Patents

Literature

128results about How to "Improve chamfering efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

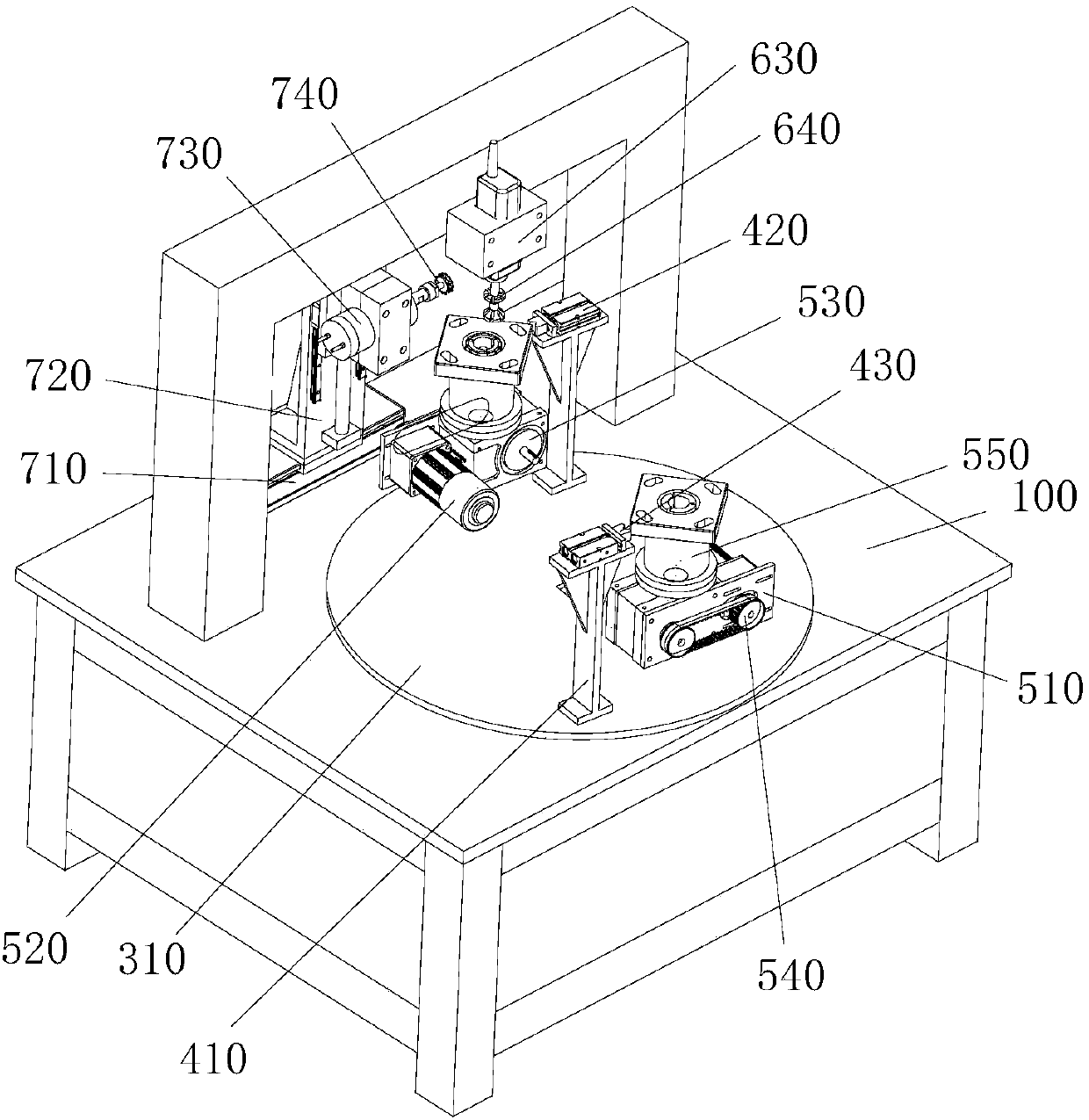

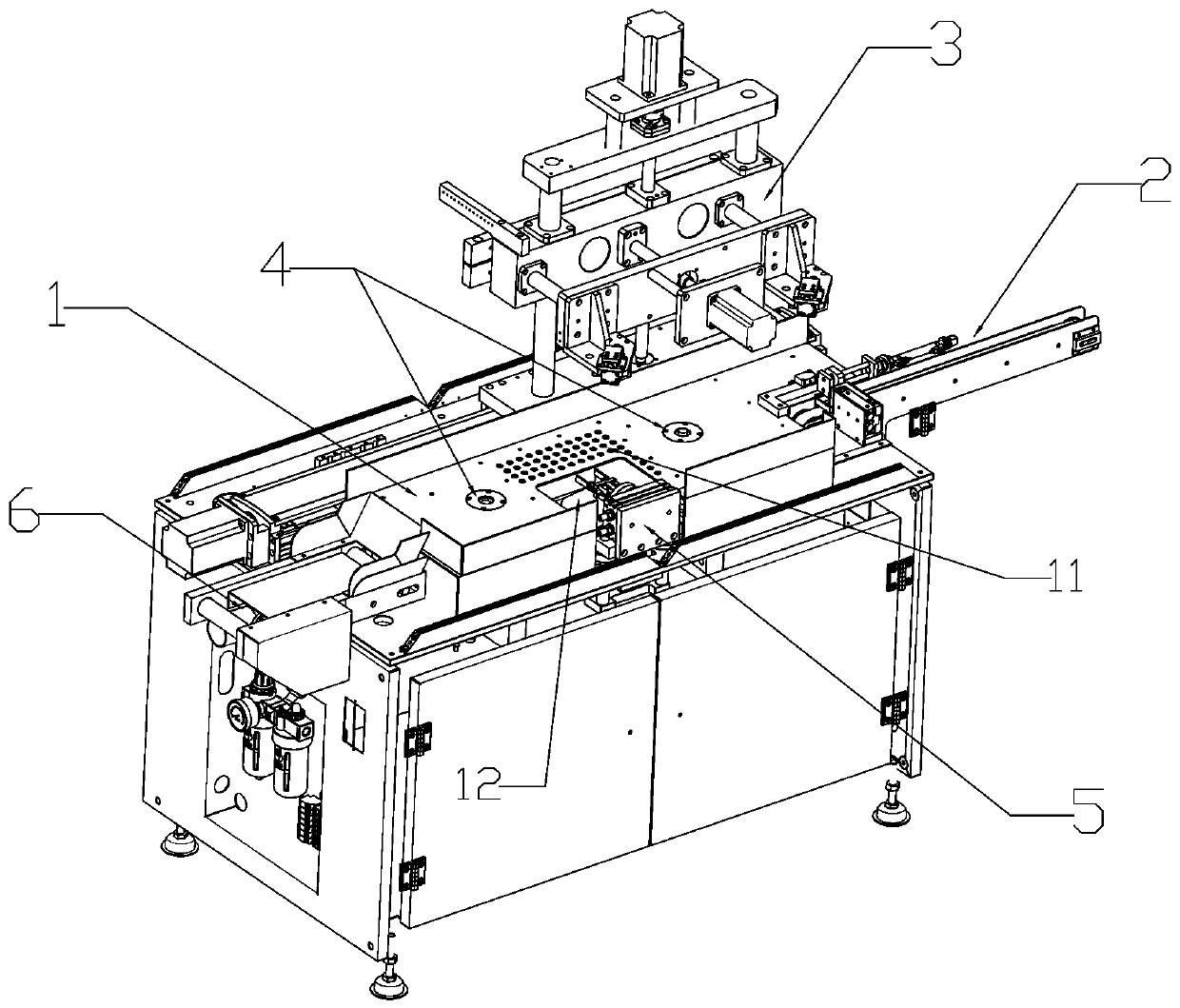

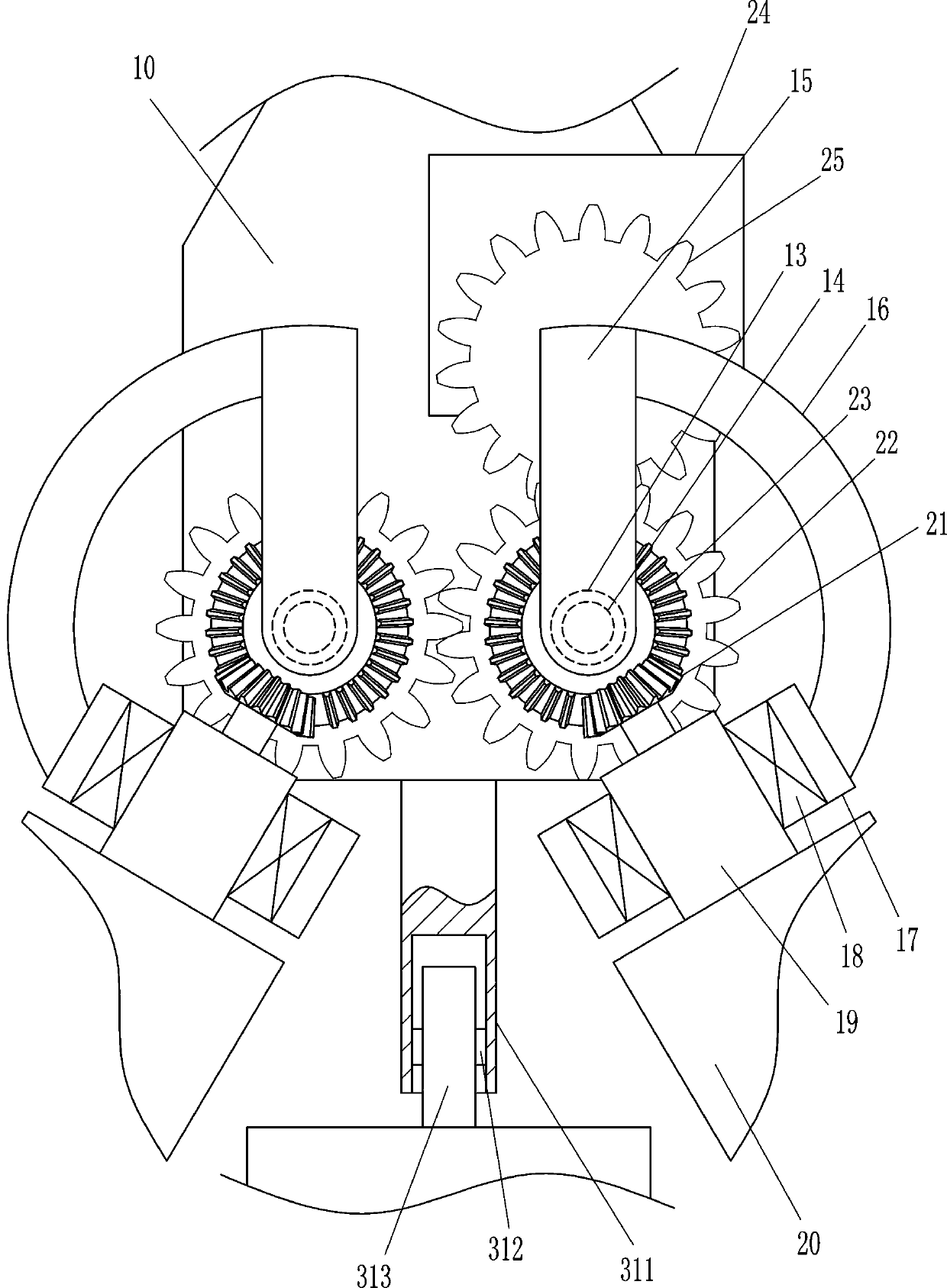

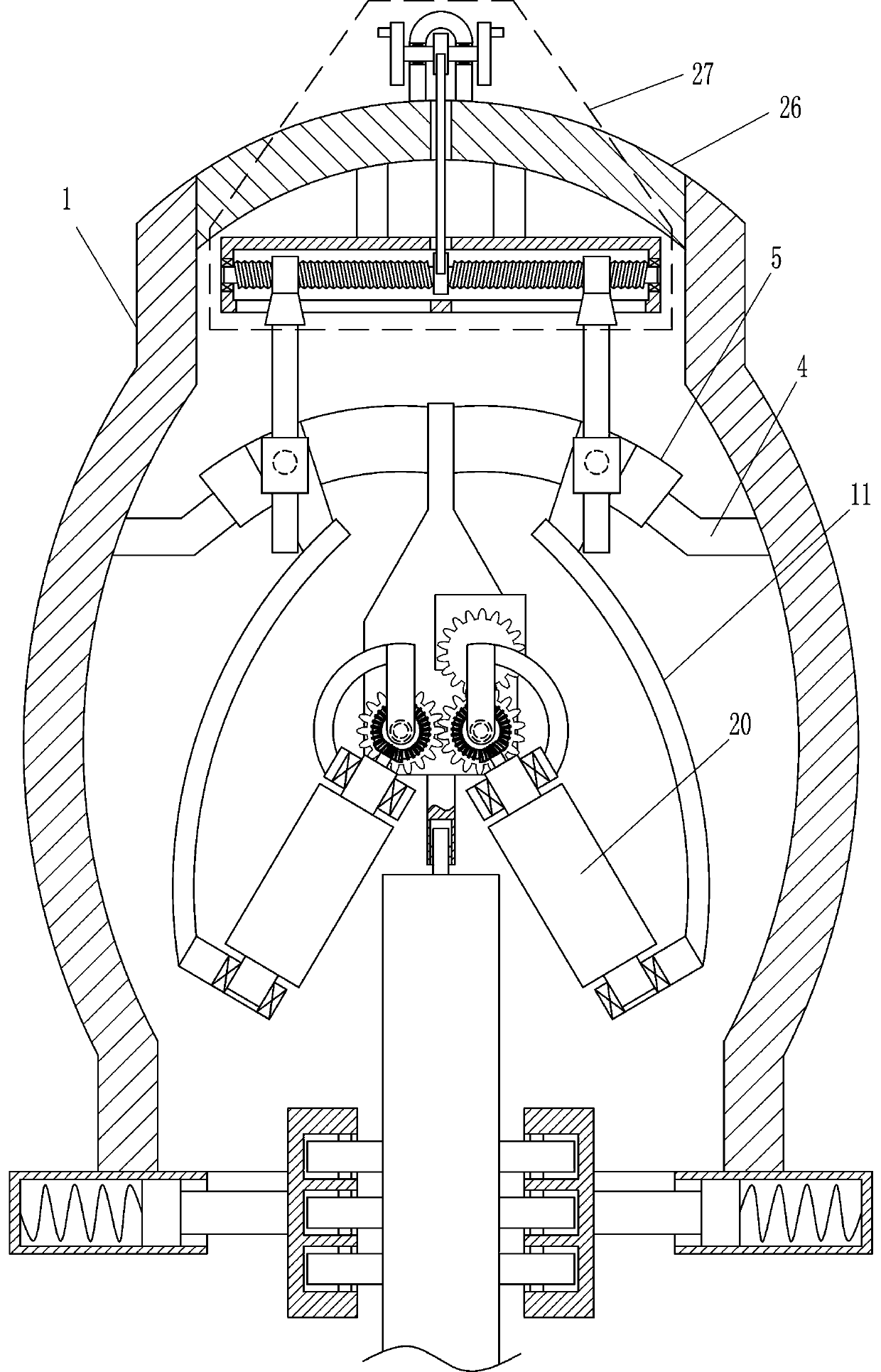

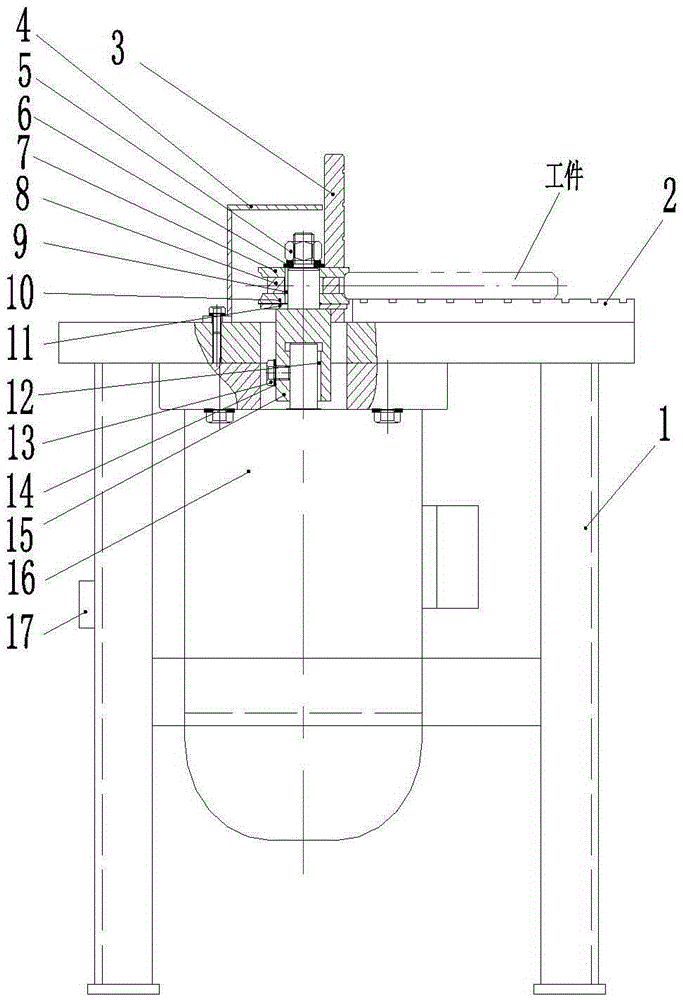

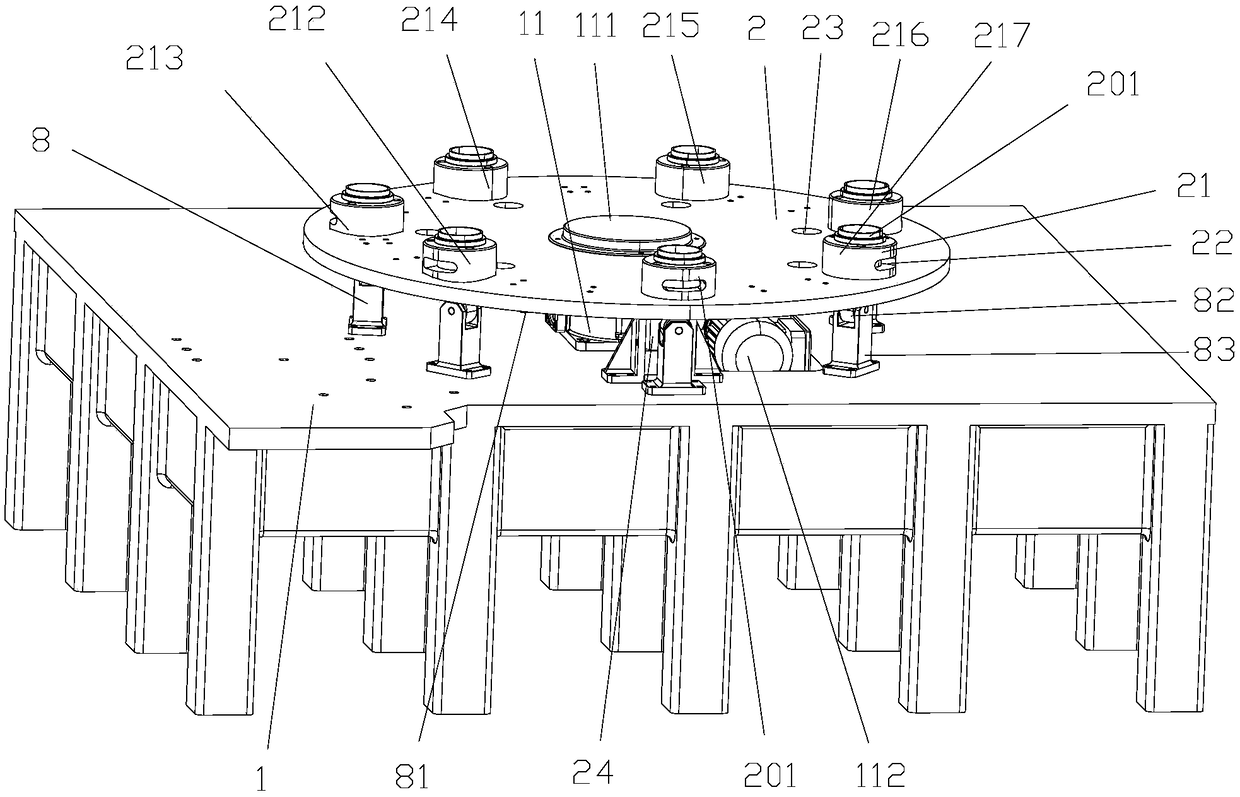

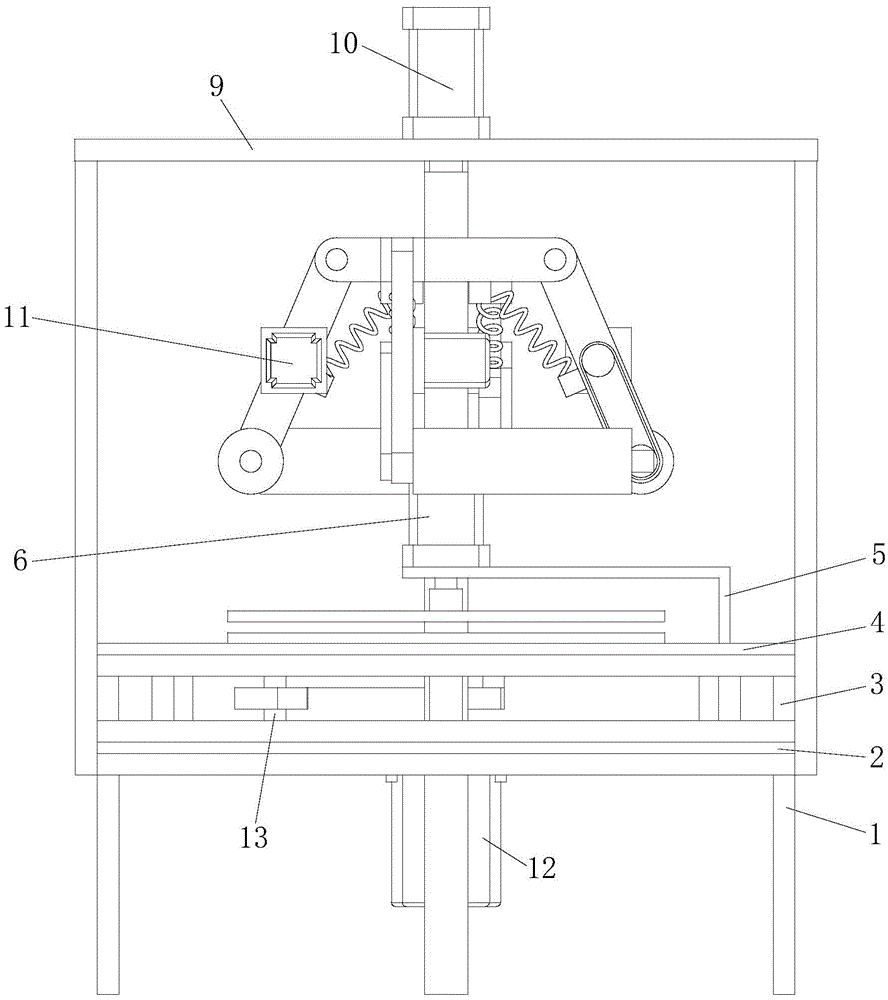

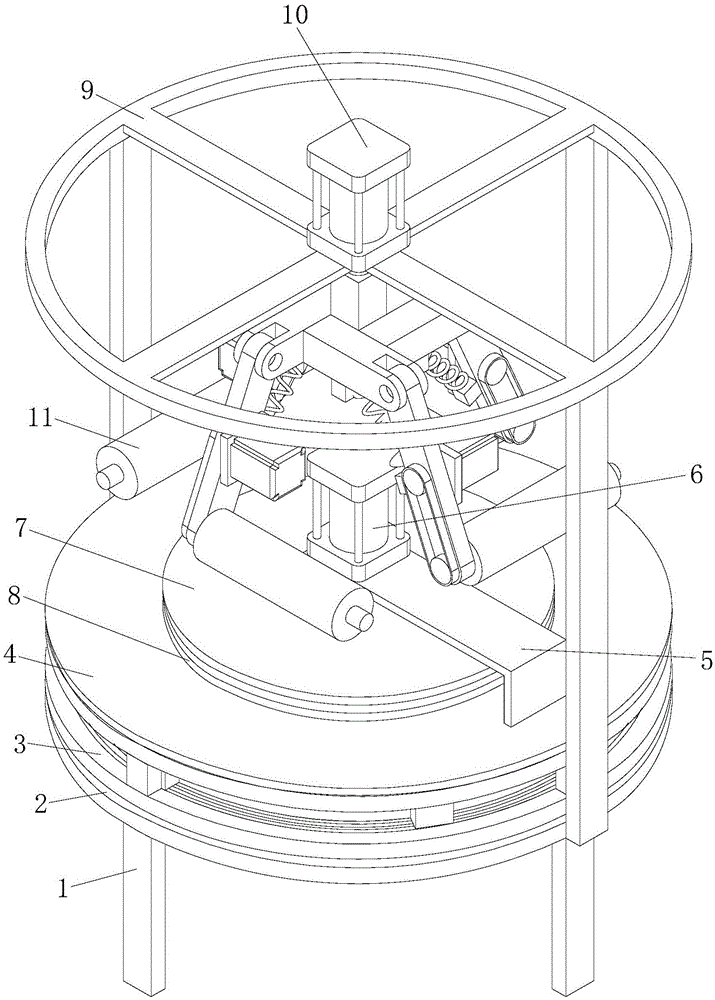

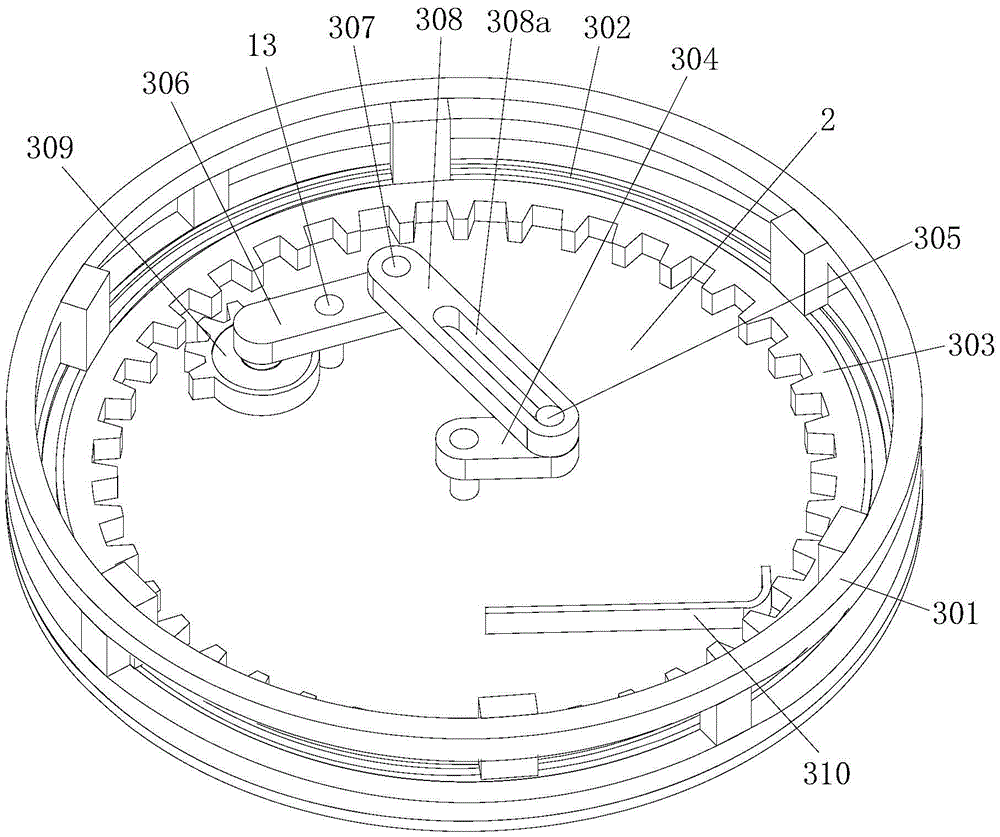

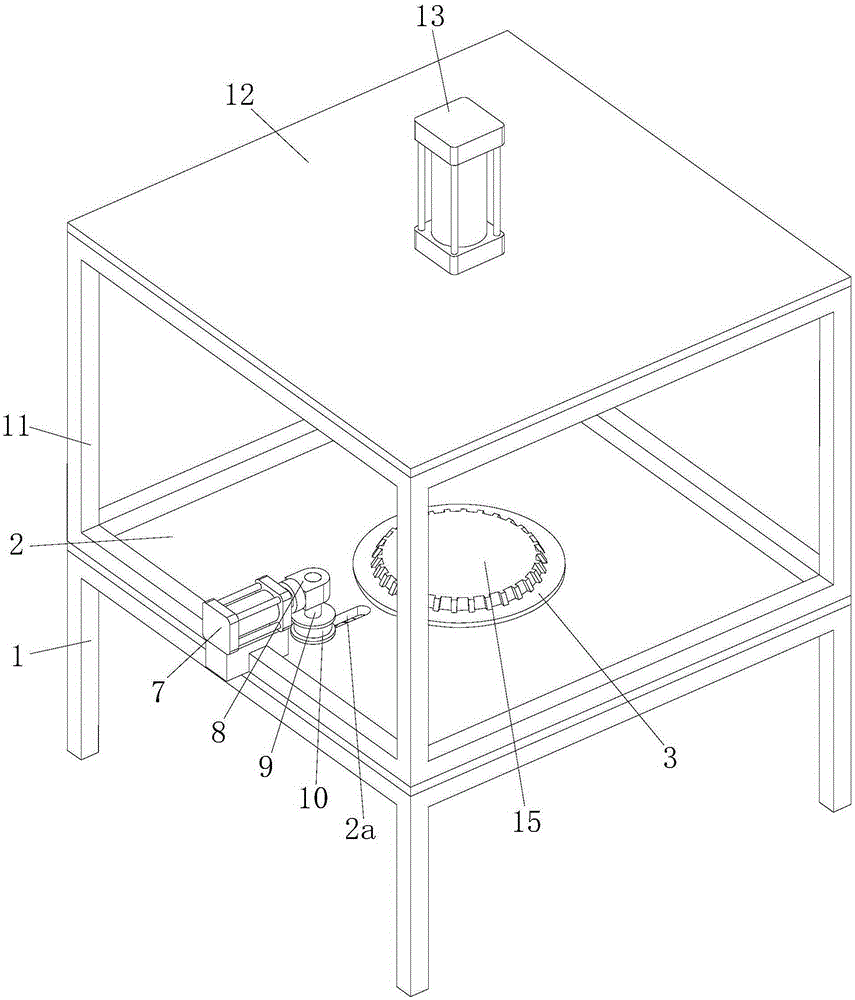

Automatic workpiece chamfering equipment and control method

PendingCN107737980AAutomatic chamferingAchieve positioningMilling equipment detailsLocking mechanismEngineering

