Automatic throwing system for foam scrubbing agent used in foam scrubbing gas production of gas reservoir with water

An automatic injection and foaming agent technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of inability to produce gas, liquid blockage, and large amount of foaming agent input, so as to improve the accuracy of injection degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

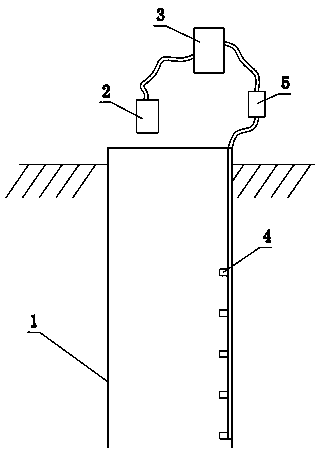

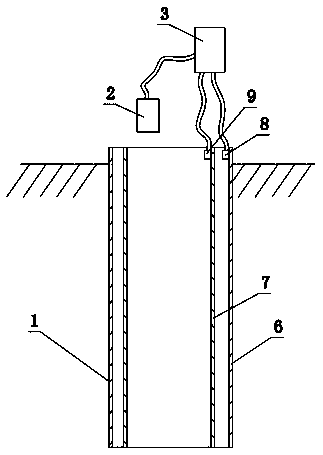

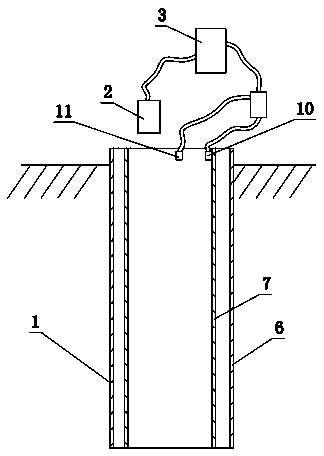

[0038] See attached figure 1 and 6 To 10, an automatic injection system for foam drainage agent for gas production in water-gas reservoirs, which includes a foam drainage agent injection device 2 located above the wellhead of a well 1 in a water-gas reservoir. The device 2 is electrically connected to the control cabinet 3 with the PLC control sheet through the cable, and the control cabinet 3 with the PLC control sheet is located in the operating room, and the motor of the foaming agent dispensing device 2 is controlled by the control cabinet 3 with the PLC control sheet. close;

[0039]A plurality of liquid level detectors 4 are fixed on the inner wall of the water and gas reservoir well 1, and the plurality of liquid level detectors 4 are electrically connected to the sensors 5 located in the operating room through cables, and the sensors 5 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com