A lock body processing machine tool

A technology for processing machine tools and lock bodies, which is applied in the direction of metal processing machine parts, metal processing, metal processing equipment, etc., can solve the problems of low processing efficiency, high processing cost, and difficult to guarantee processing accuracy, so as to improve chamfering efficiency, The effect of eliminating rotation error and improving processing efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

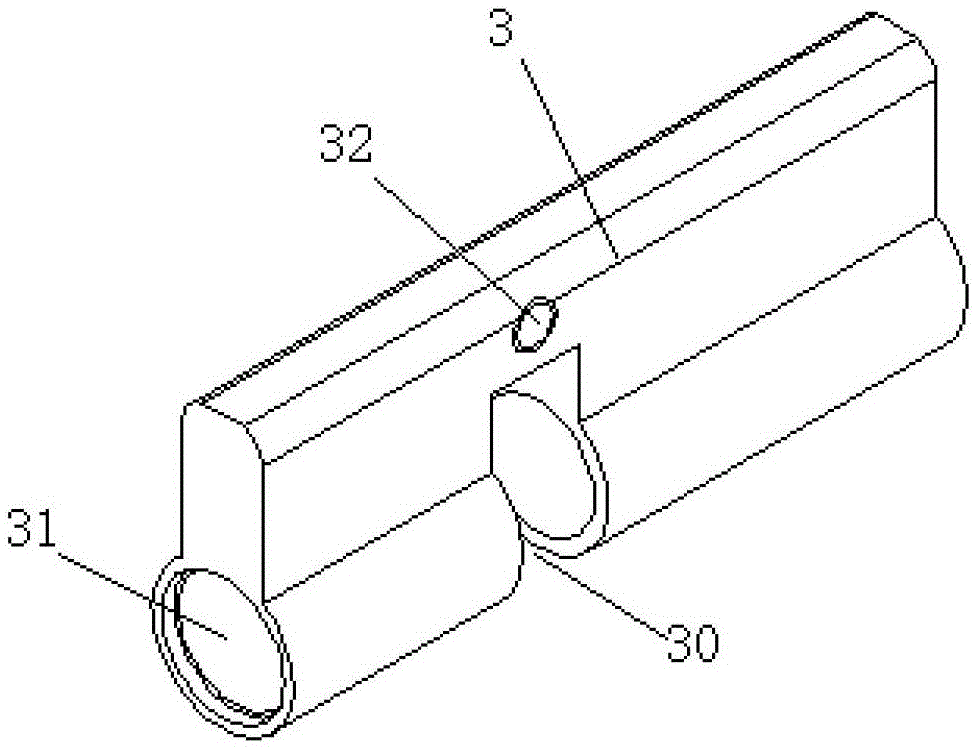

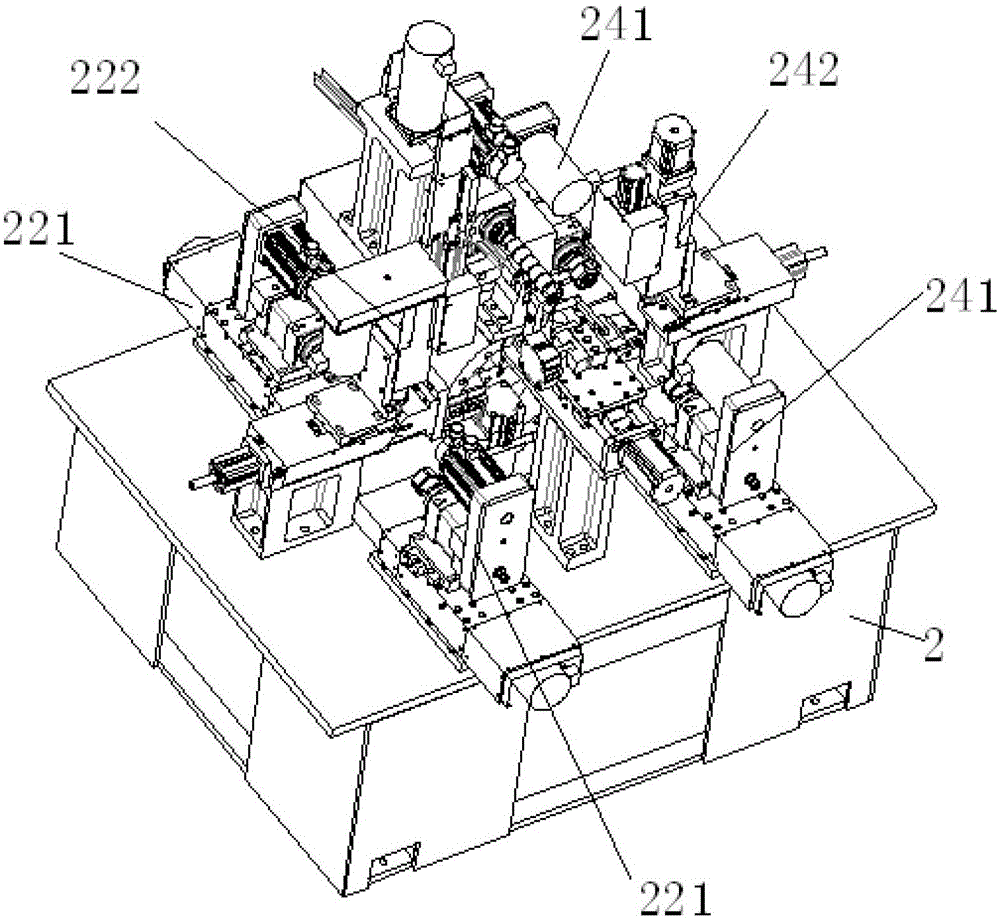

[0034] Figure 2 to Figure 3 The specific structure of the lock body processing machine tool is shown, which includes a bed 2, a turntable is provided at the center of the bed, and four lock body fixtures 13 are arranged at intervals of 90 degrees on the turntable, and the bed is arranged in a sequence around the turntable. In the clockwise direction, a material cutting device 21, a drilling device 22, a material unloading device 23 and a chamfering device 24 are sequentially arranged, wherein the material cutting device 21 is used for cutting off the lock body blank and cutting the breaking groove 30 of the lock body. Open, the drilling device 22 is used to drill out the lock core hole 31 and the through hole 32, the chamfering device 24 is used to chamfer the lock core hole 31 and the through hole 32, and the described unloading device 23 will lock The body is removed from the lock body fixture.

[0035] The material cutting device 21 includes a material cutting frame 210 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com