The invention discloses automatic workpiece chamfering equipment and a control method. The automatic workpiece chamfering equipment comprises a workbench, a portal frame, a conversion table, a positioning mechanism, a locking mechanism, a first chamfering mechanism and a second chamfering mechanism. Firstly, a workpiece is placed on a hydraulic chuck, and a positioning air cylinder and the hydraulic chuck conduct positioning and locking on the position of the workpiece; then, a rotary disc conveys the workpiece to a chamfering station; then, the first chamfering mechanism conducts R angle chamfering on the edge of the workpiece; then, the second chamfering mechanism conducts chamfering on each edge of the workpiece; and finally, a first motor acts and drives the rotary disc to rotate by 180 degrees again, a to-be-machined workpiece is conveyed to the chamfering station to the machined, the machined workpiece is conveyed to a feeding station, unloading and loading operation is conducted, the process is operated in a full automation manner, manual intervention is not needed, and an alarm can be given for warning when the fault happens or positioning is inaccurate, and accordingly theworkpiece chamfering efficiency and quality are improved. The automatic workpiece chamfering equipment and the control method have the beneficial effects that the structure is simple, manufacturing is easy, control precision is high, and operation is convenient.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

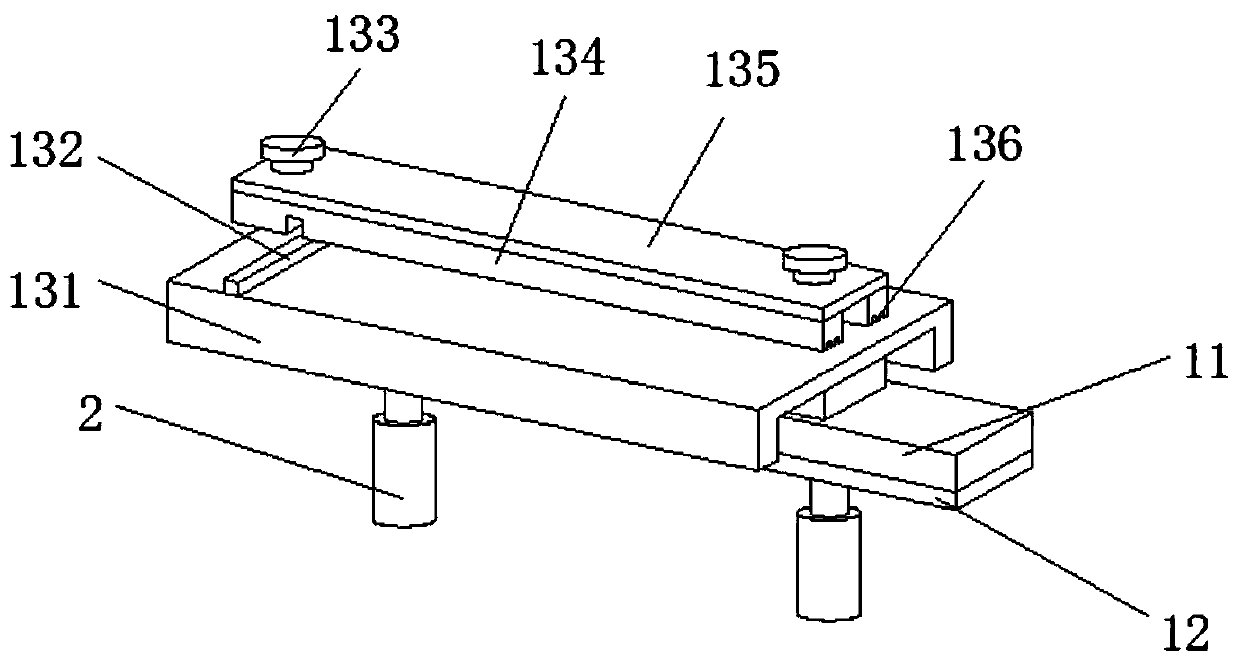

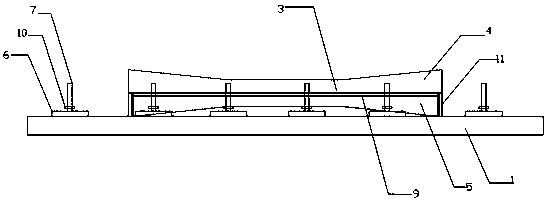

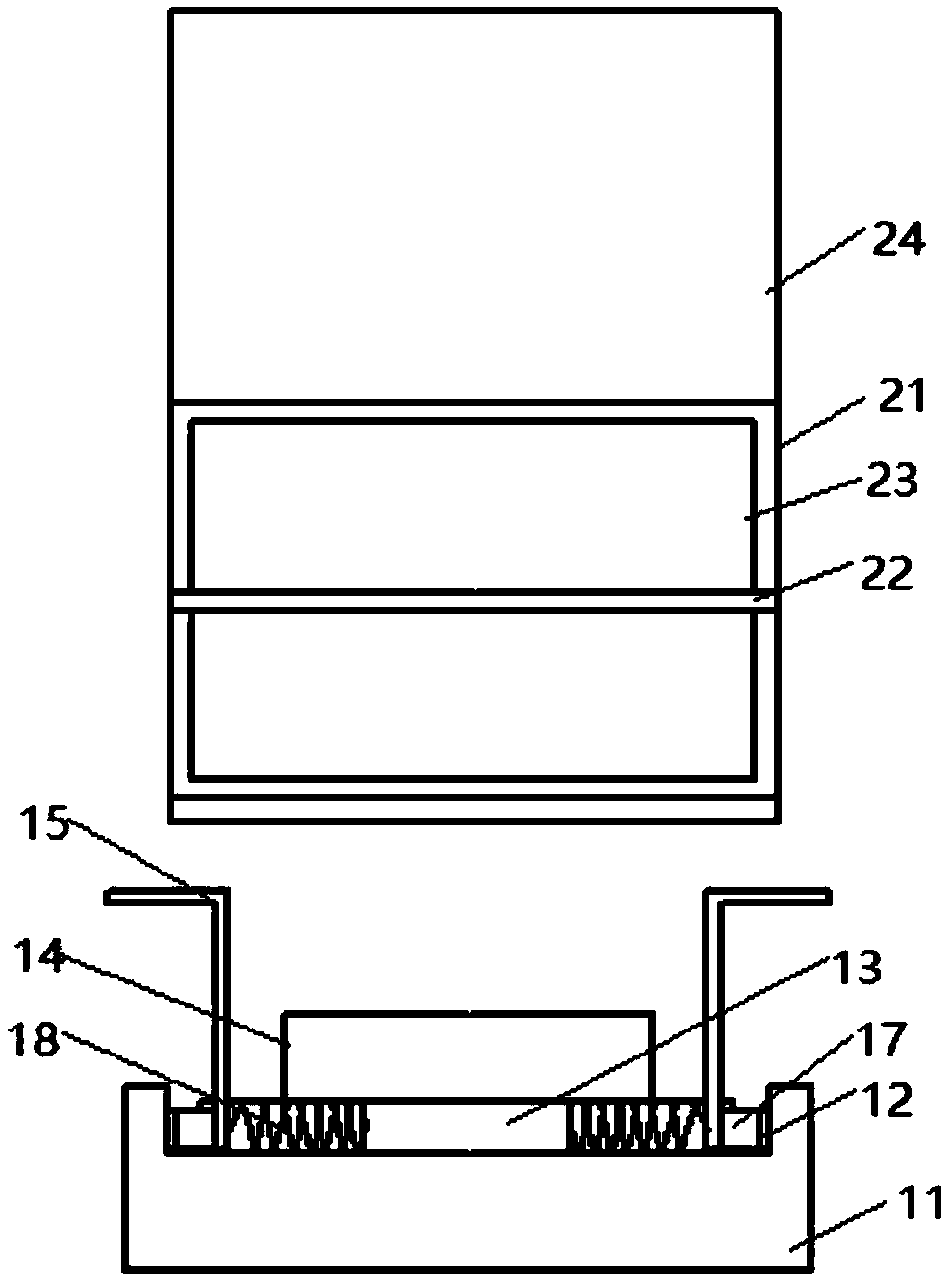

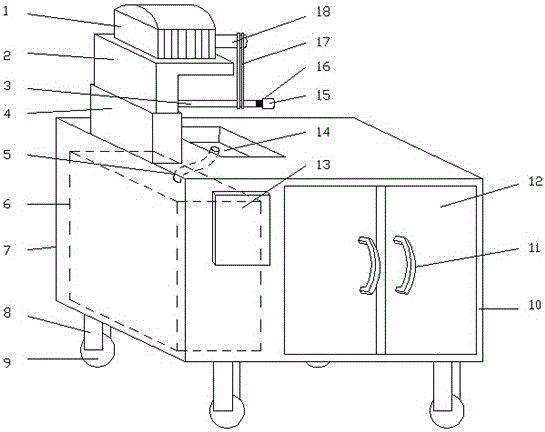

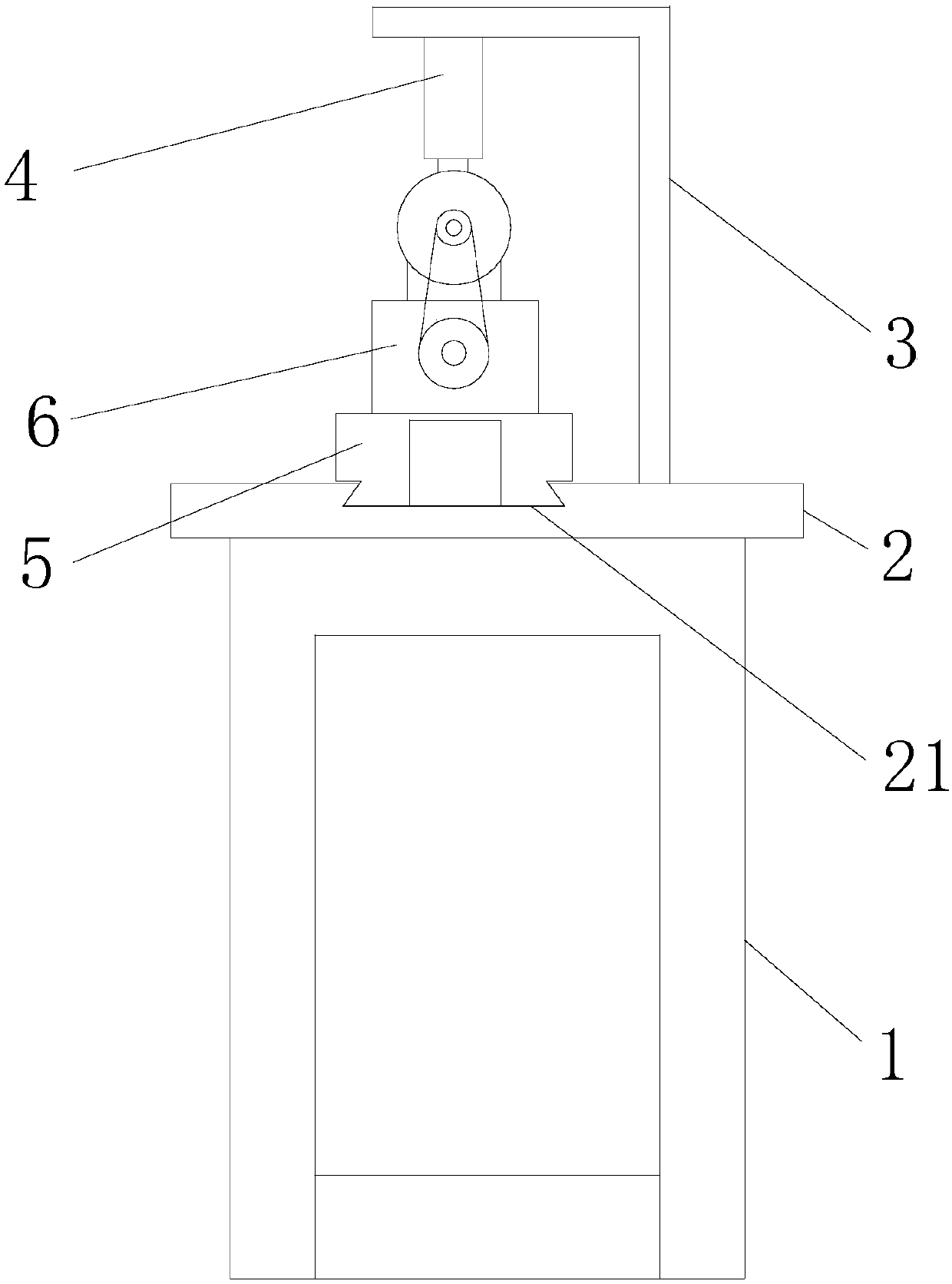

Board chamfering device for wood furniture production

InactiveCN111390699AImprove chamfering efficiencyProtection cleanEdge grinding machinesGrinding carriagesManufacturing engineeringDust control

The invention belongs to the technical field of wood furniture production, in particular to a board chamfering device for wood furniture production. Aiming at the problem that because existing chamfering machines can only chamfer the edge of one side of a board, the processing efficiency is low when chamfering treatment is required on both sides resulting in the influence on the processing efficiency of wood furniture, the invention provides a solution. The board chamfering device for wood furniture production comprises a base, wherein a plurality of electric pushing rods are fixedly mounted at the middle of the top of the base; the two sides of the top of the base are both fixedly equipped with supporting plates; and bedplates are fixedly mounted between the tops of the supporting platesand the electric pushing rods. In the board chamfering device for wood furniture production, housings on two sides are driven by electric sliding tables to approach the edges of the board, so that thetwo sides of the board can be chamfered simultaneously by virtue of rotating chamfering grinding wheels, and the chamfering processing efficiency is improved. Meanwhile, sawdust generated by chamfering enters the insides of isolation covers and is extracted by a dust removal mechanism so as to protect the cleanness of the device, facilitate the collection and cleaning of the sawdust, and provideconvenience for the operation of workers.

Owner:宁波鄞州区景行远望科技服务有限公司

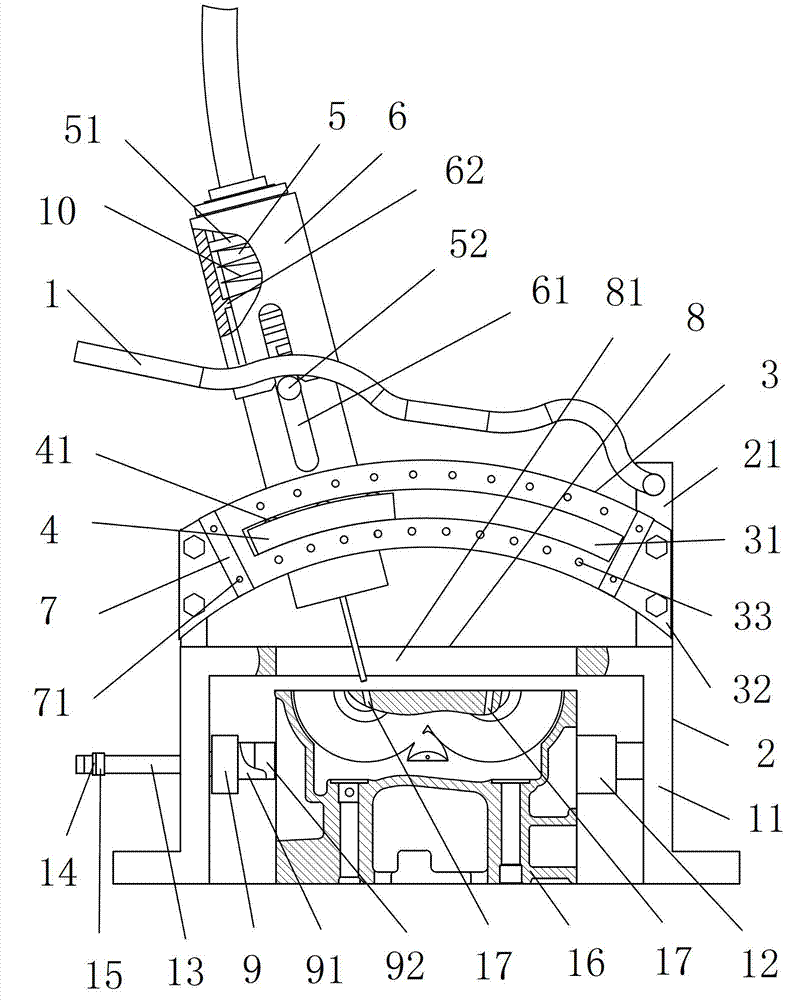

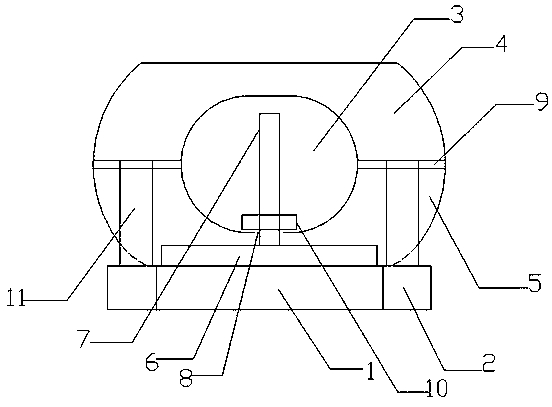

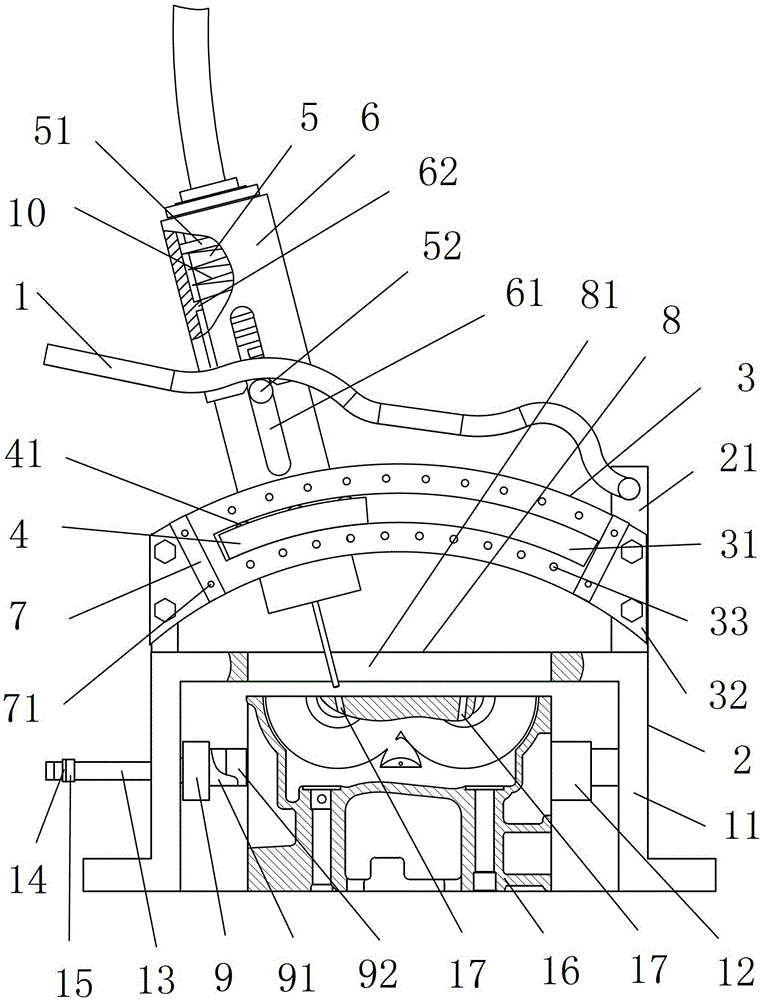

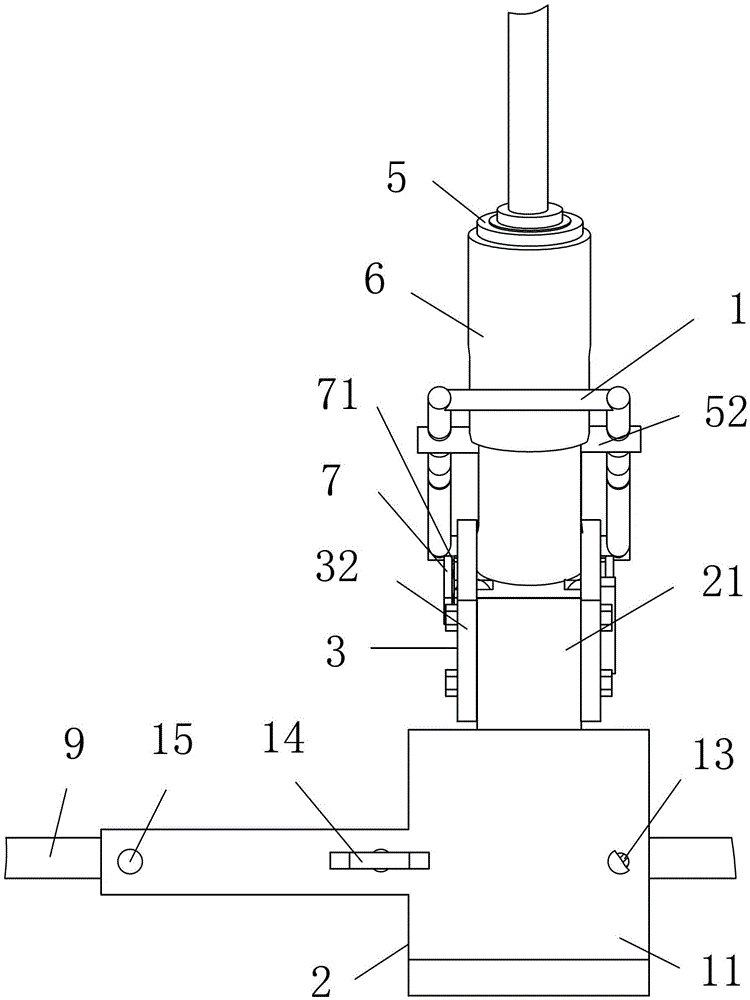

Cylinder head camshaft oil hole chamfering device

InactiveCN103586704AEasy entryPrecise positioningLarge fixed membersPositioning apparatusCylinder headCamshaft

The invention relates to the field of manufacturing of automotive engine cylinder heads, in particular to a cylinder head camshaft oil hole chamfering device. The cylinder head camshaft oil hole chamfering device comprises a support, a crossbeam, a chamfering mechanism and a corner limit mechanism, wherein the support is provided with two upper side plates, the crossbeam with each end connected with one upper side plate is provided with a circular arc sliding groove, and the chamfering mechanism is provided with a slider matched with the circular arc sliding groove. When the cylinder head camshaft oil hole chamfering device is used, a cylinder head is placed in the support, the chamfering mechanism is pulled, the corner limit mechanism is used to limit, and the chamfering mechanism chamfers one camshaft oil hole of the cylinder head; the chamfering mechanism is pulled, the corner limit mechanism is used to limit, and the chamfering mechanism chamfers the other camshaft oil hole of the cylinder head. The cylinder head camshaft oil hole chamfering device achieves chamfering operation by one-time clamping, and is good in chamfering quality and high in chamfering efficiency.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD

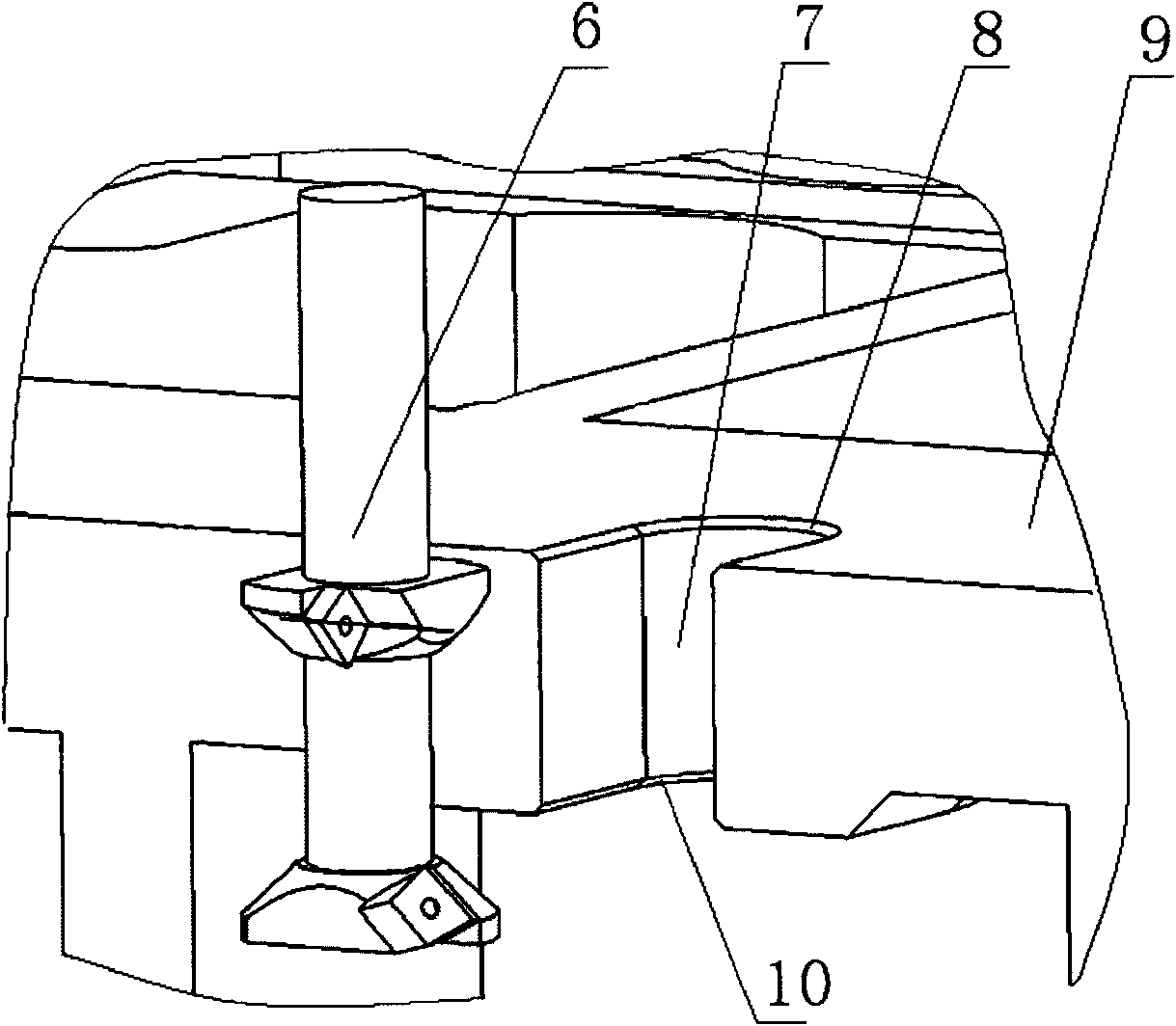

Car mold platen groove chamfer cutter

InactiveCN101658952AImprove chamfering efficiencyGuaranteed sizeMilling cuttersMilling equipment detailsAgricultural engineering

The invention discloses a car mold platen groove chamfer cutter comprising a cutter bar, a lower blade fixing base at the lower end of the cutter bar, an upper blade fixing base in the middle of the cutter bar, an upper blade and a lower blade, wherein the upper blade is detachably connected onto the upper blade fixing base, the lower blade is detachably connected onto the lower blade fixing base,and the height interval between the lower blade fixing base and the upper blade fixing base adapts to the distance between the upper chamfer and the lower chamfer of the platen groove. The car mold platen groove chamfer cutter adopts such a structure, can form the upper chamfer and the lower chamfer of the platen groove simultaneously by cutting processing, not only can improve the chamfer efficiency of the platen groove, but also can ensure the size and the beauty of the chamfer, and also lower the fabrication cost.

