Automatic throwing device for solid powder materials

An automatic feeding, solid powder technology, applied in washing devices, textiles and papermaking, other washing machines, etc., can solve the problems of driving device rotation error, inaccurate feeding amount, etc., to eliminate rotation error, ensure feeding amount, and prevent feeding amount. inaccurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

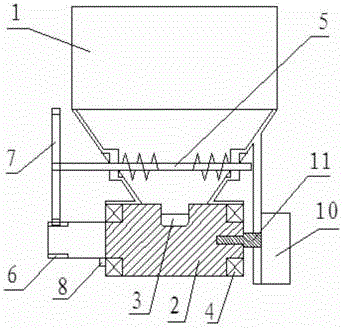

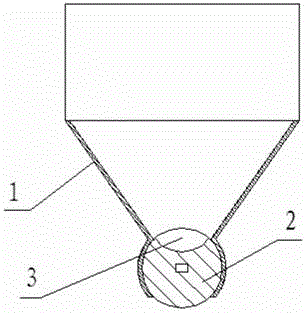

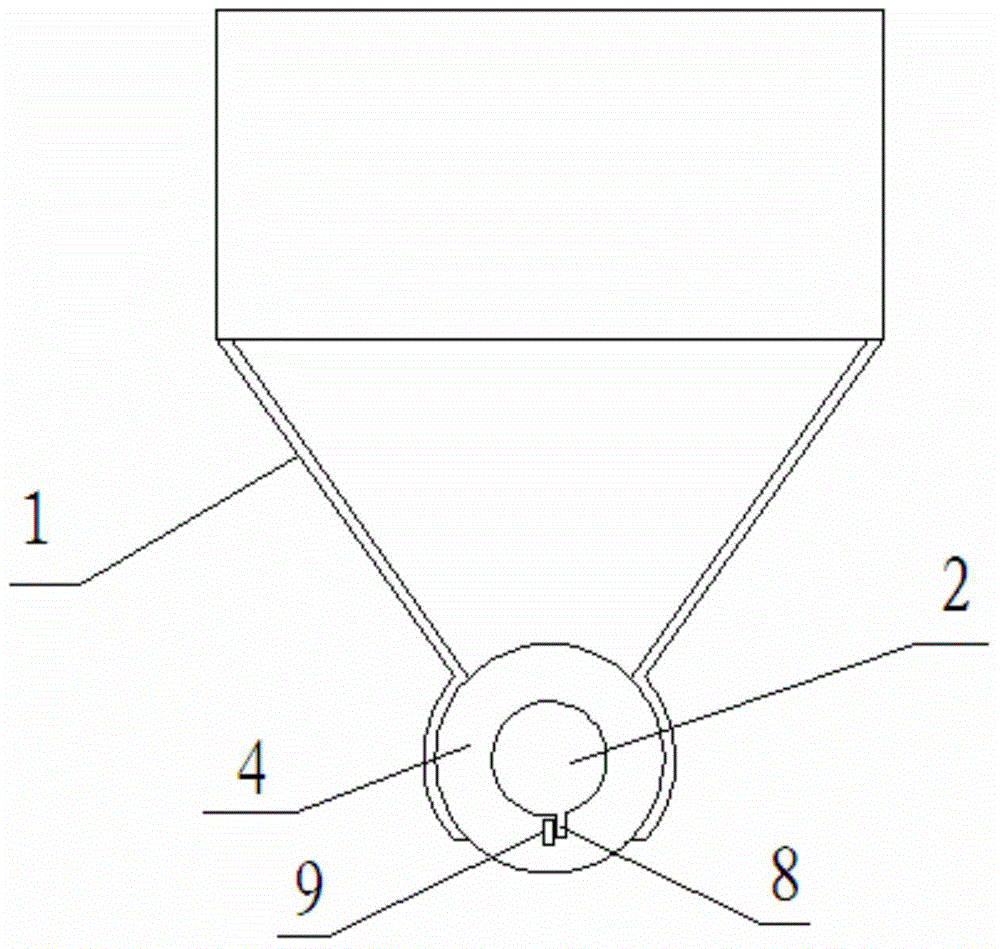

[0026] Such as figure 1 , 2 As shown, an automatic feeding device for solid powder materials includes a material box, a feeding mechanism and a stirring mechanism.

[0027] The material box includes a storage part and a delivery part, and the storage part communicates with the delivery part located below it. In order to be able to utilize self-weight blanking, the storage portion on the top of the magazine 1 is designed as a cone, with openings at the upper and lower ends of the cone. The feeding part at the bottom of the magazine 1 is a cylinder with a horizontal central axis and upper and lower openings, and the lower end opening of the cone is connected to the upper opening of the cylinder. In order to store more materials, a cylinder with the same diameter as the upper end of the cone is fixed on the top of the cone.

[0028] A stirring mechanism is installed in the cavity of the storage part on the upper part of the material box, and the two ends of the stirring mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com