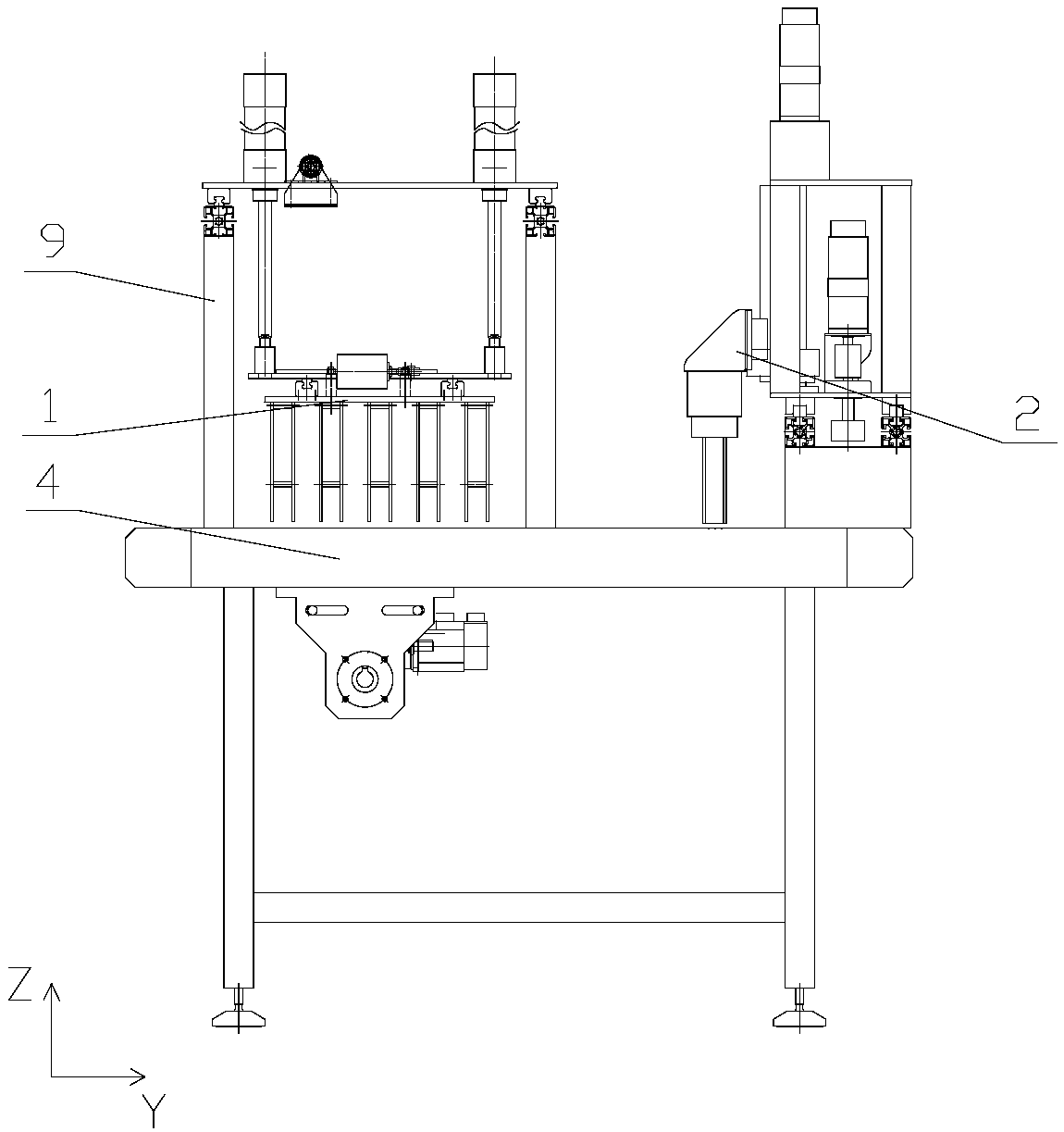

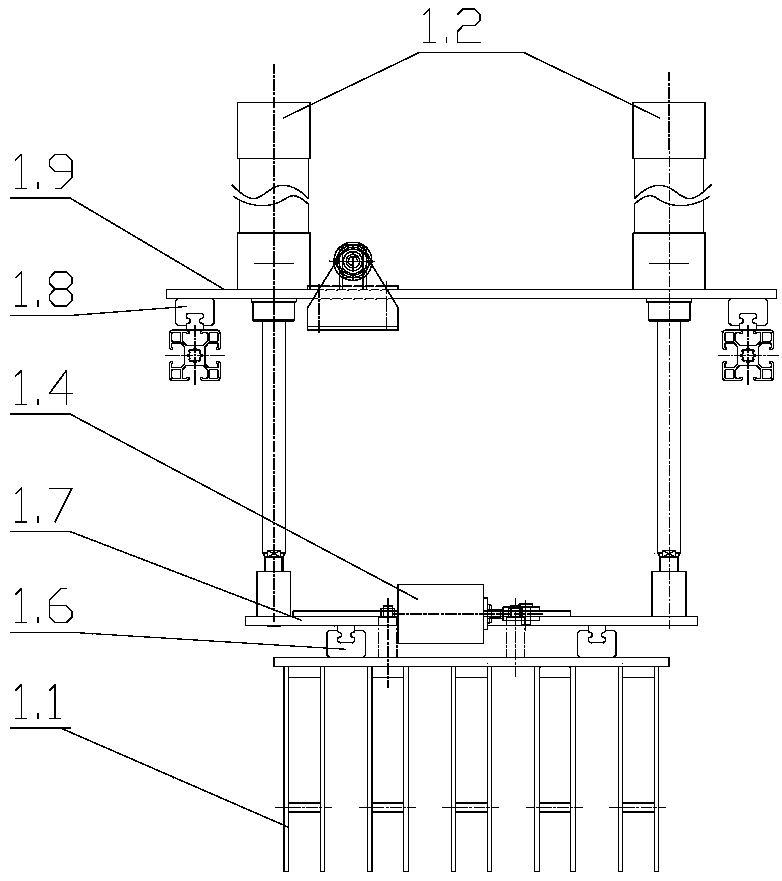

Automatic detection experimental equipment for current transformer

InactiveCN111366885AEasy to operateReliable test resultsElectrical testingControl theoryInstrument transformer

The invention belongs to the technical field of current transformer detection, and particularly relates to automatic detection experimental equipment for a current transformer. The equipment comprisesa frame, and a feeding mechanism, a grabbing mechanism, an experiment detection mechanism, a feeding conveying belt and a discharging conveying belt which are arranged on the frame. The feeding conveying belt and the discharging conveying belt are both arranged in the Y-axis direction. The experiment detection mechanism is arranged between the feeding conveying belt and the discharging conveyingbelt, and is used for detecting a current transformer. The feeding mechanism is arranged above the feeding conveying belt and is used for placing the current transformer on the feeding conveying belt.The grabbing mechanism is arranged at the end of the feeding conveying belt and the end of the discharging conveying belt and is used for conveying the current transformer between the feeding conveying belt and the experiment detection mechanism and between the experiment detection mechanism and the discharging conveying belt. Manual feeding, wiring and detection can be replaced, operation is easy, the detection result is reliable, the labor cost is reduced, and the detection efficiency and quality are improved.

Owner:DALIAN NORTH INSTR TRANSFORMER GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com