Owner:FUZHEN TECH RES ANHUI

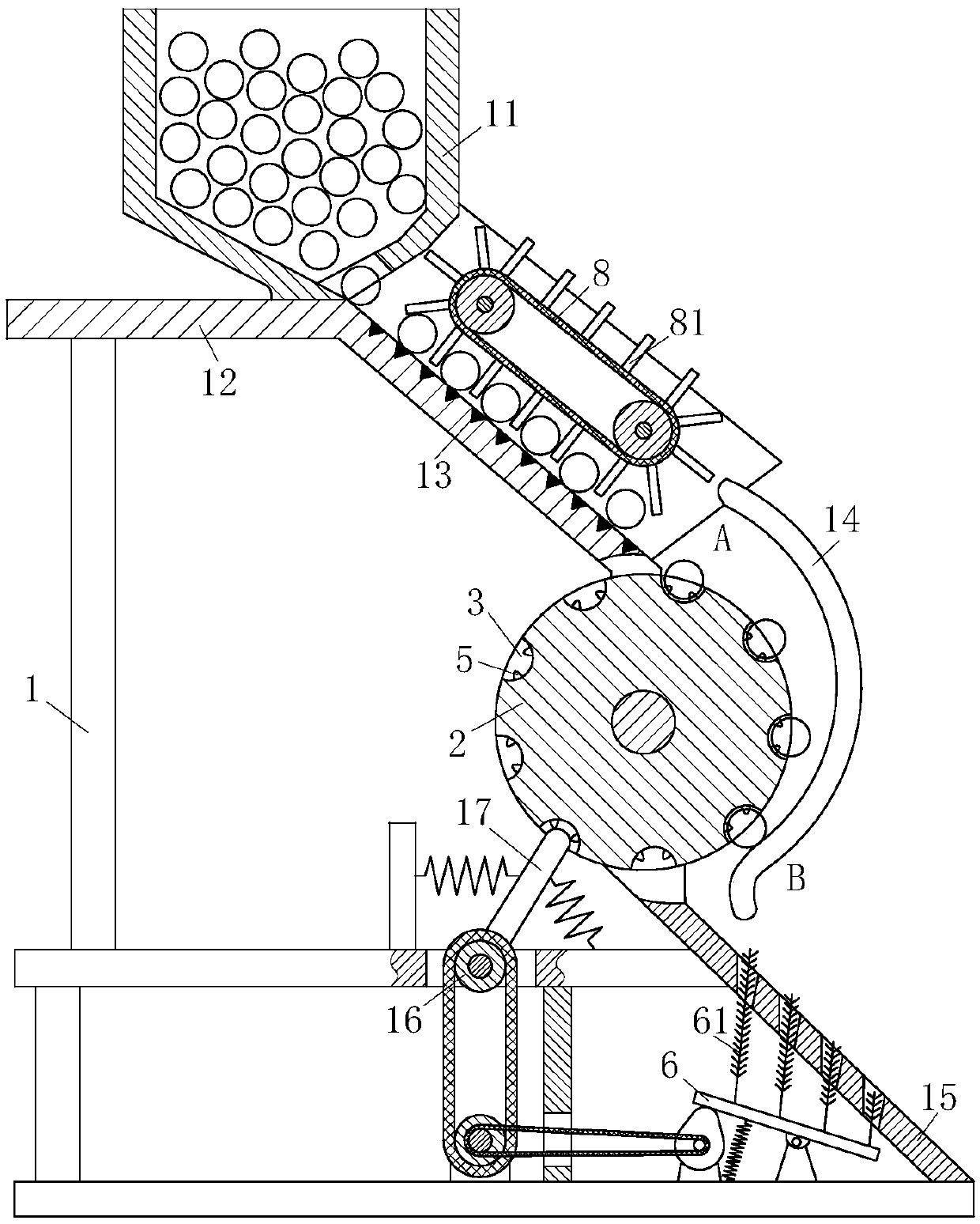

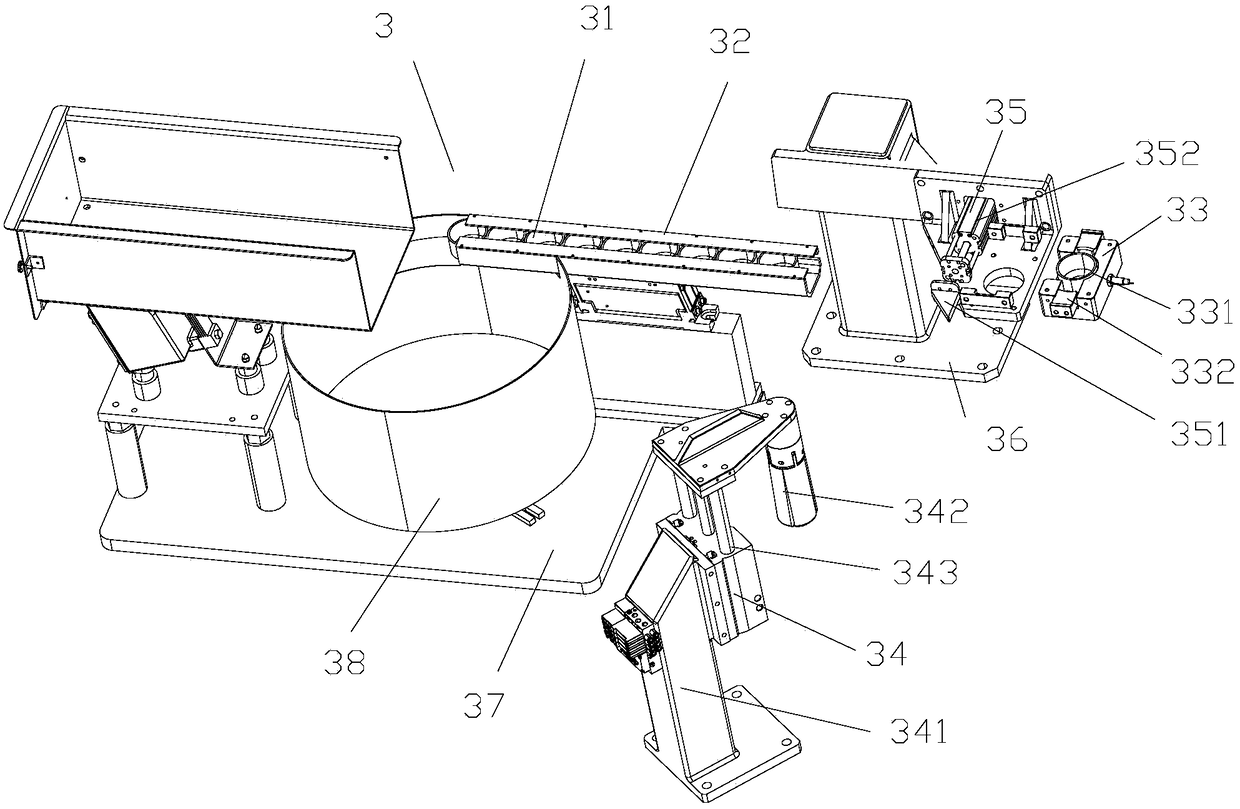

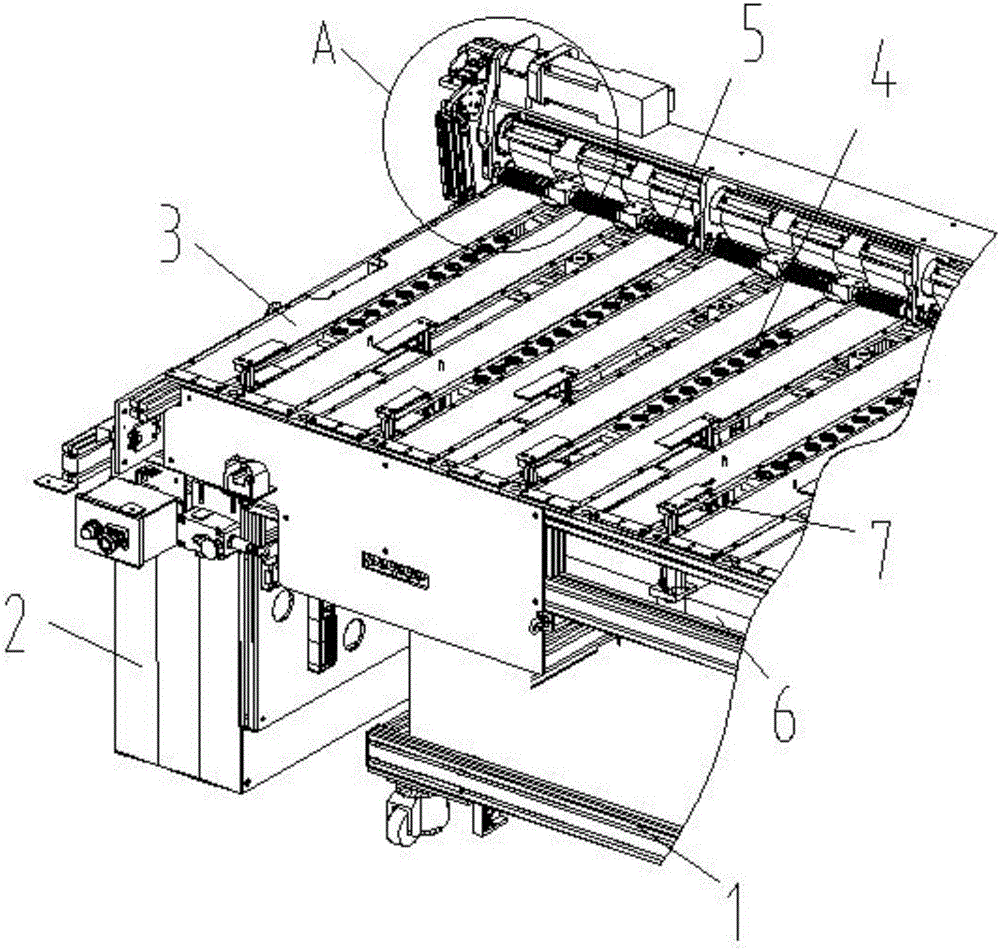

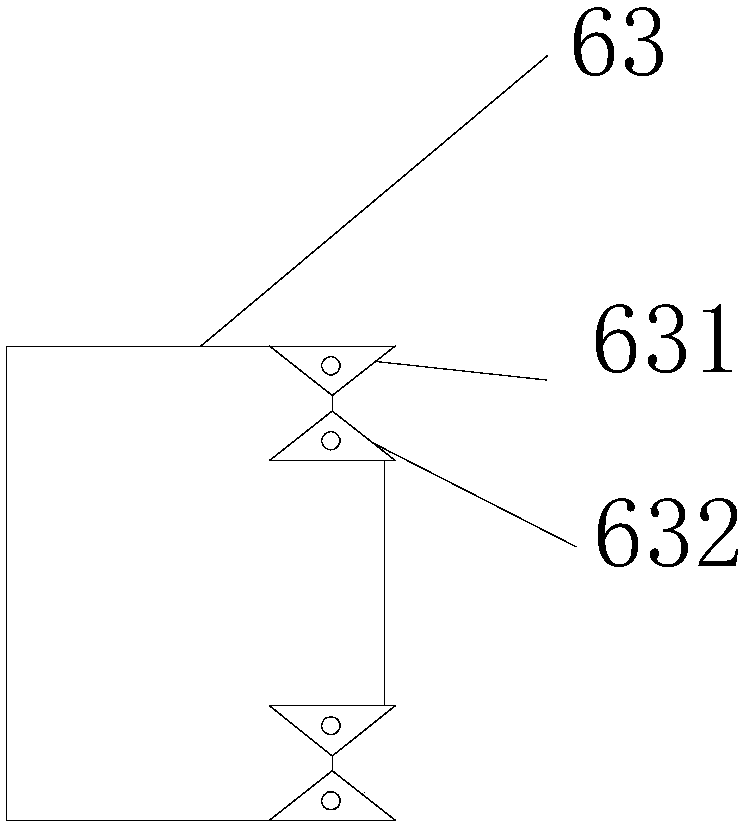

Spring chamfering machine

ActiveCN109551331AEasy to disassembleSimple maintenance and replacementEdge grinding machinesGrinding carriagesElectric machineryEngineering

The invention belongs to the technical field of spring machining equipment, and particularly relates to a spring chamfering machine. The machine comprise a machine frame, wherein a feeding hopper is fixed at the top of the machine frame, a material guide plate connected with the feeding hopper is arranged at the top of the machine frame, the right side of the material guide plate is bent to a slope, and a plurality of magnetic strips are uniformly arranged on the slope of the material guide plate; a clamping roller driven by a first motor is arranged in the machine frame, and a plurality of placing grooves are uniformly formed in the clamping roller in the circumferential direction; an arc-shaped pressing plate is arranged at the lower end of the material guide plate, the pressure plate isarranged on the front-rear face board of the material guide plate, the gap between the pressing plate and the clamping roller is gradually reduced from the position A to the position B, and when a spring moves to the position B, the spring is just clamped through the pressing plate and the clamping roller; two cylindrical chamfering blocks driven by a second motor are arranged in the machine frame, a chamfer is arranged at the front end of each chamfering block, the two chamfering blocks are front-back symmetrically distributed on the two sides of the clamping roller correspondingly, and therotating directions of the two chamfering blocks are opposite; and a discharging plate is arranged at the position, located below the clamping roller, of the machine frame, and four through grooves are uniformly formed in the discharging plate.

Owner:肇庆市肇大体育科技有限公司

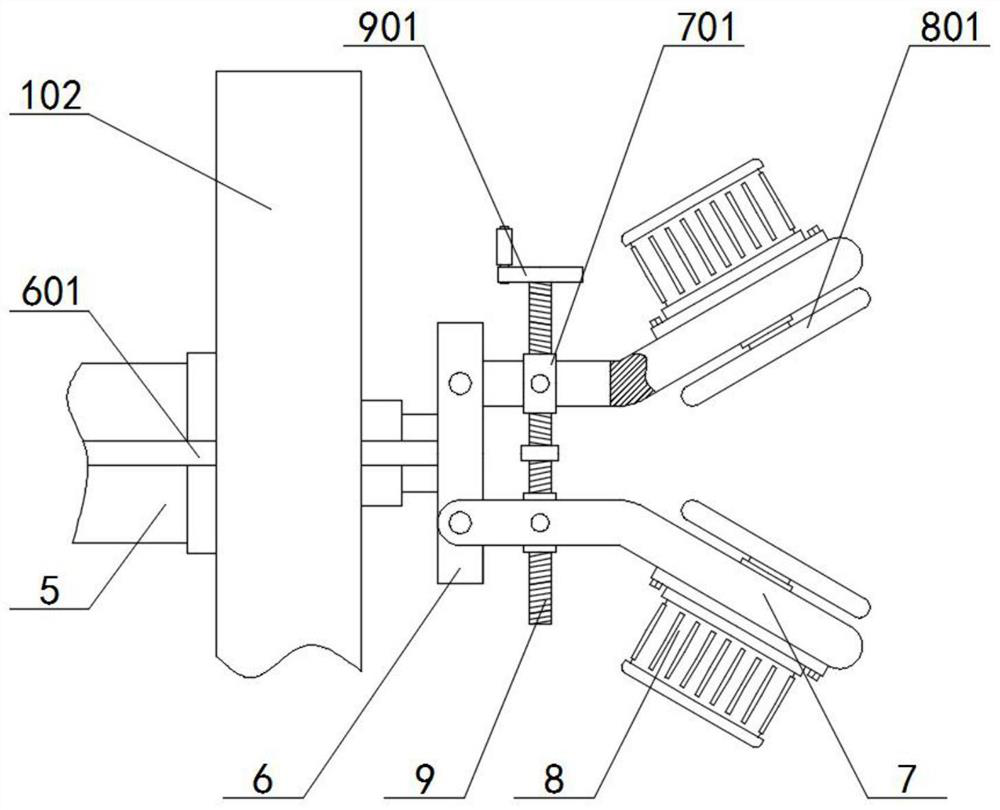

Gear chamfering device

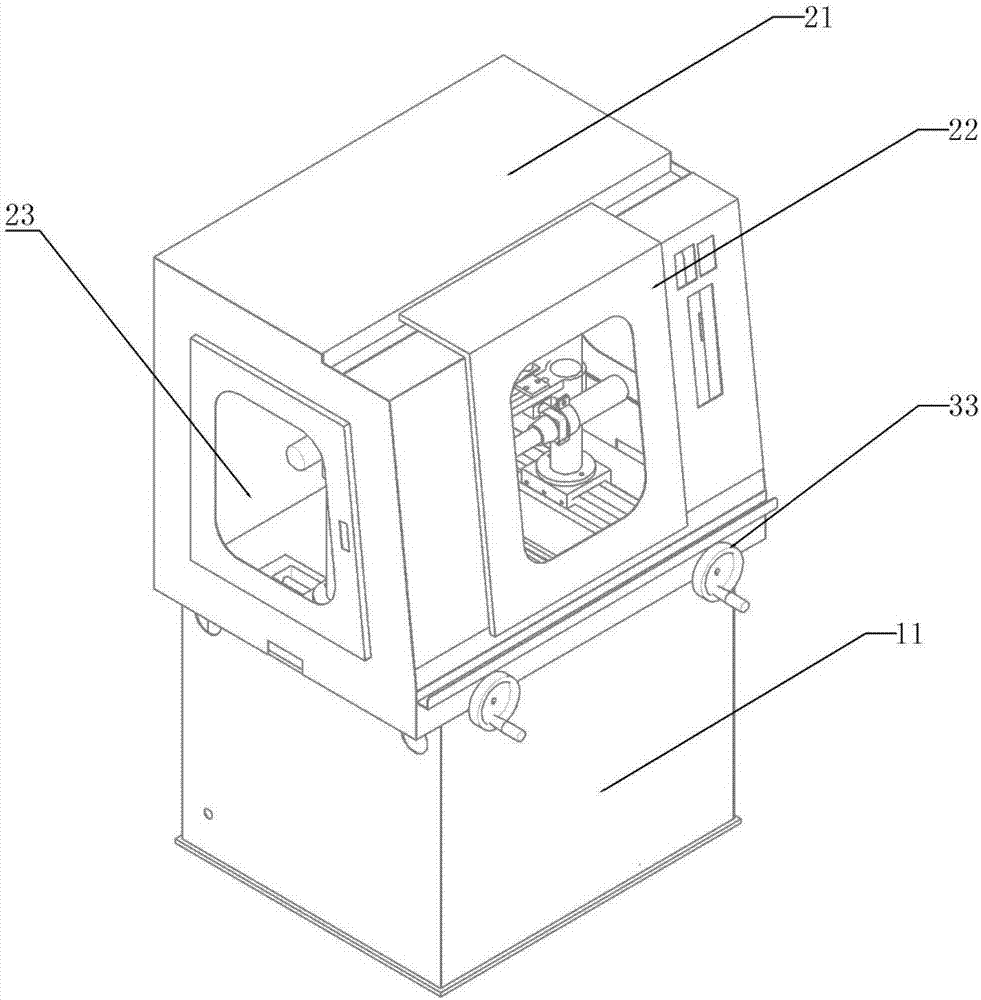

InactiveCN107999896AEasy to fixPrevent proliferationGear-cutting machinesGear teethEngineeringMechanical engineering

The invention belongs to the field of gear or rack manufacturing devices, and particularly discloses a gear chamfering device. The gear chamfering device comprises a shell, a chamfering structure anda dedusting structure. A door is arranged on the side wall of the shell. The shell is located at the upper end of the dedusting structure and communicates with the dedusting structure. A connecting plate is arranged at the lower end of the shell and provided with a plurality of through holes. The chamfering structure is located in the shell and comprises a clamping part and a polishing part. The dedusting structure comprises a dust bin. A dust collector is arranged in the dust bin and communicates with the through holes. By adoption of the gear chamfering device, a gear can be fixedly conveniently, and dust diffusion can be effectively prevented.

Owner:重庆厚朴开物科技有限公司

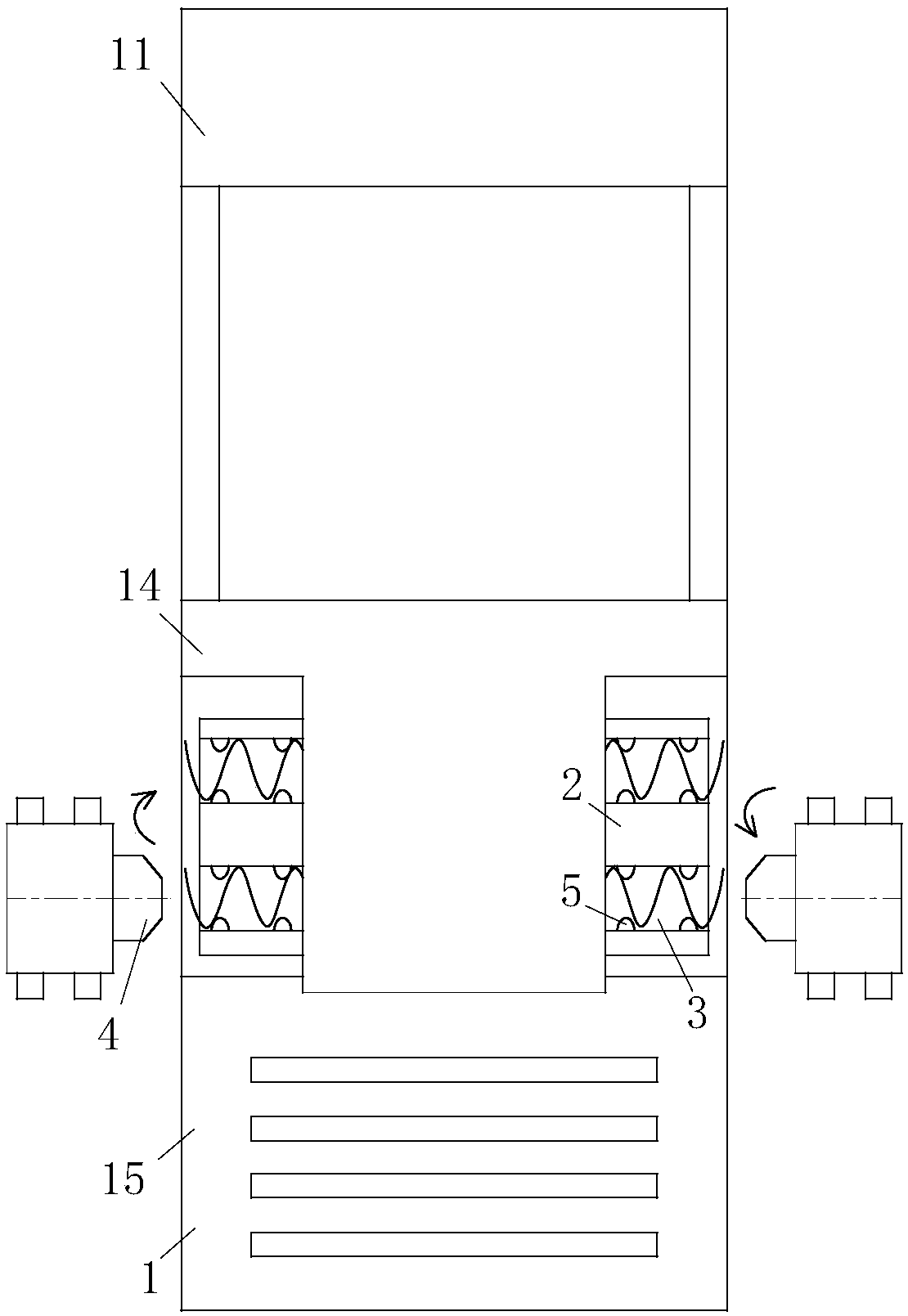

Chamfering machine

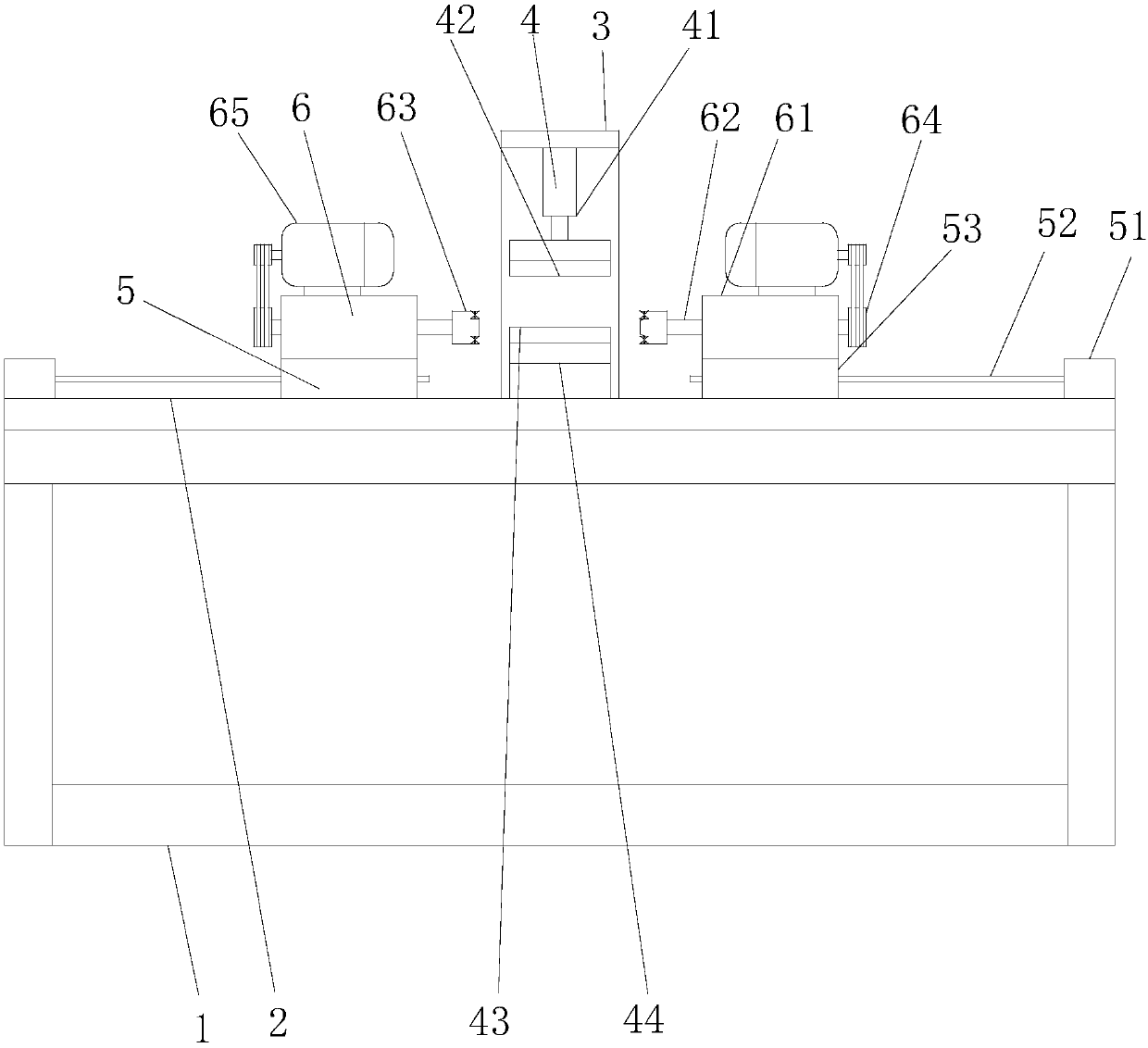

ActiveCN107738159AHigh degree of automationImprove chamfering efficiencyEdge grinding machinesRobot handMachine

The invention provides a chamfering machine which comprises a worktable, and a feeding conveying device, a feeding manipulator, chamfering devices, an overturning manipulator and a discharging conveying device which are arranged on the worktable. The feeding conveying device is arranged on the side edge of the worktable; a to-be-processed product is conveyed by the feeding manipulator; the feedingmanipulator is arranged on the side of the feeding conveying device, and can feed a to-be-processed material to the chamfering devices, the overturning manipulator and the discharging conveying device in sequence; the chamfering devices are symmetrically arranged on two sides of the overturning manipulator; and the discharging conveying device is opposite to the feeding conveying device, and is arranged on the edge of the other side of the worktable, and can convey the chamfered product. The whole chamfering process can be completed by a machine instead of a hand, the degree of automation ishigh, the chamfering efficiency is doubled, and the product quality is high.

