Rotary table of lock machining machine tool

A technology for processing machine tools and turntables, applied in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost and complex indexing mechanism structure, and achieve the effect of low cost, simple structure, and guaranteed rotation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

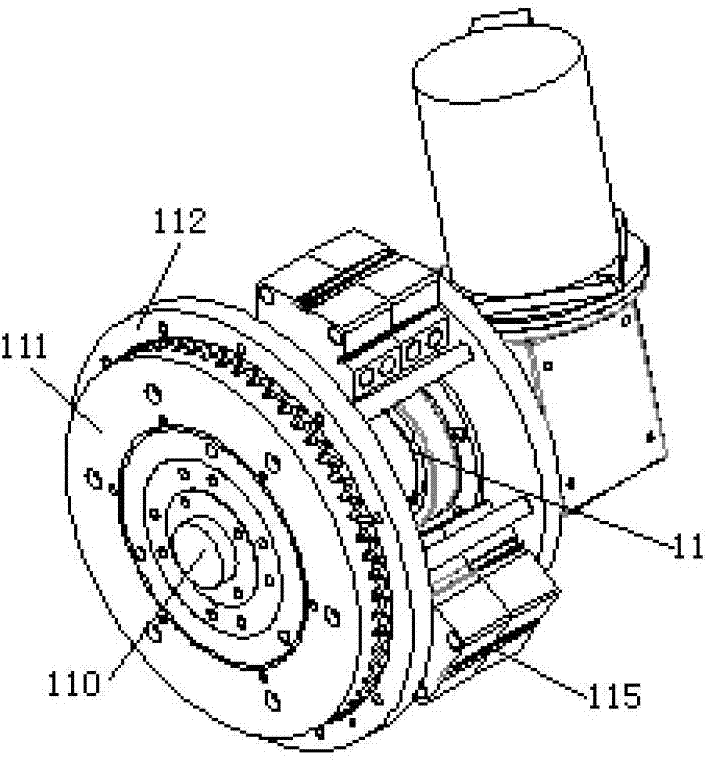

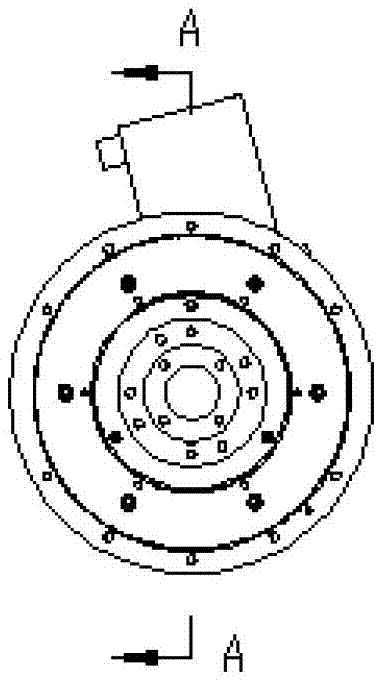

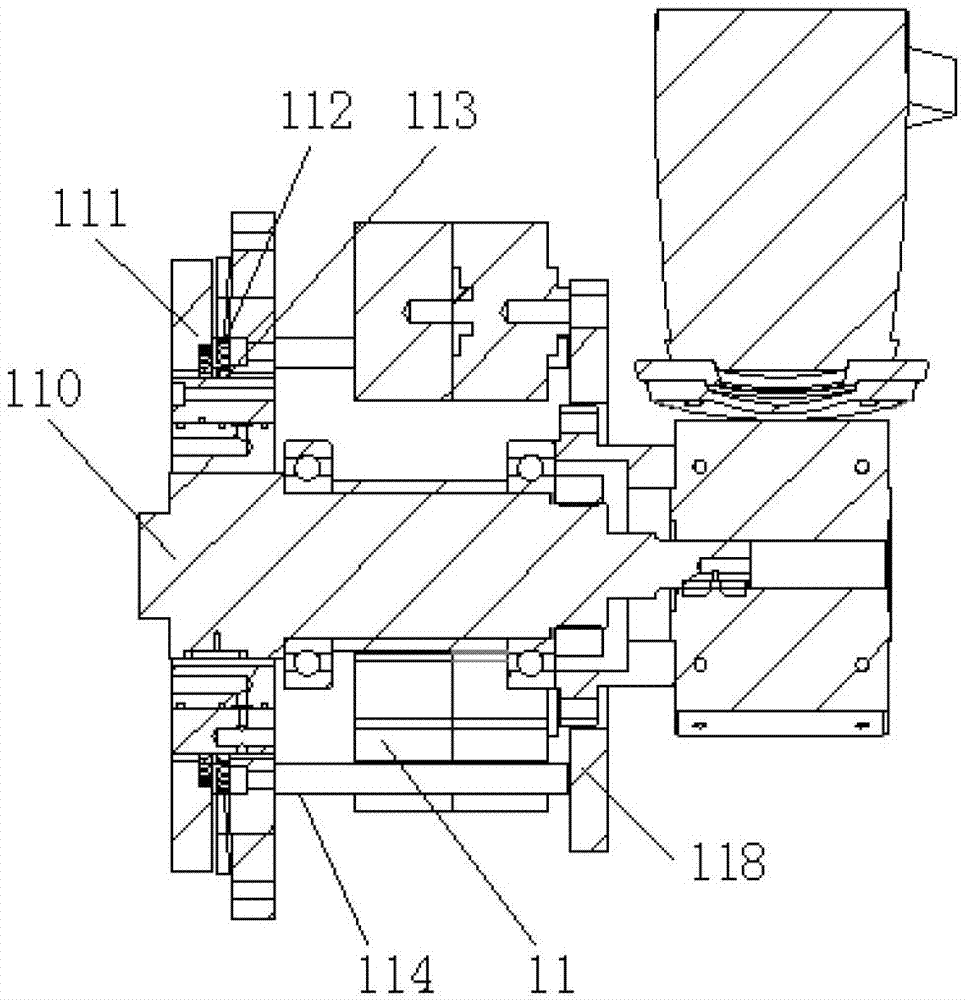

[0025] Figure 1 to Figure 10 The specific structure of the turntable of the lock body processing machine tool shown includes a turntable base 11 and a turntable main shaft 110 arranged in the turntable base 11. The front end of the turntable main shaft 110 is fixed with a turntable 12. The outer ring gear 112 is rotatably connected, and the outer ring gear 112 is fixed to the turntable 12. A circle of outer gear teeth is arranged on the front end surface of the outer ring gear. Inner ring gear 113, the inner ring gear 113 is provided with a ring of inner gear teeth corresponding to the outer gear teeth, the turntable base 11 is provided with a sliding ring 111 slidingly on the rear side of the turntable, and the rear end surface of the sliding ring 111 is provided with a ring Calibration teeth, the sliding ring 111 is connected with a pull rod 114, the pull rod 114 passes through the ring gear 113 and is connected to the pull rod driving mechanism 115 on the rear side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com