Owner:东莞市宏业精密机械有限公司

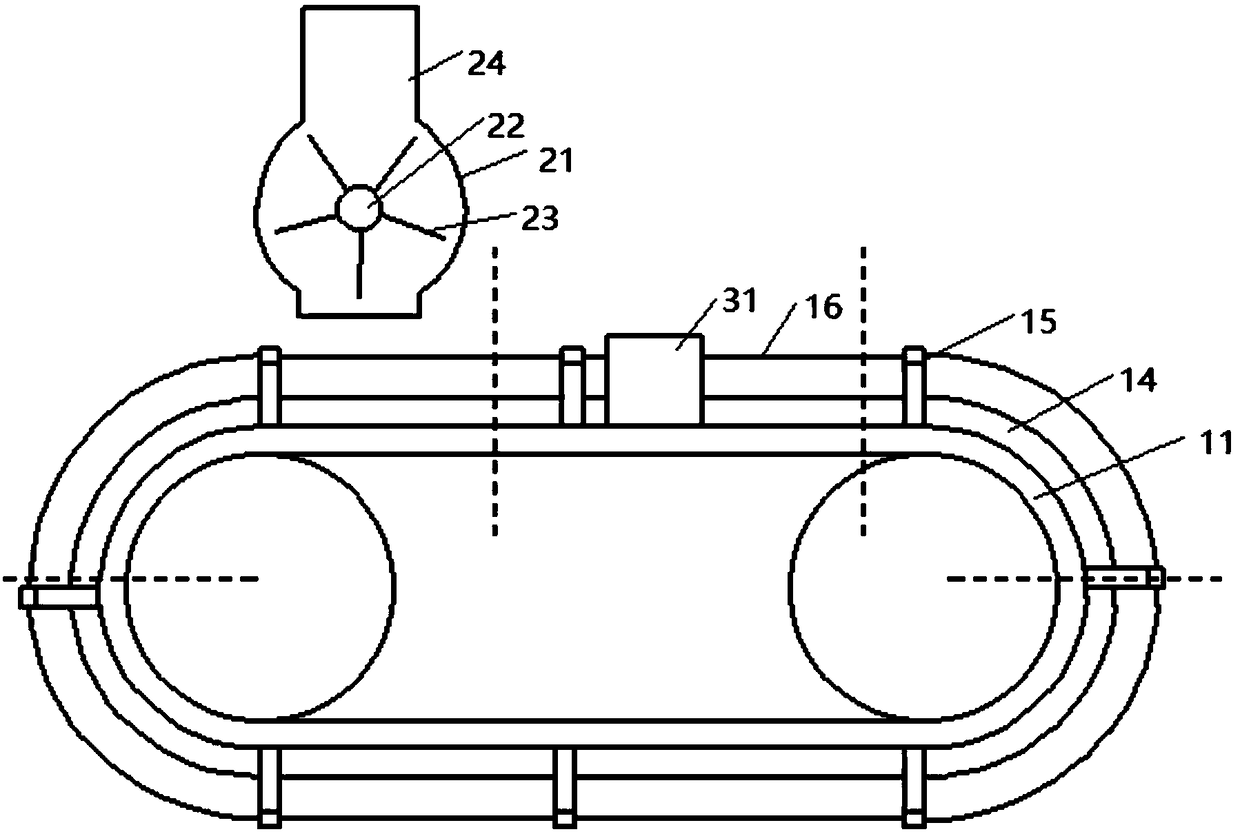

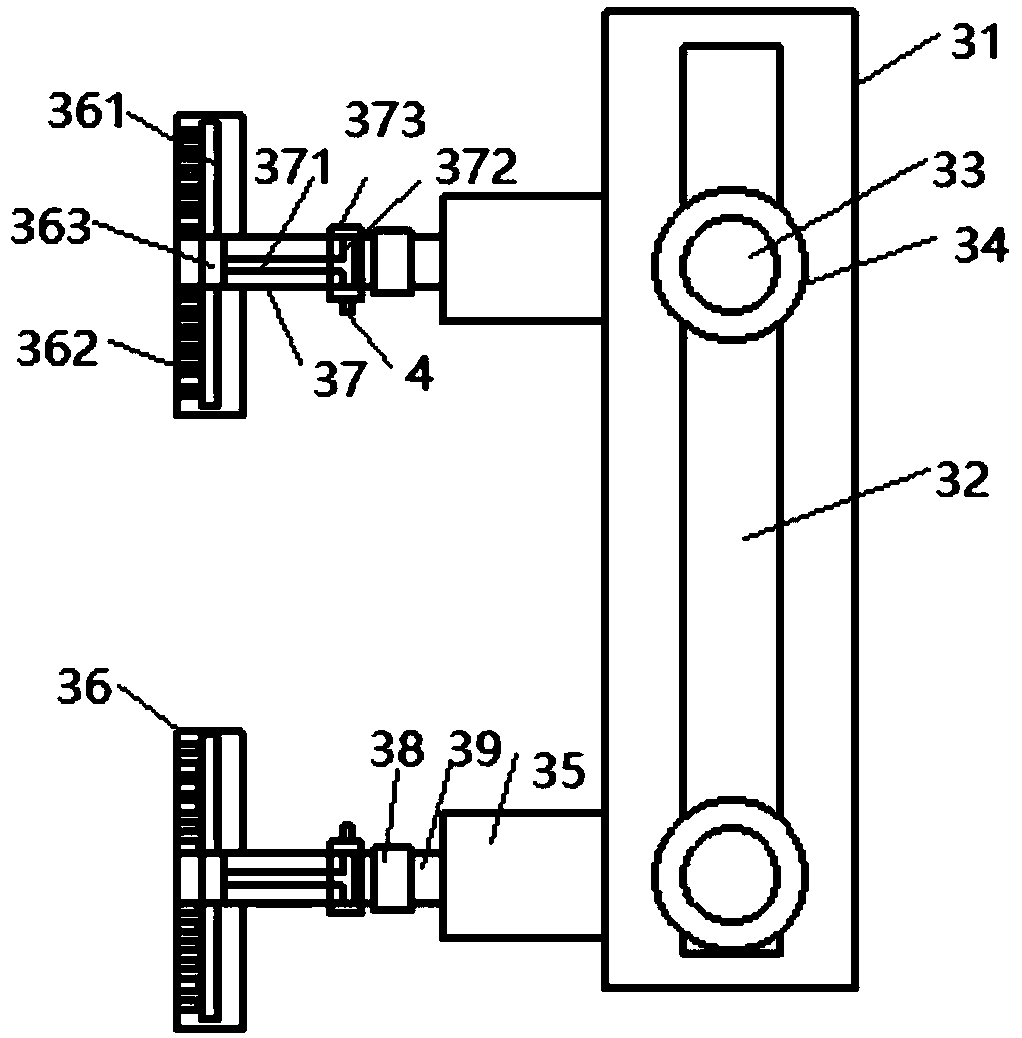

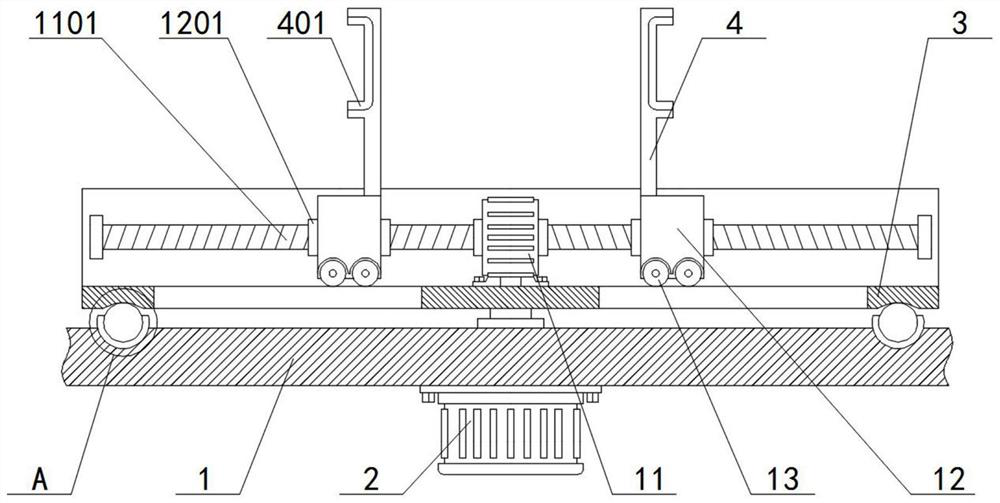

Automatic double-sided chamfering device

ActiveCN112589573AImprove chamfering efficiencyNo manual operationEdge grinding machinesGrinding drivesElectric machineryMachining process

The invention discloses an automatic double-sided chamfering device which comprises a box body. A motor and a pushing part are further installed on one side of the box body, transmission rollers and areversing mechanism are installed in the box body, the transmission rollers are matched with the motor, a bearing seat is installed on the transmission rollers in a sliding mode, the bearing seat ismatched with a discharging groove and the pushing part, and the pushing part is further fixedly connected with the reversing mechanism. The reversing mechanism is matched with the bearing seat througha spring, and the reversing mechanism comprises a rough chamfering part, a fine chamfering part and a reversing motor. NdFeB blanks to be chamfered are driven by the transmission rollers to rotate together and are matched with a rough grinding head and a fine grinding head to be subjected to double-sided chamfering, so that the chamfering efficiency is improved. The rough chamfering part, the fine chamfering part and the reversing motor form the reversing mechanism, so that the rough chamfering process and the fine chamfering process can be completed simultaneously in one machining process. The feeding process, the rough chamfering process, the fine chamfering process, the discharging process and the stacking process of the device are all completed automatically, manual operation is not needed, efficiency is higher, and meanwhile safety is improved.

Owner:赣州华京稀土新材料有限公司

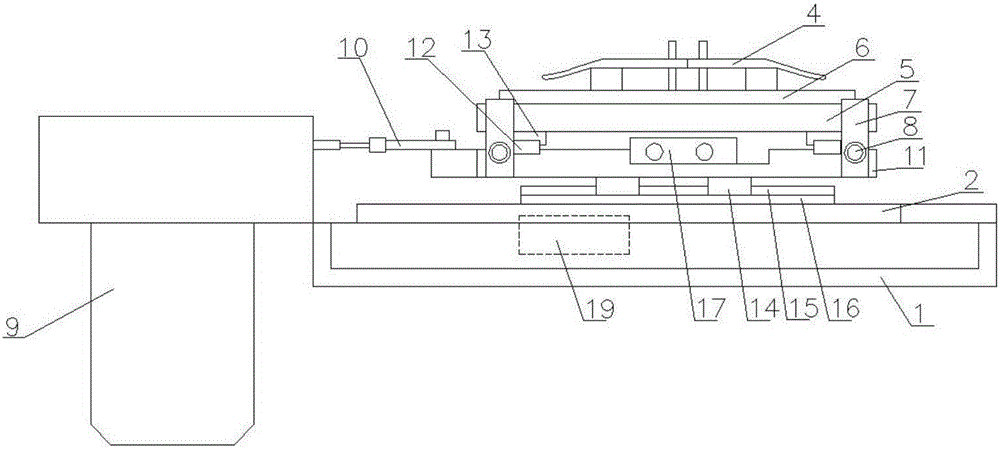

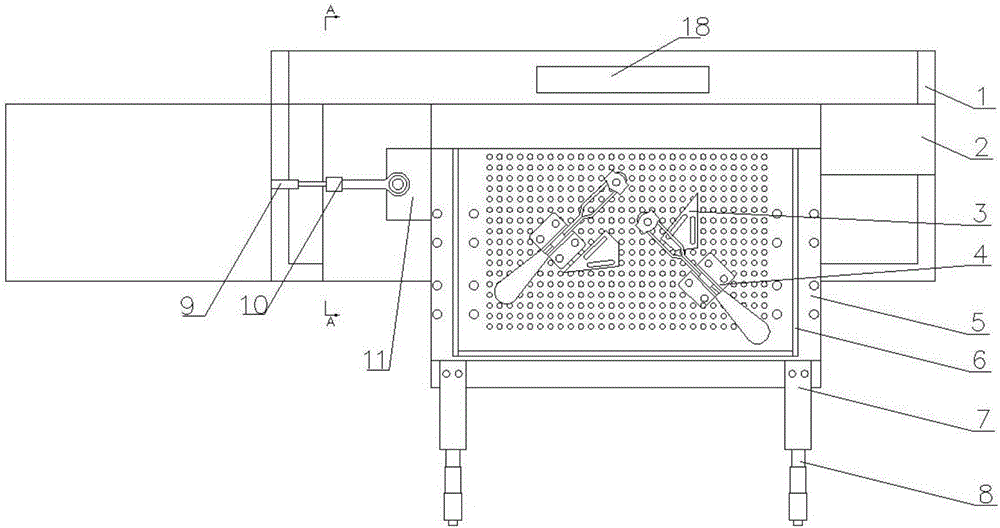

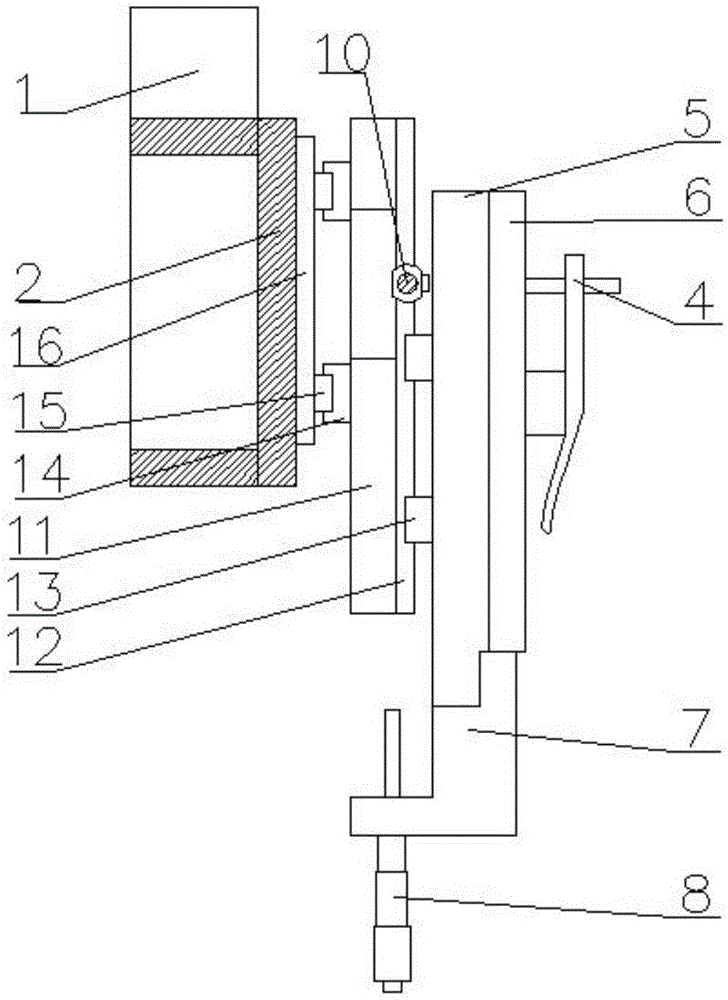

Semi-automatic chamfering machine

InactiveCN106217169AReduce work intensityRealize semi-automationEdge grinding machinesGrinding carriagesFixed frameMicrometer

The invention provides a semi-automatic chamfering machine. The semi-automatic chamfering machine comprises a base frame, a bottom plate, locating plates, locking pliers, a work table, micrometers, a motor, a movable sliding plate and an air cylinder, wherein the bottom plate is arranged on the base frame; a sliding rail fixing plate is installed on the bottom plate, a second sliding rail is arranged on the sliding rail fixing plate, a plurality of second sliding blocks are arranged on the second sliding rail, the movable sliding plate is connected to the second sliding rail through the second sliding blocks, a first sliding rail is arranged on the movable sliding plate, a plurality of first sliding blocks are arranged on the first sliding rail, and the air cylinder is arranged on one side of the first sliding rail; the motor is arranged on the left side of the base frame and is connected to the movable sliding plate through a pull rod; the work table is arranged on the first sliding blocks, the front side of the work table is connected to a micrometer fixing frame, and the micrometer fixing frame is provided with the micrometers; and a PLC is arranged inside the base frame. Compared with the prior art, the semi-automatic chamfering machine has the beneficial effects that propulsive assistance of the air cylinder replaces manual thrust, and the micrometers limit a jig so that accuracy control can be realized.

Owner:湖南晶讯光电股份有限公司

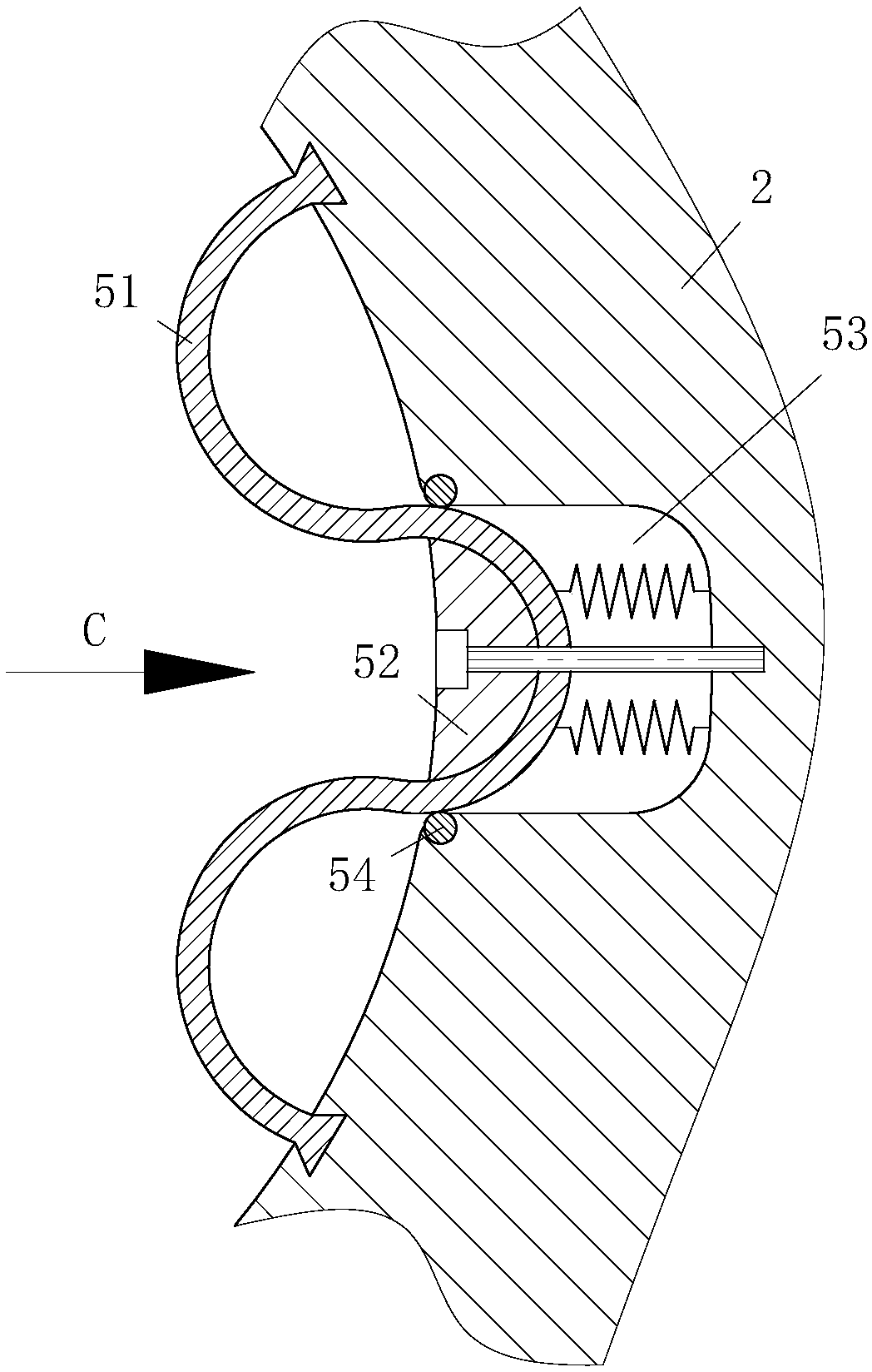

Bobbin chamfering device

InactiveCN109516296AImprove efficiencyImprove convenienceFilament handlingDirt cleaningBobbinEngineering

The invention provides a bobbin chamfering device. The bobbin chamfering device comprises a conveyor belt, wherein mounting blocks are symmetrically arranged at the two sides of the conveyor belt; a chamfering channel is arranged on the mounting blocks; the chamfering channel is positioned above the conveyor belt; the chamfering channel is wide in two sides and is narrow in middle; the chamferingchannel comprises an upper chamfering plate and a lower chamfering plate; the two sides of each of the upper chamfering plate and the lower chamfering plate are arc-shaped; more than one rotary plateis arranged on the conveyor belt; a bobbin placing frame is arranged on the rotary plate; a movable empty slot is formed in the middle of the lower chamfering plate; and the bobbin placing frame passes through the movable empty slot and extends into the chamfering channel. According to the bobbin chamfering device provided by the invention, the upper chamfering plate and the lower chamfering plateare combined into the chamfering channel, so that chamfering is performed in a bobbin conveying process; and meanwhile, multiple bobbins can be chamfered at the same time, so that chamfering efficiency is improved, and therefore, the bobbin chamfering device is suitable for being used in production.

Owner:WUHU FUCHUN DYEING & WEAVING

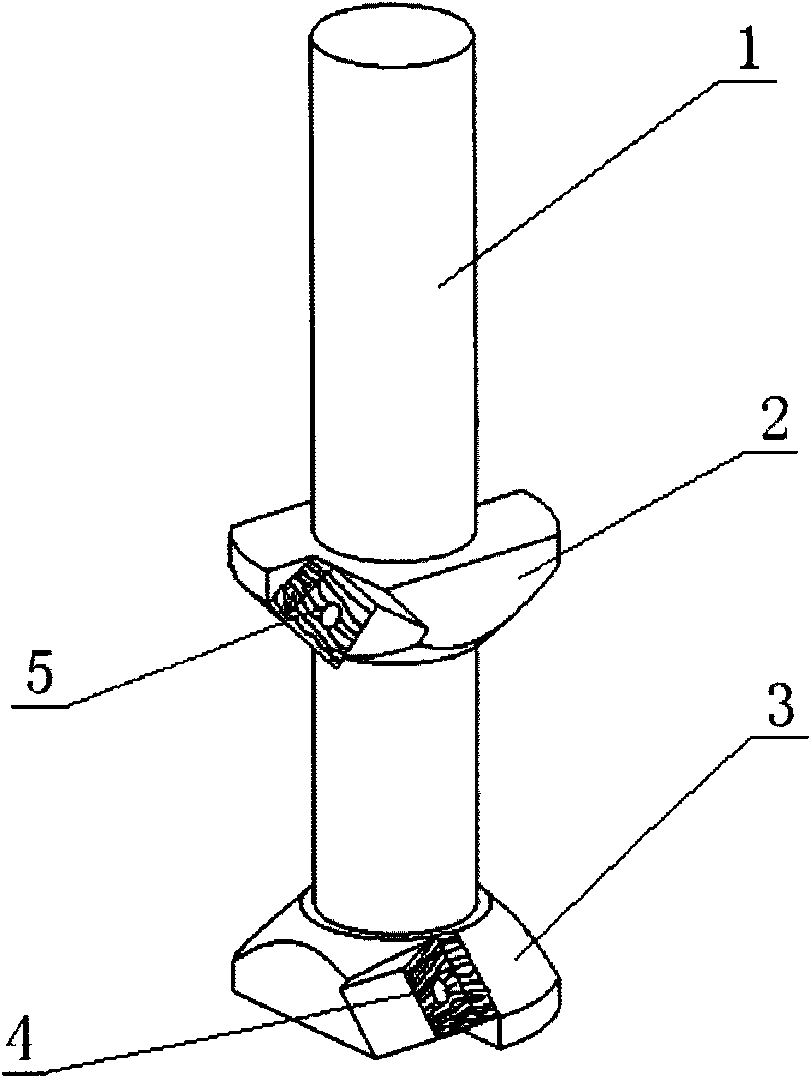

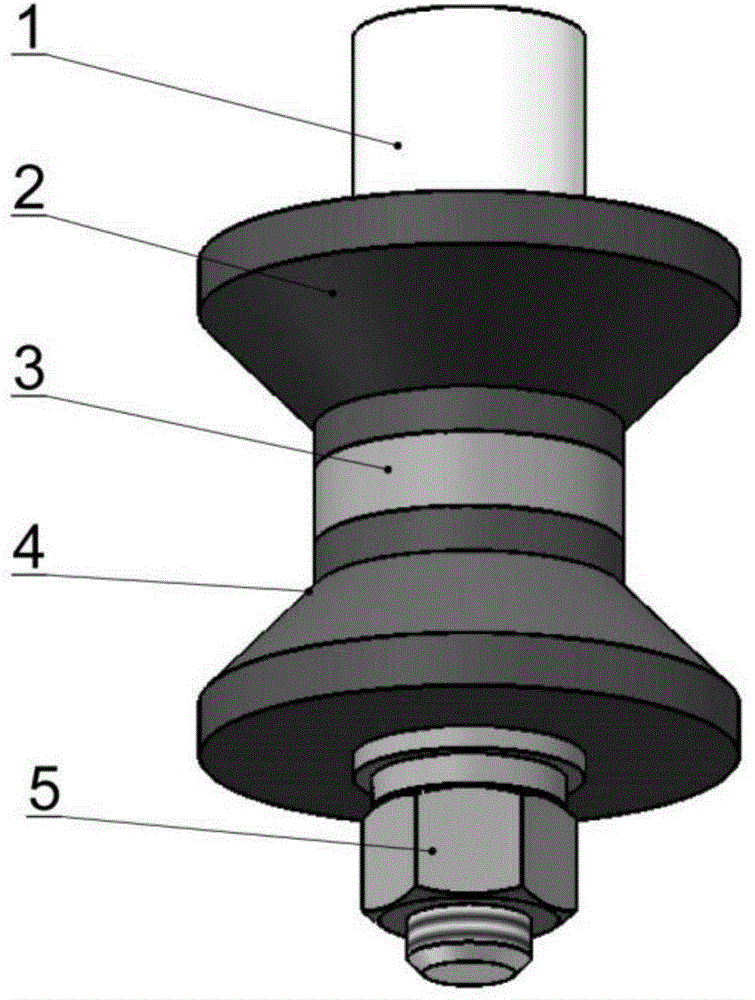

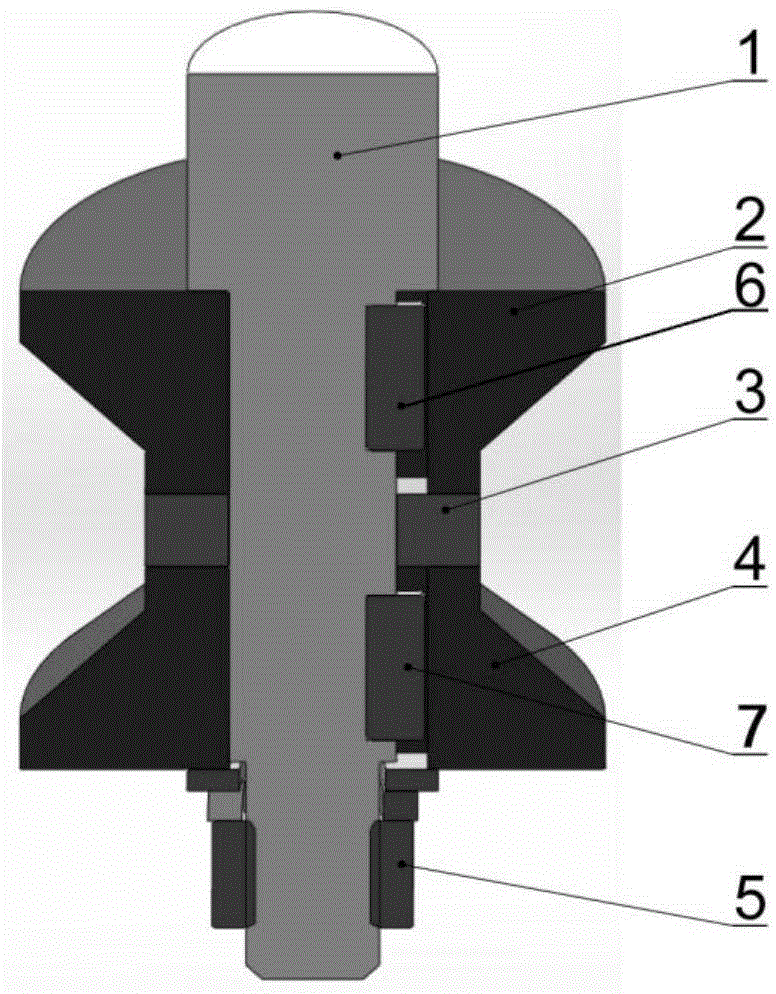

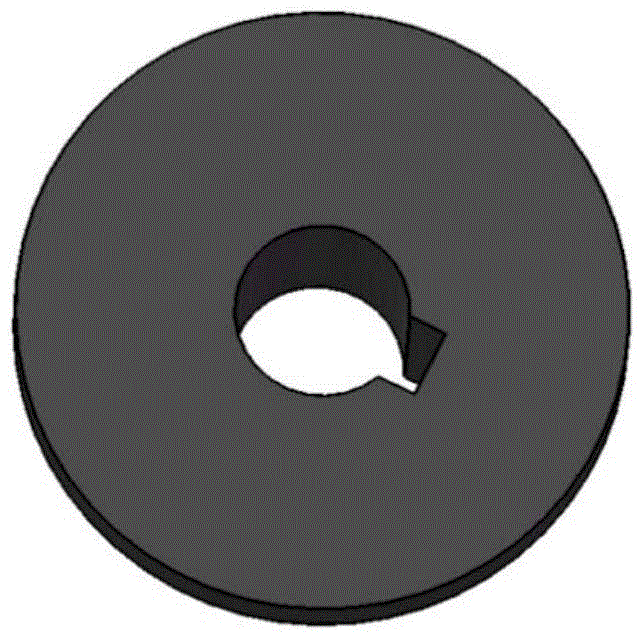

Adjustable double-sided chamfering tool for optical element

InactiveCN104589206AImprove chamfering efficiencySimple structureEdge grinding machinesGrinding headsEngineeringGasket

The invention discloses an adjustable double-sided chamfering tool for an optical element. The adjustable double-sided chamfering tool comprises a dead axle, an upper forming grinding wheel, a lower forming grinding wheel, an upper flat key, a lower flat key, a grinding wheel gasket and a fastening nut. The adjustable double-sided chamfering tool disclosed by the invention can be used for performing double-side chamfering on the optical element; the tool has the advantages that the structure is simple; the operation is convenient, stable and reliable; not only is the processing quality ensured and the chamfering consistency is high but also the chamfering efficiency of the optical element is greatly increased and the labor cost is reduced.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

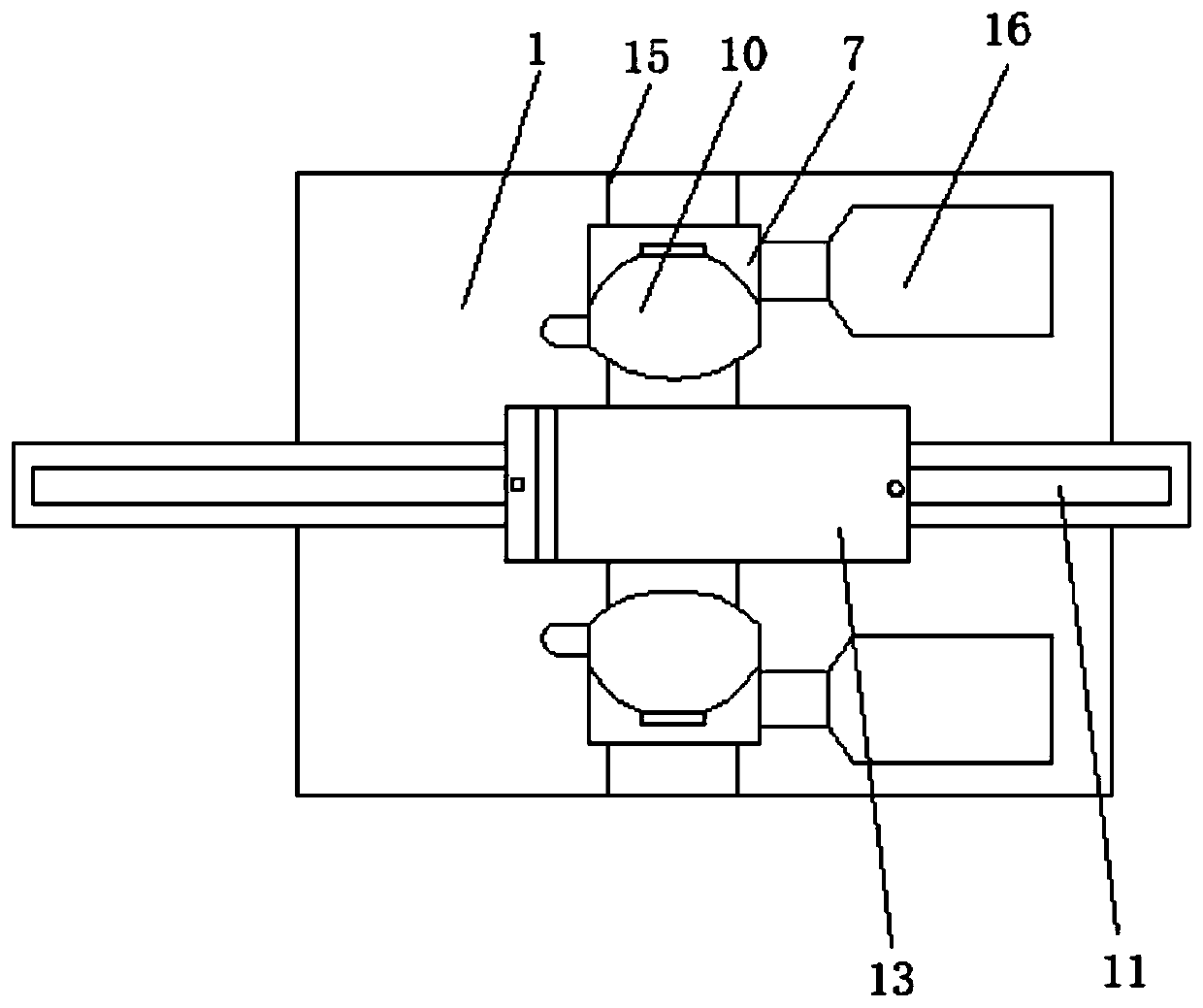

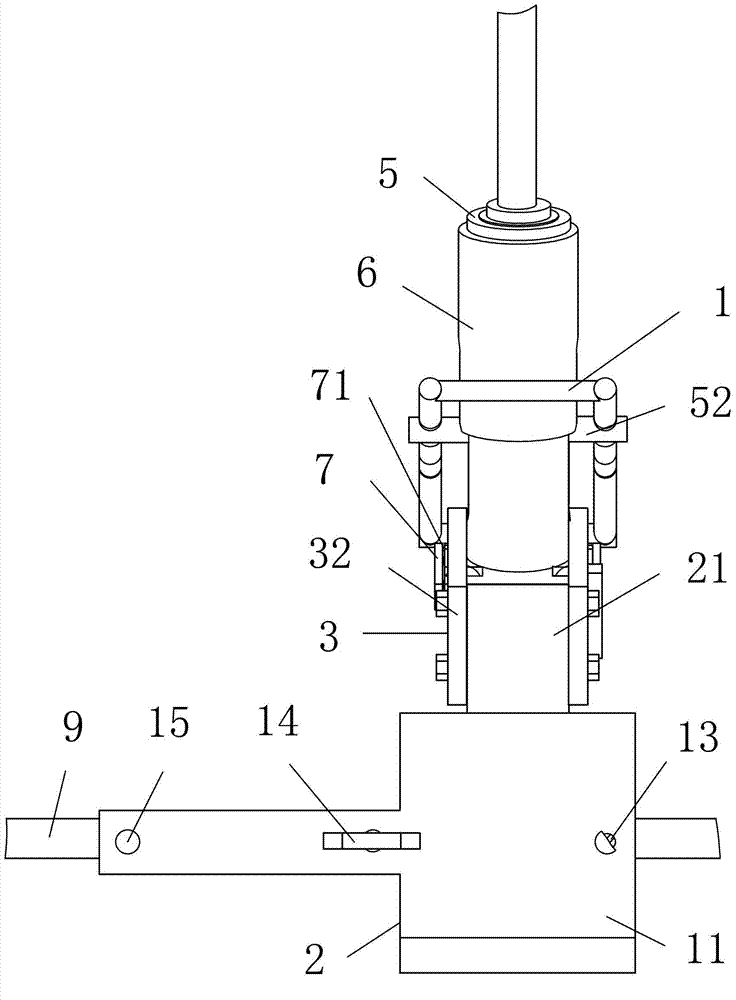

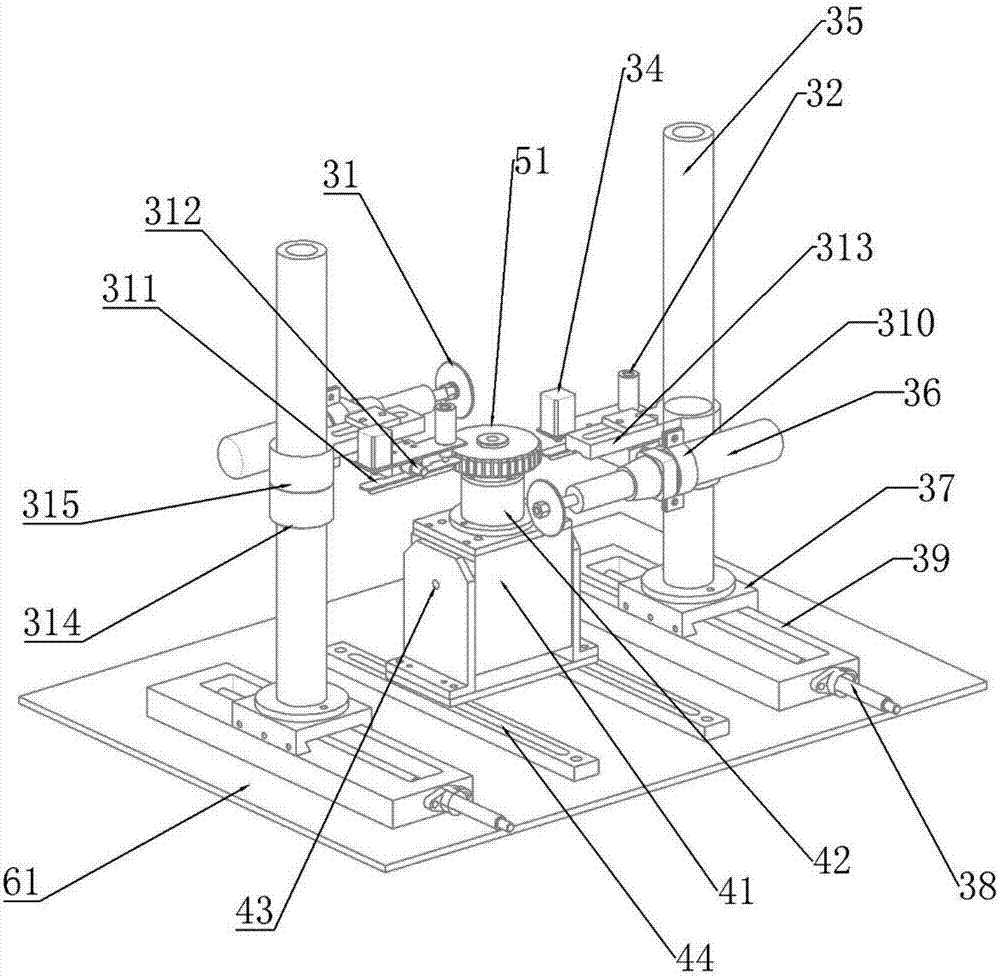

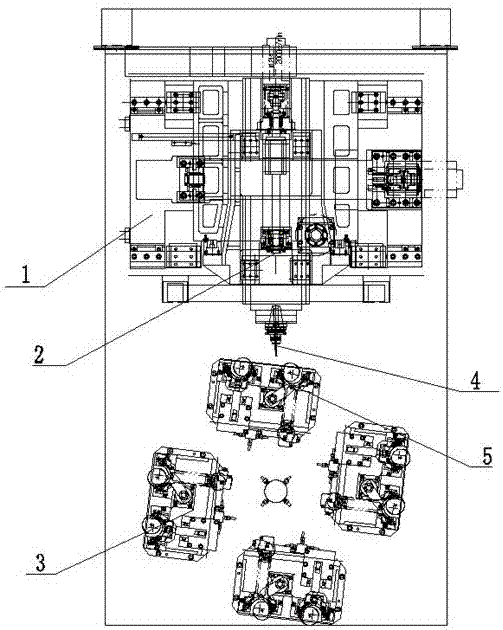

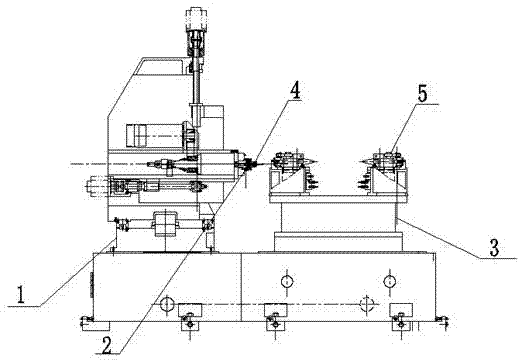

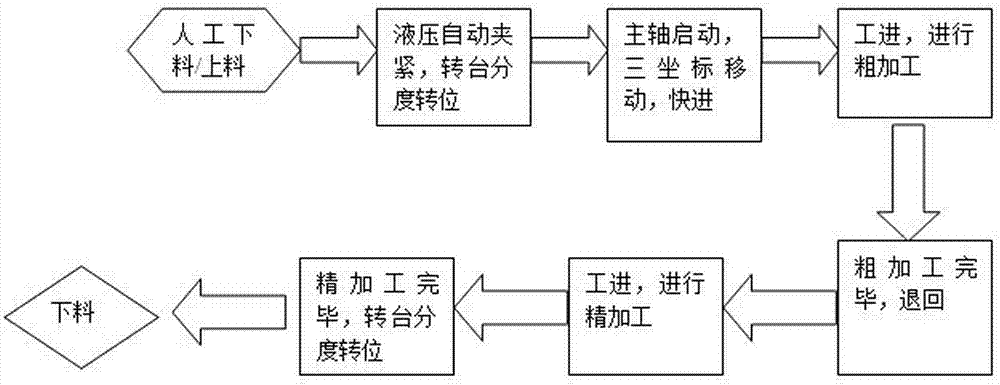

Chamfering machining equipment and chamfering machining method for curved surfaces of orifices of oil holes of connecting rods

PendingCN107127381AImprove chamfering efficiencyHigh chamfering precisionMilling equipment detailsMilling cutterSurface roughness

The invention discloses chamfering machining equipment and a chamfering machining method for curved surfaces of orifices of oil holes of connecting rods, and relates to the field of machining technologies for connecting rods of engines. The chamfering machining equipment comprises a horizontal three-coordinate driving mechanism, a servo spindle driving mechanism and an indexing worktable. The servo spindle driving mechanism is arranged on the horizontal three-coordinate driving mechanism and can be driven by the horizontal three-coordinate driving mechanism to move, a milling cutter shank is arranged at an end of the servo spindle driving mechanism, and a milling cutter is fixed onto the milling cutter shank. The chamfering machining equipment and the chamfering machining method for the curved surfaces of the orifices of the oil holes of the connecting rods have the advantages that the chamfering efficiency and the precision of the profile tolerance of the machined curved surfaces can be improved, and the chamfering consistency and the surface roughness can be enhanced.

Owner:四川普什宁江机床有限公司

Neodymium iron boron magnet chamfering device

ActiveCN109176202AIncrease widthEasy feedingEdge grinding machinesGrinding carriagesBelt conveyorElectromagnet

The invention discloses a neodymium iron boron magnet chamfering device which comprises a ribbon conveyer. A feeding area, a chamfering area and an unloading area are successively arranged from left to right on a rack on the upper part. Electromagnets are separately arranged on two sides of the racks of the feeding area and the unloading area. Pairs of blind slots are formed in a spaced manner along the length direction of a belt of the ribbon conveyor, and the any pair of blind slots is symmetrically formed along the width direction of the belt; the device also comprises a bump and pairs of adjusting rods, any pair of adjusting rods comprises two integrally formed L-shaped rods, the horizontal rods are above, the free ends of the horizontal rods are arranged outward, an elastic plate strip is connected between the free ends of two adjacent horizontal rods, vertical rods are arranged downward, and permanent magnets attractive to the electromagnets magnetically are arranged on the outersides of the free ends of the vertical rods. The device also comprises pairs of springs, any spring is arranged in each blind slot, one end of the spring is connected to the inner end surface of eachblind slot, and the other end is connected to the inner side of the free end of each vertical rod. The neodymium iron boron magnet chamfering device has the advantages of being convenient to feed anddischarge, good in chamfering quality, high in work efficiency and the like.

Owner:京磁材料科技股份有限公司

Portable wood board side edge chamfering equipment

ActiveCN110561220AAdjustable chamfer angleSmooth chamferEdge grinding machinesGrinding carriagesDrive motorEngineering

The invention relates to chamfering equipment, in particular to portable wood board side edge chamfering equipment. The portable wood board side edge chamfering equipment is capable of saving labor, stable in movement, neat in chamfering and symmetrical. According to the technical scheme, the portable wood board side edge chamfering equipment comprises a mounting box, an observation window, a connecting frame, an arc-shaped sliding rail, a first sliding block, a first rotating shaft, a first guide sleeve and the like, wherein the observation window is arranged on the upper portion of the frontside of the mounting box, and an operation hole is formed in the middle of the front side of the mounting box. According to the equipment, a moving device is used for driving left and right first guide rails to move inwards or outwards, so that left and right first connecting blocks are driven to move outwards or inwards, the lower parts of left and right grinding wheels are enabled to swing outwards or inwards, a chamfering angle of the side edge of a wood board can be adjusted, a driving motor drives the grinding wheels to rotate, so that the side edge of the wood board can be chamfered, chamfering is not needed to be conducted by manually pushing a plane, so that manpower can be saved, and the chamfering efficiency is high.

Owner:江西启来标识有限公司

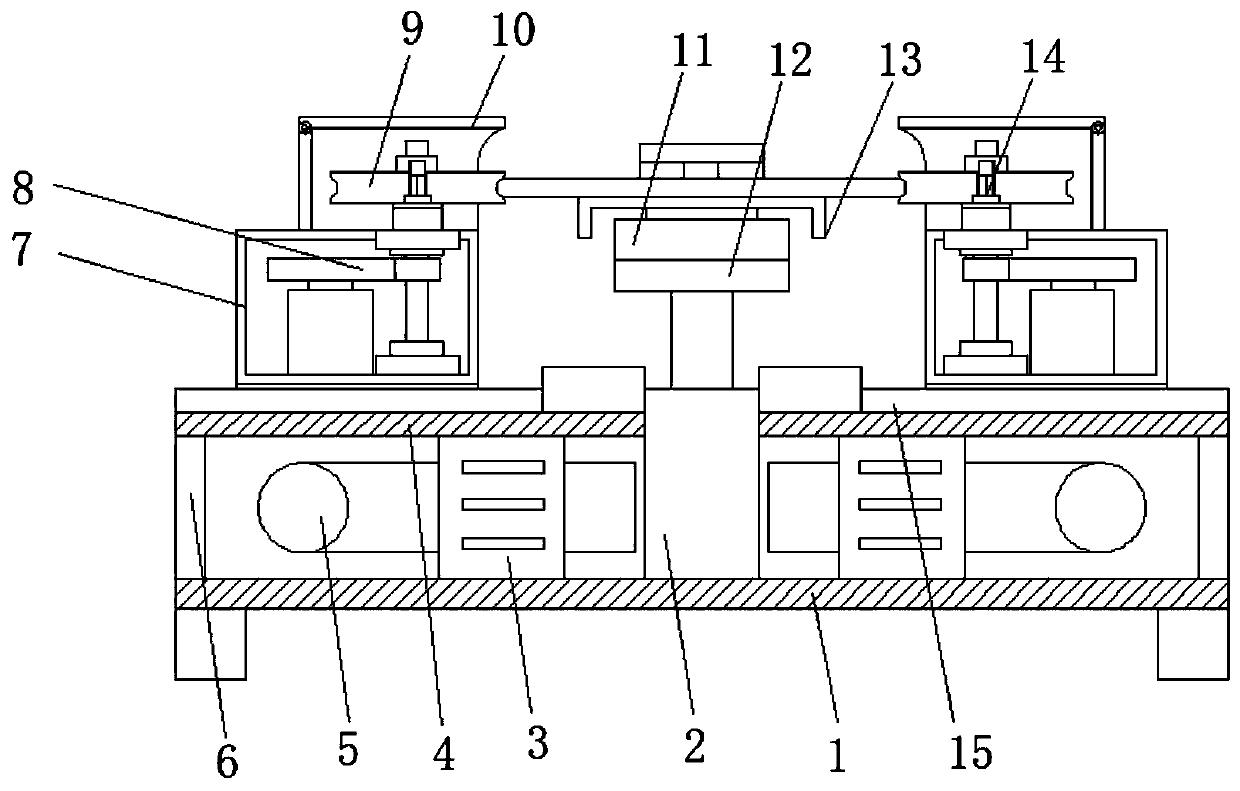

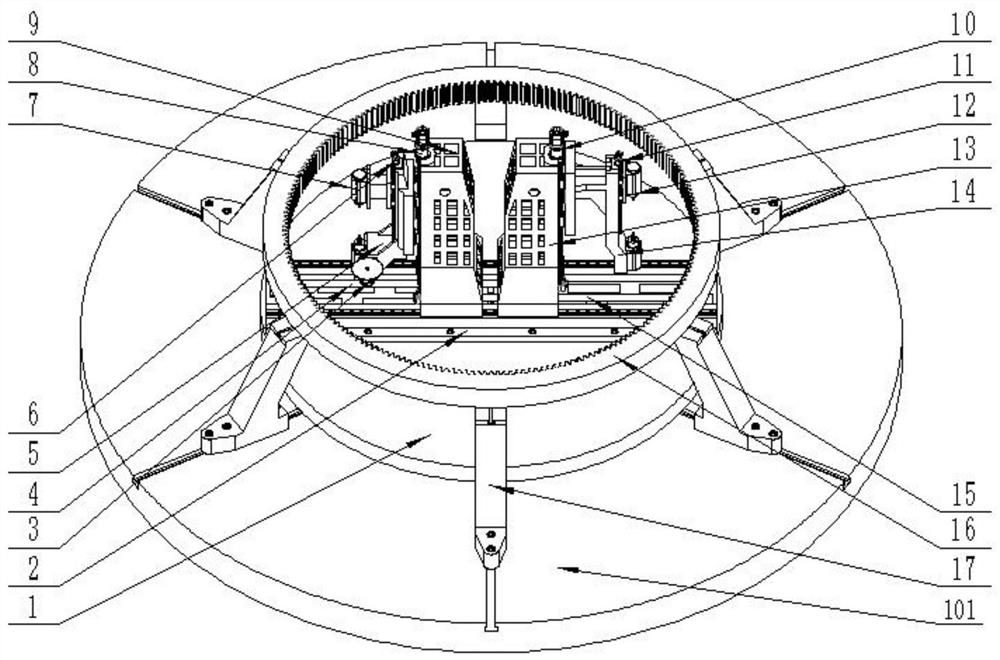

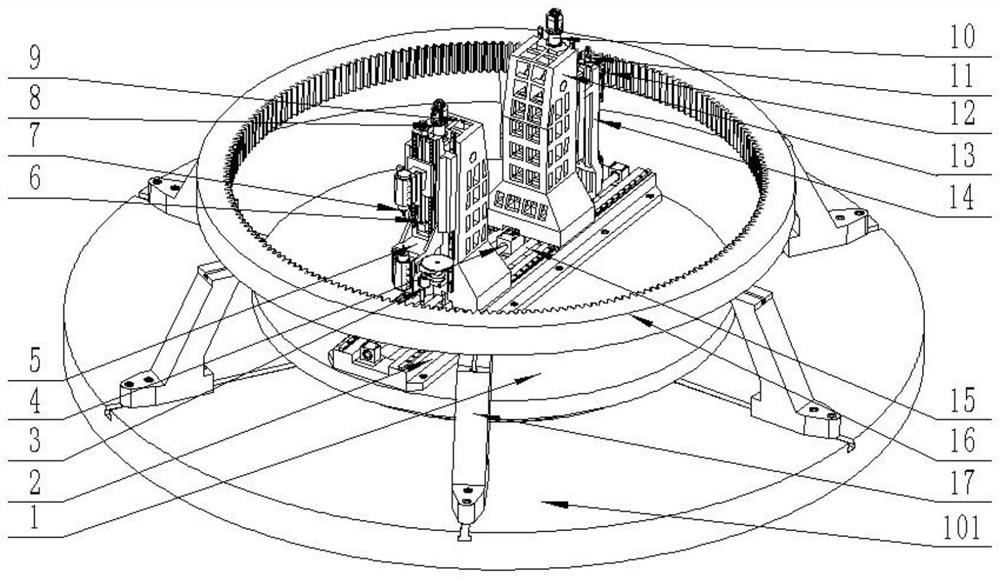

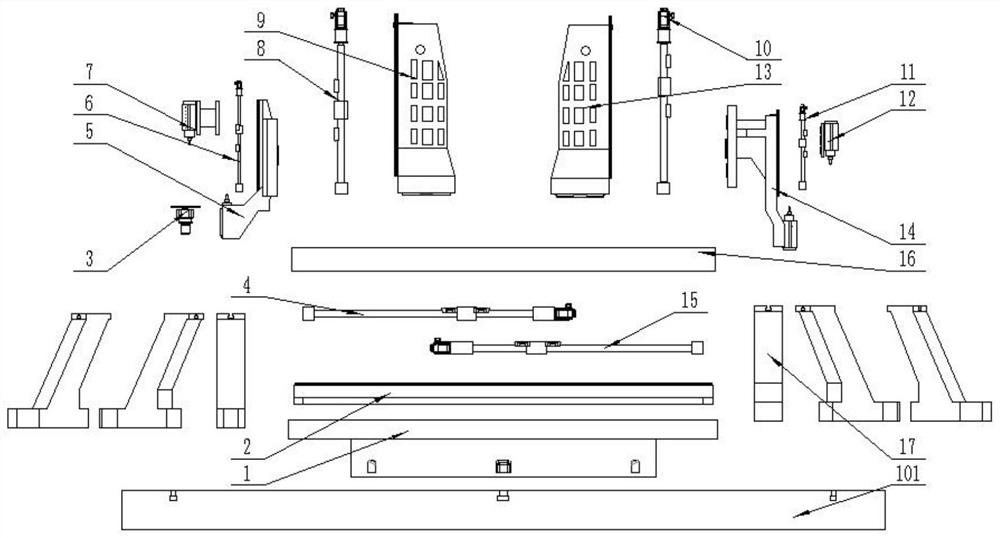

Double-end-face numerical control chamfering machine tool and method for ultra-large internal tooth gear

PendingCN112404606ASmall footprintSolve the problem that workers can only use manual chamferingGear-cutting machinesGear teethNumerical controlMilling cutter

The invention discloses a double-end-face numerical control chamfering machine tool and method for an ultra-large internal tooth gear. The machine tool comprises a numerical control rotary table, a horizontal radial sliding table, a first stand column, a second stand column, a Y1 tool rest assembly, a Y2 tool assembly, a Y3 tool rest assembly, a Y4 tool assembly, an X1-axis radial feeding system,an X2-axis radial feeding system, a Y1-axis vertical feeding system, a Y2-axis vertical feeding system, a Y3-axis vertical feeding system, a Y4-axis vertical feeding system, a steel brush deburring system and workpiece supports. According to the double-end-face numerical control chamfering machine tool, the motion mode that a workpiece is fixed and the machine tool does rotary motion is adopted, the occupied area of the numerical control machine tool for chamfering an ultra-large gear is greatly reduced, simultaneous chamfering of the end faces of the two sides of the ultra-large internal tooth gear is achieved through a hard alloy milling tool rotating at a high speed, chamfers are adjustable in size and shape, the sizes of the chamfers are consistent, tooth grooves are automatically centered, and deburring and polishing work can be carried out on tooth roots, tooth tops and other parts. The machine tool is innovative in structure, low in manufacturing cost and high in automation degree.

Owner:NANJING UNIV OF TECH +1

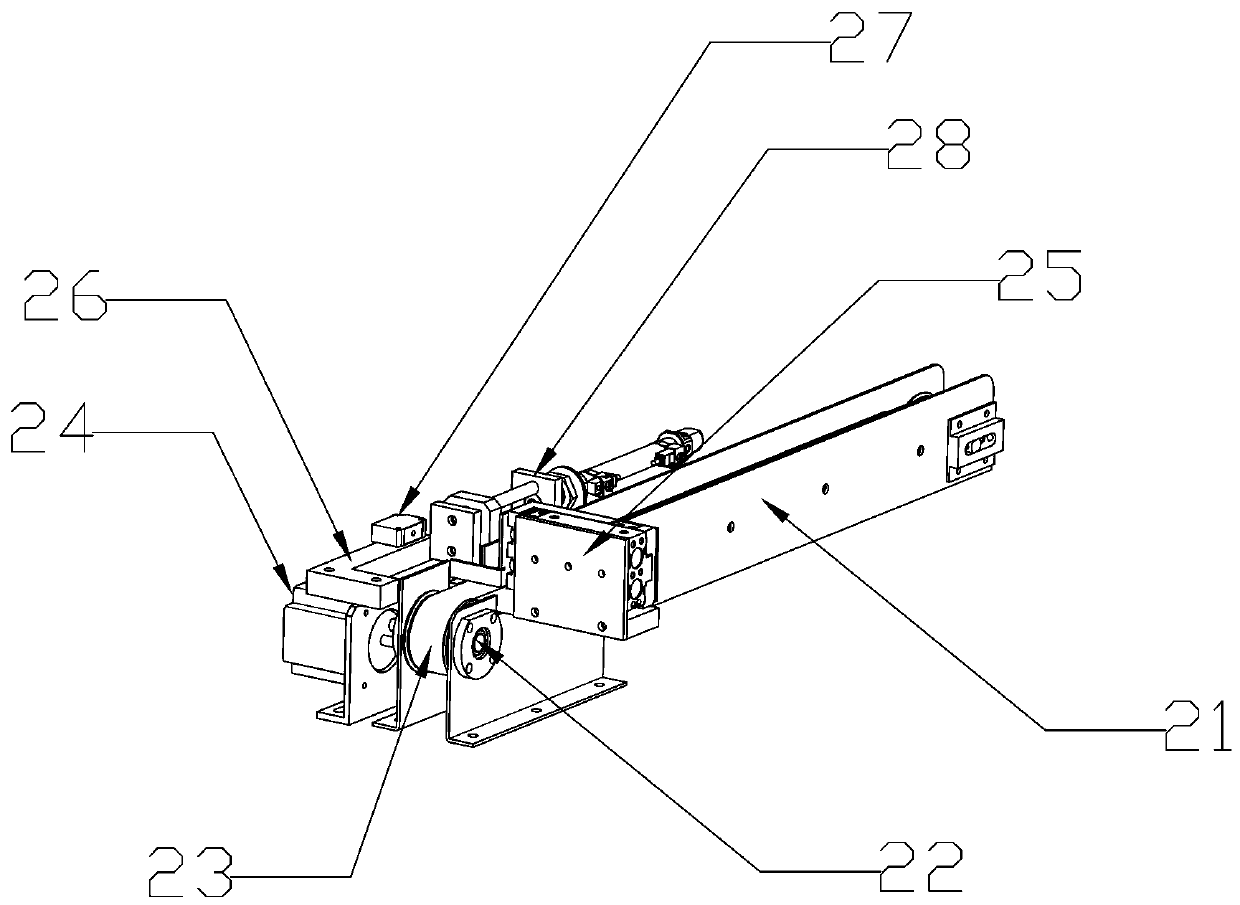

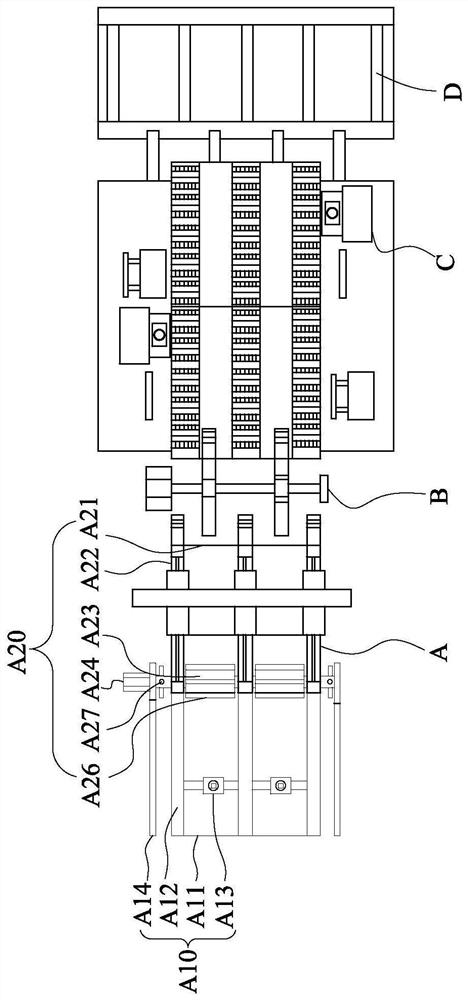

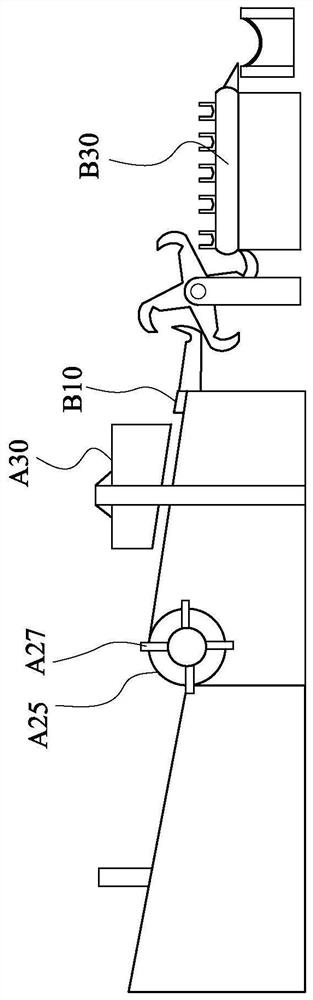

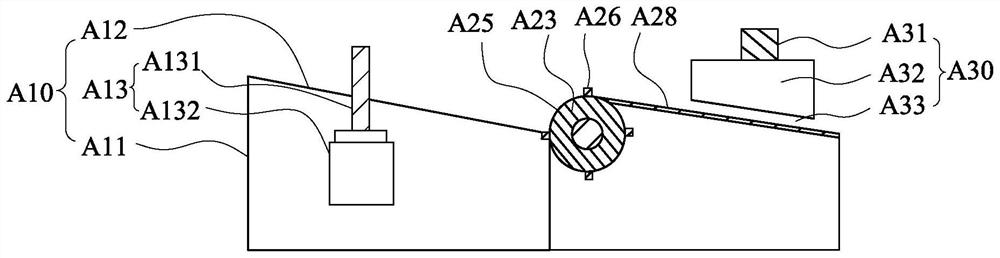

Full-automatic bidirectional chamfering system for end part of steel bar, and working method thereof

A full-automatic bidirectional chamfering system for the end part of a steel bar comprises a steel bar feeding mechanism, a steel bar turnover and transfer mechanism arranged on one side of the steelbar feeding mechanism, a steel bar bidirectional chamfering mechanism arranged on one side, far away from the steel bar feeding mechanism, of the steel bar turnover and transfer mechanism, and a steelbar discharging mechanism arranged on one side, far away from the steel bar turnover and transfer mechanism, of the steel bar bidirectional chamfering mechanism. The steel bar feeding mechanism can transfer the steel bar to the steel bar turnover and transfer mechanism, the steel bar turnover and transfer mechanism transfers the steel bar to the steel bar bidirectional chamfering mechanism, and the steel bar bidirectional chamfering mechanism transfers the steel bar to the steel bar discharging mechanism after finishing machining. The full-automatic bidirectional chamfering system for the endpart of the steel bar is high in automation degree, conveying stability is enhanced, and working efficiency is improved.

Owner:俊钛金属材料(浙江)有限公司

Gear ring end face chamfering device

InactiveCN113334173AReduce workloadEasy to use for chamferingEdge grinding machinesGrinding work supportsGear wheelControl engineering

The invention discloses a gear ring end face chamfering device. The gear ring end face chamfering device comprises a base and a grinding machine, a servo motor is installed in the middle of the lower end face of the base, a rotary table is installed at the position, located above the base, of the top of the servo motor, a double-shaft motor is installed in the middle of the inner side of the rotary table, the two ends of the double-shaft motor are in transmission connection with studs, two sets of second screw sleeves symmetrically sleeve the studs, sliding blocks are installed on the outer parts of the two sets of second screw sleeves, and inner supporting frames are fixedly connected to the top ends of the two sets of sliding blocks. According to the gear ring end face chamfering device, firstly, an inner supporting type clamping structure is adopted, automatic inner supporting and clamping treatment of a gear can be achieved, the workload of operators is reduced, the convenience of gear clamping operation is improved, and therefore chamfering machining and using of a gear disc are facilitated; and secondly, a double-face synchronous chamfering structure is adopted, synchronous chamfering treatment of the double faces of the gear can be achieved, the convenience of gear chamfering operation improved, and meanwhile, the efficiency of gear chamfering machining is improved.

Owner:湖南恒裕汽车零部件有限公司

Small plate table type chamfering machine

InactiveCN105414618AStable jobReduce labor intensityMilling equipment detailsMilling cutterAgricultural engineering

The invention relates to a small plate table type chamfering machine. The small plate table type chamfering machine comprises a frame, a motor, milling cutters, a cutter cover, a replaceable cushion block, an adjustable cushion plate, a support plate and a backup plate. The motor is arranged below a tabletop of the frame; an output shaft of the motor is connected with a main shaft; the other end of the main shaft upwards perpendicularly penetrates through the tabletop of the frame to be connected with the milling cutters; the backup plate is movably fixed at the right side end of the support plate on the tabletop of the frame; the two milling cutters are movably mounted on the main shaft; the replaceable cushion block is arranged between the upper and lower milling cutters; and the adjustable cushion plate is arranged at the bottom of the lower milling cutter. The invention discloses the novel small plate table type chamfering machine with stable work, low labor intensity, environmental protection, high chamfering efficiency, good quality, simple and safe operation and adjustable chamfered corners.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Integrated double-sided chamfering device for circular glass

InactiveCN108555724AAvoid wastingSimple structureEdge grinding machinesGrinding/polishing safety devicesAcute angleDrive shaft

The invention provides an integrated double-sided chamfering device for circular glass. The integrated double-sided chamfering device for the circular glass comprises a chamfering bracket, and a chamfering motor is fixed to the chamfering bracket. A chamfering driving shaft is connected with the output end of the chamfering motor, two driving bevel gears are fixed on the chamfering driving shaft,and a driven grinding cutter assembly is connected with each driving bevel gear. The driven grinding cutter assemblies comprise middle-passing driven shafts, the middle-passing driven shafts and the chamfering driving shaft form an acute angle, and driven bevel gears are fixed outside the middle-passing driven shafts. A grinding cutter is fixed at one end of each middle-passing driven shaft, and awater pipe is arranged at the other end of each middle-passing driven shaft. A water outlet hole is formed in the center of each grinding cutter, and the water pipes are connected with a water supplyassembly. A glass rotating mechanism is arranged at one side of the chamfering bracket. According to the integrated double-sided chamfering device for the circular glass, the circular glass can be chamfered, both sides of the glass can be processed at the same time, all chamfering processing is completed by one process, the chamfering efficiency is high, and the grinding processing place is washed and cooled while the chamfering is carried out.

Owner:DONGGUAN TAISHENG GLASS CO LTD

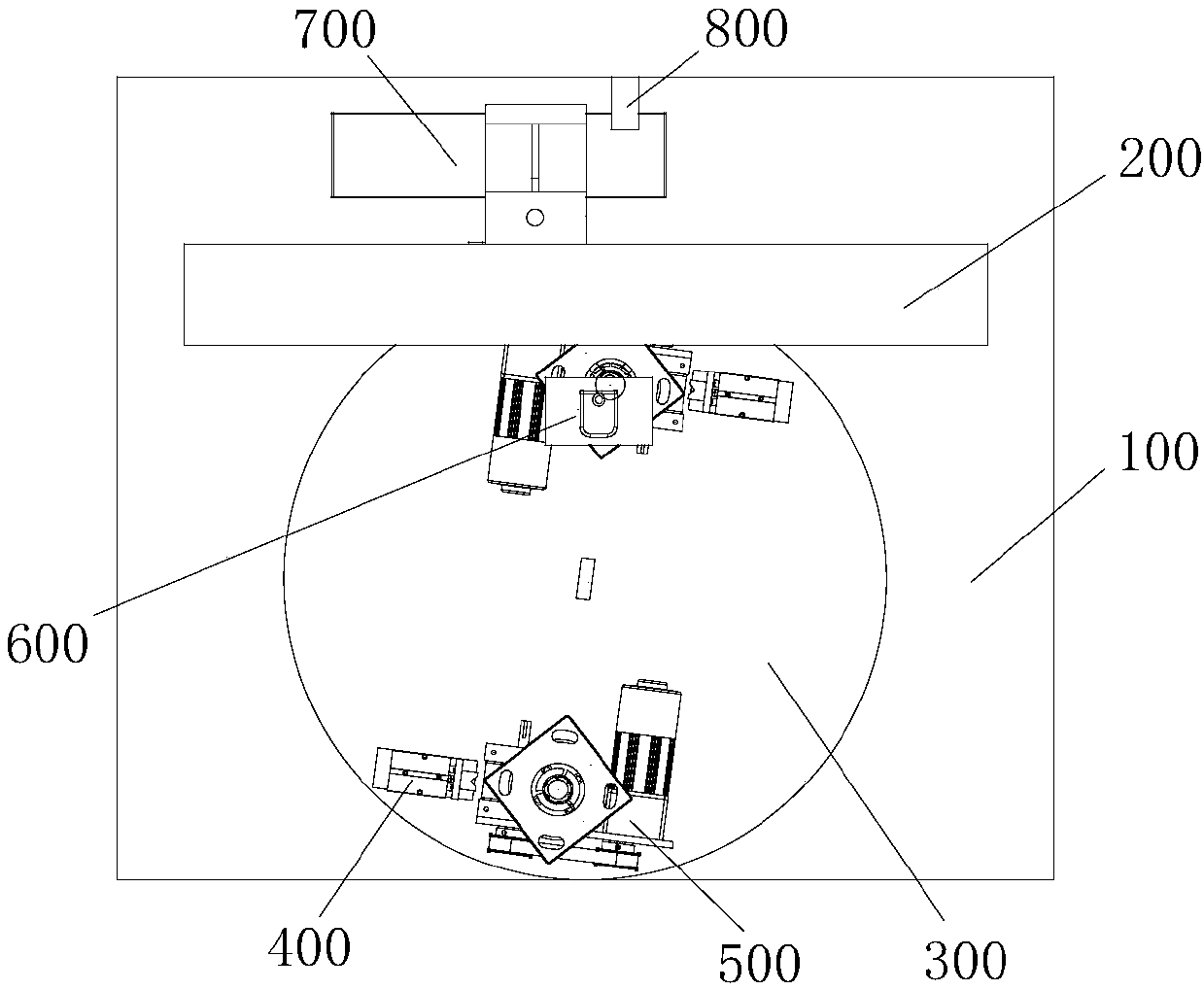

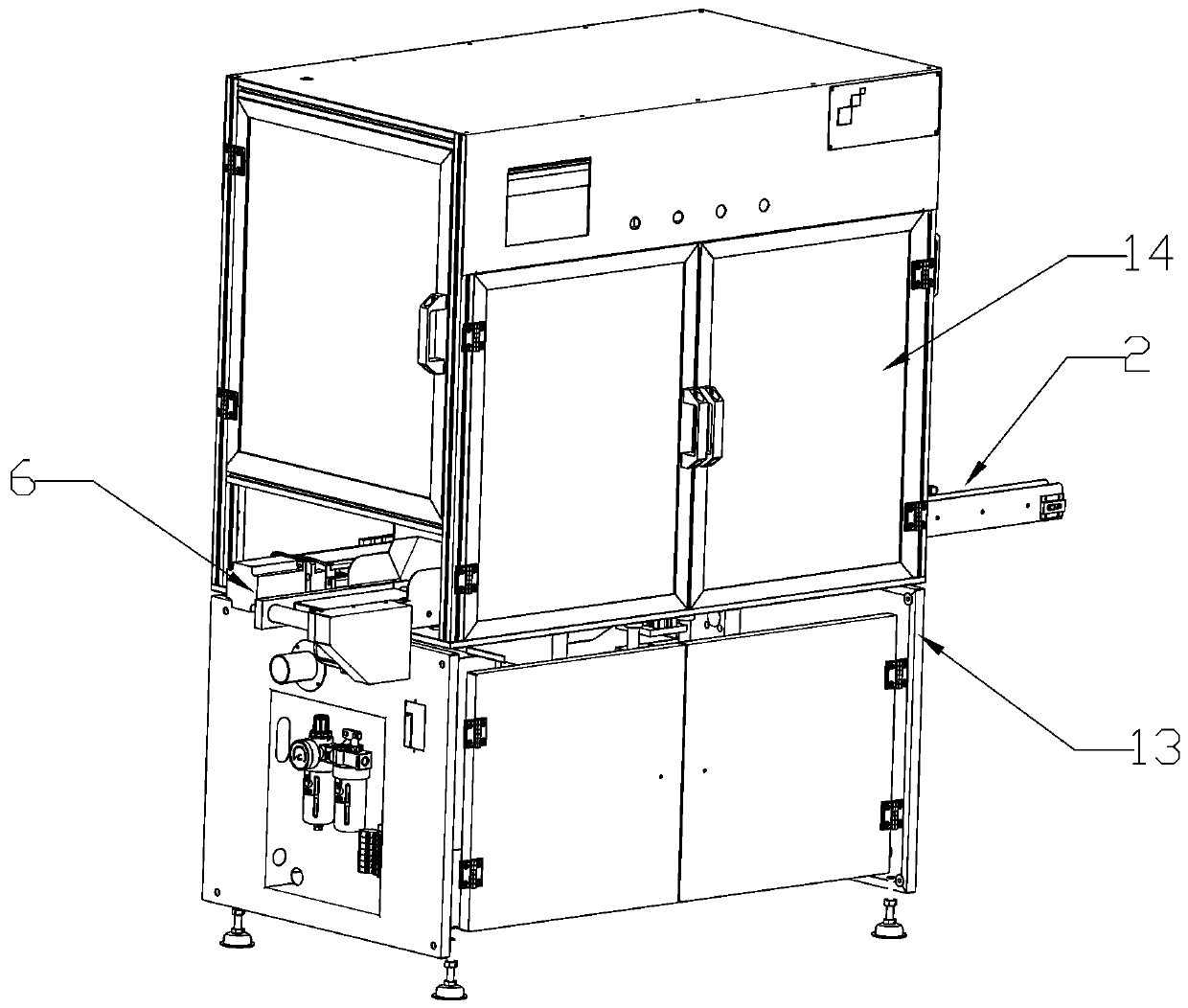

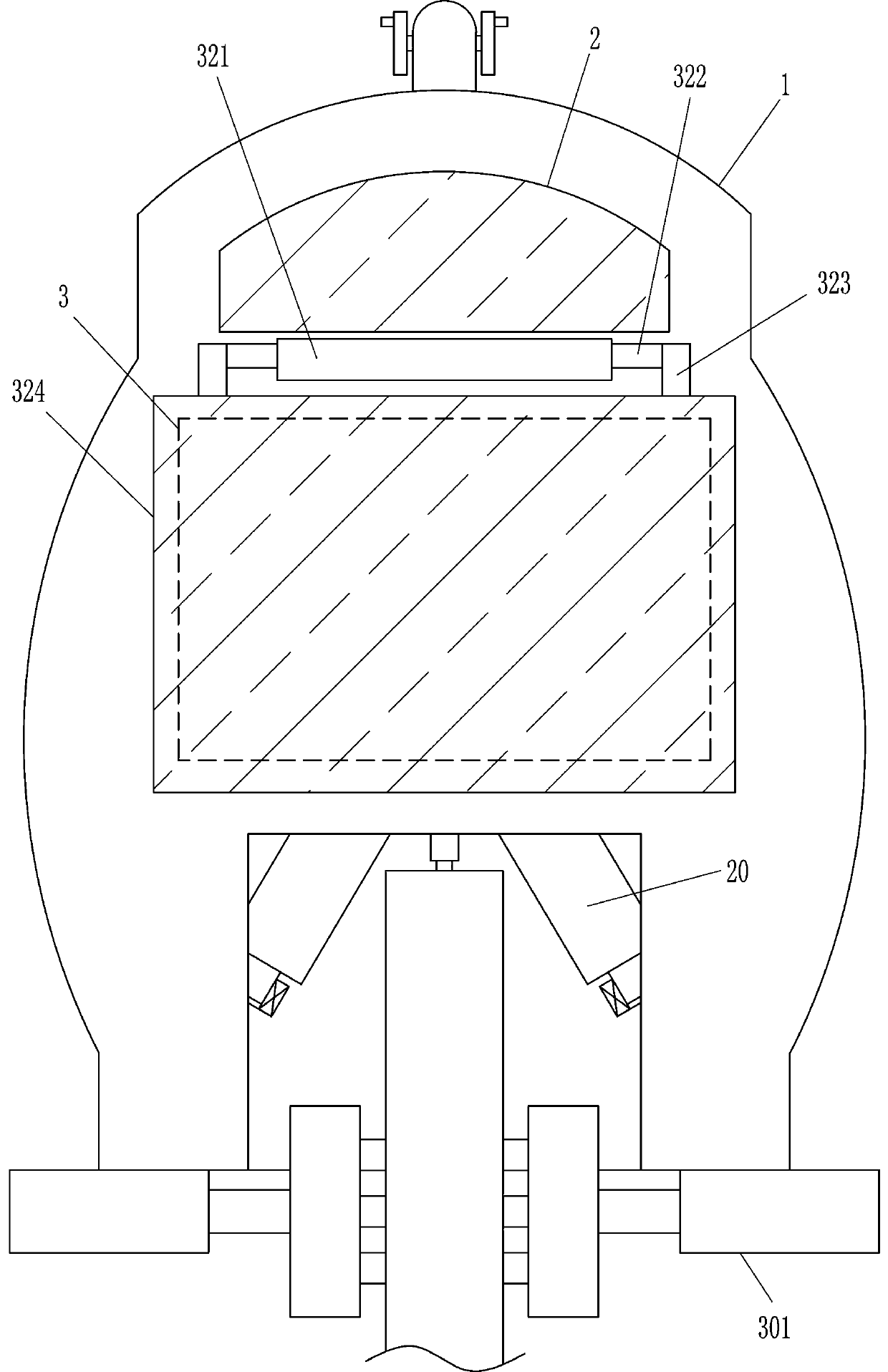

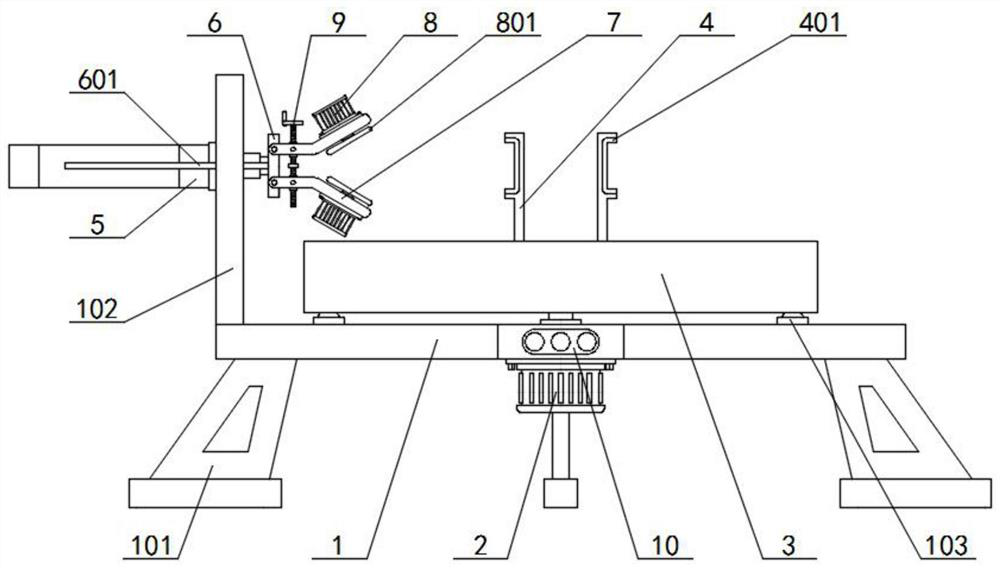

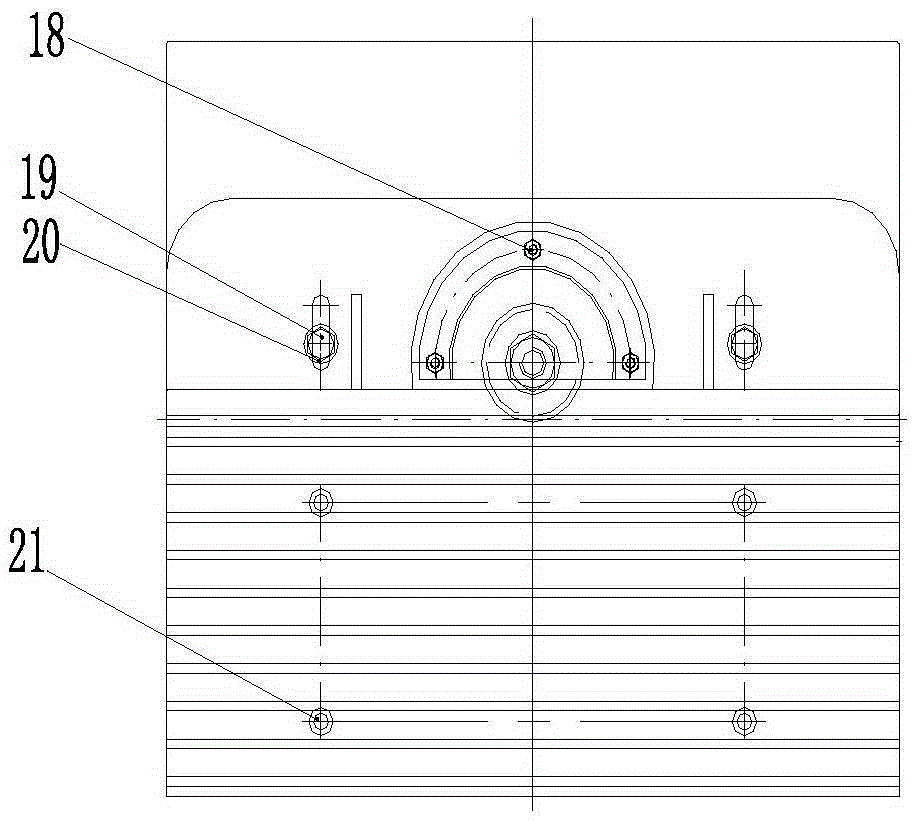

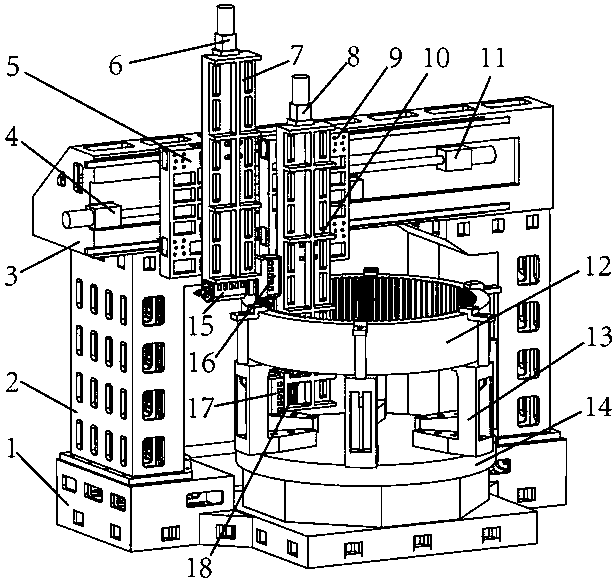

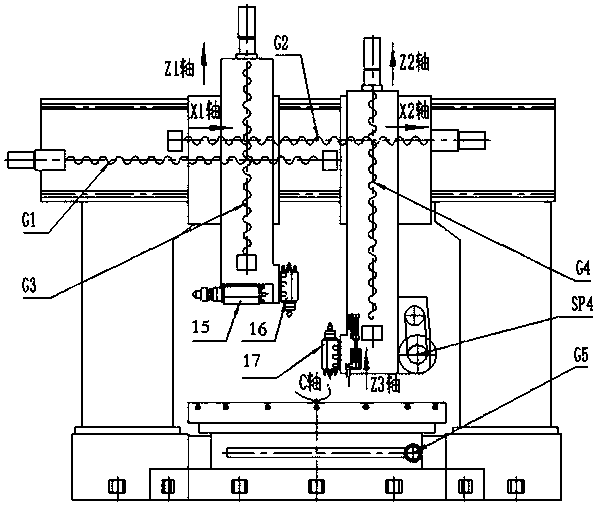

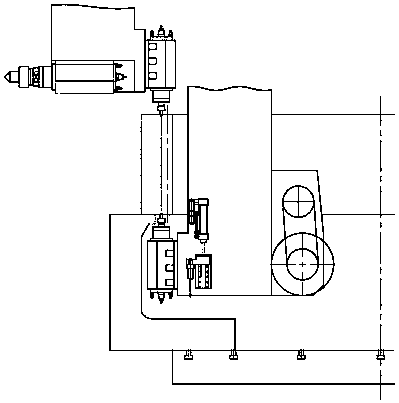

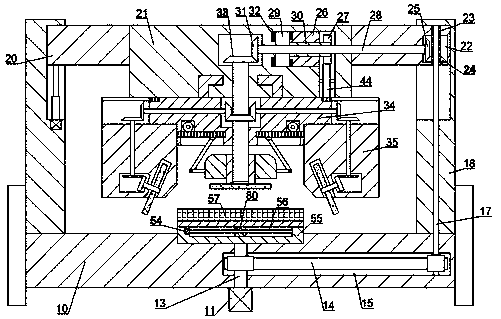

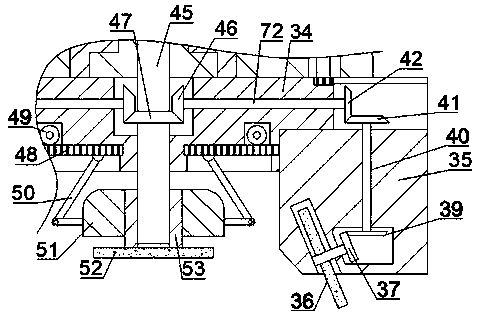

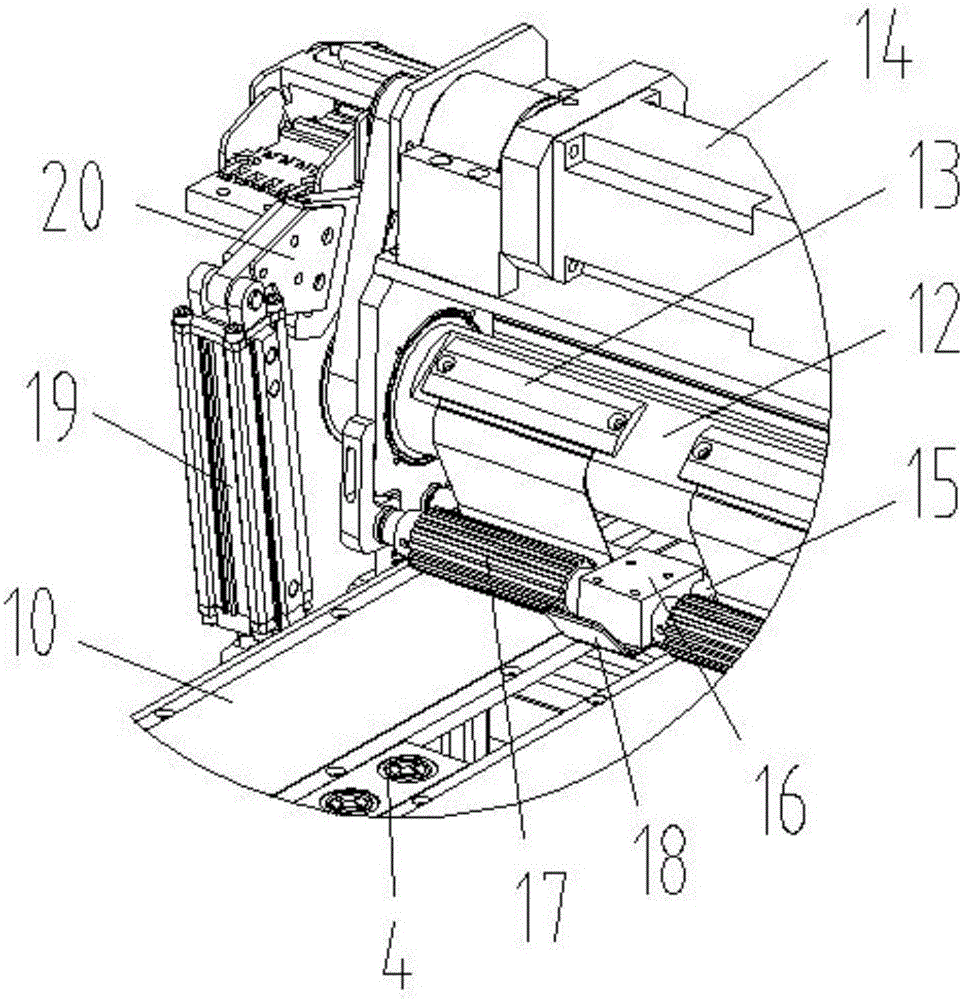

Large gantry polar coordinate CNC gear compound chamfering machine tool

ActiveCN106825786BImprove chamfering efficiencyShape adjustableLarge fixed membersGear teethNumerical controlMilling cutter

The invention discloses a large-size gantry polar coordinate numerical control gear compound chamfering machine tool. Based on a polar coordinate machining theory and a numerical control enveloping principle, compound chamfering of the end surfaces of the two sides of a tooth profile of an inner / outer straight / helical gear and simultaneous chamfering of the two sides in a tooth direction are realized by utilizing a hard alloy mill tool which rotates at a high speed; burs of tooth roots and edges and corners can be polished. The compound chamfering machine tool mainly comprises a machine tool body (1), an upright post (2), a cross beam (3), a rotary working table (14), an X1 axial and radial feeding system (4), an X2 axial and radial feeding system (11), a Z1 axial feeding system (6), a Z2 axial feeding system (8), a C shaft transmission worm gear pair (G5), a polishing wheel (SP4), a Z3 axial online probe system (18) and a chamfering main shaft system. The compound machine tool disclosed by the invention has the distinctive advantages that all chamfers in the tooth profile and the tooth direction can be completed by clamping a workpiece once; the sizes and the shapes of the chamfers are adjustable; the chamfer sizes are consistent; tooth grooves are centred automatically; the automation degree is high; the chamfering efficiency of a gear is improved.

Owner:NANJING GONGDA CNC TECH

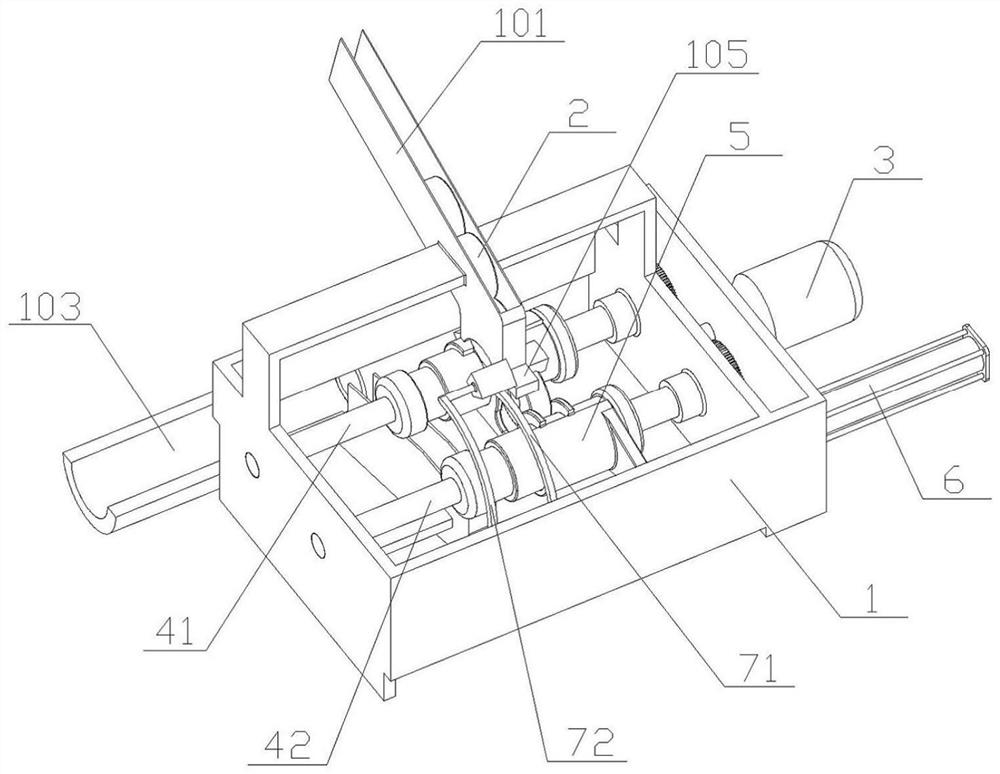

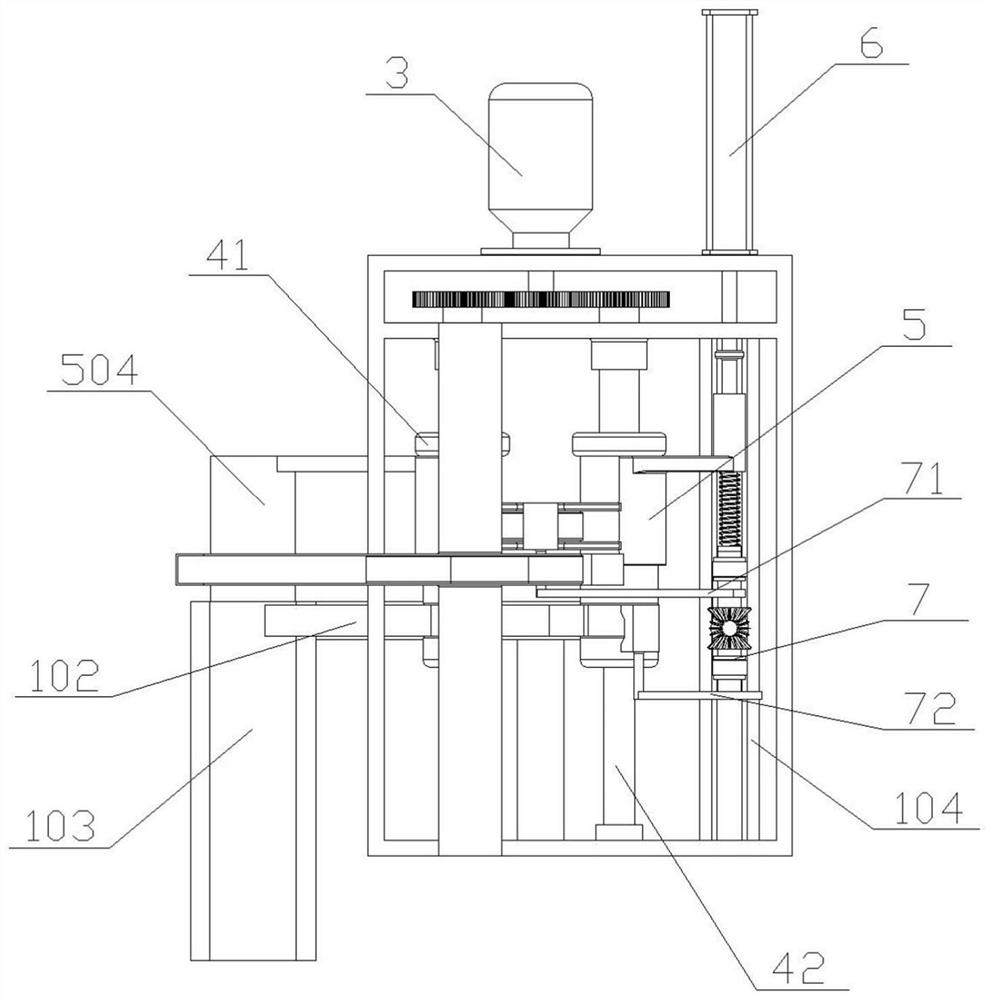

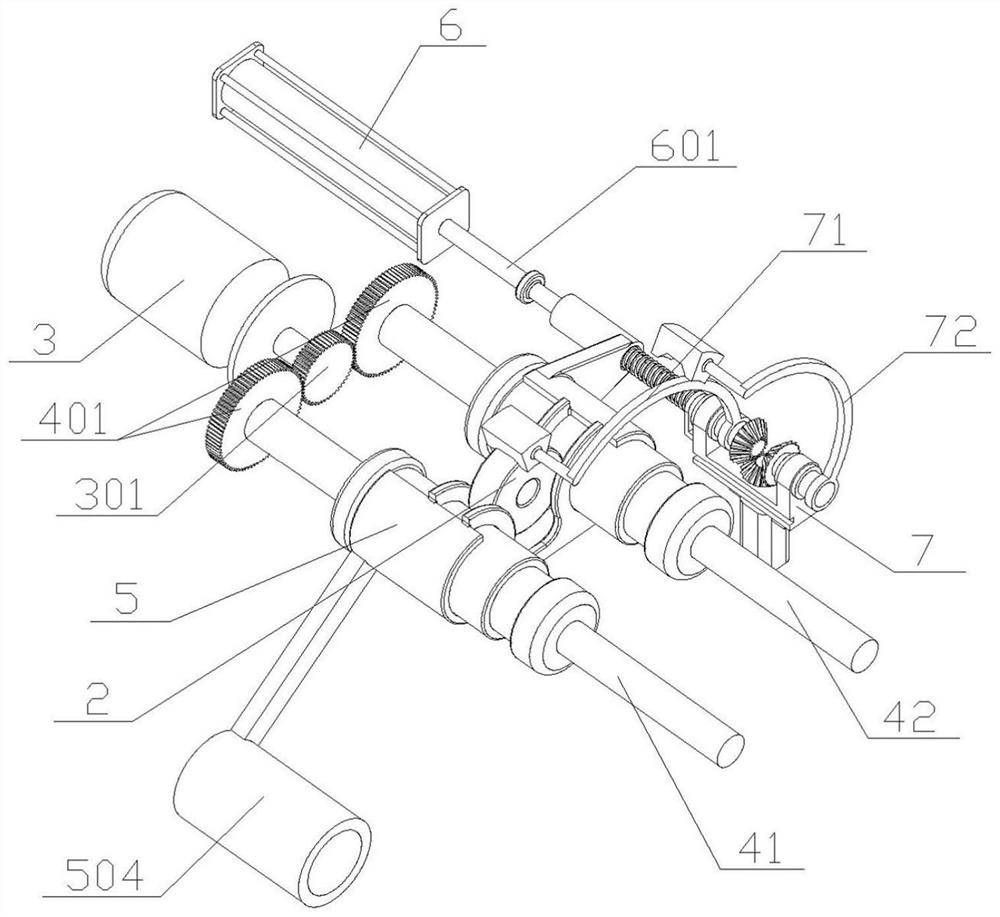

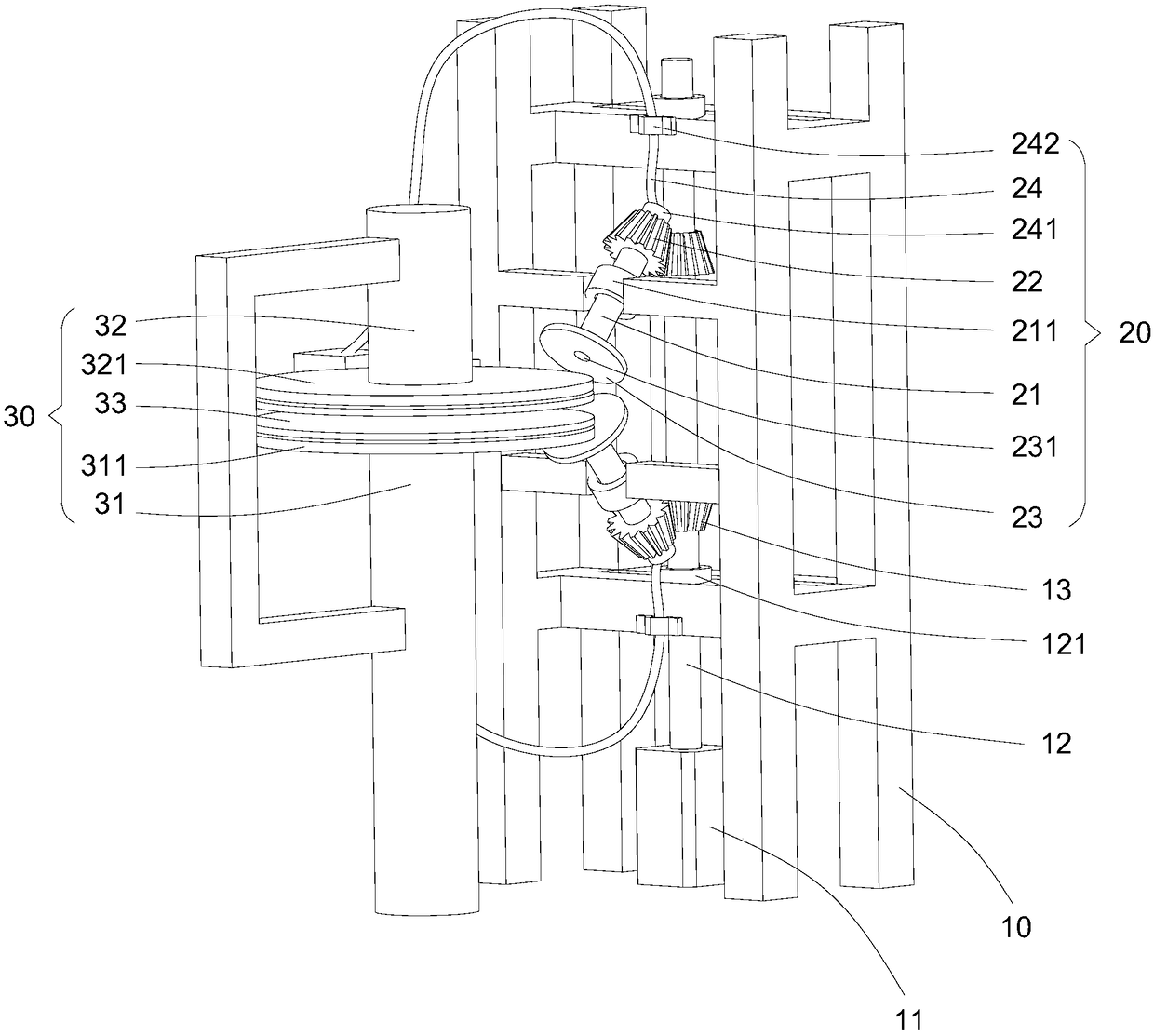

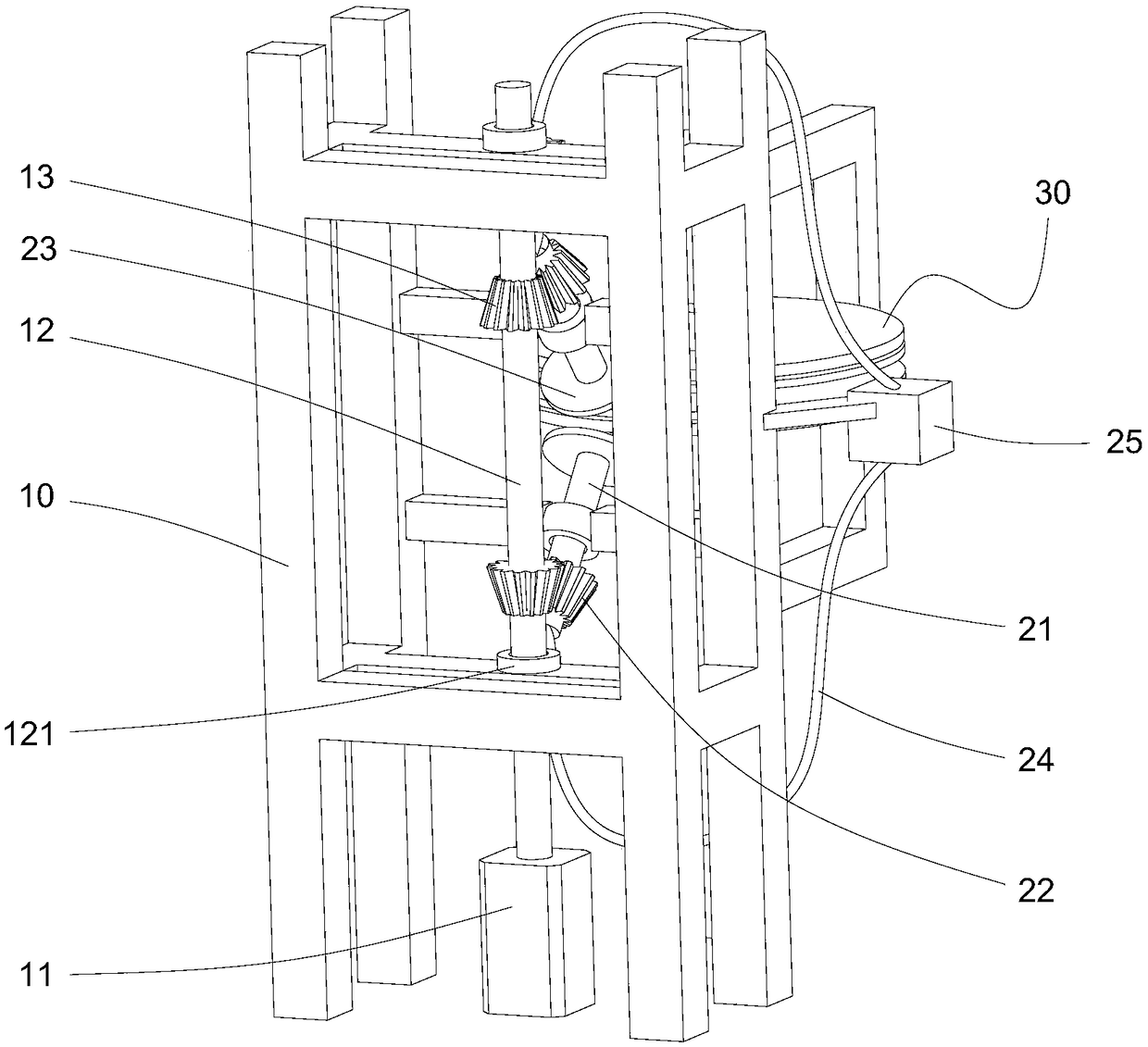

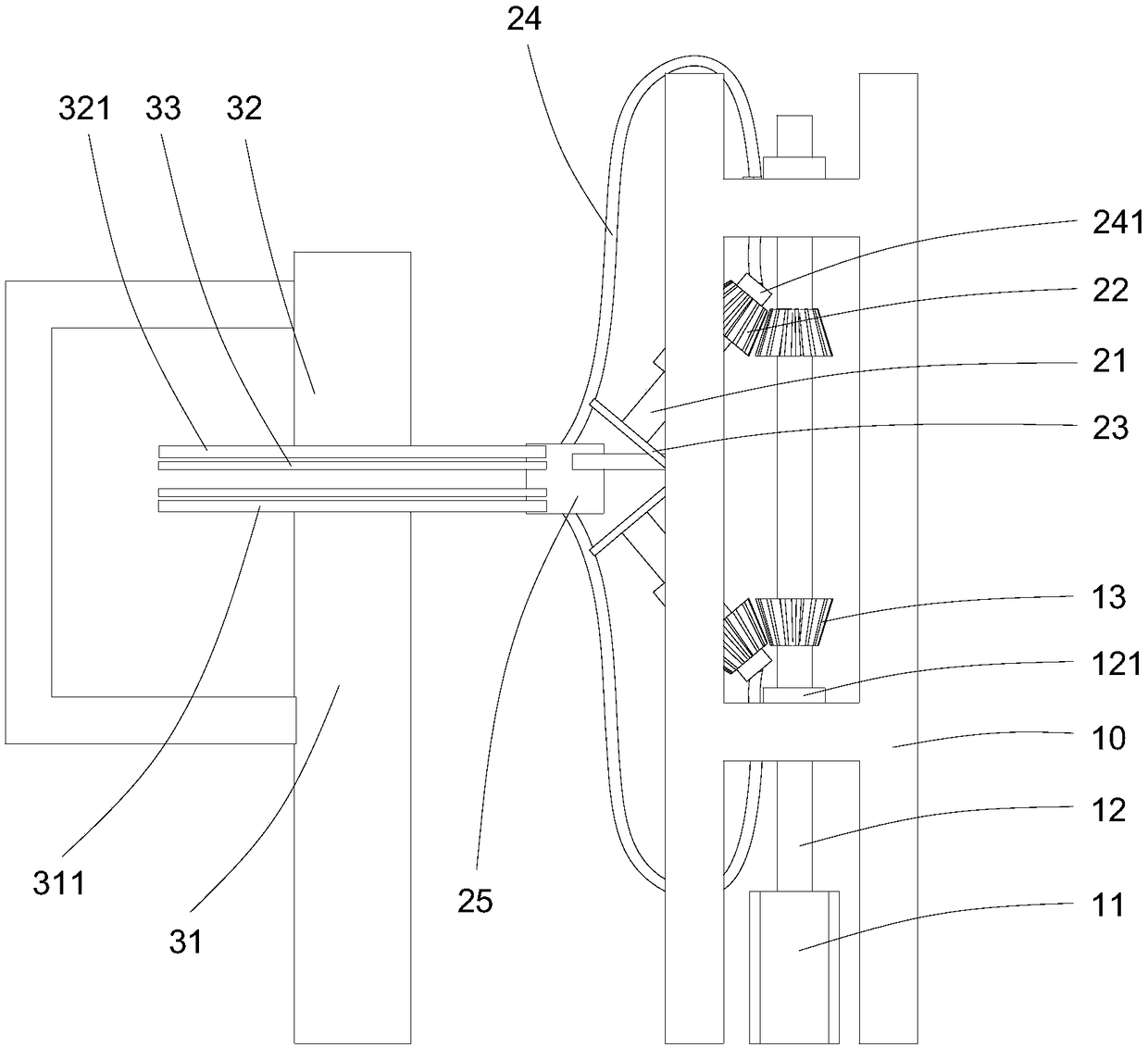

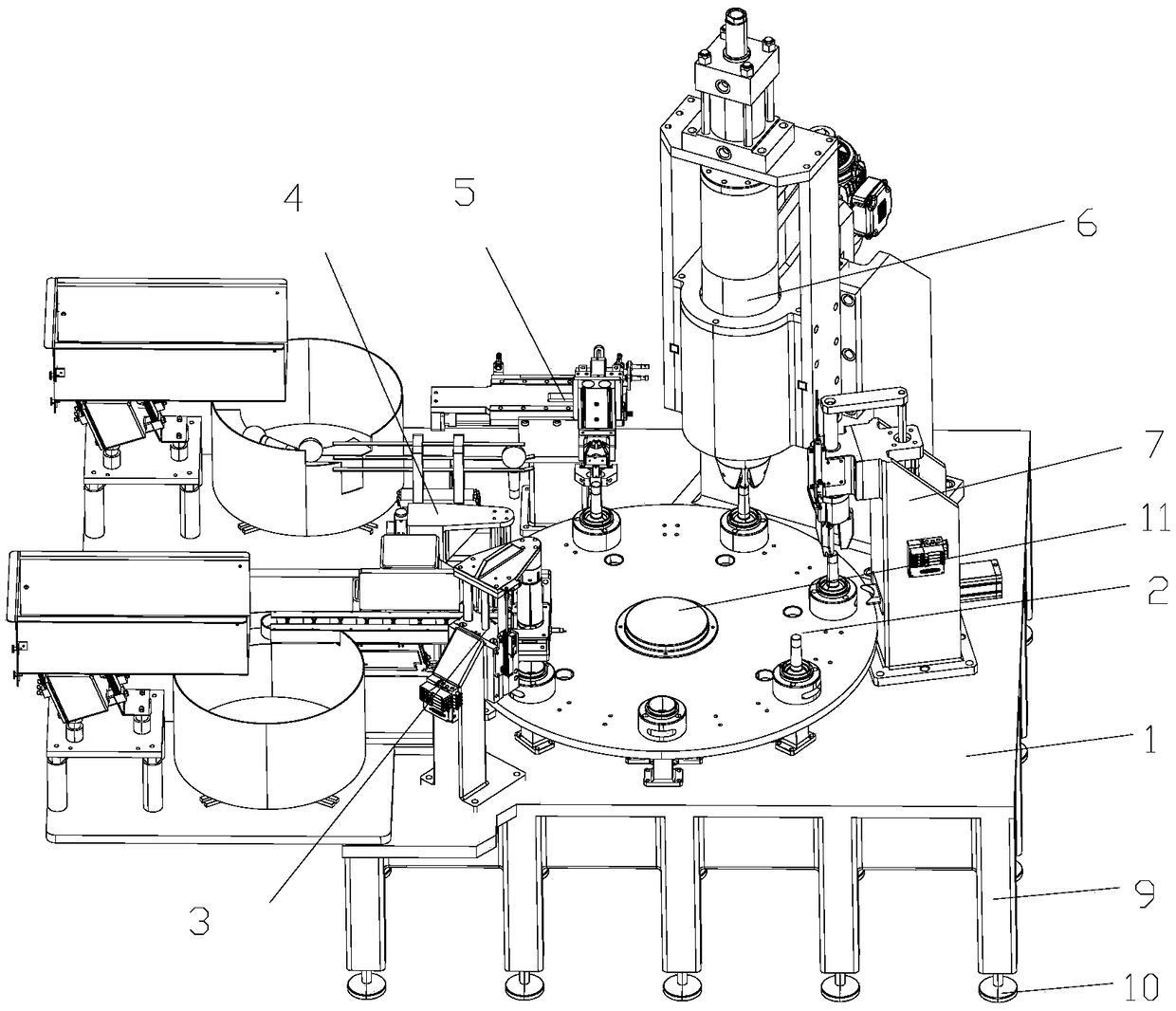

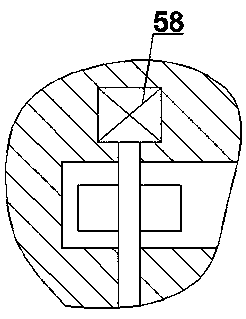

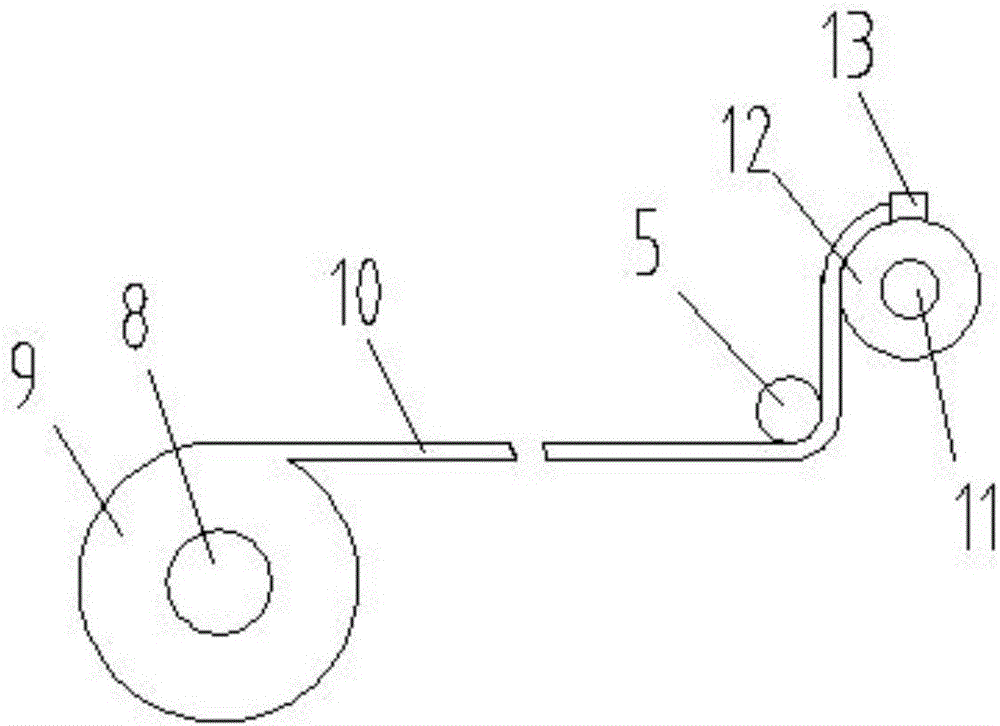

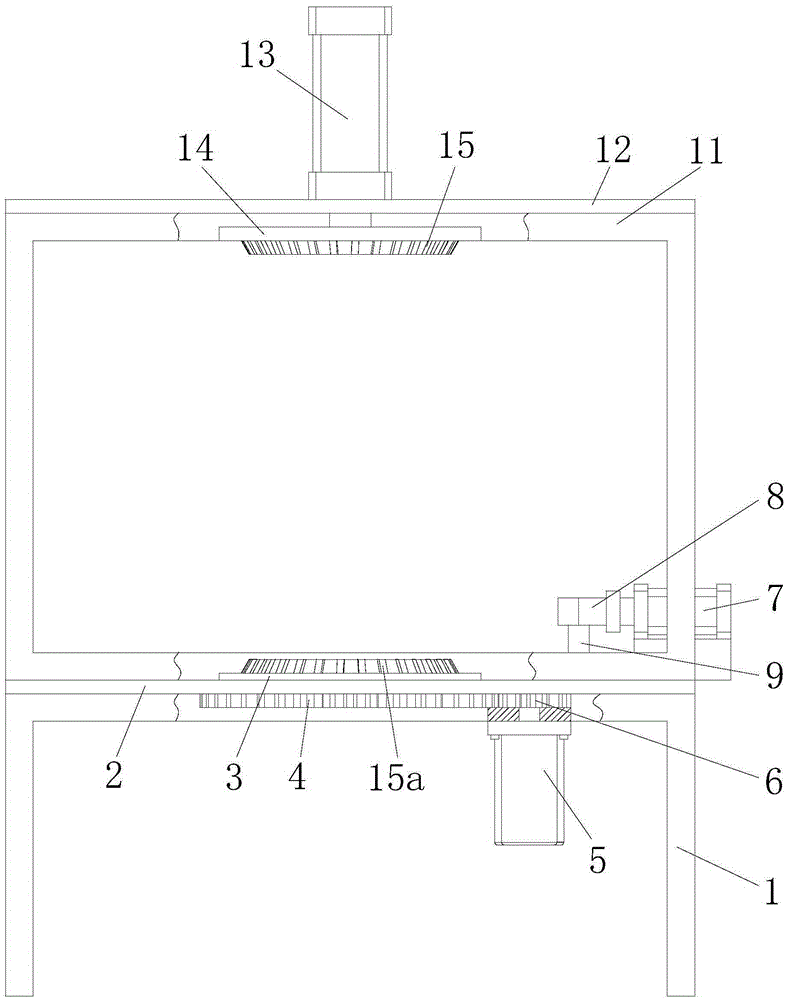

Automatic production equipment of transformer magnetic ring and magnetic ring chamfering device

InactiveCN109396995ARealize automatic chamferingImprove chamfering efficiencyEdge grinding machinesGrinding feedersBiochemical engineeringTransformer

The invention relates to the technical field of electronic component and part production and machining, in particular to automatic production equipment of a transformer magnetic ring and a magnetic ring chamfering device. The automatic chamfering device of the magnetic ring comprises a supporting cabinet, a conveying mechanism and chamfering mechanisms, a feeding mechanism is arranged on the frontside of the supporting cabinet, the first chamfering mechanism is arranged on the supporting cabinet, and the magnetic ring is conveyed to the first chamfering mechanism to be chamfered by the feeding mechanism through the conveying mechanism. According to the magnetic ring chamfering device, automatic chamfering of the magnetic ring is realized, the efficiency and quality of chamfering are high,and uniformity of the chamfering quality is ensured.

Owner:练国瑛

Circular steel plate plane milling and chamfering equipment

InactiveCN110961931AShorten the timeReduce the inconvenience time caused by two devicesOther manufacturing equipments/toolsHydraulic pumpStructural engineering

The invention discloses circular steel plate plane milling and chamfering equipment. The equipment comprises a base. Two sets of stand columns which are symmetrical left and right are fixedly arrangedon the top face of the base. A transverse plate is arranged between the two sets of stand columns in a sliding mode. The transverse plate can move up and down under the control of a hydraulic pump; atop box is fixedly arranged on the transverse plate; a rotating box is rotationally arranged at the bottom of the top box; according to the invention, the corner milling function and the plane milling function are combined and are integrated into one equipment, so inconvenience caused by two equipment is greatly reduced, the step of transferring the steel plate to the chamfering equipment after plane milling is omitted, time is shortened, the sliding box can rotate, the rotary disc can drive the steel plate to rotate in the opposite direction, and the chamfering and milling efficiency is greatly improved.

Owner:PUJIANG JISHU MASCH TECH CO LTD

Chamfering machine for regular polygon-shaped steel plate

ActiveCN105538080ARealize automatic chamferingEnsure chamfering qualityEdge grinding machinesGrinding drivesArchitectural engineeringMaterial resources

The invention discloses a chamfering machine for a regular polygon-shaped steel plate. The chamfering machine comprises a support frame, wherein a lower mounting plate is fixed at the upper end of the support frame; an intermittent driving device is fixed at the upper end of the lower mounting plate; an upper mounting plate is fixed at the upper end of the intermittent driving device; a fixing seat is fixed at the upper end of the upper mounting plate; a fixing frame is fixed on the support frame; an air cylinder II is mounted at the upper end of the fixing frame; an edge grinding device is fixed at the lower end of the air cylinder II; a motor I is fixed at the lower end of the lower mounting plate; and a vertical shaft is fixed at the upper end of the lower mounting plate. The chamfering machine has the advantages of reasonable structural design, convenience in use and the like, realizes automatic chamfering of the regular polygon-shaped plate through the cooperation of the intermittent driving device and the edge grinding device, replaces manual chamfering, has a high degree of automation, ensures the chamfering quality of the regular polygon-shaped plate, improves the chamfering efficiency of the regular polygon-shaped plate and saves manpower and material resources.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

Cylinder head camshaft oil hole chamfering device

InactiveCN103586704BEasy entryPrecise positioningLarge fixed membersPositioning apparatusCylinder headEngineering

The invention relates to the field of manufacturing of automotive engine cylinder heads, in particular to a cylinder head camshaft oil hole chamfering device. The cylinder head camshaft oil hole chamfering device comprises a support, a crossbeam, a chamfering mechanism and a corner limit mechanism, wherein the support is provided with two upper side plates, the crossbeam with each end connected with one upper side plate is provided with a circular arc sliding groove, and the chamfering mechanism is provided with a slider matched with the circular arc sliding groove. When the cylinder head camshaft oil hole chamfering device is used, a cylinder head is placed in the support, the chamfering mechanism is pulled, the corner limit mechanism is used to limit, and the chamfering mechanism chamfers one camshaft oil hole of the cylinder head; the chamfering mechanism is pulled, the corner limit mechanism is used to limit, and the chamfering mechanism chamfers the other camshaft oil hole of the cylinder head. The cylinder head camshaft oil hole chamfering device achieves chamfering operation by one-time clamping, and is good in chamfering quality and high in chamfering efficiency.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD

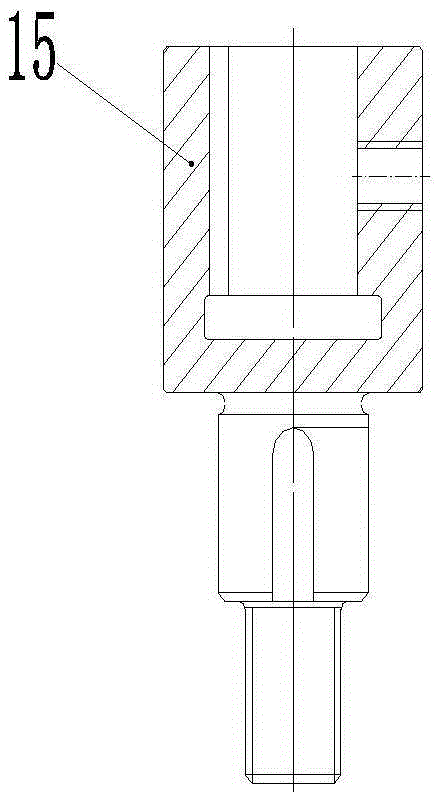

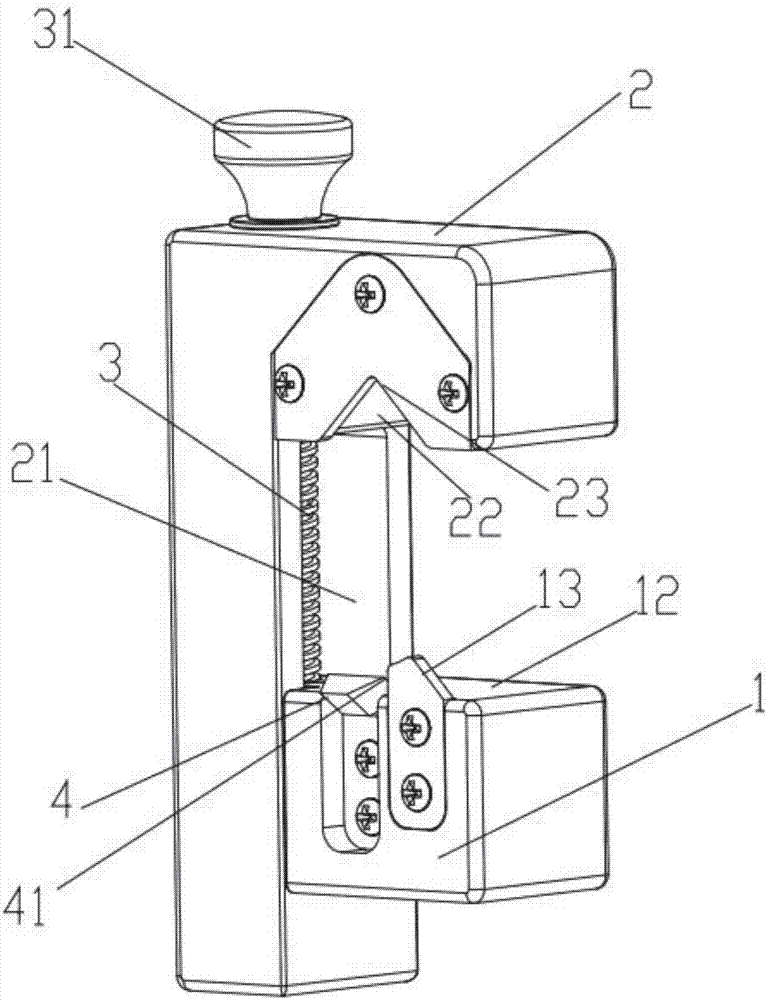

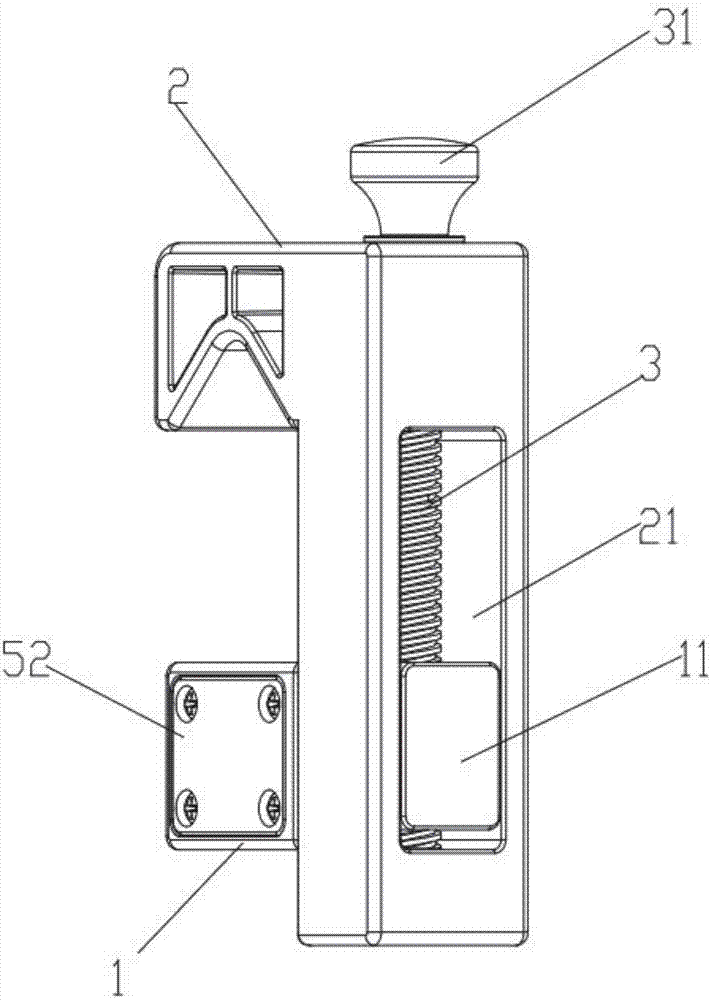

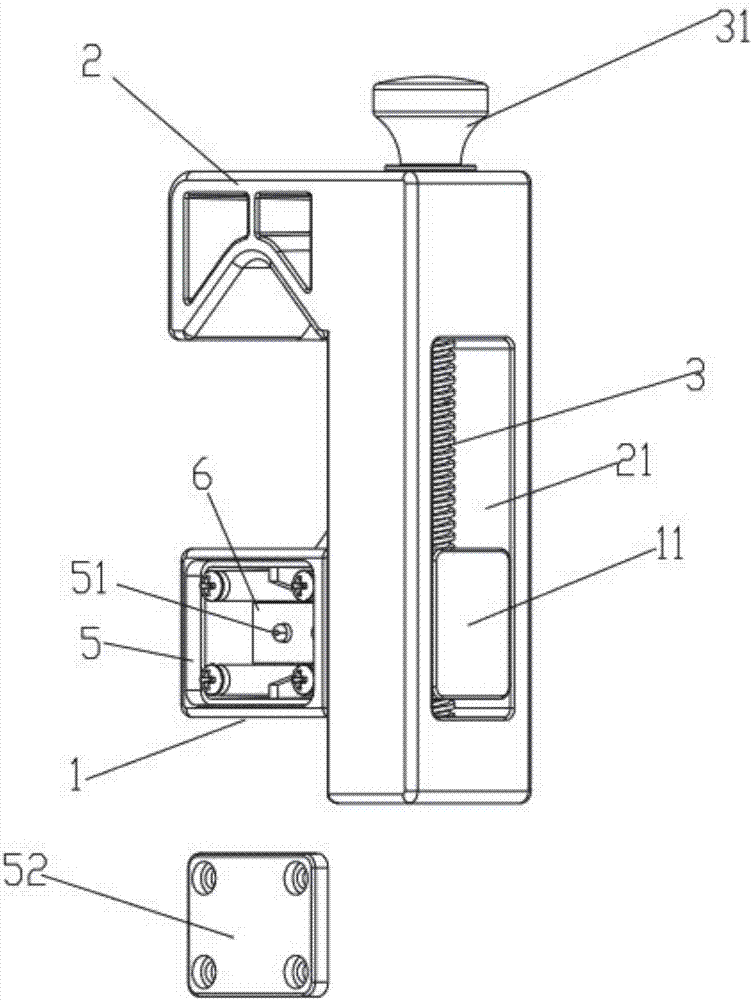

Cable chamfer peeler

PendingCN107508204AImprove chamfering efficiencyUniform depthApparatus for removing/armouring cablesReciprocating motionClassical mechanics

The invention relates to the cable cutter field, and specifically relates to a cable chamfer peeler comprising a first knife rest, a second knife rest, and an adjusting screw rod; one side of the second knife rest is provided with a guide straight slot; one side of the first knife rest is provided with a guide block; the guide block is embedded in the guide straight slot so as to make reciprocating motions; the adjusting screw rod penetrates the guide straight slot and is threaded with the guide block; two ends of the adjusting screw rod are respectively connected with two ends of the guide straight slot in a rotary manner; the first and second knife rests are provided with a first clamping surface and a second clamping surface arranged in opposite; either the first knife rest or the second knife rest are fixedly provided with a chamfer blade; a chamfer cutting blade of the chamfer blade extends outside the corresponding clamping surface, and form an obtuse angle with the clamping surface. The advantages are that the cable chamfering is high in efficiency, and the chamfering depth and angle are even, thus effectively preventing cable inner structure damages in a chamfering process; the cable chamfer peeler is suitable for cables of different diameters, good in versatility, simple in structure, and safe and reliable.

Owner:GUANGZHOU PANYU CABLE WORKS

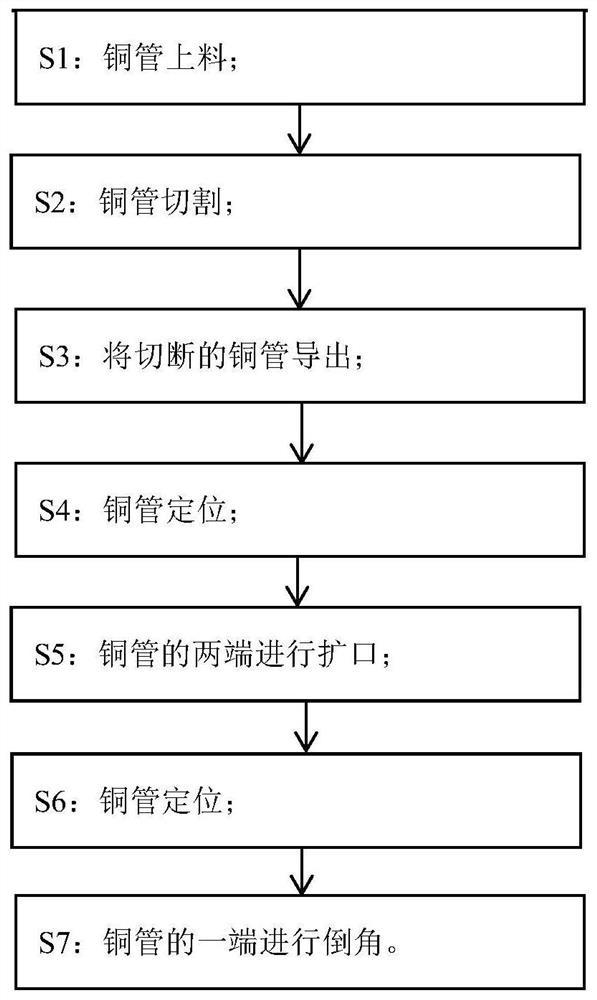

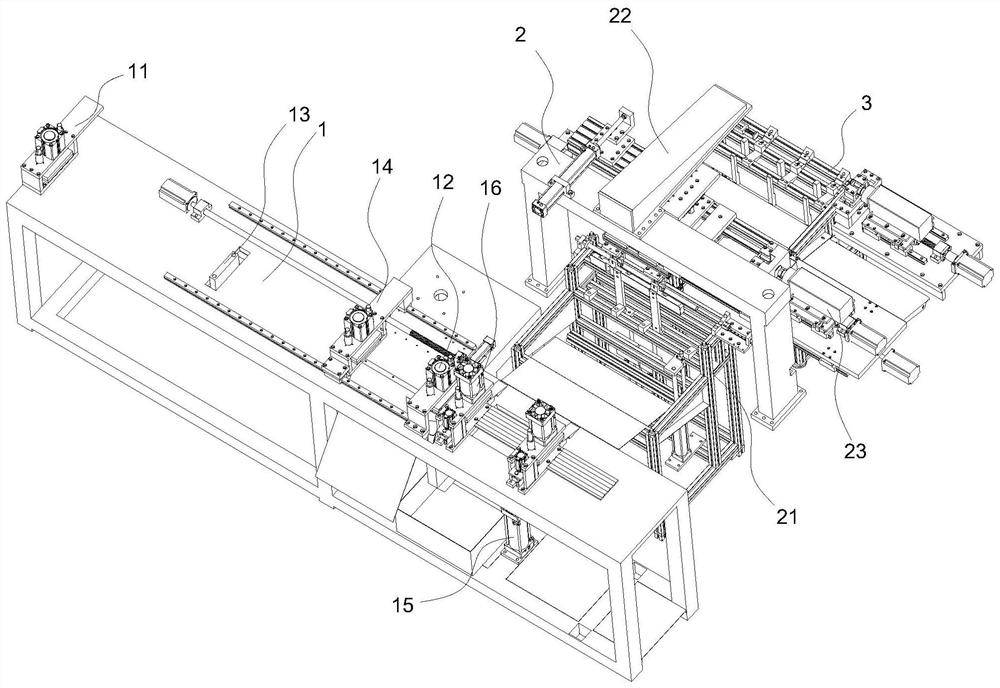

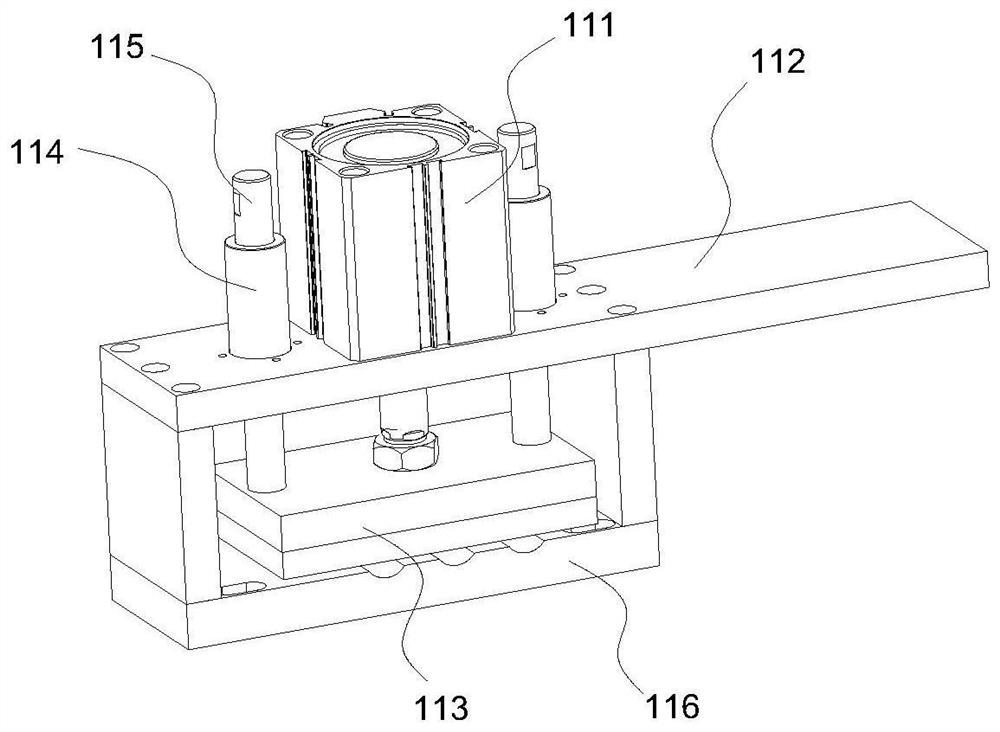

Copper pipe flaring and chamfering processing method and production equipment thereof

InactiveCN113275890AClosely connectedImprove production and processing efficiencyMetal sawing devicesMetal-working feeding devicesStructural engineeringMachining

The invention relates to the field of copper pipe machining, in particular to a copper pipe flaring and chamfering machining method and production equipment thereof. Equipment adopted in the method comprises a rack, a copper pipe feeding and cutting device, a flaring device and a chamfering device, wherein the copper pipe feeding and cutting device, the flaring device and the chamfering device are installed on the rack. The copper pipe feeding and cutting device, the flaring device and the chamfering device are arranged side by side. The discharging end of the copper pipe feeding and cutting device is connected with the flaring device, and the discharging end of the flaring device is connected with the chamfering device. The copper pipe feeding and cutting device is used for conveying copper pipes, cutting the copper pipes in a fixed-length mode and conveying the cut copper pipes into the flaring device. The flaring device is used for conducting flaring operation on the two ends of the copper pipe and conveying the flaring copper pipe into the chamfering device. The chamfering device is used for chamfering one end of the copper pipe. The devices are tightly connected, the cutting, flaring and chamfering operations of the copper pipe can be completed through one device, and the production and machining efficiency is improved.

Owner:杜洋

Chamfering machine

InactiveCN105710450AReduce pollutionIncrease profitLarge fixed membersMaintainance and safety accessoriesPhysical healthEngineering

The invention discloses a chamfering machine, which comprises a chamfering device and a support base. A storage cabinet is arranged at the right end of the inner cavity of the support base, and a cabinet door is provided on the outer surface of the storage cabinet. The outer surface of the cabinet door is A handle is provided, and a dust collection box is provided at the left end of the inner cavity of the support seat, and the dust collection box is connected with a vacuum cleaner through a pipe, and the vacuum cleaner is embedded in the top end of the outer surface of the support seat, and the left end of the top of the outer surface of the support seat An active hydraulic rod is provided, the top of the outer surface of the active hydraulic rod is provided with a driven hydraulic rod, and the driven hydraulic rod is sleeved in the inner cavity of the active hydraulic rod, and the top of the outer surface of the driven hydraulic rod is provided with There is a motor, and the middle end on the right side of the outer surface of the motor is provided with a first rotating shaft. The chamfering machine is equipped with a vacuum cleaner, which can absorb the dust generated during the working process of the chamfering machine and store it in the dust collection box, which not only reduces environmental pollution, but also improves the utilization rate of materials and protects people. of good health.

Owner:陈建荣

Automatic polishing chamfering machine of table board

ActiveCN106670933AAvoid slack strap situationsEnsure consistencyGrinding drivesBelt grinding machinesDistribution controlEngineering

The invention relates to an automatic polishing chamfering machine of a table board. The automatic polishing chamfering machine comprises a rack and a distribution control box. The rack is uniformly provided with polishing chamfering devices, each polishing chamfering device comprises an abrasive belt which is arranged on the rack and is upwards inclined from front to back, and a feeding mechanism matched with the table board and making the table board be fed in a front-rear horizontal manner is arranged in a gap between every two adjacent abrasive belts; and each feeding mechanism comprises a feeding device arranged on the rack and being capable of performing front-rear feeding, each feeding device is provided with a feeding clamper matched with the table board, and the feeding devices and the feeding clampers are connected to the distribution control box. According to the automatic polishing chamfering machine of the table board, the abrasive belts which are arranged in an inclined manner are adopted as the polishing chamfering devices in cooperation with the feeding mechanisms capable of making the table board be fed in a horizontal front-rear manner to achieve fixed-angle chamfering of the table board, chamfering efficiency is improved, the situation that abrasive belts are loose is avoided, and consistency of polishing chamfering is guaranteed.

Owner:广东顺德恒丽宝商用厨具有限公司

Double-end chamfering machine

PendingCN107755822AImprove chamfering efficiencyImprove chamfering precisionFeeding apparatusPositioning apparatusElectric machineryStructural engineering

The invention discloses a double-end chamfering machine. The double-end chamfering machine comprises a rack, a base arranged above the rack and sliding grooves formed in the base. An inverted-L-shapedlongitudinal beam is arranged in the middle of the base. A clamping device for fixing a pipe to be chamfered is arranged below the top of the longitudinal beam. Sliding devices are correspondingly arranged at the two ends of the base. A cutting device is arranged on each sliding device. Each sliding device comprises a stepping motor, a lead screw and a sliding block. The stepping motors are fixedly connected with the base. The sliding blocks are located in the sliding grooves of the base. One end of each lead screw is connected with the corresponding stepping motor, and the other end of eachlead screw is connected with the corresponding sliding block. The double-end chamfering machine has the beneficial effects that the two ends can be chamfered at the same time, the chamfering accuracyis high, and the chamfering machining efficiency of the pipe is improved.

Owner:汉升机械(江苏)有限公司

Chamfering device for valve body

InactiveCN105312682AImprove chamfering efficiencySimple structural designPositioning apparatusMetal working apparatusMaterial resourcesEngineering

The invention discloses a chamfering device for a valve body. The chamfering device for the valve body comprises a supporting frame. A lower end plate is fixed to the upper end of the supporting frame. A lower positioning seat is arranged in the middle of the lower end plate. A gear ring is fixed to the outer wall of the lower positioning seat. A first air cylinder is installed on the right of the lower end plate, a connecting block is fixed to the left end of the first air cylinder, a connecting rod is fixed to the connecting block, and a chamfering wheel is fixed to the outer wall of the connecting rod. A supporting framework is fixed to the upper end of the lower end plate, an upper end plate is fixed to the upper end of the supporting framework, a second air cylinder is installed on the upper end plate, and an upper positioning seat is fixed to the lower end of the second air cylinder. Circular truncated cone shaped positioning blocks are fixed to the upper positioning seat and the lower positioning seat. The chamfering device for the valve body has the advantages of being simple in structural design, convenient to use and the like. A flange of the valve body is chamfered through the chamfering wheel, the chamfering efficiency of the valve body is improved, the production time is shortened, and the production cost is reduced. The circular truncated cone shaped positioning blocks are used for positioning the valve body, the positioning efficiency is improved, and manpower and material resources are saved.

Owner:WUHU HENGHAO MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com